Polyglutamic Acid in the Reformulation of Biodegradable Fishing Nets

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PGA Fishing Net Background and Objectives

Polyglutamic acid (PGA) has emerged as a promising material in the reformulation of biodegradable fishing nets, addressing the critical issue of marine plastic pollution. The fishing industry has long relied on synthetic materials for net production, primarily due to their durability and cost-effectiveness. However, these conventional nets contribute significantly to ocean pollution, as they persist in marine environments for decades, entangling marine life and degrading ecosystems.

The development of PGA-based fishing nets represents a paradigm shift in sustainable fishing practices. PGA, a naturally occurring biopolymer, offers a unique combination of biodegradability and strength, making it an ideal candidate for eco-friendly fishing gear. This research initiative aims to explore the potential of PGA in creating fishing nets that maintain the necessary performance characteristics while significantly reducing environmental impact.

The primary objective of this research is to develop a PGA-based fishing net that matches or exceeds the performance of traditional synthetic nets in terms of tensile strength, durability, and resistance to marine conditions. Concurrently, the project seeks to ensure that these nets degrade harmlessly in marine environments within a reasonable timeframe, typically ranging from 6 to 24 months, depending on specific application requirements.

Another crucial goal is to optimize the production process of PGA-based nets to make them economically viable for widespread adoption in the fishing industry. This involves investigating cost-effective methods for PGA synthesis, exploring potential additives to enhance material properties, and developing efficient manufacturing techniques for net production.

The research also aims to conduct comprehensive environmental impact assessments of PGA-based nets throughout their lifecycle. This includes evaluating the sourcing of raw materials, energy consumption during production, performance during use, and the environmental effects of degradation products in marine ecosystems.

Furthermore, this project seeks to establish collaborations with fishing industry stakeholders, marine biologists, and environmental agencies to ensure that the developed nets meet practical requirements while adhering to evolving environmental regulations. These partnerships will be crucial in field-testing prototypes and gathering real-world performance data.

Lastly, the research aims to contribute to the broader scientific understanding of biodegradable materials in marine applications. By thoroughly investigating the behavior of PGA in various marine conditions, this project will generate valuable data that can inform future developments in sustainable marine technologies beyond fishing nets.

The development of PGA-based fishing nets represents a paradigm shift in sustainable fishing practices. PGA, a naturally occurring biopolymer, offers a unique combination of biodegradability and strength, making it an ideal candidate for eco-friendly fishing gear. This research initiative aims to explore the potential of PGA in creating fishing nets that maintain the necessary performance characteristics while significantly reducing environmental impact.

The primary objective of this research is to develop a PGA-based fishing net that matches or exceeds the performance of traditional synthetic nets in terms of tensile strength, durability, and resistance to marine conditions. Concurrently, the project seeks to ensure that these nets degrade harmlessly in marine environments within a reasonable timeframe, typically ranging from 6 to 24 months, depending on specific application requirements.

Another crucial goal is to optimize the production process of PGA-based nets to make them economically viable for widespread adoption in the fishing industry. This involves investigating cost-effective methods for PGA synthesis, exploring potential additives to enhance material properties, and developing efficient manufacturing techniques for net production.

The research also aims to conduct comprehensive environmental impact assessments of PGA-based nets throughout their lifecycle. This includes evaluating the sourcing of raw materials, energy consumption during production, performance during use, and the environmental effects of degradation products in marine ecosystems.

Furthermore, this project seeks to establish collaborations with fishing industry stakeholders, marine biologists, and environmental agencies to ensure that the developed nets meet practical requirements while adhering to evolving environmental regulations. These partnerships will be crucial in field-testing prototypes and gathering real-world performance data.

Lastly, the research aims to contribute to the broader scientific understanding of biodegradable materials in marine applications. By thoroughly investigating the behavior of PGA in various marine conditions, this project will generate valuable data that can inform future developments in sustainable marine technologies beyond fishing nets.

Market Analysis for Eco-Friendly Fishing Gear

The market for eco-friendly fishing gear has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations aimed at protecting marine ecosystems. The global fishing nets market, valued at $1.5 billion in 2020, is projected to reach $2.1 billion by 2027, with biodegradable fishing nets emerging as a key segment within this market.

