Role of Polyglutamic Acid in Heat-resistant Gel Formulations

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PGA in Heat-Resistant Gels: Background and Objectives

Polyglutamic acid (PGA) has emerged as a promising component in the development of heat-resistant gel formulations, attracting significant attention from researchers and industry professionals alike. The exploration of PGA's role in this context stems from the growing demand for materials that can maintain their structural integrity and functional properties under elevated temperature conditions.

The journey of PGA in heat-resistant gel formulations can be traced back to the early 2000s when scientists began investigating its unique properties. PGA, a biodegradable and biocompatible polymer, was initially recognized for its potential in various biomedical applications. However, its exceptional water-retention capabilities and thermal stability soon caught the attention of materials scientists seeking to enhance the performance of gel-based products in high-temperature environments.

As research progressed, the focus shifted towards understanding the molecular mechanisms by which PGA contributes to heat resistance in gel systems. Studies revealed that PGA's long-chain structure and numerous carboxyl groups play a crucial role in forming robust networks within the gel matrix. These networks not only enhance the gel's overall stability but also create a protective barrier against thermal degradation.

The evolution of PGA-based heat-resistant gels has been driven by the increasing need for advanced materials in diverse industries. From cosmetics and personal care products to industrial lubricants and thermal management systems, the potential applications of these gels have expanded significantly. This growing interest has fueled further research into optimizing PGA formulations for specific temperature ranges and performance requirements.

Recent technological advancements have enabled more precise control over PGA's molecular weight and degree of crosslinking, allowing for tailored heat-resistant properties. Researchers are now exploring various combinations of PGA with other polymers and additives to create synergistic effects and push the boundaries of thermal stability even further.

The primary objectives of current research in this field are multifaceted. Scientists aim to develop PGA-based gel formulations that can withstand temperatures exceeding 200°C while maintaining their structural integrity and functional properties. Additionally, there is a strong focus on enhancing the gels' mechanical strength, improving their long-term stability, and ensuring their compatibility with a wide range of other materials and substances.

Another key goal is to optimize the production processes for PGA-based heat-resistant gels, making them more cost-effective and scalable for industrial applications. This includes investigating sustainable sourcing methods for PGA and developing eco-friendly manufacturing techniques that align with growing environmental concerns.

As we look towards the future, the role of PGA in heat-resistant gel formulations is expected to become increasingly significant. The ongoing research and development efforts are likely to yield innovative solutions that address current limitations and open up new possibilities for high-temperature applications across various sectors.

The journey of PGA in heat-resistant gel formulations can be traced back to the early 2000s when scientists began investigating its unique properties. PGA, a biodegradable and biocompatible polymer, was initially recognized for its potential in various biomedical applications. However, its exceptional water-retention capabilities and thermal stability soon caught the attention of materials scientists seeking to enhance the performance of gel-based products in high-temperature environments.

As research progressed, the focus shifted towards understanding the molecular mechanisms by which PGA contributes to heat resistance in gel systems. Studies revealed that PGA's long-chain structure and numerous carboxyl groups play a crucial role in forming robust networks within the gel matrix. These networks not only enhance the gel's overall stability but also create a protective barrier against thermal degradation.

The evolution of PGA-based heat-resistant gels has been driven by the increasing need for advanced materials in diverse industries. From cosmetics and personal care products to industrial lubricants and thermal management systems, the potential applications of these gels have expanded significantly. This growing interest has fueled further research into optimizing PGA formulations for specific temperature ranges and performance requirements.

Recent technological advancements have enabled more precise control over PGA's molecular weight and degree of crosslinking, allowing for tailored heat-resistant properties. Researchers are now exploring various combinations of PGA with other polymers and additives to create synergistic effects and push the boundaries of thermal stability even further.

The primary objectives of current research in this field are multifaceted. Scientists aim to develop PGA-based gel formulations that can withstand temperatures exceeding 200°C while maintaining their structural integrity and functional properties. Additionally, there is a strong focus on enhancing the gels' mechanical strength, improving their long-term stability, and ensuring their compatibility with a wide range of other materials and substances.

Another key goal is to optimize the production processes for PGA-based heat-resistant gels, making them more cost-effective and scalable for industrial applications. This includes investigating sustainable sourcing methods for PGA and developing eco-friendly manufacturing techniques that align with growing environmental concerns.

As we look towards the future, the role of PGA in heat-resistant gel formulations is expected to become increasingly significant. The ongoing research and development efforts are likely to yield innovative solutions that address current limitations and open up new possibilities for high-temperature applications across various sectors.

Market Analysis for Heat-Resistant Gel Products

The market for heat-resistant gel products has experienced significant growth in recent years, driven by increasing demand across various industries. These gels find applications in sectors such as cosmetics, pharmaceuticals, food and beverage, and industrial manufacturing. The global market for heat-resistant gels is expected to continue its upward trajectory, with a compound annual growth rate projected to remain strong over the next five years.

