How Polyglutamic Acid Assists in Building Bio-inspired Materials

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PGA in Bio-Materials: Background and Objectives

Polyglutamic acid (PGA) has emerged as a promising biomaterial in recent years, drawing significant attention from researchers and industry professionals alike. This naturally occurring biopolymer, produced by various microorganisms, particularly Bacillus subtilis, has a rich history dating back to its discovery in the 1930s. Initially recognized for its role in traditional Japanese fermented foods, PGA has since evolved into a versatile compound with applications spanning multiple fields.

The evolution of PGA research has been marked by several key milestones. In the 1950s, scientists began to unravel its chemical structure and properties, laying the groundwork for future applications. The 1980s saw a surge in interest as researchers explored PGA's potential in drug delivery systems. By the turn of the millennium, the focus shifted towards its use in tissue engineering and regenerative medicine, aligning with the growing field of biomaterials.

In the context of bio-inspired materials, PGA's unique properties make it an ideal candidate for mimicking natural structures and functions. Its biodegradability, biocompatibility, and ability to form complex structures have positioned it at the forefront of biomaterial research. The polymer's capacity to interact with various biological entities, coupled with its adaptability to different forms such as hydrogels, nanoparticles, and scaffolds, has opened up new avenues for creating advanced bio-inspired materials.

The primary objective of PGA research in bio-inspired materials is to harness its inherent characteristics to develop innovative solutions that emulate natural systems. This includes creating materials with enhanced mechanical properties, improved biocompatibility, and the ability to respond to environmental stimuli. Researchers aim to exploit PGA's versatility to address challenges in tissue engineering, drug delivery, wound healing, and environmental remediation.

Another critical goal is to understand and optimize the interaction between PGA and other biological components, such as cells, proteins, and other polymers. This knowledge is essential for designing composite materials that can more accurately mimic the complexity of natural tissues and organs. Additionally, there is a growing emphasis on developing sustainable production methods for PGA, aligning with the broader trend towards eco-friendly materials in various industries.

As we look towards the future, the trajectory of PGA in bio-inspired materials is poised for significant advancements. The integration of PGA with emerging technologies like 3D bioprinting and nanotechnology presents exciting possibilities for creating highly sophisticated biomaterials. Moreover, the potential for PGA to contribute to the development of smart, responsive materials that can adapt to biological environments holds promise for revolutionary applications in personalized medicine and advanced healthcare solutions.

The evolution of PGA research has been marked by several key milestones. In the 1950s, scientists began to unravel its chemical structure and properties, laying the groundwork for future applications. The 1980s saw a surge in interest as researchers explored PGA's potential in drug delivery systems. By the turn of the millennium, the focus shifted towards its use in tissue engineering and regenerative medicine, aligning with the growing field of biomaterials.

In the context of bio-inspired materials, PGA's unique properties make it an ideal candidate for mimicking natural structures and functions. Its biodegradability, biocompatibility, and ability to form complex structures have positioned it at the forefront of biomaterial research. The polymer's capacity to interact with various biological entities, coupled with its adaptability to different forms such as hydrogels, nanoparticles, and scaffolds, has opened up new avenues for creating advanced bio-inspired materials.

The primary objective of PGA research in bio-inspired materials is to harness its inherent characteristics to develop innovative solutions that emulate natural systems. This includes creating materials with enhanced mechanical properties, improved biocompatibility, and the ability to respond to environmental stimuli. Researchers aim to exploit PGA's versatility to address challenges in tissue engineering, drug delivery, wound healing, and environmental remediation.

Another critical goal is to understand and optimize the interaction between PGA and other biological components, such as cells, proteins, and other polymers. This knowledge is essential for designing composite materials that can more accurately mimic the complexity of natural tissues and organs. Additionally, there is a growing emphasis on developing sustainable production methods for PGA, aligning with the broader trend towards eco-friendly materials in various industries.

As we look towards the future, the trajectory of PGA in bio-inspired materials is poised for significant advancements. The integration of PGA with emerging technologies like 3D bioprinting and nanotechnology presents exciting possibilities for creating highly sophisticated biomaterials. Moreover, the potential for PGA to contribute to the development of smart, responsive materials that can adapt to biological environments holds promise for revolutionary applications in personalized medicine and advanced healthcare solutions.