The demand for biodegradable fishing nets, particularly those incorporating polyglutamic acid, is on the rise due to their potential to mitigate the harmful effects of ghost fishing and marine plastic pollution. Ghost fishing, caused by abandoned or lost fishing gear, is responsible for the entanglement and death of millions of marine animals annually. This has led to a growing interest in sustainable alternatives among fishing communities, environmental organizations, and regulatory bodies.

Several factors are driving the market demand for eco-friendly fishing gear. Firstly, there is increasing pressure from consumers and environmental groups for sustainable fishing practices. This has prompted major retailers and seafood companies to commit to sourcing fish caught using environmentally friendly methods, including biodegradable fishing gear.

Secondly, government regulations and international agreements are playing a crucial role in shaping the market. The European Union, for instance, has implemented measures to reduce marine litter, including incentives for the use of biodegradable fishing gear. Similarly, the United Nations' Sustainable Development Goal 14 emphasizes the importance of sustainable use of marine resources, further driving the adoption of eco-friendly fishing practices.

The market for biodegradable fishing nets is not without challenges. The higher cost of production compared to traditional synthetic nets remains a significant barrier to widespread adoption, particularly in developing countries where cost is a primary concern. However, as technology advances and production scales up, the price gap is expected to narrow, making eco-friendly options more accessible.

Geographically, Europe and North America currently lead the market for eco-friendly fishing gear, owing to stricter environmental regulations and higher consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the increasing focus on sustainable fishing practices in countries with large fishing industries such as China, Japan, and Indonesia.

In conclusion, the market for eco-friendly fishing gear, particularly biodegradable fishing nets incorporating polyglutamic acid, shows promising growth potential. As environmental concerns continue to mount and technological advancements make these solutions more viable, the demand for such products is expected to surge, reshaping the fishing industry towards more sustainable practices.

The demand for biodegradable fishing nets, particularly those incorporating polyglutamic acid, is on the rise due to their potential to mitigate the harmful effects of ghost fishing and marine plastic pollution. Ghost fishing, caused by abandoned or lost fishing gear, is responsible for the entanglement and death of millions of marine animals annually. This has led to a growing interest in sustainable alternatives among fishing communities, environmental organizations, and regulatory bodies.

Several factors are driving the market demand for eco-friendly fishing gear. Firstly, there is increasing pressure from consumers and environmental groups for sustainable fishing practices. This has prompted major retailers and seafood companies to commit to sourcing fish caught using environmentally friendly methods, including biodegradable fishing gear.

Secondly, government regulations and international agreements are playing a crucial role in shaping the market. The European Union, for instance, has implemented measures to reduce marine litter, including incentives for the use of biodegradable fishing gear. Similarly, the United Nations' Sustainable Development Goal 14 emphasizes the importance of sustainable use of marine resources, further driving the adoption of eco-friendly fishing practices.

The market for biodegradable fishing nets is not without challenges. The higher cost of production compared to traditional synthetic nets remains a significant barrier to widespread adoption, particularly in developing countries where cost is a primary concern. However, as technology advances and production scales up, the price gap is expected to narrow, making eco-friendly options more accessible.

Geographically, Europe and North America currently lead the market for eco-friendly fishing gear, owing to stricter environmental regulations and higher consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the increasing focus on sustainable fishing practices in countries with large fishing industries such as China, Japan, and Indonesia.

In conclusion, the market for eco-friendly fishing gear, particularly biodegradable fishing nets incorporating polyglutamic acid, shows promising growth potential. As environmental concerns continue to mount and technological advancements make these solutions more viable, the demand for such products is expected to surge, reshaping the fishing industry towards more sustainable practices.

Current PGA Technology and Challenges

Polyglutamic acid (PGA) has emerged as a promising material for the development of biodegradable fishing nets, addressing the critical issue of marine plastic pollution. The current state of PGA technology in this application is characterized by significant advancements but also faces several challenges that require further research and innovation.

