Formulation Strategies for Polyglutamic Acid Biodegradable Plastics

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PGA Plastic Development

Polyglutamic acid (PGA) has emerged as a promising candidate for biodegradable plastics due to its unique properties and environmental benefits. The development of PGA-based plastics has gained significant momentum in recent years, driven by the growing demand for sustainable alternatives to conventional petroleum-based plastics.

PGA is a naturally occurring biopolymer produced by various microorganisms, particularly Bacillus subtilis. Its biodegradability, biocompatibility, and non-toxicity make it an attractive material for a wide range of applications, including packaging, medical devices, and agricultural products. The development of PGA plastics involves several key stages, from raw material production to final product formulation.

The first critical step in PGA plastic development is the efficient production of the polymer. Microbial fermentation has been the primary method for PGA synthesis, with ongoing research focused on optimizing fermentation conditions and strain engineering to enhance yield and reduce production costs. Recent advancements in metabolic engineering and synthetic biology have led to the development of genetically modified strains capable of producing PGA with tailored molecular weights and compositions.

Once the raw PGA is obtained, the next challenge lies in formulating it into a viable plastic material. This process involves blending PGA with other biodegradable polymers or additives to enhance its mechanical properties and processability. Common approaches include the creation of PGA-based composites, copolymerization with other monomers, and the incorporation of plasticizers or reinforcing agents.

A significant focus in PGA plastic development has been on improving its moisture resistance and thermal stability. These properties are crucial for expanding the application range of PGA-based materials, particularly in packaging and consumer goods. Researchers have explored various strategies, such as chemical modifications and the development of multi-layer structures, to address these challenges while maintaining the material's biodegradability.

The processing of PGA into final products represents another critical aspect of its development. Conventional plastic processing techniques, such as extrusion, injection molding, and film blowing, have been adapted for PGA-based materials. However, the unique properties of PGA often require modifications to these processes, leading to innovations in processing technology specifically tailored for biodegradable polymers.

As the field of PGA plastic development continues to evolve, researchers are increasingly focusing on scalability and cost-effectiveness. Efforts are underway to optimize production processes, reduce raw material costs, and develop more efficient formulation strategies. These advancements are crucial for bridging the gap between laboratory-scale production and commercial viability, paving the way for widespread adoption of PGA-based biodegradable plastics in various industries.

PGA is a naturally occurring biopolymer produced by various microorganisms, particularly Bacillus subtilis. Its biodegradability, biocompatibility, and non-toxicity make it an attractive material for a wide range of applications, including packaging, medical devices, and agricultural products. The development of PGA plastics involves several key stages, from raw material production to final product formulation.

The first critical step in PGA plastic development is the efficient production of the polymer. Microbial fermentation has been the primary method for PGA synthesis, with ongoing research focused on optimizing fermentation conditions and strain engineering to enhance yield and reduce production costs. Recent advancements in metabolic engineering and synthetic biology have led to the development of genetically modified strains capable of producing PGA with tailored molecular weights and compositions.

Once the raw PGA is obtained, the next challenge lies in formulating it into a viable plastic material. This process involves blending PGA with other biodegradable polymers or additives to enhance its mechanical properties and processability. Common approaches include the creation of PGA-based composites, copolymerization with other monomers, and the incorporation of plasticizers or reinforcing agents.

A significant focus in PGA plastic development has been on improving its moisture resistance and thermal stability. These properties are crucial for expanding the application range of PGA-based materials, particularly in packaging and consumer goods. Researchers have explored various strategies, such as chemical modifications and the development of multi-layer structures, to address these challenges while maintaining the material's biodegradability.

The processing of PGA into final products represents another critical aspect of its development. Conventional plastic processing techniques, such as extrusion, injection molding, and film blowing, have been adapted for PGA-based materials. However, the unique properties of PGA often require modifications to these processes, leading to innovations in processing technology specifically tailored for biodegradable polymers.

As the field of PGA plastic development continues to evolve, researchers are increasingly focusing on scalability and cost-effectiveness. Efforts are underway to optimize production processes, reduce raw material costs, and develop more efficient formulation strategies. These advancements are crucial for bridging the gap between laboratory-scale production and commercial viability, paving the way for widespread adoption of PGA-based biodegradable plastics in various industries.

