Polyglutamic Acid as a Film-forming Agent for Improved Solar Cells

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PGA in Solar Cells: Background and Objectives

Polyglutamic acid (PGA) has emerged as a promising film-forming agent in the field of solar cell technology, offering potential improvements in efficiency and durability. The development of PGA as a component in solar cells is rooted in the broader context of renewable energy research and the ongoing quest for more sustainable power generation methods.

The evolution of solar cell technology has been marked by continuous efforts to enhance performance and reduce costs. Traditional silicon-based solar cells, while effective, have limitations in terms of efficiency and manufacturing complexity. This has led researchers to explore alternative materials and structures, including organic and hybrid solar cells, which offer the potential for lower-cost production and improved flexibility.

PGA, a biodegradable and environmentally friendly polymer, has attracted attention due to its unique properties. Its ability to form uniform, stable films makes it an attractive candidate for incorporation into solar cell designs. The use of PGA aligns with the growing emphasis on green technologies and sustainable materials in the renewable energy sector.

The primary objective of integrating PGA into solar cells is to address several key challenges in current photovoltaic technologies. These include improving charge transport, enhancing light absorption, and increasing the overall stability and longevity of the devices. By leveraging the film-forming properties of PGA, researchers aim to create more efficient and durable solar cells that can compete with or surpass the performance of traditional silicon-based systems.

Another significant goal is to explore the potential of PGA in next-generation solar technologies, such as perovskite solar cells and organic photovoltaics. These emerging technologies offer the promise of higher efficiencies and lower production costs but often face challenges related to stability and scalability. The incorporation of PGA as a film-forming agent could potentially address some of these issues, paving the way for more commercially viable advanced solar cell designs.

The development of PGA-based solar cell components also aligns with broader industry trends towards more sustainable and environmentally friendly manufacturing processes. As the global demand for clean energy solutions continues to grow, there is an increasing focus on developing solar technologies that not only deliver high performance but also minimize environmental impact throughout their lifecycle.

In the context of these objectives, research into PGA as a film-forming agent for improved solar cells represents a convergence of materials science, renewable energy technology, and sustainable manufacturing practices. The potential outcomes of this research could have far-reaching implications for the future of solar energy, contributing to the ongoing transition towards more efficient, cost-effective, and environmentally sustainable power generation solutions.

The evolution of solar cell technology has been marked by continuous efforts to enhance performance and reduce costs. Traditional silicon-based solar cells, while effective, have limitations in terms of efficiency and manufacturing complexity. This has led researchers to explore alternative materials and structures, including organic and hybrid solar cells, which offer the potential for lower-cost production and improved flexibility.

PGA, a biodegradable and environmentally friendly polymer, has attracted attention due to its unique properties. Its ability to form uniform, stable films makes it an attractive candidate for incorporation into solar cell designs. The use of PGA aligns with the growing emphasis on green technologies and sustainable materials in the renewable energy sector.

The primary objective of integrating PGA into solar cells is to address several key challenges in current photovoltaic technologies. These include improving charge transport, enhancing light absorption, and increasing the overall stability and longevity of the devices. By leveraging the film-forming properties of PGA, researchers aim to create more efficient and durable solar cells that can compete with or surpass the performance of traditional silicon-based systems.

Another significant goal is to explore the potential of PGA in next-generation solar technologies, such as perovskite solar cells and organic photovoltaics. These emerging technologies offer the promise of higher efficiencies and lower production costs but often face challenges related to stability and scalability. The incorporation of PGA as a film-forming agent could potentially address some of these issues, paving the way for more commercially viable advanced solar cell designs.

The development of PGA-based solar cell components also aligns with broader industry trends towards more sustainable and environmentally friendly manufacturing processes. As the global demand for clean energy solutions continues to grow, there is an increasing focus on developing solar technologies that not only deliver high performance but also minimize environmental impact throughout their lifecycle.

In the context of these objectives, research into PGA as a film-forming agent for improved solar cells represents a convergence of materials science, renewable energy technology, and sustainable manufacturing practices. The potential outcomes of this research could have far-reaching implications for the future of solar energy, contributing to the ongoing transition towards more efficient, cost-effective, and environmentally sustainable power generation solutions.

Market Analysis for PGA-enhanced Solar Cells

The market for PGA-enhanced solar cells is poised for significant growth, driven by the increasing demand for more efficient and sustainable energy solutions. As the global push for renewable energy intensifies, solar technology continues to evolve, with PGA-based film-forming agents emerging as a promising innovation to boost solar cell performance.