PGA, a biodegradable polymer produced by microbial fermentation, has shown remarkable potential in creating eco-friendly fishing gear. Its biodegradability in marine environments, coupled with its strength and durability, makes it an ideal candidate for replacing conventional synthetic materials used in fishing nets. Recent studies have demonstrated that PGA-based nets can maintain their structural integrity for the required fishing period while degrading naturally afterward, significantly reducing the environmental impact of lost or discarded fishing gear.

One of the primary technological achievements in PGA-based fishing nets is the development of optimized production processes. Researchers have made substantial progress in enhancing the efficiency of PGA synthesis through improved fermentation techniques and strain selection. This has led to increased yields and reduced production costs, making PGA more economically viable for large-scale applications in the fishing industry.

However, despite these advancements, several challenges persist in the widespread adoption of PGA technology for fishing nets. One of the main obstacles is the variability in degradation rates under different marine conditions. Factors such as water temperature, salinity, and microbial activity can significantly affect the degradation process, making it difficult to predict the lifespan of PGA-based nets accurately. This uncertainty poses challenges for fishermen who require reliable gear with predictable performance characteristics.

Another significant challenge lies in the mechanical properties of PGA-based materials. While PGA exhibits good strength and flexibility, achieving the optimal balance between durability and biodegradability remains a complex task. Researchers are working on developing composite materials and blends that can enhance the mechanical properties of PGA without compromising its biodegradability. This includes exploring various additives and processing techniques to improve tensile strength, knot strength, and abrasion resistance, which are crucial for fishing net applications.

The scalability of PGA production also presents a considerable challenge. Current production methods are primarily focused on small-scale or laboratory settings, and scaling up to meet the demands of the global fishing industry requires significant technological and infrastructural investments. This includes developing more efficient fermentation processes, optimizing downstream processing, and establishing robust supply chains for raw materials.

Furthermore, the regulatory landscape surrounding biodegradable fishing gear is still evolving. The lack of standardized testing methods and certification processes for biodegradable fishing nets creates uncertainty for manufacturers and end-users alike. Developing internationally recognized standards for assessing the performance and environmental impact of PGA-based fishing nets is crucial for their widespread adoption and regulatory approval.

In conclusion, while PGA technology shows great promise in reformulating biodegradable fishing nets, it faces a complex set of challenges that span material science, production technology, and regulatory frameworks. Addressing these challenges requires a multidisciplinary approach, combining expertise from polymer science, marine biology, and environmental engineering to develop innovative solutions that can revolutionize the fishing industry and contribute to the preservation of marine ecosystems.

PGA, a biodegradable polymer produced by microbial fermentation, has shown remarkable potential in creating eco-friendly fishing gear. Its biodegradability in marine environments, coupled with its strength and durability, makes it an ideal candidate for replacing conventional synthetic materials used in fishing nets. Recent studies have demonstrated that PGA-based nets can maintain their structural integrity for the required fishing period while degrading naturally afterward, significantly reducing the environmental impact of lost or discarded fishing gear.

One of the primary technological achievements in PGA-based fishing nets is the development of optimized production processes. Researchers have made substantial progress in enhancing the efficiency of PGA synthesis through improved fermentation techniques and strain selection. This has led to increased yields and reduced production costs, making PGA more economically viable for large-scale applications in the fishing industry.

However, despite these advancements, several challenges persist in the widespread adoption of PGA technology for fishing nets. One of the main obstacles is the variability in degradation rates under different marine conditions. Factors such as water temperature, salinity, and microbial activity can significantly affect the degradation process, making it difficult to predict the lifespan of PGA-based nets accurately. This uncertainty poses challenges for fishermen who require reliable gear with predictable performance characteristics.

Another significant challenge lies in the mechanical properties of PGA-based materials. While PGA exhibits good strength and flexibility, achieving the optimal balance between durability and biodegradability remains a complex task. Researchers are working on developing composite materials and blends that can enhance the mechanical properties of PGA without compromising its biodegradability. This includes exploring various additives and processing techniques to improve tensile strength, knot strength, and abrasion resistance, which are crucial for fishing net applications.