Market Analysis

The market for polyglutamic acid (PGA) biodegradable plastics is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. The global biodegradable plastics market, which includes PGA-based materials, is projected to reach $7.8 billion by 2025, growing at a CAGR of 9.5% from 2020 to 2025. This growth is primarily attributed to the rising demand for eco-friendly packaging solutions across various industries.

The packaging sector represents the largest market segment for PGA biodegradable plastics, accounting for approximately 60% of the total market share. This is due to the material's excellent barrier properties, biodegradability, and compatibility with food contact applications. The food and beverage industry, in particular, is showing strong interest in PGA-based packaging solutions as a sustainable alternative to conventional plastics.

Agriculture is another key market for PGA biodegradable plastics, with applications in mulch films, seed coatings, and controlled-release fertilizers. The agricultural sector is expected to witness the highest growth rate in the coming years, driven by the increasing adoption of sustainable farming practices and the need for soil-friendly materials.

The healthcare and pharmaceutical industries are also emerging as promising markets for PGA biodegradable plastics. The material's biocompatibility and controlled degradation properties make it suitable for drug delivery systems, tissue engineering scaffolds, and medical implants. This sector is projected to grow at a CAGR of 12% from 2020 to 2025.

Geographically, Europe leads the market for PGA biodegradable plastics, followed by North America and Asia-Pacific. Europe's dominance is attributed to stringent regulations on single-use plastics and a strong focus on circular economy initiatives. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental awareness, and government support for sustainable materials.

Despite the positive market outlook, several challenges remain for the widespread adoption of PGA biodegradable plastics. These include higher production costs compared to conventional plastics, limited production capacity, and the need for improved mechanical properties to match the performance of traditional plastics in certain applications. Addressing these challenges through innovative formulation strategies and process optimizations will be crucial for expanding the market potential of PGA biodegradable plastics.

The packaging sector represents the largest market segment for PGA biodegradable plastics, accounting for approximately 60% of the total market share. This is due to the material's excellent barrier properties, biodegradability, and compatibility with food contact applications. The food and beverage industry, in particular, is showing strong interest in PGA-based packaging solutions as a sustainable alternative to conventional plastics.

Agriculture is another key market for PGA biodegradable plastics, with applications in mulch films, seed coatings, and controlled-release fertilizers. The agricultural sector is expected to witness the highest growth rate in the coming years, driven by the increasing adoption of sustainable farming practices and the need for soil-friendly materials.

The healthcare and pharmaceutical industries are also emerging as promising markets for PGA biodegradable plastics. The material's biocompatibility and controlled degradation properties make it suitable for drug delivery systems, tissue engineering scaffolds, and medical implants. This sector is projected to grow at a CAGR of 12% from 2020 to 2025.

Geographically, Europe leads the market for PGA biodegradable plastics, followed by North America and Asia-Pacific. Europe's dominance is attributed to stringent regulations on single-use plastics and a strong focus on circular economy initiatives. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental awareness, and government support for sustainable materials.

Despite the positive market outlook, several challenges remain for the widespread adoption of PGA biodegradable plastics. These include higher production costs compared to conventional plastics, limited production capacity, and the need for improved mechanical properties to match the performance of traditional plastics in certain applications. Addressing these challenges through innovative formulation strategies and process optimizations will be crucial for expanding the market potential of PGA biodegradable plastics.

Technical Challenges

The development of polyglutamic acid (PGA) biodegradable plastics faces several significant technical challenges that need to be addressed for widespread adoption and commercialization. One of the primary obstacles is the high production cost of PGA compared to conventional plastics. The fermentation process used to produce PGA is complex and requires expensive raw materials, making it difficult to compete with petroleum-based plastics on a cost basis.

Another major challenge is the limited mechanical properties of PGA-based plastics. While PGA exhibits excellent biodegradability, its inherent brittleness and low tensile strength restrict its application in many areas where durability is required. Improving the mechanical properties without compromising biodegradability remains a significant hurdle for researchers and manufacturers.

The processing of PGA into various plastic products also presents technical difficulties. PGA has a high melting point and tends to degrade during thermal processing, which limits the range of manufacturing techniques that can be employed. This constraint affects the ability to produce diverse product forms and shapes, potentially limiting market penetration.