Market Analysis for PGA-Based Bio-inspired Materials

The market for polyglutamic acid (PGA)-based bio-inspired materials is experiencing significant growth, driven by increasing demand for sustainable and biodegradable alternatives across various industries. PGA, a naturally occurring biopolymer, has gained attention for its unique properties that make it suitable for developing bio-inspired materials with diverse applications.

In the healthcare sector, PGA-based materials are finding applications in drug delivery systems, tissue engineering, and wound healing. The global market for biodegradable polymers in medical applications is projected to reach several billion dollars by 2025, with PGA-based materials expected to capture a substantial share. The cosmetics industry is another key market for PGA-based materials, particularly in skincare products, where PGA's moisture-retaining properties are highly valued.

The food and beverage industry is also adopting PGA-based materials for packaging solutions, driven by the growing consumer demand for eco-friendly alternatives to traditional plastics. This sector's shift towards sustainable packaging is expected to create significant opportunities for PGA-based materials in the coming years.

In the agricultural sector, PGA-based materials are being explored for controlled-release fertilizers and soil conditioners, addressing the need for more sustainable farming practices. The global market for biodegradable agricultural films and other eco-friendly agricultural inputs is expanding rapidly, presenting a promising avenue for PGA-based materials.

The textile industry is another potential growth area for PGA-based materials, with applications in biodegradable fibers and fabrics. As consumers become more environmentally conscious, the demand for sustainable textiles is increasing, creating opportunities for PGA-based innovations.

Geographically, North America and Europe are currently the leading markets for PGA-based bio-inspired materials, due to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable technologies.

Key market challenges include the relatively high production costs of PGA compared to conventional synthetic polymers and the need for further research to optimize PGA-based materials for specific applications. However, ongoing technological advancements and increasing economies of scale are expected to gradually address these challenges, further driving market growth.

In the healthcare sector, PGA-based materials are finding applications in drug delivery systems, tissue engineering, and wound healing. The global market for biodegradable polymers in medical applications is projected to reach several billion dollars by 2025, with PGA-based materials expected to capture a substantial share. The cosmetics industry is another key market for PGA-based materials, particularly in skincare products, where PGA's moisture-retaining properties are highly valued.

The food and beverage industry is also adopting PGA-based materials for packaging solutions, driven by the growing consumer demand for eco-friendly alternatives to traditional plastics. This sector's shift towards sustainable packaging is expected to create significant opportunities for PGA-based materials in the coming years.

In the agricultural sector, PGA-based materials are being explored for controlled-release fertilizers and soil conditioners, addressing the need for more sustainable farming practices. The global market for biodegradable agricultural films and other eco-friendly agricultural inputs is expanding rapidly, presenting a promising avenue for PGA-based materials.

The textile industry is another potential growth area for PGA-based materials, with applications in biodegradable fibers and fabrics. As consumers become more environmentally conscious, the demand for sustainable textiles is increasing, creating opportunities for PGA-based innovations.

Geographically, North America and Europe are currently the leading markets for PGA-based bio-inspired materials, due to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable technologies.

Key market challenges include the relatively high production costs of PGA compared to conventional synthetic polymers and the need for further research to optimize PGA-based materials for specific applications. However, ongoing technological advancements and increasing economies of scale are expected to gradually address these challenges, further driving market growth.

Current Challenges in PGA Synthesis and Application

Despite the promising potential of polyglutamic acid (PGA) in bio-inspired materials, several challenges persist in its synthesis and application. One of the primary obstacles is the high cost and complexity of PGA production. Current methods, including microbial fermentation and chemical synthesis, often yield low productivity and require extensive purification processes, making large-scale production economically unfeasible for many applications.

The control of PGA molecular weight and polydispersity remains a significant challenge. The ability to precisely tailor these properties is crucial for optimizing PGA's performance in various bio-inspired materials. However, current synthesis methods often result in heterogeneous products with broad molecular weight distributions, limiting their effectiveness in specific applications that require uniform properties.

