How Polyglutamic Acid Assists in Developing Flexible Biocomposites

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PGA in Biocomposites: Background and Objectives

Polyglutamic acid (PGA) has emerged as a promising biopolymer in the development of flexible biocomposites, marking a significant advancement in sustainable materials science. The evolution of PGA-based biocomposites stems from the increasing demand for environmentally friendly and biodegradable materials across various industries. This technology aims to address the limitations of traditional petroleum-based plastics while offering comparable or superior mechanical properties.

The journey of PGA in biocomposites began with its discovery as a naturally occurring polymer produced by certain bacteria. Over time, researchers have explored its potential in creating flexible, durable, and eco-friendly materials. The primary objective of incorporating PGA into biocomposites is to enhance the overall performance of these materials, particularly in terms of flexibility, strength, and biodegradability.

Recent technological advancements have focused on optimizing PGA production methods and improving its integration with other biopolymers and natural fibers. This has led to the development of a new generation of biocomposites with enhanced properties, suitable for applications ranging from packaging to biomedical devices. The goal is to create materials that not only meet the performance requirements of various industries but also contribute to reducing environmental impact.

One of the key drivers behind PGA-based biocomposite research is the growing awareness of environmental issues associated with conventional plastics. As governments and industries worldwide push for more sustainable solutions, PGA offers a viable alternative that aligns with circular economy principles. The technology aims to create materials that can be easily recycled or biodegraded at the end of their lifecycle, thus reducing waste and pollution.

The development of PGA-assisted flexible biocomposites also addresses the need for materials with tailored properties. By manipulating the composition and processing techniques, researchers aim to create biocomposites with specific characteristics such as improved water resistance, thermal stability, or mechanical strength. This versatility opens up new possibilities for customized materials in various applications, from consumer goods to advanced industrial products.

As the field progresses, the objectives extend beyond mere material development to encompass scalable production methods and cost-effective manufacturing processes. The ultimate goal is to make PGA-based biocomposites commercially viable and competitive with traditional materials, paving the way for widespread adoption across multiple sectors.

The journey of PGA in biocomposites began with its discovery as a naturally occurring polymer produced by certain bacteria. Over time, researchers have explored its potential in creating flexible, durable, and eco-friendly materials. The primary objective of incorporating PGA into biocomposites is to enhance the overall performance of these materials, particularly in terms of flexibility, strength, and biodegradability.

Recent technological advancements have focused on optimizing PGA production methods and improving its integration with other biopolymers and natural fibers. This has led to the development of a new generation of biocomposites with enhanced properties, suitable for applications ranging from packaging to biomedical devices. The goal is to create materials that not only meet the performance requirements of various industries but also contribute to reducing environmental impact.

One of the key drivers behind PGA-based biocomposite research is the growing awareness of environmental issues associated with conventional plastics. As governments and industries worldwide push for more sustainable solutions, PGA offers a viable alternative that aligns with circular economy principles. The technology aims to create materials that can be easily recycled or biodegraded at the end of their lifecycle, thus reducing waste and pollution.

The development of PGA-assisted flexible biocomposites also addresses the need for materials with tailored properties. By manipulating the composition and processing techniques, researchers aim to create biocomposites with specific characteristics such as improved water resistance, thermal stability, or mechanical strength. This versatility opens up new possibilities for customized materials in various applications, from consumer goods to advanced industrial products.

As the field progresses, the objectives extend beyond mere material development to encompass scalable production methods and cost-effective manufacturing processes. The ultimate goal is to make PGA-based biocomposites commercially viable and competitive with traditional materials, paving the way for widespread adoption across multiple sectors.

Market Analysis for Flexible Biocomposites

The market for flexible biocomposites is experiencing significant growth, driven by increasing demand for sustainable and eco-friendly materials across various industries. Polyglutamic acid (PGA) plays a crucial role in this market expansion, offering unique properties that enhance the development of flexible biocomposites.

The global flexible biocomposites market is projected to witness substantial growth in the coming years, with a compound annual growth rate (CAGR) expected to exceed 10% between 2021 and 2026. This growth is primarily attributed to the rising awareness of environmental issues and the shift towards renewable and biodegradable materials in industries such as packaging, automotive, construction, and consumer goods.

Polyglutamic acid's ability to assist in developing flexible biocomposites addresses several key market needs. Firstly, it enhances the mechanical properties of biocomposites, improving their flexibility and durability. This makes PGA-based biocomposites suitable for a wide range of applications, from food packaging to automotive interiors.