The scalability of PGA production also presents a considerable challenge. Current production methods are primarily focused on small-scale or laboratory settings, and scaling up to meet the demands of the global fishing industry requires significant technological and infrastructural investments. This includes developing more efficient fermentation processes, optimizing downstream processing, and establishing robust supply chains for raw materials.

Furthermore, the regulatory landscape surrounding biodegradable fishing gear is still evolving. The lack of standardized testing methods and certification processes for biodegradable fishing nets creates uncertainty for manufacturers and end-users alike. Developing internationally recognized standards for assessing the performance and environmental impact of PGA-based fishing nets is crucial for their widespread adoption and regulatory approval.

In conclusion, while PGA technology shows great promise in reformulating biodegradable fishing nets, it faces a complex set of challenges that span material science, production technology, and regulatory frameworks. Addressing these challenges requires a multidisciplinary approach, combining expertise from polymer science, marine biology, and environmental engineering to develop innovative solutions that can revolutionize the fishing industry and contribute to the preservation of marine ecosystems.

Existing PGA-based Fishing Net Solutions

01 Biodegradability of polyglutamic acid

Polyglutamic acid is a naturally occurring biopolymer that exhibits excellent biodegradability. It can be broken down by various microorganisms in the environment, making it an eco-friendly alternative to synthetic polymers. The biodegradation process of polyglutamic acid typically involves enzymatic hydrolysis, resulting in the formation of non-toxic byproducts that can be easily assimilated by microorganisms.- Biodegradability of polyglutamic acid: Polyglutamic acid is a naturally occurring biopolymer that exhibits excellent biodegradability. It can be broken down by various microorganisms in the environment, making it an eco-friendly alternative to synthetic polymers. The biodegradation process of polyglutamic acid typically involves hydrolysis and enzymatic degradation, resulting in non-toxic byproducts that can be safely assimilated into the ecosystem.

- Production methods for biodegradable polyglutamic acid: Various methods have been developed to produce biodegradable polyglutamic acid. These include microbial fermentation using bacteria such as Bacillus subtilis, enzymatic polymerization, and chemical synthesis. The production methods can be optimized to enhance the biodegradability of the resulting polyglutamic acid by controlling factors such as molecular weight, degree of crosslinking, and the presence of specific functional groups.

- Applications of biodegradable polyglutamic acid: Biodegradable polyglutamic acid finds applications in various fields due to its environmentally friendly nature. It is used in agriculture as a soil conditioner and fertilizer coating, in the medical field for drug delivery systems and tissue engineering scaffolds, in the cosmetics industry as a moisturizer and film-forming agent, and in the food industry as a thickener and preservative. Its biodegradability makes it particularly suitable for disposable products and packaging materials.

- Factors affecting polyglutamic acid biodegradability: Several factors influence the biodegradability of polyglutamic acid. These include its molecular weight, degree of crosslinking, environmental conditions such as temperature and pH, and the presence of specific enzymes or microorganisms. Research has shown that lower molecular weight and less crosslinking generally lead to faster biodegradation. Additionally, the biodegradation rate can be enhanced by modifying the polymer structure or incorporating biodegradation-promoting additives.

- Biodegradation testing and standards for polyglutamic acid: To assess the biodegradability of polyglutamic acid, various testing methods and standards have been developed. These include standardized tests such as the CO2 evolution test, biochemical oxygen demand (BOD) test, and soil burial test. The results of these tests are used to determine the extent and rate of biodegradation under different environmental conditions. Compliance with international standards for biodegradability is crucial for the commercial use of polyglutamic acid in environmentally sensitive applications.