Another hurdle is the limited understanding of PGA's structure-function relationships in complex biological environments. While PGA shows promise in mimicking natural materials, its interactions with other biomolecules and its behavior under different physiological conditions are not fully elucidated. This knowledge gap hinders the rational design of PGA-based bio-inspired materials for targeted applications.

The modification of PGA to enhance its functionality and compatibility with other materials presents additional challenges. Although various chemical modifications have been explored, many result in undesired side reactions or compromise the biodegradability of PGA. Developing selective and efficient modification strategies that preserve PGA's beneficial properties while introducing new functionalities remains an active area of research.

Scalability and reproducibility in PGA-based material fabrication pose significant obstacles. The transition from laboratory-scale synthesis to industrial production often encounters issues related to batch-to-batch variability and process control. Ensuring consistent quality and properties of PGA-based materials across different production scales is essential for their commercial viability.

Lastly, the long-term stability and degradation kinetics of PGA in various environments need further investigation. While biodegradability is often a desired trait, controlling the rate and products of degradation is crucial for many applications, particularly in biomedical and environmental fields. Understanding and manipulating these aspects remain challenging, especially when PGA is incorporated into complex, multi-component bio-inspired materials.

Addressing these challenges requires interdisciplinary approaches, combining advances in biotechnology, polymer chemistry, materials science, and engineering. Overcoming these hurdles will be critical in realizing the full potential of PGA in the development of innovative bio-inspired materials across various sectors.

The control of PGA molecular weight and polydispersity remains a significant challenge. The ability to precisely tailor these properties is crucial for optimizing PGA's performance in various bio-inspired materials. However, current synthesis methods often result in heterogeneous products with broad molecular weight distributions, limiting their effectiveness in specific applications that require uniform properties.

Another hurdle is the limited understanding of PGA's structure-function relationships in complex biological environments. While PGA shows promise in mimicking natural materials, its interactions with other biomolecules and its behavior under different physiological conditions are not fully elucidated. This knowledge gap hinders the rational design of PGA-based bio-inspired materials for targeted applications.

The modification of PGA to enhance its functionality and compatibility with other materials presents additional challenges. Although various chemical modifications have been explored, many result in undesired side reactions or compromise the biodegradability of PGA. Developing selective and efficient modification strategies that preserve PGA's beneficial properties while introducing new functionalities remains an active area of research.

Scalability and reproducibility in PGA-based material fabrication pose significant obstacles. The transition from laboratory-scale synthesis to industrial production often encounters issues related to batch-to-batch variability and process control. Ensuring consistent quality and properties of PGA-based materials across different production scales is essential for their commercial viability.

Lastly, the long-term stability and degradation kinetics of PGA in various environments need further investigation. While biodegradability is often a desired trait, controlling the rate and products of degradation is crucial for many applications, particularly in biomedical and environmental fields. Understanding and manipulating these aspects remain challenging, especially when PGA is incorporated into complex, multi-component bio-inspired materials.

Addressing these challenges requires interdisciplinary approaches, combining advances in biotechnology, polymer chemistry, materials science, and engineering. Overcoming these hurdles will be critical in realizing the full potential of PGA in the development of innovative bio-inspired materials across various sectors.

Existing PGA-Based Bio-inspired Material Solutions

01 Production methods of polyglutamic acid

Various methods for producing polyglutamic acid are described, including fermentation techniques using microorganisms, enzymatic synthesis, and chemical synthesis. These methods aim to optimize yield, purity, and molecular weight of the resulting polyglutamic acid.- Production methods of polyglutamic acid: Various methods for producing polyglutamic acid are described, including fermentation techniques using microorganisms, enzymatic synthesis, and chemical synthesis. These methods aim to optimize yield, purity, and molecular weight of the resulting polyglutamic acid.

- Applications in cosmetics and personal care: Polyglutamic acid is utilized in cosmetic and personal care products due to its moisturizing, anti-aging, and skin-conditioning properties. It can be incorporated into formulations such as creams, lotions, and serums to improve skin hydration and texture.

- Medical and pharmaceutical applications: Polyglutamic acid has various medical and pharmaceutical applications, including drug delivery systems, tissue engineering scaffolds, and wound healing materials. Its biocompatibility and biodegradability make it suitable for use in medical devices and drug formulations.