The packaging industry represents a significant market segment for flexible biocomposites, driven by consumer demand for sustainable packaging solutions. PGA-assisted biocomposites offer excellent barrier properties and biodegradability, making them ideal for food packaging and disposable containers. This segment is expected to witness the highest growth rate within the flexible biocomposites market.

In the automotive sector, there is a growing trend towards lightweight and eco-friendly materials to improve fuel efficiency and reduce carbon emissions. Flexible biocomposites incorporating PGA are gaining traction in this industry for interior components, panels, and non-structural parts. The automotive segment is projected to be a major contributor to the overall market growth.

The construction industry is another key market for flexible biocomposites, with applications in insulation materials, flooring, and decorative panels. PGA-enhanced biocomposites offer improved thermal and acoustic properties, along with moisture resistance, making them attractive alternatives to traditional construction materials.

Geographically, North America and Europe currently dominate the flexible biocomposites market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing disposable income, and growing environmental concerns in countries like China and India.

Despite the positive market outlook, challenges such as higher production costs compared to conventional materials and limited awareness among end-users persist. However, ongoing research and development efforts, coupled with supportive government policies promoting sustainable materials, are expected to address these challenges and further drive market growth for PGA-assisted flexible biocomposites.

The global flexible biocomposites market is projected to witness substantial growth in the coming years, with a compound annual growth rate (CAGR) expected to exceed 10% between 2021 and 2026. This growth is primarily attributed to the rising awareness of environmental issues and the shift towards renewable and biodegradable materials in industries such as packaging, automotive, construction, and consumer goods.

Polyglutamic acid's ability to assist in developing flexible biocomposites addresses several key market needs. Firstly, it enhances the mechanical properties of biocomposites, improving their flexibility and durability. This makes PGA-based biocomposites suitable for a wide range of applications, from food packaging to automotive interiors.

The packaging industry represents a significant market segment for flexible biocomposites, driven by consumer demand for sustainable packaging solutions. PGA-assisted biocomposites offer excellent barrier properties and biodegradability, making them ideal for food packaging and disposable containers. This segment is expected to witness the highest growth rate within the flexible biocomposites market.

In the automotive sector, there is a growing trend towards lightweight and eco-friendly materials to improve fuel efficiency and reduce carbon emissions. Flexible biocomposites incorporating PGA are gaining traction in this industry for interior components, panels, and non-structural parts. The automotive segment is projected to be a major contributor to the overall market growth.

The construction industry is another key market for flexible biocomposites, with applications in insulation materials, flooring, and decorative panels. PGA-enhanced biocomposites offer improved thermal and acoustic properties, along with moisture resistance, making them attractive alternatives to traditional construction materials.

Geographically, North America and Europe currently dominate the flexible biocomposites market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing disposable income, and growing environmental concerns in countries like China and India.

Despite the positive market outlook, challenges such as higher production costs compared to conventional materials and limited awareness among end-users persist. However, ongoing research and development efforts, coupled with supportive government policies promoting sustainable materials, are expected to address these challenges and further drive market growth for PGA-assisted flexible biocomposites.

Current Challenges in PGA-based Biocomposites

Despite the promising potential of polyglutamic acid (PGA) in developing flexible biocomposites, several significant challenges persist in this field. One of the primary obstacles is the inherent hydrophilicity of PGA, which can lead to poor water resistance in the resulting biocomposites. This characteristic often results in reduced mechanical properties and dimensional stability when the composites are exposed to moisture, limiting their applicability in certain environments.

Another major challenge lies in the processability of PGA-based biocomposites. The high melting point and thermal degradation temperature of PGA can make it difficult to process using conventional thermoplastic techniques. This limitation necessitates the development of specialized processing methods or the use of plasticizers, which can potentially alter the desired properties of the final composite.

The compatibility between PGA and other biopolymers or reinforcing agents presents another hurdle. Achieving good interfacial adhesion between PGA and other components in the biocomposite is crucial for enhancing mechanical properties and overall performance. However, the chemical structure of PGA can sometimes lead to poor compatibility with certain materials, resulting in phase separation or weak interfaces within the composite.

Cost-effectiveness remains a significant challenge in the widespread adoption of PGA-based biocomposites. The production of PGA, particularly through fermentation processes, can be relatively expensive compared to conventional polymers. This higher cost can limit the commercial viability of PGA-based biocomposites, especially in applications where cost is a critical factor.