In the cosmetics industry, heat-resistant gels are gaining popularity in hair styling products, sunscreens, and long-lasting makeup formulations. Consumers are increasingly seeking products that can withstand high temperatures and maintain their efficacy throughout the day. This trend has led to a surge in demand for innovative heat-resistant gel formulations that offer both performance and comfort.

The pharmaceutical sector represents another key market for heat-resistant gels. These products are utilized in transdermal drug delivery systems, wound dressings, and topical medications. The ability of heat-resistant gels to maintain their structural integrity and drug release properties under varying temperature conditions makes them particularly valuable in this field.

Food and beverage manufacturers are also exploring the potential of heat-resistant gels for applications such as food packaging, edible coatings, and texture modifiers. The growing emphasis on food safety and extended shelf life has fueled interest in heat-resistant gel solutions that can withstand processing temperatures and protect food products from spoilage.

In industrial applications, heat-resistant gels are finding use in lubricants, sealants, and thermal management systems. The increasing focus on energy efficiency and equipment longevity has driven demand for gels that can maintain their properties under extreme temperature conditions.

Market analysis indicates that North America and Europe currently dominate the heat-resistant gel market, owing to their advanced research and development capabilities and high adoption rates across various industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing awareness of advanced materials.

Key factors influencing market growth include ongoing technological advancements, increasing research and development activities, and the rising demand for sustainable and eco-friendly formulations. The incorporation of novel ingredients, such as polyglutamic acid, in heat-resistant gel formulations is expected to open up new opportunities and drive market expansion.

Challenges facing the market include the high cost of advanced heat-resistant gel formulations and regulatory hurdles in certain applications, particularly in the pharmaceutical and food industries. However, these challenges are expected to be offset by the growing demand for high-performance materials and the potential for cost reduction through economies of scale and technological improvements.

In the cosmetics industry, heat-resistant gels are gaining popularity in hair styling products, sunscreens, and long-lasting makeup formulations. Consumers are increasingly seeking products that can withstand high temperatures and maintain their efficacy throughout the day. This trend has led to a surge in demand for innovative heat-resistant gel formulations that offer both performance and comfort.

The pharmaceutical sector represents another key market for heat-resistant gels. These products are utilized in transdermal drug delivery systems, wound dressings, and topical medications. The ability of heat-resistant gels to maintain their structural integrity and drug release properties under varying temperature conditions makes them particularly valuable in this field.

Food and beverage manufacturers are also exploring the potential of heat-resistant gels for applications such as food packaging, edible coatings, and texture modifiers. The growing emphasis on food safety and extended shelf life has fueled interest in heat-resistant gel solutions that can withstand processing temperatures and protect food products from spoilage.

In industrial applications, heat-resistant gels are finding use in lubricants, sealants, and thermal management systems. The increasing focus on energy efficiency and equipment longevity has driven demand for gels that can maintain their properties under extreme temperature conditions.

Market analysis indicates that North America and Europe currently dominate the heat-resistant gel market, owing to their advanced research and development capabilities and high adoption rates across various industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing awareness of advanced materials.

Key factors influencing market growth include ongoing technological advancements, increasing research and development activities, and the rising demand for sustainable and eco-friendly formulations. The incorporation of novel ingredients, such as polyglutamic acid, in heat-resistant gel formulations is expected to open up new opportunities and drive market expansion.

Challenges facing the market include the high cost of advanced heat-resistant gel formulations and regulatory hurdles in certain applications, particularly in the pharmaceutical and food industries. However, these challenges are expected to be offset by the growing demand for high-performance materials and the potential for cost reduction through economies of scale and technological improvements.

Current Challenges in Heat-Resistant Gel Formulations

Heat-resistant gel formulations face several significant challenges in their development and application. One of the primary issues is maintaining gel stability at elevated temperatures. As temperatures rise, the molecular structure of gels tends to break down, leading to a loss of viscosity and structural integrity. This instability can result in reduced performance and limited applicability in high-temperature environments.

Another challenge lies in achieving consistent rheological properties across a wide temperature range. Many gels exhibit drastic changes in their flow behavior and mechanical properties as temperatures fluctuate, making it difficult to maintain desired performance characteristics in variable thermal conditions. This inconsistency can be particularly problematic in industries where precise control over gel properties is crucial.

The selection of appropriate gelling agents and stabilizers for heat-resistant formulations presents another hurdle. Traditional gelling agents often fail to provide adequate thermal stability, necessitating the exploration of novel compounds or combinations of materials. This search for suitable ingredients is complicated by the need to balance heat resistance with other desirable properties such as biocompatibility, biodegradability, and cost-effectiveness.