- Agricultural and environmental uses: Polyglutamic acid finds applications in agriculture and environmental protection, such as soil conditioners, plant growth promoters, and water treatment agents. It can improve soil structure, enhance nutrient uptake by plants, and aid in the removal of pollutants from water.

- Modifications and derivatives of polyglutamic acid: Various modifications and derivatives of polyglutamic acid are developed to enhance its properties or create new functionalities. These include chemical modifications, copolymerization with other monomers, and the creation of composite materials incorporating polyglutamic acid.

02 Applications in cosmetics and personal care

Polyglutamic acid is utilized in cosmetic and personal care products due to its moisturizing, anti-aging, and skin-conditioning properties. It can be incorporated into formulations such as creams, lotions, and serums to improve skin hydration and texture.Expand Specific Solutions03 Medical and pharmaceutical applications

Polyglutamic acid has various medical and pharmaceutical applications, including drug delivery systems, tissue engineering scaffolds, and wound healing materials. Its biocompatibility and biodegradability make it suitable for use in medical devices and treatments.Expand Specific Solutions04 Agricultural and environmental uses

Polyglutamic acid finds applications in agriculture and environmental protection, such as soil conditioners, plant growth promoters, and water treatment agents. It can improve soil structure, enhance nutrient uptake by plants, and aid in water purification processes.Expand Specific Solutions05 Modifications and derivatives of polyglutamic acid

Research focuses on developing modified forms and derivatives of polyglutamic acid to enhance its properties or create new functionalities. These modifications can include chemical alterations, crosslinking, or combining with other materials to create novel composites or hybrid materials.Expand Specific Solutions

Key Players in PGA Research and Bio-material Industry

The development of bio-inspired materials using polyglutamic acid is in an emerging phase, with significant potential for growth. The market size is expanding as researchers explore applications in various fields, including biomedicine, tissue engineering, and sustainable materials. The technology's maturity is progressing, with key players like Massachusetts Institute of Technology, Tufts University, and Osaka University leading research efforts. Companies such as Toyobo Co., Ltd. and METabolic EXplorer SA are also contributing to the field's advancement. While still in early stages, the competitive landscape is dynamic, with academic institutions and industry players collaborating to push the boundaries of this promising technology.

Sichuan University

Technical Solution: Sichuan University has developed a unique approach to using PGA in bio-inspired materials, focusing on its application in drug delivery systems and tissue engineering. Their research involves creating PGA-based nanoparticles that can encapsulate and deliver therapeutic agents more effectively[6]. These nanoparticles show improved cellular uptake and controlled release profiles. The university has also explored the use of PGA in creating bioactive scaffolds for bone tissue engineering, incorporating minerals and growth factors to enhance bone regeneration[7]. Additionally, they have investigated the potential of PGA-based hydrogels for wound healing applications, leveraging the material's biocompatibility and biodegradability[8].

Strengths: Strong focus on pharmaceutical and biomedical applications, innovative nanoparticle technology, and diverse range of potential uses. Weaknesses: May face challenges in translating research findings into commercial products and navigating regulatory pathways.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach to using polyglutamic acid (PGA) in bio-inspired materials. Their research focuses on creating self-healing hydrogels by incorporating PGA into a polymer network. The PGA chains form reversible ionic crosslinks, allowing the material to repair itself after damage[1]. This technology has potential applications in soft robotics and biomedical devices. MIT researchers have also explored using PGA as a building block for creating biomimetic materials that mimic the properties of natural tissues, such as cartilage and tendons[3].

Strengths: Advanced self-healing capabilities, biocompatibility, and potential for diverse applications. Weaknesses: May face challenges in scaling up production and ensuring long-term stability in various environments.

Innovative PGA Applications in Bio-inspired Materials

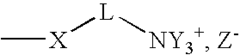

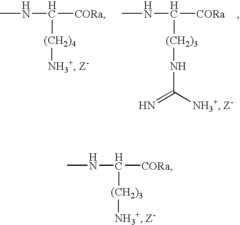

Polyglutamic acids functionalized by cationic groups and hydrophobic groups and applications thereof, in particular therapeutic applications thereof

PatentInactiveEP2152782A1

Innovation

- Development of amphiphilic copolyglutamates with both cationic and hydrophobic groups, allowing for the formation of stable colloidal suspensions that can reversibly associate with active principles, modulate charge, and degrade into non-toxic products.