The biodegradability of PGA, while generally considered an advantage, can also pose challenges in certain applications. Controlling the rate of degradation to match the intended lifespan of the biocomposite product is crucial. Achieving a balance between biodegradability and long-term stability remains a complex task, particularly in applications requiring extended durability.

Furthermore, the scalability of PGA production and biocomposite manufacturing processes presents ongoing challenges. Transitioning from laboratory-scale production to industrial-scale manufacturing while maintaining consistent quality and properties is a significant hurdle that needs to be addressed for widespread commercial adoption.

Lastly, the regulatory landscape surrounding the use of PGA-based biocomposites, especially in sensitive applications such as biomedical or food packaging, can be complex. Ensuring compliance with various regulatory standards and obtaining necessary approvals can be time-consuming and resource-intensive, potentially slowing down the development and commercialization of these materials.

Another major challenge lies in the processability of PGA-based biocomposites. The high melting point and thermal degradation temperature of PGA can make it difficult to process using conventional thermoplastic techniques. This limitation necessitates the development of specialized processing methods or the use of plasticizers, which can potentially alter the desired properties of the final composite.

The compatibility between PGA and other biopolymers or reinforcing agents presents another hurdle. Achieving good interfacial adhesion between PGA and other components in the biocomposite is crucial for enhancing mechanical properties and overall performance. However, the chemical structure of PGA can sometimes lead to poor compatibility with certain materials, resulting in phase separation or weak interfaces within the composite.

Cost-effectiveness remains a significant challenge in the widespread adoption of PGA-based biocomposites. The production of PGA, particularly through fermentation processes, can be relatively expensive compared to conventional polymers. This higher cost can limit the commercial viability of PGA-based biocomposites, especially in applications where cost is a critical factor.

The biodegradability of PGA, while generally considered an advantage, can also pose challenges in certain applications. Controlling the rate of degradation to match the intended lifespan of the biocomposite product is crucial. Achieving a balance between biodegradability and long-term stability remains a complex task, particularly in applications requiring extended durability.

Furthermore, the scalability of PGA production and biocomposite manufacturing processes presents ongoing challenges. Transitioning from laboratory-scale production to industrial-scale manufacturing while maintaining consistent quality and properties is a significant hurdle that needs to be addressed for widespread commercial adoption.

Lastly, the regulatory landscape surrounding the use of PGA-based biocomposites, especially in sensitive applications such as biomedical or food packaging, can be complex. Ensuring compliance with various regulatory standards and obtaining necessary approvals can be time-consuming and resource-intensive, potentially slowing down the development and commercialization of these materials.

Existing PGA-Biocomposite Formulations

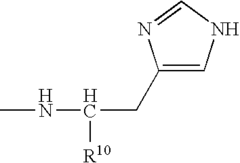

01 Molecular structure and flexibility of polyglutamic acid

Polyglutamic acid exhibits unique flexibility due to its molecular structure. The polymer chain can adopt various conformations, allowing it to adapt to different environments and interact with other molecules. This flexibility contributes to its versatility in various applications, including drug delivery systems and biomaterials.- Molecular structure and properties of polyglutamic acid: Polyglutamic acid exhibits flexibility due to its unique molecular structure. The polymer chain consists of repeating glutamic acid units connected by peptide bonds, allowing for rotational freedom around these bonds. This structural characteristic contributes to the overall flexibility of the molecule, enabling it to adapt to various conformations and interact with different substances.

- Applications in cosmetics and personal care: The flexibility of polyglutamic acid makes it valuable in cosmetic and personal care formulations. Its ability to form films and retain moisture on the skin surface enhances product efficacy. The polymer can be used in various products such as moisturizers, anti-aging creams, and hair care items, providing benefits like improved hydration and skin elasticity.

- Biomedical applications and drug delivery: Polyglutamic acid's flexibility is advantageous in biomedical applications, particularly in drug delivery systems. The polymer can be modified to encapsulate or conjugate with various drugs, allowing for controlled release and improved bioavailability. Its biodegradability and biocompatibility make it suitable for tissue engineering and regenerative medicine applications.

- Production methods and modifications: Various production methods and modifications can influence the flexibility of polyglutamic acid. Techniques such as microbial fermentation, chemical synthesis, and enzymatic polymerization can be employed to produce polyglutamic acid with different molecular weights and degrees of flexibility. Chemical modifications, such as cross-linking or grafting, can further alter the polymer's properties to suit specific applications.