Compatibility issues between heat-resistant gel components and other ingredients in formulations pose additional challenges. The interactions between various constituents can lead to unexpected changes in gel properties or even phase separation at high temperatures. Ensuring that all components work synergistically under thermal stress requires extensive research and testing.

Scalability and manufacturing consistency of heat-resistant gel formulations represent significant industrial challenges. Producing these gels on a large scale while maintaining uniform properties and performance can be technically demanding and cost-intensive. The need for specialized equipment and precise process control adds complexity to manufacturing operations.

Environmental and regulatory concerns also impact the development of heat-resistant gels. As sustainability becomes increasingly important, there is growing pressure to develop formulations that are not only thermally stable but also environmentally friendly and compliant with evolving regulations. This necessitates a careful balance between performance, safety, and ecological considerations.

Lastly, the long-term stability and shelf life of heat-resistant gel formulations remain areas of concern. Ensuring that these gels maintain their properties over extended periods, especially when subjected to repeated thermal cycling or prolonged exposure to high temperatures, is crucial for their practical application in various industries.

Another challenge lies in achieving consistent rheological properties across a wide temperature range. Many gels exhibit drastic changes in their flow behavior and mechanical properties as temperatures fluctuate, making it difficult to maintain desired performance characteristics in variable thermal conditions. This inconsistency can be particularly problematic in industries where precise control over gel properties is crucial.

The selection of appropriate gelling agents and stabilizers for heat-resistant formulations presents another hurdle. Traditional gelling agents often fail to provide adequate thermal stability, necessitating the exploration of novel compounds or combinations of materials. This search for suitable ingredients is complicated by the need to balance heat resistance with other desirable properties such as biocompatibility, biodegradability, and cost-effectiveness.

Compatibility issues between heat-resistant gel components and other ingredients in formulations pose additional challenges. The interactions between various constituents can lead to unexpected changes in gel properties or even phase separation at high temperatures. Ensuring that all components work synergistically under thermal stress requires extensive research and testing.

Scalability and manufacturing consistency of heat-resistant gel formulations represent significant industrial challenges. Producing these gels on a large scale while maintaining uniform properties and performance can be technically demanding and cost-intensive. The need for specialized equipment and precise process control adds complexity to manufacturing operations.

Environmental and regulatory concerns also impact the development of heat-resistant gels. As sustainability becomes increasingly important, there is growing pressure to develop formulations that are not only thermally stable but also environmentally friendly and compliant with evolving regulations. This necessitates a careful balance between performance, safety, and ecological considerations.

Lastly, the long-term stability and shelf life of heat-resistant gel formulations remain areas of concern. Ensuring that these gels maintain their properties over extended periods, especially when subjected to repeated thermal cycling or prolonged exposure to high temperatures, is crucial for their practical application in various industries.

Existing PGA-based Heat-Resistant Gel Solutions

01 Improving heat resistance of polyglutamic acid

Various methods are employed to enhance the heat resistance of polyglutamic acid, including chemical modifications, blending with other polymers, and incorporating additives. These techniques aim to increase the thermal stability and maintain the structural integrity of polyglutamic acid at elevated temperatures.- Improving heat resistance of polyglutamic acid: Various methods are employed to enhance the heat resistance of polyglutamic acid, including chemical modifications, blending with other polymers, and incorporating additives. These techniques aim to increase the thermal stability and maintain the structural integrity of polyglutamic acid at elevated temperatures.

- Polyglutamic acid-based heat-resistant materials: Development of new materials combining polyglutamic acid with other components to create heat-resistant composites. These materials find applications in various industries where thermal stability is crucial, such as packaging, coatings, and textiles.

- Enzymatic production of heat-stable polyglutamic acid: Utilization of specific enzymes and microbial strains to produce polyglutamic acid with improved heat resistance. This approach focuses on optimizing fermentation conditions and selecting appropriate microorganisms to enhance the thermal properties of the resulting polymer.

- Heat-resistant polyglutamic acid for biomedical applications: Development of heat-resistant polyglutamic acid formulations for use in biomedical fields, such as drug delivery systems, tissue engineering, and medical devices. The focus is on maintaining biocompatibility while improving thermal stability for sterilization and in vivo applications.

- Characterization and testing of heat-resistant polyglutamic acid: Methods and techniques for evaluating the heat resistance of polyglutamic acid, including thermal analysis, mechanical testing at elevated temperatures, and accelerated aging studies. These approaches help in understanding the thermal behavior and degradation mechanisms of polyglutamic acid under various conditions.