Polyglutamic acids functionalized by cationic groups and hydrophobic groups and applications thereof, in particular therapeutic applications thereof

PatentInactiveUS20090012028A1

Innovation

- Development of novel amphiphilic copolyglutamates with pendant cationic and hydrophobic groups that form stable colloidal suspensions, associate with active principles, and degrade into non-toxic products, allowing for controlled release and enhanced bioavailability.

Environmental Impact of PGA-Based Materials

The environmental impact of PGA-based materials is a crucial consideration in the development and application of bio-inspired materials. Polyglutamic acid (PGA), as a biodegradable and biocompatible polymer, offers significant advantages in terms of sustainability and eco-friendliness compared to traditional synthetic materials.

One of the primary environmental benefits of PGA-based materials is their biodegradability. Unlike many conventional plastics that persist in the environment for hundreds of years, PGA can be broken down by natural processes within a relatively short timeframe. This characteristic significantly reduces the accumulation of waste in landfills and oceans, mitigating the long-term environmental impact associated with non-biodegradable materials.

Furthermore, the production of PGA through microbial fermentation processes is generally considered more environmentally friendly than the synthesis of petroleum-based polymers. The renewable nature of the raw materials used in PGA production, such as agricultural by-products, contributes to a reduced carbon footprint and decreased reliance on fossil fuel resources.

PGA-based materials also demonstrate potential in various environmental applications. For instance, they can be used in the development of eco-friendly packaging solutions, reducing the environmental burden of single-use plastics. Additionally, PGA has shown promise in soil remediation and water treatment applications, offering sustainable alternatives to conventional chemical treatments.

However, it is important to consider the full life cycle of PGA-based materials when assessing their environmental impact. While the end-of-life phase may be more environmentally benign due to biodegradability, the production and processing stages still require energy and resources. Ongoing research is focused on optimizing these processes to further reduce the overall environmental footprint of PGA-based materials.

The scalability of PGA production and its integration into existing manufacturing processes are key factors that will influence the widespread adoption and consequent environmental impact of these materials. As production techniques improve and become more efficient, the potential for PGA to replace less environmentally friendly materials in various applications increases.

In conclusion, while PGA-based materials offer significant environmental advantages, particularly in terms of biodegradability and renewable sourcing, continued research and development are necessary to fully realize their potential as sustainable alternatives across diverse industries. The ongoing assessment of their life cycle impact and the optimization of production processes will be crucial in maximizing the positive environmental contributions of PGA-based bio-inspired materials.

One of the primary environmental benefits of PGA-based materials is their biodegradability. Unlike many conventional plastics that persist in the environment for hundreds of years, PGA can be broken down by natural processes within a relatively short timeframe. This characteristic significantly reduces the accumulation of waste in landfills and oceans, mitigating the long-term environmental impact associated with non-biodegradable materials.

Furthermore, the production of PGA through microbial fermentation processes is generally considered more environmentally friendly than the synthesis of petroleum-based polymers. The renewable nature of the raw materials used in PGA production, such as agricultural by-products, contributes to a reduced carbon footprint and decreased reliance on fossil fuel resources.

PGA-based materials also demonstrate potential in various environmental applications. For instance, they can be used in the development of eco-friendly packaging solutions, reducing the environmental burden of single-use plastics. Additionally, PGA has shown promise in soil remediation and water treatment applications, offering sustainable alternatives to conventional chemical treatments.

However, it is important to consider the full life cycle of PGA-based materials when assessing their environmental impact. While the end-of-life phase may be more environmentally benign due to biodegradability, the production and processing stages still require energy and resources. Ongoing research is focused on optimizing these processes to further reduce the overall environmental footprint of PGA-based materials.

The scalability of PGA production and its integration into existing manufacturing processes are key factors that will influence the widespread adoption and consequent environmental impact of these materials. As production techniques improve and become more efficient, the potential for PGA to replace less environmentally friendly materials in various applications increases.