Moisture sensitivity is another critical issue for PGA-based plastics. The material's hydrophilic nature can lead to rapid degradation in humid environments, affecting product shelf life and performance. Developing effective moisture barrier technologies or modifying PGA's molecular structure to reduce water absorption is crucial for expanding its application range.

Consistency in material properties is also a significant challenge. The molecular weight and degree of polymerization of PGA can vary depending on production conditions, leading to inconsistencies in the final product's characteristics. Achieving reproducible and standardized material properties is essential for quality control and meeting industry specifications.

Furthermore, the biodegradation rate of PGA plastics needs careful control. While rapid biodegradation is desirable for environmental reasons, it can be problematic for product longevity and performance. Balancing the biodegradation rate with the intended product lifespan requires sophisticated formulation strategies and potentially the development of novel additives or copolymers.

Lastly, scaling up production from laboratory to industrial levels presents its own set of challenges. Maintaining product quality, optimizing fermentation processes, and developing efficient downstream processing techniques are all critical aspects that need to be addressed for successful commercialization of PGA-based biodegradable plastics.

Another major challenge is the limited mechanical properties of PGA-based plastics. While PGA exhibits excellent biodegradability, its inherent brittleness and low tensile strength restrict its application in many areas where durability is required. Improving the mechanical properties without compromising biodegradability remains a significant hurdle for researchers and manufacturers.

The processing of PGA into various plastic products also presents technical difficulties. PGA has a high melting point and tends to degrade during thermal processing, which limits the range of manufacturing techniques that can be employed. This constraint affects the ability to produce diverse product forms and shapes, potentially limiting market penetration.

Moisture sensitivity is another critical issue for PGA-based plastics. The material's hydrophilic nature can lead to rapid degradation in humid environments, affecting product shelf life and performance. Developing effective moisture barrier technologies or modifying PGA's molecular structure to reduce water absorption is crucial for expanding its application range.

Consistency in material properties is also a significant challenge. The molecular weight and degree of polymerization of PGA can vary depending on production conditions, leading to inconsistencies in the final product's characteristics. Achieving reproducible and standardized material properties is essential for quality control and meeting industry specifications.

Furthermore, the biodegradation rate of PGA plastics needs careful control. While rapid biodegradation is desirable for environmental reasons, it can be problematic for product longevity and performance. Balancing the biodegradation rate with the intended product lifespan requires sophisticated formulation strategies and potentially the development of novel additives or copolymers.

Lastly, scaling up production from laboratory to industrial levels presents its own set of challenges. Maintaining product quality, optimizing fermentation processes, and developing efficient downstream processing techniques are all critical aspects that need to be addressed for successful commercialization of PGA-based biodegradable plastics.

Current Formulations

01 Production methods for polyglutamic acid

Various methods for producing polyglutamic acid (PGA) are described, including microbial fermentation and enzymatic synthesis. These processes can be optimized for higher yield and purity, which is essential for the production of biodegradable plastics. Different strains of bacteria and enzymes are utilized to synthesize PGA with specific properties suitable for plastic applications.- Production methods for polyglutamic acid: Various methods for producing polyglutamic acid (PGA) are described, including microbial fermentation and enzymatic synthesis. These methods aim to optimize the production process, increase yield, and improve the quality of PGA for use in biodegradable plastics.

- Blending polyglutamic acid with other polymers: Techniques for blending polyglutamic acid with other biodegradable polymers to enhance the properties of the resulting material. This approach can improve the mechanical strength, flexibility, and biodegradability of the plastic, making it suitable for various applications.

- Modification of polyglutamic acid structure: Methods for modifying the chemical structure of polyglutamic acid to enhance its properties for use in biodegradable plastics. This includes cross-linking, grafting, and other chemical modifications to improve the material's durability, water resistance, and thermal stability.

- Applications of polyglutamic acid-based biodegradable plastics: Various applications of polyglutamic acid-based biodegradable plastics are explored, including packaging materials, agricultural films, medical devices, and personal care products. The focus is on developing sustainable alternatives to conventional plastics in different industries.

- Biodegradation and environmental impact studies: Research on the biodegradation process of polyglutamic acid-based plastics and their environmental impact. This includes studies on degradation rates in various environments, eco-toxicity assessments, and the development of strategies to optimize the material's end-of-life management.