02 Polyglutamic acid-based heat-resistant materials

Development of new materials combining polyglutamic acid with other components to create heat-resistant composites. These materials find applications in various industries where thermal stability is crucial, such as packaging, coatings, and biomedical devices.Expand Specific Solutions03 Enzymatic production of heat-stable polyglutamic acid

Utilization of specific enzymes and microbial strains to produce polyglutamic acid with enhanced heat resistance. This approach focuses on optimizing fermentation conditions and selecting appropriate microorganisms to synthesize thermally stable polyglutamic acid.Expand Specific Solutions04 Heat-resistant polyglutamic acid for cosmetic applications

Formulation of cosmetic products incorporating heat-resistant polyglutamic acid. These formulations aim to improve the stability and efficacy of skincare and haircare products under various temperature conditions, enhancing their shelf life and performance.Expand Specific Solutions05 Crosslinking techniques for heat-resistant polyglutamic acid

Development of crosslinking methods to improve the heat resistance of polyglutamic acid. These techniques involve creating chemical bonds between polymer chains, resulting in a more stable structure that can withstand higher temperatures without degradation.Expand Specific Solutions

Key Players in PGA and Heat-Resistant Gel Industry

The role of polyglutamic acid in heat-resistant gel formulations represents an emerging field with significant potential. The market is in its early growth stage, characterized by increasing research and development activities. While the market size is still relatively small, it is expected to expand rapidly due to growing demand for heat-stable materials in various industries. Technologically, the field is progressing, with companies like Kureha Corp., MOA Life Plus Co., Ltd., and CP Kelco US, Inc. leading innovation. Academic institutions such as Osaka University and Nankai University are also contributing to advancements. The involvement of diverse players, including established chemical companies and specialized biotech firms, indicates a competitive landscape with ample room for technological breakthroughs and market expansion.

Kureha Corp.

Technical Solution: Kureha Corp. has developed a novel heat-resistant gel formulation incorporating polyglutamic acid (PGA) as a key ingredient. Their approach involves cross-linking PGA with other polymers to create a stable, three-dimensional network structure. This network enhances the gel's thermal stability, allowing it to maintain its integrity at elevated temperatures. The company has optimized the molecular weight and concentration of PGA to achieve the desired viscoelastic properties[1]. Additionally, Kureha has implemented a proprietary processing technique that ensures uniform distribution of PGA within the gel matrix, resulting in consistent heat resistance throughout the product[2].

Strengths: Excellent thermal stability, consistent performance, and potential for customization. Weaknesses: Possibly higher production costs and limited scalability due to specialized processing requirements.

CP Kelco US, Inc.