- Environmental applications and biodegradability: The flexibility and biodegradability of polyglutamic acid make it suitable for environmental applications. It can be used in water treatment processes, such as flocculants or chelating agents for heavy metal removal. The polymer's ability to degrade naturally in the environment without producing harmful byproducts makes it an eco-friendly alternative to synthetic polymers in various industrial and consumer products.

02 Modification techniques to enhance polyglutamic acid flexibility

Various modification techniques can be employed to enhance the flexibility of polyglutamic acid. These may include chemical modifications, such as crosslinking or grafting with other polymers, as well as physical modifications like blending or forming composites. These modifications can tailor the flexibility properties for specific applications.Expand Specific Solutions03 Applications utilizing polyglutamic acid flexibility

The flexibility of polyglutamic acid is exploited in numerous applications across different fields. In cosmetics, it can be used as a film-forming agent or moisturizer. In biomedical applications, its flexibility allows for the development of scaffolds for tissue engineering or controlled release systems for drug delivery.Expand Specific Solutions04 Factors influencing polyglutamic acid flexibility

Several factors can influence the flexibility of polyglutamic acid, including molecular weight, pH, temperature, and ionic strength of the surrounding environment. Understanding these factors is crucial for optimizing the polymer's performance in various applications and controlling its behavior under different conditions.Expand Specific Solutions05 Characterization methods for polyglutamic acid flexibility

Various analytical techniques are employed to characterize the flexibility of polyglutamic acid. These may include rheological measurements, dynamic mechanical analysis, and spectroscopic methods such as NMR or FTIR. These techniques provide insights into the polymer's conformational changes and mechanical properties under different conditions.Expand Specific Solutions

Key Players in PGA and Biocomposite Industry

The development of flexible biocomposites using polyglutamic acid is in an early stage of industry growth, with a relatively small but expanding market. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like MIT, Tufts University, and Nanjing University. Companies such as Nitto Denko, Toyobo, and Poly-Med are actively involved in advancing this field, indicating growing commercial interest. The competitive landscape is diverse, with both established chemical firms and specialized biotech companies like Zymochem contributing to innovation. As the technology progresses, we can expect increased market competition and potential breakthroughs in material properties and applications.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach to creating flexible biocomposites using polyglutamic acid (PGA) as a key component. Their research focuses on enhancing the mechanical properties and biodegradability of these materials. The team has successfully incorporated PGA into various polymer matrices, resulting in biocomposites with improved flexibility and strength[1]. They have also explored the use of PGA-based nanofibers to create scaffolds for tissue engineering applications, demonstrating excellent cell adhesion and proliferation properties[3]. MIT's work has shown that PGA can act as an effective plasticizer in biocomposite formulations, reducing brittleness and increasing overall flexibility without compromising biodegradability[5].

Strengths: Cutting-edge research in biocomposite development, expertise in nanomaterial integration, and strong focus on practical applications. Weaknesses: Potential scalability issues for industrial production and higher costs associated with advanced materials.

Sichuan University

Technical Solution: Sichuan University has made significant strides in developing flexible biocomposites using polyglutamic acid. Their research team has focused on creating PGA-based hydrogels with tunable mechanical properties for various biomedical applications. They have successfully synthesized PGA-grafted polymers that exhibit excellent flexibility and biocompatibility[2]. The university has also explored the use of PGA in combination with other biopolymers to create composite materials with enhanced mechanical strength and flexibility. Their work has shown promising results in developing wound dressing materials and drug delivery systems using these PGA-based biocomposites[4]. Additionally, they have investigated the use of PGA as a compatibilizer in blends of natural and synthetic polymers, improving the overall flexibility and biodegradability of the resulting materials[6].

Strengths: Strong focus on biomedical applications, expertise in polymer grafting techniques, and successful development of practical biocomposite materials. Weaknesses: May face challenges in scaling up production for commercial applications and potential regulatory hurdles for medical-grade materials.

Innovations in PGA-Enhanced Flexibility

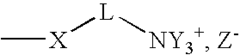

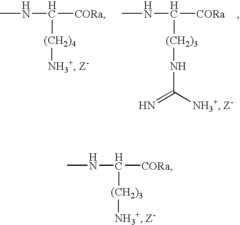

Polyglutamic acids functionalized by cationic groups and hydrophobic groups and applications thereof, in particular therapeutic applications thereof

PatentInactiveUS20090012028A1

Innovation

- Development of novel amphiphilic copolyglutamates with pendant cationic and hydrophobic groups that form stable colloidal suspensions, associate with active principles, and degrade into non-toxic products, allowing for controlled release and enhanced bioavailability.