02 Blending polyglutamic acid with other polymers

Polyglutamic acid can be blended with other biodegradable polymers to enhance its properties for plastic applications. These blends can improve mechanical strength, flexibility, and processability of the resulting material. Various combinations of PGA with other biopolymers or synthetic biodegradable polymers are explored to create composite materials with tailored characteristics.Expand Specific Solutions03 Modification of polyglutamic acid structure

Chemical modifications of polyglutamic acid are investigated to improve its properties for use in biodegradable plastics. These modifications can include crosslinking, grafting, or introducing functional groups to enhance thermal stability, mechanical properties, or water resistance. Such structural changes can significantly affect the biodegradability and applicability of PGA-based plastics.Expand Specific Solutions04 Applications of polyglutamic acid-based biodegradable plastics

Polyglutamic acid-based biodegradable plastics find applications in various fields such as packaging, agriculture, and biomedical devices. These materials offer environmentally friendly alternatives to conventional plastics, with the added benefit of being biocompatible in many cases. Specific applications include food packaging, agricultural films, and drug delivery systems.Expand Specific Solutions05 Biodegradation and environmental impact studies

Research is conducted on the biodegradation mechanisms and environmental impact of polyglutamic acid-based plastics. Studies focus on degradation rates in various environments, the influence of molecular weight and structure on biodegradability, and the ecological effects of degradation products. These investigations aim to ensure the sustainability and safety of PGA-based biodegradable plastics.Expand Specific Solutions

Industry Leaders

The formulation strategies for polyglutamic acid biodegradable plastics are in a developing stage, with the market showing significant growth potential. The industry is transitioning from research to early commercialization, driven by increasing environmental concerns and regulatory pressures. Market size is expanding, though still relatively small compared to traditional plastics. Technologically, the field is progressing rapidly, with companies like Toyobo Co., Ltd., Nitto Denko Corp., and METabolic EXplorer SA leading innovation. These firms are advancing formulation techniques, improving material properties, and exploring diverse applications. However, the technology is not yet fully mature, with ongoing challenges in scalability, cost-effectiveness, and performance optimization compared to conventional plastics.

Toyobo Co., Ltd.

Technical Solution: Toyobo has developed innovative formulation strategies for polyglutamic acid (PGA) biodegradable plastics. Their approach involves blending PGA with other biodegradable polymers to enhance mechanical properties and processability. They have successfully created PGA-based films with improved flexibility and moisture resistance by incorporating plasticizers and hydrophobic additives[1]. Toyobo's formulation also includes the use of nucleating agents to control crystallization, resulting in enhanced thermal stability and mechanical strength[2]. The company has implemented a proprietary extrusion process that allows for the production of PGA-based sheets and films with consistent quality and reduced degradation during processing[3].

Strengths: Improved mechanical properties, enhanced processability, and increased moisture resistance. Weaknesses: Potentially higher production costs due to specialized additives and processing techniques.

METabolic EXplorer SA

Technical Solution: METabolic EXplorer has developed a unique fermentation-based process for producing bio-sourced 1,3-propanediol, which is used as a key ingredient in their PGA formulation strategy. Their approach involves incorporating this bio-based monomer into PGA to create copolymers with enhanced properties[1]. The company has also developed a proprietary crosslinking technique that improves the mechanical strength and water resistance of PGA-based materials[2]. METabolic EXplorer's formulation includes the use of natural plasticizers derived from renewable resources, which enhances the biodegradability of the final product while maintaining flexibility[3]. They have successfully scaled up their production process, achieving a capacity of several thousand tons per year[4].

Strengths: Bio-based raw materials, improved mechanical properties, and enhanced biodegradability. Weaknesses: Limited range of applications compared to conventional plastics, potential scalability challenges.

Key PGA Innovations

Biodegradable plastics

PatentWO2002051907A1

Innovation

- A biodegradable plastic composed of radiation-crosslinked γ-polyglutamic acid or γ-polyglutamic acid with a molecular weight of 10,000,000 or more, which is blended with solvents and additives to enhance viscosity and processability, allowing for rapid decomposition and diversification through chemical modification.