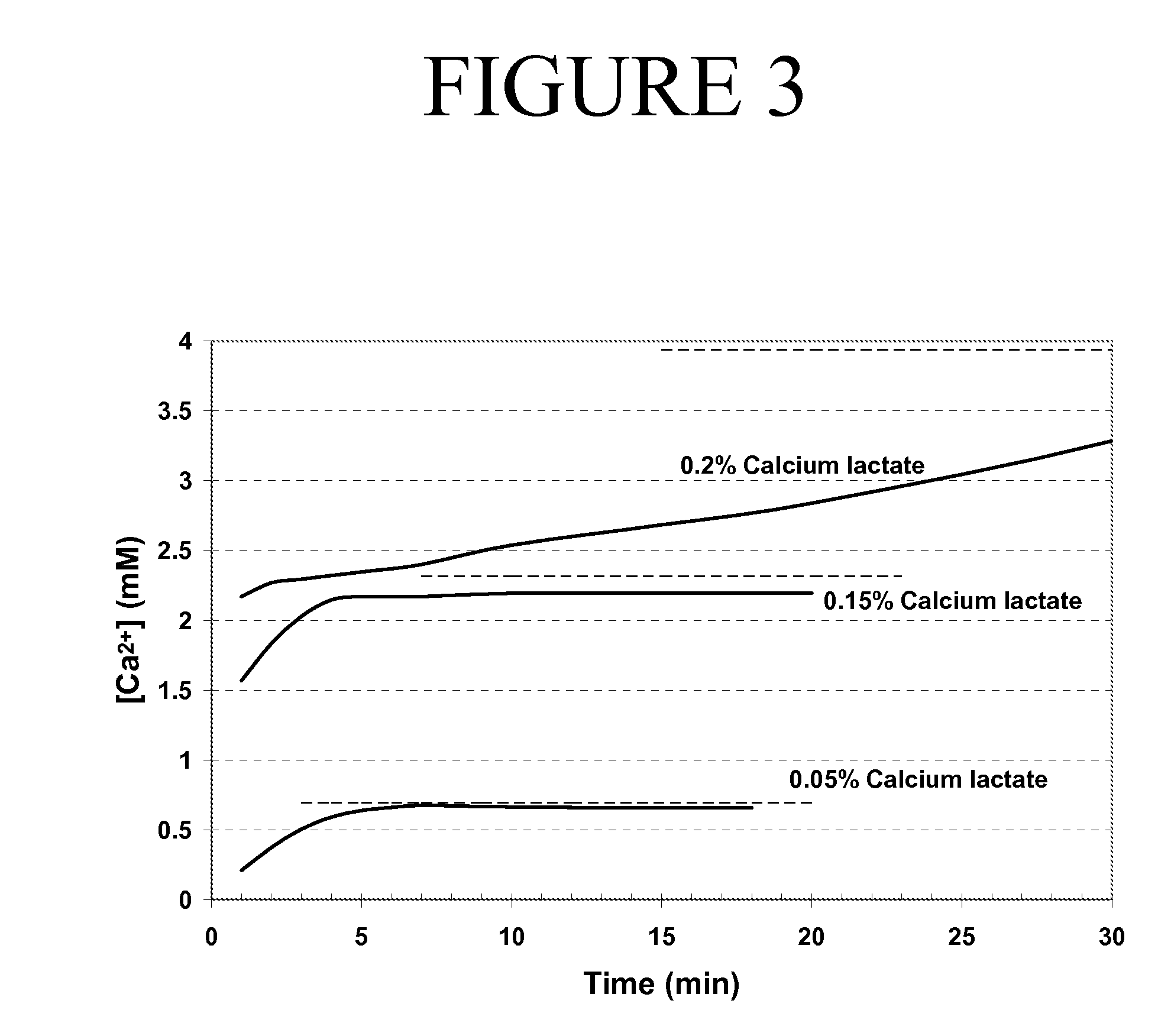

Technical Solution: CP Kelco US, Inc. has developed an innovative heat-resistant gel formulation utilizing polyglutamic acid (PGA) in combination with their proprietary cellulose-based hydrocolloids. Their approach involves creating a synergistic blend of PGA and modified cellulose derivatives, which results in a gel with enhanced thermal stability and improved texture. The company has fine-tuned the ratio of PGA to cellulose components to optimize heat resistance while maintaining desirable rheological properties[3]. CP Kelco's formulation also incorporates specific ions that promote cross-linking between PGA molecules, further enhancing the gel's structure and heat resistance[4].

Strengths: Versatile application range, leveraging existing expertise in hydrocolloids. Weaknesses: Potential challenges in achieving consistent quality across different batches due to complex formulation.