02 Production methods for biodegradable polyglutamic acid

Various methods have been developed to produce biodegradable polyglutamic acid. These include microbial fermentation using bacteria such as Bacillus subtilis, enzymatic polymerization, and chemical synthesis. The production method can significantly influence the properties of the resulting polyglutamic acid, including its molecular weight, structure, and biodegradability.Expand Specific Solutions03 Applications of biodegradable polyglutamic acid

Biodegradable polyglutamic acid has found applications in various fields due to its unique properties. It is used in the production of environmentally friendly packaging materials, agricultural films, and drug delivery systems. In cosmetics, it serves as a moisturizing agent and film former. Its biodegradability makes it particularly suitable for applications where environmental impact is a concern.Expand Specific Solutions04 Factors affecting polyglutamic acid biodegradability

Several factors can influence the biodegradability of polyglutamic acid. These include its molecular weight, degree of crosslinking, environmental conditions such as temperature and pH, and the presence of specific enzymes. Understanding these factors is crucial for optimizing the biodegradation rate of polyglutamic acid-based products for different applications.Expand Specific Solutions05 Enhancing biodegradability of polyglutamic acid

Research has focused on enhancing the biodegradability of polyglutamic acid through various methods. These include blending with other biodegradable polymers, modifying its chemical structure, and incorporating additives that promote microbial growth. Such enhancements aim to improve the material's environmental performance while maintaining its desirable properties for specific applications.Expand Specific Solutions

Key Players in Biodegradable Fishing Net Industry

The research on polyglutamic acid in biodegradable fishing nets is in an emerging stage, with growing market potential due to increasing environmental concerns. The global market for biodegradable fishing gear is expanding, driven by regulatory pressures and sustainability initiatives. Technologically, the field is still developing, with companies like Kureha Corp., Toyobo Co., Ltd., and UBE Corp. leading innovation in biodegradable polymers. These firms, along with research institutions such as Zhejiang University and South China University of Technology, are advancing the application of polyglutamic acid in fishing net reformulation. While the technology shows promise, further research and development are needed to optimize performance and cost-effectiveness for widespread commercial adoption.

Kureha Corp.

Technical Solution: Kureha Corp. has developed a biodegradable fishing net using polyglutamic acid (PGA) as a key component. Their approach involves blending PGA with other biodegradable polymers to create a composite material that maintains strength and durability during use but degrades safely in marine environments. The company has optimized the PGA production process using bacterial fermentation, achieving a high molecular weight PGA that contributes to the net's tensile strength[1]. Kureha's nets incorporate a controlled degradation mechanism, where the PGA component begins to break down after a predetermined period, typically 6-12 months, depending on water conditions[2]. This allows for the net to maintain its fishing effectiveness while ensuring it doesn't persist as marine debris.

Strengths: Controlled biodegradation timeline, high tensile strength, environmentally friendly. Weaknesses: Potentially higher production costs, limited long-term durability compared to traditional nets.

Toyobo Co., Ltd.

Technical Solution: Toyobo Co., Ltd. has pioneered a novel approach to biodegradable fishing nets by incorporating polyglutamic acid (PGA) into their existing biodegradable polymer blends. Their technology focuses on creating a multi-layer net structure, where PGA is strategically placed in layers that are most exposed to water and marine microorganisms[3]. This design allows for accelerated biodegradation of the outer layers while maintaining the net's core strength. Toyobo has also developed a proprietary coating process that applies a thin layer of PGA-based material to conventional netting, enhancing biodegradability without completely redesigning the net structure[4]. The company's research has shown that their PGA-enhanced nets can degrade up to 60% faster than standard biodegradable nets in marine environments, while still providing comparable fishing performance[5].

Strengths: Faster biodegradation, adaptable to existing net designs, maintains fishing performance. Weaknesses: Potential for microplastic formation during degradation, may require specialized handling and storage.

Core Innovations in PGA Fishing Net Technology

Biodegradable net

PatentPendingUS20250066078A1

Innovation

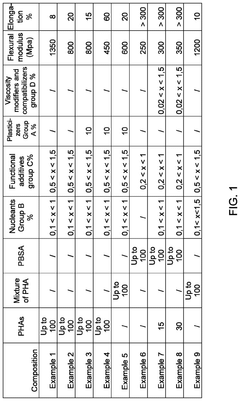

- A biodegradable net composed of a polymeric composition primarily based on polyhydroxyalkanoate (PHA), copolymer of 1,4-butanediol, succinic acid, and adipic acid (PBSA), or polybutylene succinate (PBS), with optional additives such as plasticizers, nucleants, and functional additives, to achieve the desired mechanical properties and biodegradability.