Polyglutamic acids functionalized by cationic groups and hydrophobic groups and applications thereof, in particular therapeutic applications thereof

PatentInactiveUS20090012028A1

Innovation

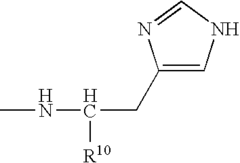

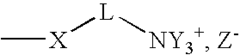

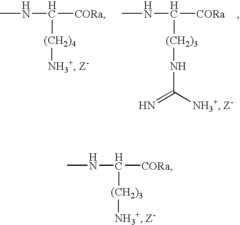

- Development of novel amphiphilic copolyglutamates with pendant cationic and hydrophobic groups that form stable colloidal suspensions, associate with active principles, and degrade into non-toxic products, allowing for controlled release and enhanced bioavailability.

Environmental Impact

The environmental impact of polyglutamic acid (PGA) biodegradable plastics is a critical aspect to consider in their development and implementation. PGA-based plastics offer significant advantages over conventional petroleum-based plastics in terms of environmental sustainability. These materials are derived from renewable resources and can be biodegraded by microorganisms, reducing the accumulation of plastic waste in landfills and oceans.

One of the primary environmental benefits of PGA biodegradable plastics is their ability to decompose naturally in various environments. Unlike traditional plastics that persist for hundreds of years, PGA-based materials can break down into harmless components within months to a few years, depending on the specific formulation and environmental conditions. This characteristic significantly reduces the long-term environmental burden associated with plastic pollution.

The production of PGA biodegradable plastics also has a lower carbon footprint compared to conventional plastics. The raw materials used in PGA synthesis, such as glutamic acid, can be obtained from renewable sources like agricultural by-products or fermentation processes. This reduces reliance on fossil fuels and decreases greenhouse gas emissions associated with plastic production.

Furthermore, the biodegradation of PGA plastics does not release harmful substances into the environment. As these materials break down, they form natural compounds that can be assimilated by microorganisms and plants, potentially contributing to soil fertility. This closed-loop cycle aligns with principles of circular economy and sustainable resource management.

However, it is essential to consider the entire life cycle of PGA biodegradable plastics when assessing their environmental impact. While they offer clear advantages in end-of-life scenarios, the production process may still require energy and resources. Optimizing manufacturing techniques and sourcing sustainable raw materials are crucial steps in minimizing the overall environmental footprint of these materials.

The widespread adoption of PGA biodegradable plastics could lead to significant reductions in plastic pollution, particularly in marine environments. As these materials degrade more rapidly than conventional plastics, they are less likely to accumulate in oceans and pose threats to marine life. This potential for reducing marine plastic pollution is a key driver for research and development in PGA-based materials.

In conclusion, the environmental impact of PGA biodegradable plastics is largely positive, offering a more sustainable alternative to traditional plastics. Their biodegradability, renewable sourcing, and reduced carbon footprint contribute to a cleaner environment and support circular economy principles. However, ongoing research and development are necessary to further optimize their production and performance, ensuring that PGA-based materials deliver on their promise of environmental sustainability across their entire lifecycle.

One of the primary environmental benefits of PGA biodegradable plastics is their ability to decompose naturally in various environments. Unlike traditional plastics that persist for hundreds of years, PGA-based materials can break down into harmless components within months to a few years, depending on the specific formulation and environmental conditions. This characteristic significantly reduces the long-term environmental burden associated with plastic pollution.

The production of PGA biodegradable plastics also has a lower carbon footprint compared to conventional plastics. The raw materials used in PGA synthesis, such as glutamic acid, can be obtained from renewable sources like agricultural by-products or fermentation processes. This reduces reliance on fossil fuels and decreases greenhouse gas emissions associated with plastic production.

Furthermore, the biodegradation of PGA plastics does not release harmful substances into the environment. As these materials break down, they form natural compounds that can be assimilated by microorganisms and plants, potentially contributing to soil fertility. This closed-loop cycle aligns with principles of circular economy and sustainable resource management.

However, it is essential to consider the entire life cycle of PGA biodegradable plastics when assessing their environmental impact. While they offer clear advantages in end-of-life scenarios, the production process may still require energy and resources. Optimizing manufacturing techniques and sourcing sustainable raw materials are crucial steps in minimizing the overall environmental footprint of these materials.

The widespread adoption of PGA biodegradable plastics could lead to significant reductions in plastic pollution, particularly in marine environments. As these materials degrade more rapidly than conventional plastics, they are less likely to accumulate in oceans and pose threats to marine life. This potential for reducing marine plastic pollution is a key driver for research and development in PGA-based materials.