Core Innovations in PGA for Heat Resistance

Isothermal preparation of heat-resistant gellan gels with reduced syneresis

PatentInactiveUS20090104141A1

Innovation

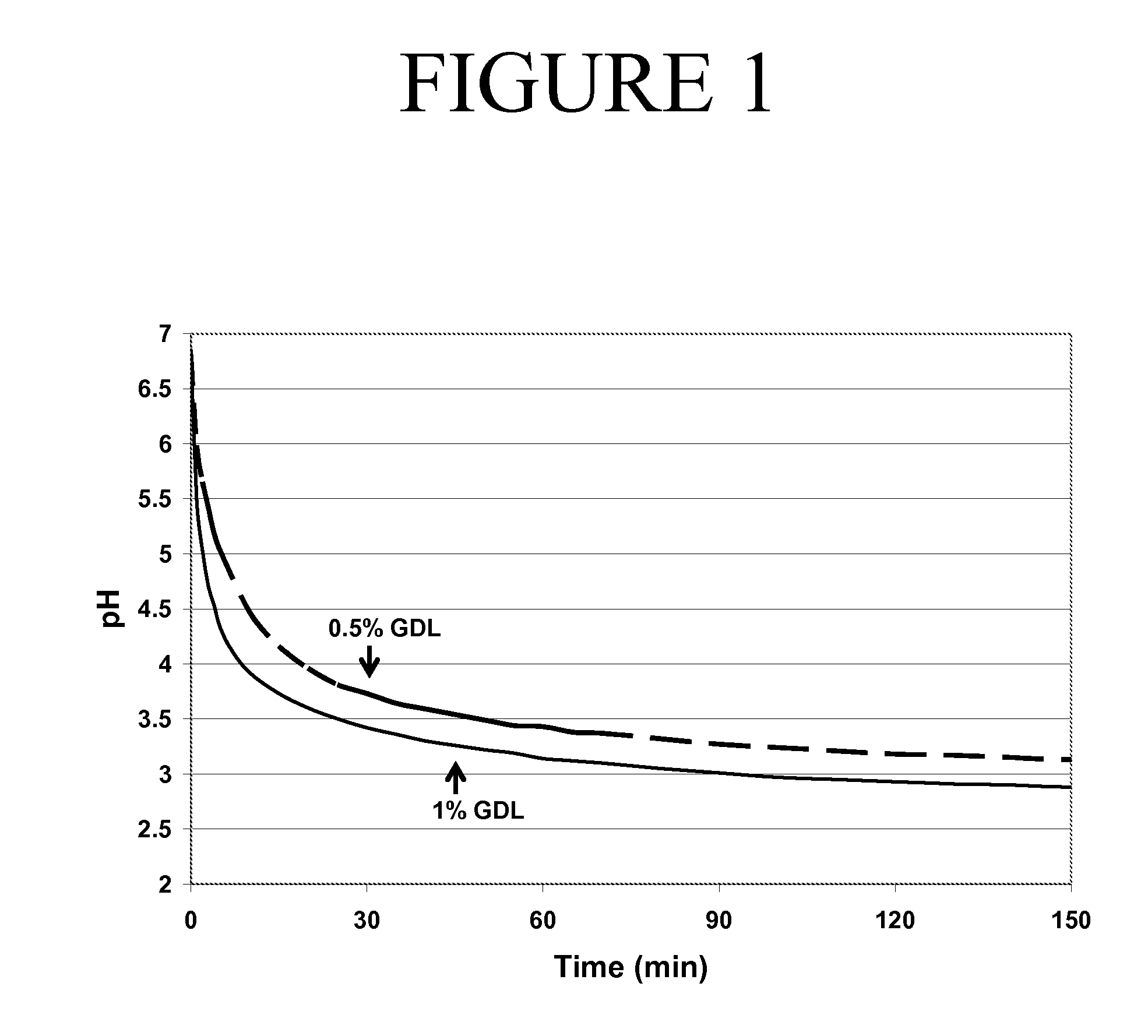

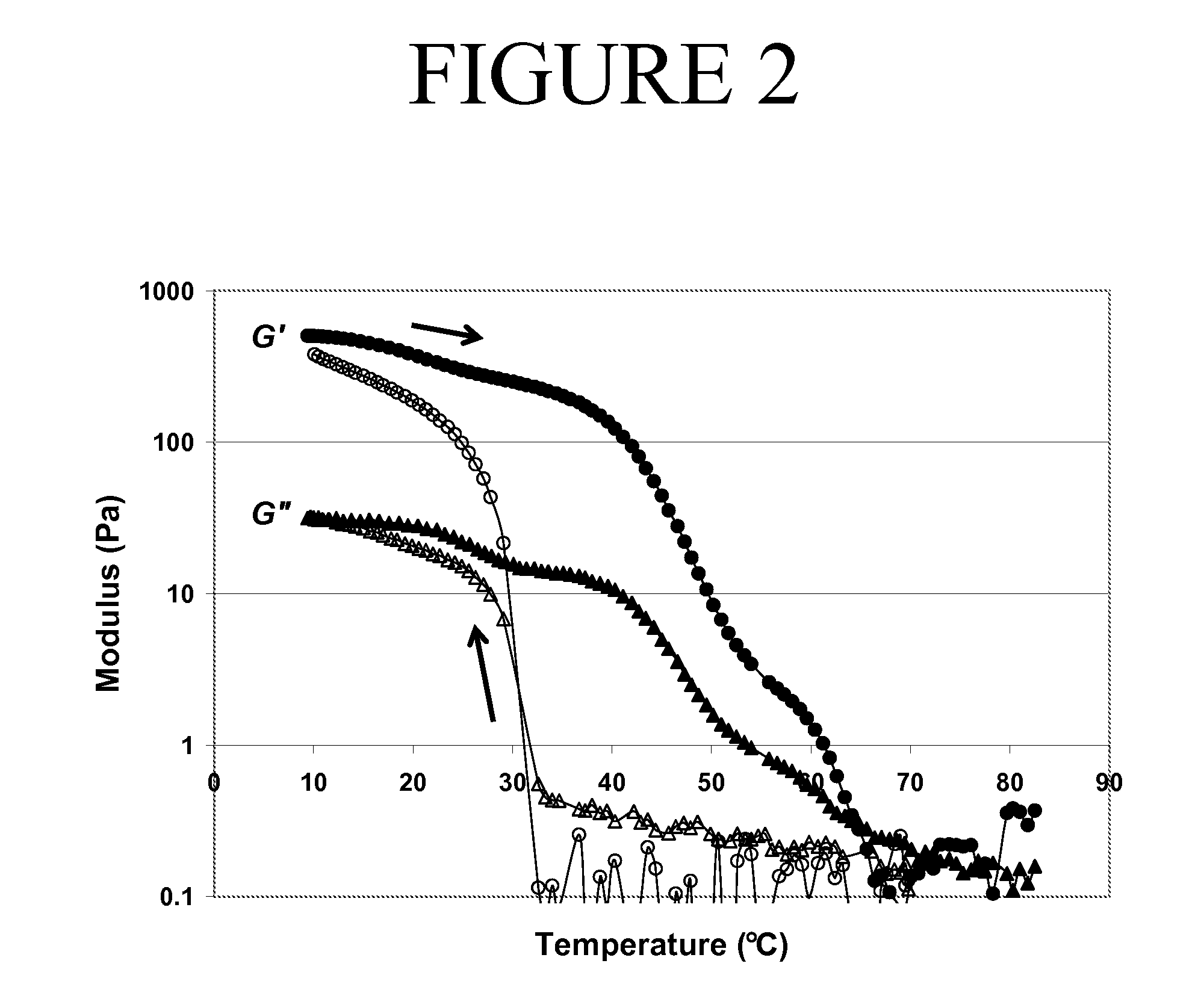

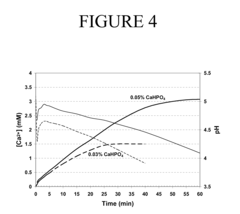

- The use of deacylated gellan gum, combined with a sequestrant, a syneresis control agent like tamarind seed xyloglucan, and a gelation inducer such as glucono-δ-lactone, to form heat-resistant gels isothermally without heat treatments, reducing syneresis and preserving fragrance.

Heat-resistant gelling formulation and heat-resistant gel

PatentActiveJP2023143409A

Innovation

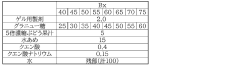

- A formulation combining LM pectin, tamarind seed gum, divalent cation salt, and sequestering agent in specific ratios to create a heat-resistant gel that can adjust texture from smooth to jelly-like and maintain stability across varying Brix and pH levels.

Environmental Impact of PGA-based Gel Formulations

The environmental impact of PGA-based gel formulations is a critical consideration in the development and application of heat-resistant gels. Polyglutamic acid (PGA), as a biodegradable and biocompatible polymer, offers significant advantages over traditional synthetic polymers in terms of environmental sustainability.

PGA-based gel formulations have shown promising results in reducing the ecological footprint of various industries. These gels are derived from renewable resources, primarily through bacterial fermentation, which significantly reduces the reliance on petrochemical-based raw materials. This shift towards bio-based materials aligns with global efforts to minimize carbon emissions and promote circular economy principles.

The biodegradability of PGA-based gels is a key factor in their environmental profile. Unlike many synthetic polymers that persist in the environment for extended periods, PGA-based gels can be broken down by naturally occurring microorganisms. This characteristic reduces the accumulation of plastic waste in ecosystems and mitigates the long-term environmental impact associated with traditional gel formulations.

Water conservation is another area where PGA-based gel formulations demonstrate environmental benefits. These gels exhibit excellent water retention properties, which can lead to reduced water consumption in various applications, such as agriculture and personal care products. By improving water efficiency, PGA-based gels contribute to the conservation of this vital resource and help address water scarcity issues in many regions.