Sustained-release lipid pre-concentrate

PatentPendingUS20240180865A1

Innovation

- A sustained-release lipid pre-concentrate formulation that forms liquid crystals in an aqueous medium, comprising vegetable oils with unsaturated fatty acids (14-20 carbon atoms) and cholesterol or sugar alcohols, providing excellent biocompatibility, biodegradability, and low viscosity, enabling easy injection and sustained drug release for two weeks to one month.

Environmental Impact of PGA Biocomposites

The environmental impact of polyglutamic acid (PGA) biocomposites is a crucial aspect to consider in the development of flexible biocomposites. PGA, a biodegradable polymer produced by microbial fermentation, offers significant advantages in terms of sustainability and eco-friendliness compared to traditional petroleum-based plastics.

One of the primary environmental benefits of PGA biocomposites is their biodegradability. Unlike conventional plastics that persist in the environment for hundreds of years, PGA-based materials can decompose naturally within a relatively short period, typically ranging from a few months to a few years depending on environmental conditions. This characteristic significantly reduces the accumulation of plastic waste in landfills and oceans, mitigating the long-term environmental impact associated with non-biodegradable materials.

Furthermore, the production of PGA biocomposites generally has a lower carbon footprint compared to traditional plastic manufacturing processes. The microbial fermentation used to produce PGA consumes less energy and generates fewer greenhouse gas emissions than the extraction and processing of fossil fuels required for conventional plastics. This contributes to the overall reduction of the carbon footprint in the materials industry.

PGA biocomposites also offer the potential for sustainable resource management. As PGA can be derived from renewable resources such as agricultural by-products or waste materials, it promotes the circular economy concept by utilizing resources that would otherwise be discarded. This approach not only reduces waste but also decreases the demand for virgin raw materials, further minimizing environmental impact.

The use of PGA in biocomposites can also lead to improved end-of-life scenarios for products. As these materials break down, they do not release harmful toxins or microplastics into the environment, which is a significant concern with traditional plastics. Instead, PGA biocomposites can potentially be composted or biodegraded in controlled environments, returning nutrients to the soil and completing the natural cycle.

However, it is important to note that the environmental impact of PGA biocomposites is not entirely without challenges. The production of PGA through microbial fermentation requires careful management of resources, including water and nutrients. Additionally, the energy consumption during the manufacturing process of biocomposites, while generally lower than traditional plastics, still needs to be optimized to further reduce environmental impact.

In conclusion, PGA biocomposites offer a promising alternative to conventional plastics with significant environmental benefits. Their biodegradability, lower carbon footprint, and potential for sustainable resource management contribute to a more environmentally friendly approach in materials science. As research and development in this field continue, further improvements in production efficiency and end-of-life management are expected to enhance the overall environmental performance of PGA biocomposites.

One of the primary environmental benefits of PGA biocomposites is their biodegradability. Unlike conventional plastics that persist in the environment for hundreds of years, PGA-based materials can decompose naturally within a relatively short period, typically ranging from a few months to a few years depending on environmental conditions. This characteristic significantly reduces the accumulation of plastic waste in landfills and oceans, mitigating the long-term environmental impact associated with non-biodegradable materials.

Furthermore, the production of PGA biocomposites generally has a lower carbon footprint compared to traditional plastic manufacturing processes. The microbial fermentation used to produce PGA consumes less energy and generates fewer greenhouse gas emissions than the extraction and processing of fossil fuels required for conventional plastics. This contributes to the overall reduction of the carbon footprint in the materials industry.

PGA biocomposites also offer the potential for sustainable resource management. As PGA can be derived from renewable resources such as agricultural by-products or waste materials, it promotes the circular economy concept by utilizing resources that would otherwise be discarded. This approach not only reduces waste but also decreases the demand for virgin raw materials, further minimizing environmental impact.

The use of PGA in biocomposites can also lead to improved end-of-life scenarios for products. As these materials break down, they do not release harmful toxins or microplastics into the environment, which is a significant concern with traditional plastics. Instead, PGA biocomposites can potentially be composted or biodegraded in controlled environments, returning nutrients to the soil and completing the natural cycle.