In conclusion, the environmental impact of PGA biodegradable plastics is largely positive, offering a more sustainable alternative to traditional plastics. Their biodegradability, renewable sourcing, and reduced carbon footprint contribute to a cleaner environment and support circular economy principles. However, ongoing research and development are necessary to further optimize their production and performance, ensuring that PGA-based materials deliver on their promise of environmental sustainability across their entire lifecycle.

Regulatory Framework

The regulatory framework surrounding polyglutamic acid (PGA) biodegradable plastics is complex and evolving, reflecting the growing interest in sustainable materials and environmental protection. At the international level, several organizations play crucial roles in shaping the regulatory landscape. The United Nations Environment Programme (UNEP) has been instrumental in promoting sustainable practices and has endorsed the use of biodegradable plastics as part of its strategy to combat plastic pollution.

In the European Union, the European Committee for Standardization (CEN) has developed standards for biodegradable plastics, including EN 13432 for compostable packaging. These standards set specific criteria for biodegradability, compostability, and ecotoxicity. The EU has also implemented the Single-Use Plastics Directive, which encourages the use of sustainable alternatives like PGA-based plastics.

In the United States, the regulatory framework is primarily governed by the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA). The EPA oversees environmental aspects, while the FDA regulates food contact applications. The Biodegradable Products Institute (BPI) provides certification for compostable products, which can include PGA-based plastics meeting specific criteria.

Asian countries, particularly Japan and China, have been at the forefront of PGA research and development. Japan's Biomass Plastics Association has established guidelines for biodegradable plastics, while China has implemented its own standards through the Standardization Administration of China (SAC).

Regulatory challenges persist in the field of PGA biodegradable plastics. One key issue is the lack of global harmonization in standards and definitions. What constitutes "biodegradable" can vary between jurisdictions, creating confusion for manufacturers and consumers alike. Additionally, there is ongoing debate about the appropriate disposal methods for these materials and the infrastructure required to support their decomposition.

The regulatory landscape also intersects with waste management policies. Many countries are implementing extended producer responsibility (EPR) schemes, which could impact the production and disposal of PGA-based plastics. Furthermore, labeling requirements for biodegradable products are becoming more stringent to prevent greenwashing and ensure consumer transparency.

As the technology for PGA biodegradable plastics advances, regulators face the challenge of keeping pace with innovation. There is a growing need for adaptive regulatory frameworks that can accommodate new formulations and applications while maintaining environmental and safety standards. This may involve the development of new testing methodologies and lifecycle assessment tools specific to PGA-based materials.

In the European Union, the European Committee for Standardization (CEN) has developed standards for biodegradable plastics, including EN 13432 for compostable packaging. These standards set specific criteria for biodegradability, compostability, and ecotoxicity. The EU has also implemented the Single-Use Plastics Directive, which encourages the use of sustainable alternatives like PGA-based plastics.

In the United States, the regulatory framework is primarily governed by the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA). The EPA oversees environmental aspects, while the FDA regulates food contact applications. The Biodegradable Products Institute (BPI) provides certification for compostable products, which can include PGA-based plastics meeting specific criteria.

Asian countries, particularly Japan and China, have been at the forefront of PGA research and development. Japan's Biomass Plastics Association has established guidelines for biodegradable plastics, while China has implemented its own standards through the Standardization Administration of China (SAC).

Regulatory challenges persist in the field of PGA biodegradable plastics. One key issue is the lack of global harmonization in standards and definitions. What constitutes "biodegradable" can vary between jurisdictions, creating confusion for manufacturers and consumers alike. Additionally, there is ongoing debate about the appropriate disposal methods for these materials and the infrastructure required to support their decomposition.

The regulatory landscape also intersects with waste management policies. Many countries are implementing extended producer responsibility (EPR) schemes, which could impact the production and disposal of PGA-based plastics. Furthermore, labeling requirements for biodegradable products are becoming more stringent to prevent greenwashing and ensure consumer transparency.

As the technology for PGA biodegradable plastics advances, regulators face the challenge of keeping pace with innovation. There is a growing need for adaptive regulatory frameworks that can accommodate new formulations and applications while maintaining environmental and safety standards. This may involve the development of new testing methodologies and lifecycle assessment tools specific to PGA-based materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!