The production process of PGA-based gels also presents opportunities for environmental improvement. Compared to the energy-intensive manufacturing of synthetic polymers, the bacterial fermentation used to produce PGA typically requires less energy and generates fewer greenhouse gas emissions. This aspect further enhances the overall environmental sustainability of PGA-based gel formulations.

However, it is important to note that the environmental impact of PGA-based gels is not entirely without challenges. The large-scale production of these gels may require significant agricultural resources for the cultivation of bacteria or the sourcing of raw materials. This could potentially lead to land-use changes and competition with food crops, which must be carefully managed to ensure sustainable production practices.

Additionally, the end-of-life management of PGA-based gel products requires consideration. While biodegradable, proper disposal and recycling systems need to be in place to fully realize the environmental benefits of these materials. Education and infrastructure development are crucial to ensure that consumers and industries handle PGA-based gel products responsibly throughout their lifecycle.

In conclusion, PGA-based gel formulations offer substantial environmental advantages over traditional synthetic alternatives. Their biodegradability, renewable sourcing, and potential for water conservation contribute positively to sustainability efforts. However, ongoing research and development are necessary to optimize production processes, address potential resource competition, and establish effective end-of-life management strategies to maximize the environmental benefits of these innovative materials.

PGA-based gel formulations have shown promising results in reducing the ecological footprint of various industries. These gels are derived from renewable resources, primarily through bacterial fermentation, which significantly reduces the reliance on petrochemical-based raw materials. This shift towards bio-based materials aligns with global efforts to minimize carbon emissions and promote circular economy principles.

The biodegradability of PGA-based gels is a key factor in their environmental profile. Unlike many synthetic polymers that persist in the environment for extended periods, PGA-based gels can be broken down by naturally occurring microorganisms. This characteristic reduces the accumulation of plastic waste in ecosystems and mitigates the long-term environmental impact associated with traditional gel formulations.

Water conservation is another area where PGA-based gel formulations demonstrate environmental benefits. These gels exhibit excellent water retention properties, which can lead to reduced water consumption in various applications, such as agriculture and personal care products. By improving water efficiency, PGA-based gels contribute to the conservation of this vital resource and help address water scarcity issues in many regions.