However, it is important to note that the environmental impact of PGA biocomposites is not entirely without challenges. The production of PGA through microbial fermentation requires careful management of resources, including water and nutrients. Additionally, the energy consumption during the manufacturing process of biocomposites, while generally lower than traditional plastics, still needs to be optimized to further reduce environmental impact.

In conclusion, PGA biocomposites offer a promising alternative to conventional plastics with significant environmental benefits. Their biodegradability, lower carbon footprint, and potential for sustainable resource management contribute to a more environmentally friendly approach in materials science. As research and development in this field continue, further improvements in production efficiency and end-of-life management are expected to enhance the overall environmental performance of PGA biocomposites.

Regulatory Framework for Biocomposite Materials

The regulatory framework for biocomposite materials plays a crucial role in the development and commercialization of flexible biocomposites incorporating polyglutamic acid (PGA). As these materials gain traction in various industries, regulatory bodies worldwide are adapting their guidelines to ensure safety, quality, and environmental sustainability.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of biocomposite materials used in food packaging, medical devices, and cosmetics. The FDA's approach focuses on the safety assessment of individual components and the final product. For PGA-based biocomposites, manufacturers must demonstrate that the material meets the FDA's standards for food contact substances or medical-grade materials, depending on the intended application.

The European Union has implemented a comprehensive regulatory framework for biocomposite materials through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH requires manufacturers to register and provide safety data for all chemical substances used in biocomposites, including PGA. Additionally, the EU's Biocidal Products Regulation (BPR) may apply to biocomposites with antimicrobial properties, necessitating further compliance measures.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates biocomposite materials used in food packaging and medical applications. The Japanese regulatory approach emphasizes the evaluation of migration levels of substances from biocomposites to ensure consumer safety. Manufacturers must provide extensive data on the composition and potential health impacts of PGA-based biocomposites.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific guidelines for biocomposite materials. ISO 17088:2021, for instance, outlines the specifications for compostable plastics, which may apply to certain PGA-based biocomposites. These standards provide a framework for testing and certifying the biodegradability and compostability of biocomposite materials.

As the field of flexible biocomposites evolves, regulatory bodies are increasingly focusing on the environmental impact and end-of-life considerations of these materials. The concept of circular economy is being integrated into regulatory frameworks, encouraging manufacturers to design biocomposites that can be easily recycled or biodegraded. This shift is particularly relevant for PGA-based biocomposites, given their potential for biodegradability.

Emerging regulations are also addressing the use of nanotechnology in biocomposite materials. As PGA-based biocomposites may incorporate nanoparticles for enhanced properties, manufacturers must navigate the evolving landscape of nanotech regulations. These regulations often require additional safety assessments and labeling requirements for nanomaterials used in consumer products.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of biocomposite materials used in food packaging, medical devices, and cosmetics. The FDA's approach focuses on the safety assessment of individual components and the final product. For PGA-based biocomposites, manufacturers must demonstrate that the material meets the FDA's standards for food contact substances or medical-grade materials, depending on the intended application.

The European Union has implemented a comprehensive regulatory framework for biocomposite materials through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH requires manufacturers to register and provide safety data for all chemical substances used in biocomposites, including PGA. Additionally, the EU's Biocidal Products Regulation (BPR) may apply to biocomposites with antimicrobial properties, necessitating further compliance measures.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates biocomposite materials used in food packaging and medical applications. The Japanese regulatory approach emphasizes the evaluation of migration levels of substances from biocomposites to ensure consumer safety. Manufacturers must provide extensive data on the composition and potential health impacts of PGA-based biocomposites.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific guidelines for biocomposite materials. ISO 17088:2021, for instance, outlines the specifications for compostable plastics, which may apply to certain PGA-based biocomposites. These standards provide a framework for testing and certifying the biodegradability and compostability of biocomposite materials.

As the field of flexible biocomposites evolves, regulatory bodies are increasingly focusing on the environmental impact and end-of-life considerations of these materials. The concept of circular economy is being integrated into regulatory frameworks, encouraging manufacturers to design biocomposites that can be easily recycled or biodegraded. This shift is particularly relevant for PGA-based biocomposites, given their potential for biodegradability.

Emerging regulations are also addressing the use of nanotechnology in biocomposite materials. As PGA-based biocomposites may incorporate nanoparticles for enhanced properties, manufacturers must navigate the evolving landscape of nanotech regulations. These regulations often require additional safety assessments and labeling requirements for nanomaterials used in consumer products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!