Environmental Impact Assessment

The environmental impact assessment of using polyglutamic acid (PGA) in the reformulation of biodegradable fishing nets reveals significant potential benefits for marine ecosystems. Traditional fishing nets, often made from synthetic materials like nylon or polyethylene, contribute substantially to marine pollution and pose severe threats to aquatic life. In contrast, PGA-based biodegradable nets offer a promising alternative that could dramatically reduce the ecological footprint of fishing activities.

PGA-based nets are designed to degrade naturally in marine environments, typically within 6-12 months, depending on water conditions and microbial activity. This characteristic addresses one of the most pressing issues in marine conservation: ghost fishing. Abandoned or lost conventional nets can continue to trap and kill marine life for years, whereas biodegradable nets would disintegrate, minimizing long-term ecological damage.

The degradation process of PGA nets produces non-toxic byproducts, primarily consisting of amino acids and small peptides. These substances are readily assimilated into the marine food web, posing minimal risk to aquatic organisms. Furthermore, the absence of microplastic pollution typically associated with the breakdown of synthetic nets represents a significant environmental advantage.

Research indicates that the use of PGA-based nets could lead to a substantial reduction in marine plastic pollution. Studies estimate that fishing gear accounts for approximately 10% of marine debris by volume. By transitioning to biodegradable alternatives, this figure could be dramatically reduced, contributing to cleaner oceans and healthier marine ecosystems.

The impact on marine biodiversity is another crucial aspect of the assessment. Conventional nets often entangle non-target species, including endangered marine mammals, sea turtles, and seabirds. PGA-based nets, due to their biodegradable nature, would significantly reduce the risk of long-term entanglement, potentially leading to improved conservation outcomes for vulnerable species.

However, the environmental impact assessment also highlights some areas of concern that require further investigation. The large-scale production of PGA could potentially lead to increased agricultural land use for raw materials, which may have indirect environmental consequences. Additionally, the energy requirements and carbon footprint of PGA production processes need to be carefully evaluated to ensure a net positive environmental impact.

In conclusion, the environmental impact assessment of PGA-based biodegradable fishing nets indicates a promising direction for sustainable fishing practices. While challenges remain, the potential benefits in terms of reduced marine pollution, decreased ghost fishing, and improved biodiversity conservation are significant. Further research and development in this area could lead to a transformative shift in the fishing industry, aligning it more closely with global marine conservation goals.

PGA-based nets are designed to degrade naturally in marine environments, typically within 6-12 months, depending on water conditions and microbial activity. This characteristic addresses one of the most pressing issues in marine conservation: ghost fishing. Abandoned or lost conventional nets can continue to trap and kill marine life for years, whereas biodegradable nets would disintegrate, minimizing long-term ecological damage.

The degradation process of PGA nets produces non-toxic byproducts, primarily consisting of amino acids and small peptides. These substances are readily assimilated into the marine food web, posing minimal risk to aquatic organisms. Furthermore, the absence of microplastic pollution typically associated with the breakdown of synthetic nets represents a significant environmental advantage.

Research indicates that the use of PGA-based nets could lead to a substantial reduction in marine plastic pollution. Studies estimate that fishing gear accounts for approximately 10% of marine debris by volume. By transitioning to biodegradable alternatives, this figure could be dramatically reduced, contributing to cleaner oceans and healthier marine ecosystems.

The impact on marine biodiversity is another crucial aspect of the assessment. Conventional nets often entangle non-target species, including endangered marine mammals, sea turtles, and seabirds. PGA-based nets, due to their biodegradable nature, would significantly reduce the risk of long-term entanglement, potentially leading to improved conservation outcomes for vulnerable species.

However, the environmental impact assessment also highlights some areas of concern that require further investigation. The large-scale production of PGA could potentially lead to increased agricultural land use for raw materials, which may have indirect environmental consequences. Additionally, the energy requirements and carbon footprint of PGA production processes need to be carefully evaluated to ensure a net positive environmental impact.