The production process of PGA-based gels also presents opportunities for environmental improvement. Compared to the energy-intensive manufacturing of synthetic polymers, the bacterial fermentation used to produce PGA typically requires less energy and generates fewer greenhouse gas emissions. This aspect further enhances the overall environmental sustainability of PGA-based gel formulations.

However, it is important to note that the environmental impact of PGA-based gels is not entirely without challenges. The large-scale production of these gels may require significant agricultural resources for the cultivation of bacteria or the sourcing of raw materials. This could potentially lead to land-use changes and competition with food crops, which must be carefully managed to ensure sustainable production practices.

Additionally, the end-of-life management of PGA-based gel products requires consideration. While biodegradable, proper disposal and recycling systems need to be in place to fully realize the environmental benefits of these materials. Education and infrastructure development are crucial to ensure that consumers and industries handle PGA-based gel products responsibly throughout their lifecycle.

In conclusion, PGA-based gel formulations offer substantial environmental advantages over traditional synthetic alternatives. Their biodegradability, renewable sourcing, and potential for water conservation contribute positively to sustainability efforts. However, ongoing research and development are necessary to optimize production processes, address potential resource competition, and establish effective end-of-life management strategies to maximize the environmental benefits of these innovative materials.

Scalability and Cost Analysis of PGA in Gels

The scalability and cost analysis of polyglutamic acid (PGA) in gel formulations is crucial for assessing its commercial viability in heat-resistant applications. PGA production can be scaled up through fermentation processes using various bacterial strains, with Bacillus subtilis and Bacillus licheniformis being the most common. The scalability of PGA production is generally favorable, as these bacteria can be cultivated in large bioreactors under controlled conditions.

Industrial-scale production of PGA typically involves a two-stage fermentation process. The first stage focuses on cell growth, while the second stage optimizes PGA production. This approach allows for efficient use of resources and maximizes yield. However, the scalability of PGA production is not without challenges. Maintaining consistent quality across large batches and optimizing fermentation conditions for maximum yield are ongoing areas of research and development.

From a cost perspective, PGA production is relatively economical compared to some other biopolymers. The raw materials required for fermentation, such as glucose and glutamic acid, are readily available and cost-effective. However, the purification process can significantly impact the overall production cost. Advanced separation techniques, such as membrane filtration and chromatography, are often employed to achieve high-purity PGA, which can increase production expenses.

When considering the use of PGA in heat-resistant gel formulations, the cost-effectiveness becomes more nuanced. While PGA itself may be produced at a reasonable cost, its incorporation into gel formulations may require additional processing steps or specialized equipment. This could potentially increase the overall production cost of the final heat-resistant gel product.

The scalability of PGA-based heat-resistant gels also depends on the specific formulation and production process. Factors such as the concentration of PGA required, the need for additional additives, and the complexity of the gel formation process all influence scalability. In general, gel production processes are often amenable to scale-up, but careful consideration must be given to maintaining gel properties and performance at larger scales.

Market demand plays a crucial role in determining the economic viability of scaling up PGA-based heat-resistant gel production. As the applications for such gels expand in industries like cosmetics, pharmaceuticals, and food processing, the potential for large-scale production becomes more attractive. However, manufacturers must carefully balance production capacity with market demand to ensure cost-effectiveness and avoid overproduction.

Industrial-scale production of PGA typically involves a two-stage fermentation process. The first stage focuses on cell growth, while the second stage optimizes PGA production. This approach allows for efficient use of resources and maximizes yield. However, the scalability of PGA production is not without challenges. Maintaining consistent quality across large batches and optimizing fermentation conditions for maximum yield are ongoing areas of research and development.

From a cost perspective, PGA production is relatively economical compared to some other biopolymers. The raw materials required for fermentation, such as glucose and glutamic acid, are readily available and cost-effective. However, the purification process can significantly impact the overall production cost. Advanced separation techniques, such as membrane filtration and chromatography, are often employed to achieve high-purity PGA, which can increase production expenses.

When considering the use of PGA in heat-resistant gel formulations, the cost-effectiveness becomes more nuanced. While PGA itself may be produced at a reasonable cost, its incorporation into gel formulations may require additional processing steps or specialized equipment. This could potentially increase the overall production cost of the final heat-resistant gel product.

The scalability of PGA-based heat-resistant gels also depends on the specific formulation and production process. Factors such as the concentration of PGA required, the need for additional additives, and the complexity of the gel formation process all influence scalability. In general, gel production processes are often amenable to scale-up, but careful consideration must be given to maintaining gel properties and performance at larger scales.

Market demand plays a crucial role in determining the economic viability of scaling up PGA-based heat-resistant gel production. As the applications for such gels expand in industries like cosmetics, pharmaceuticals, and food processing, the potential for large-scale production becomes more attractive. However, manufacturers must carefully balance production capacity with market demand to ensure cost-effectiveness and avoid overproduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!