In conclusion, while PGA-based materials offer significant environmental advantages, particularly in terms of biodegradability and renewable sourcing, continued research and development are necessary to fully realize their potential as sustainable alternatives across diverse industries. The ongoing assessment of their life cycle impact and the optimization of production processes will be crucial in maximizing the positive environmental contributions of PGA-based bio-inspired materials.

Scalability and Cost-effectiveness of PGA Production

The scalability and cost-effectiveness of polyglutamic acid (PGA) production are crucial factors in determining its viability for large-scale applications in bio-inspired materials. Current production methods primarily rely on microbial fermentation, with Bacillus subtilis and related strains being the most common producers. While these methods have shown promise, there are several challenges to overcome for industrial-scale production.

One of the main hurdles is the optimization of fermentation conditions to maximize PGA yield. Factors such as pH, temperature, oxygen levels, and nutrient composition significantly impact production efficiency. Recent advancements in bioreactor design and process control have led to improved yields, but further refinements are necessary to achieve economically viable production rates.

The choice of raw materials also plays a critical role in the cost-effectiveness of PGA production. Traditional carbon sources like glucose can be expensive, prompting research into alternative substrates. Promising results have been obtained using agricultural and industrial by-products, such as molasses, corn steep liquor, and glycerol. These low-cost substrates not only reduce production expenses but also contribute to sustainable manufacturing practices.

Downstream processing and purification of PGA represent another significant challenge in scaling up production. Current methods often involve multiple steps, including cell separation, precipitation, and dialysis, which can be time-consuming and costly. Innovations in separation technologies, such as membrane filtration and chromatography, are being explored to streamline these processes and reduce overall production costs.

The development of genetically engineered strains offers a potential solution to enhance PGA production efficiency. By manipulating key enzymes involved in PGA synthesis or introducing genes from high-yielding strains, researchers aim to create "super-producer" microorganisms. While promising, this approach requires careful consideration of regulatory and safety aspects, particularly for applications in biomedical fields.

As demand for bio-inspired materials grows, economies of scale are expected to drive down PGA production costs. However, this will require significant investment in infrastructure and process optimization. Collaborations between academic institutions and industry partners are crucial for translating laboratory-scale successes into commercially viable production methods.

In conclusion, while challenges remain in scaling up PGA production, ongoing research and technological advancements are steadily improving its cost-effectiveness. The successful integration of these innovations will be key to unlocking the full potential of PGA in the development of bio-inspired materials across various industries.

One of the main hurdles is the optimization of fermentation conditions to maximize PGA yield. Factors such as pH, temperature, oxygen levels, and nutrient composition significantly impact production efficiency. Recent advancements in bioreactor design and process control have led to improved yields, but further refinements are necessary to achieve economically viable production rates.

The choice of raw materials also plays a critical role in the cost-effectiveness of PGA production. Traditional carbon sources like glucose can be expensive, prompting research into alternative substrates. Promising results have been obtained using agricultural and industrial by-products, such as molasses, corn steep liquor, and glycerol. These low-cost substrates not only reduce production expenses but also contribute to sustainable manufacturing practices.

Downstream processing and purification of PGA represent another significant challenge in scaling up production. Current methods often involve multiple steps, including cell separation, precipitation, and dialysis, which can be time-consuming and costly. Innovations in separation technologies, such as membrane filtration and chromatography, are being explored to streamline these processes and reduce overall production costs.

The development of genetically engineered strains offers a potential solution to enhance PGA production efficiency. By manipulating key enzymes involved in PGA synthesis or introducing genes from high-yielding strains, researchers aim to create "super-producer" microorganisms. While promising, this approach requires careful consideration of regulatory and safety aspects, particularly for applications in biomedical fields.

As demand for bio-inspired materials grows, economies of scale are expected to drive down PGA production costs. However, this will require significant investment in infrastructure and process optimization. Collaborations between academic institutions and industry partners are crucial for translating laboratory-scale successes into commercially viable production methods.

In conclusion, while challenges remain in scaling up PGA production, ongoing research and technological advancements are steadily improving its cost-effectiveness. The successful integration of these innovations will be key to unlocking the full potential of PGA in the development of bio-inspired materials across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!