In conclusion, the environmental impact assessment of PGA-based biodegradable fishing nets indicates a promising direction for sustainable fishing practices. While challenges remain, the potential benefits in terms of reduced marine pollution, decreased ghost fishing, and improved biodiversity conservation are significant. Further research and development in this area could lead to a transformative shift in the fishing industry, aligning it more closely with global marine conservation goals.

Regulatory Framework for Marine Biodegradable Materials

The regulatory framework for marine biodegradable materials is a critical aspect of the development and implementation of biodegradable fishing nets using polyglutamic acid. This framework encompasses various international, regional, and national regulations that govern the use of materials in marine environments, with a focus on environmental protection and sustainability.

At the international level, the United Nations Convention on the Law of the Sea (UNCLOS) provides the overarching legal framework for marine environmental protection. While it does not specifically address biodegradable materials, it establishes the obligation for states to protect and preserve the marine environment. This obligation extends to the regulation of materials used in fishing gear.

The International Maritime Organization (IMO) has also played a significant role in developing guidelines for the reduction of marine plastic litter from ships. Although these guidelines do not directly regulate biodegradable fishing nets, they set a precedent for the use of environmentally friendly materials in marine applications.

Regional organizations, such as the European Union, have implemented more specific regulations. The EU Marine Strategy Framework Directive requires member states to achieve Good Environmental Status in their marine waters by 2020, which includes addressing marine litter. This directive has led to increased interest in biodegradable fishing gear as a means of reducing plastic pollution.

At the national level, countries have begun to implement regulations that encourage or mandate the use of biodegradable materials in fishing gear. For example, South Korea has introduced legislation requiring the use of biodegradable fishing nets in certain fisheries. Similarly, Indonesia has set targets for the adoption of biodegradable fishing gear as part of its national plan to reduce marine plastic debris.

The regulatory landscape for marine biodegradable materials is evolving rapidly. As research on polyglutamic acid and other biodegradable materials progresses, it is likely that new standards and certifications will be developed to ensure the safety and efficacy of these materials in marine environments. These standards will need to address factors such as degradation rates, toxicity, and impact on marine ecosystems.

Compliance with these regulations and standards will be crucial for the successful implementation of biodegradable fishing nets made with polyglutamic acid. Manufacturers and researchers will need to work closely with regulatory bodies to ensure that their products meet all necessary requirements and contribute to the overall goal of reducing marine pollution.

At the international level, the United Nations Convention on the Law of the Sea (UNCLOS) provides the overarching legal framework for marine environmental protection. While it does not specifically address biodegradable materials, it establishes the obligation for states to protect and preserve the marine environment. This obligation extends to the regulation of materials used in fishing gear.

The International Maritime Organization (IMO) has also played a significant role in developing guidelines for the reduction of marine plastic litter from ships. Although these guidelines do not directly regulate biodegradable fishing nets, they set a precedent for the use of environmentally friendly materials in marine applications.

Regional organizations, such as the European Union, have implemented more specific regulations. The EU Marine Strategy Framework Directive requires member states to achieve Good Environmental Status in their marine waters by 2020, which includes addressing marine litter. This directive has led to increased interest in biodegradable fishing gear as a means of reducing plastic pollution.

At the national level, countries have begun to implement regulations that encourage or mandate the use of biodegradable materials in fishing gear. For example, South Korea has introduced legislation requiring the use of biodegradable fishing nets in certain fisheries. Similarly, Indonesia has set targets for the adoption of biodegradable fishing gear as part of its national plan to reduce marine plastic debris.

The regulatory landscape for marine biodegradable materials is evolving rapidly. As research on polyglutamic acid and other biodegradable materials progresses, it is likely that new standards and certifications will be developed to ensure the safety and efficacy of these materials in marine environments. These standards will need to address factors such as degradation rates, toxicity, and impact on marine ecosystems.

Compliance with these regulations and standards will be crucial for the successful implementation of biodegradable fishing nets made with polyglutamic acid. Manufacturers and researchers will need to work closely with regulatory bodies to ensure that their products meet all necessary requirements and contribute to the overall goal of reducing marine pollution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!