The current solar cell market is dominated by silicon-based technologies, which have seen incremental improvements in efficiency over the years. However, the introduction of PGA as a film-forming agent represents a potential leap forward in solar cell design and performance. This innovation addresses key market demands for higher efficiency, lower production costs, and improved durability of solar panels.

Market research indicates that the global solar energy market is expected to grow substantially in the coming years, with a compound annual growth rate (CAGR) projected to be in the double digits. The integration of PGA-enhanced solar cells into this expanding market could capture a significant share, particularly in regions with high solar energy potential and strong environmental policies.

Consumer trends show an increasing preference for eco-friendly and high-performance energy solutions. PGA, being a biodegradable and renewable material, aligns well with these consumer values. This alignment could drive adoption in both residential and commercial sectors, where sustainability is becoming a key decision factor.

The industrial sector presents another substantial market opportunity for PGA-enhanced solar cells. Large-scale solar farms and industrial rooftop installations could benefit greatly from the improved efficiency and durability offered by this technology. The potential for reduced maintenance costs and increased energy output over the lifetime of the solar panels is particularly attractive to industrial consumers.

Geographically, markets with high solar irradiance and supportive renewable energy policies are likely to be early adopters of PGA-enhanced solar cell technology. Regions such as North America, Europe, and parts of Asia-Pacific have shown strong growth in solar energy adoption and are potential key markets for this innovation.

However, market penetration will depend on several factors, including the cost-effectiveness of PGA-enhanced solar cells compared to traditional technologies, the scalability of production processes, and the ability to integrate this new technology into existing solar panel manufacturing lines. Overcoming these challenges will be crucial for widespread market adoption.

In conclusion, the market analysis for PGA-enhanced solar cells reveals a promising landscape with significant growth potential. The technology's alignment with market trends towards higher efficiency, sustainability, and cost-effectiveness positions it well for future success in the rapidly evolving solar energy sector.

The current solar cell market is dominated by silicon-based technologies, which have seen incremental improvements in efficiency over the years. However, the introduction of PGA as a film-forming agent represents a potential leap forward in solar cell design and performance. This innovation addresses key market demands for higher efficiency, lower production costs, and improved durability of solar panels.

Market research indicates that the global solar energy market is expected to grow substantially in the coming years, with a compound annual growth rate (CAGR) projected to be in the double digits. The integration of PGA-enhanced solar cells into this expanding market could capture a significant share, particularly in regions with high solar energy potential and strong environmental policies.

Consumer trends show an increasing preference for eco-friendly and high-performance energy solutions. PGA, being a biodegradable and renewable material, aligns well with these consumer values. This alignment could drive adoption in both residential and commercial sectors, where sustainability is becoming a key decision factor.

The industrial sector presents another substantial market opportunity for PGA-enhanced solar cells. Large-scale solar farms and industrial rooftop installations could benefit greatly from the improved efficiency and durability offered by this technology. The potential for reduced maintenance costs and increased energy output over the lifetime of the solar panels is particularly attractive to industrial consumers.

Geographically, markets with high solar irradiance and supportive renewable energy policies are likely to be early adopters of PGA-enhanced solar cell technology. Regions such as North America, Europe, and parts of Asia-Pacific have shown strong growth in solar energy adoption and are potential key markets for this innovation.

However, market penetration will depend on several factors, including the cost-effectiveness of PGA-enhanced solar cells compared to traditional technologies, the scalability of production processes, and the ability to integrate this new technology into existing solar panel manufacturing lines. Overcoming these challenges will be crucial for widespread market adoption.

In conclusion, the market analysis for PGA-enhanced solar cells reveals a promising landscape with significant growth potential. The technology's alignment with market trends towards higher efficiency, sustainability, and cost-effectiveness positions it well for future success in the rapidly evolving solar energy sector.

Current Challenges in PGA Film Formation

The application of polyglutamic acid (PGA) as a film-forming agent in solar cells presents several significant challenges that researchers and manufacturers must address. One of the primary issues is achieving consistent and uniform film thickness across large surface areas. PGA's molecular structure and its interaction with various substrates can lead to uneven distribution during the film formation process, resulting in areas of varying thickness. This non-uniformity can significantly impact the solar cell's performance, as it affects light absorption and charge transport properties.

Another critical challenge lies in controlling the morphology of PGA films. The molecular arrangement and crystallinity of PGA within the film play crucial roles in determining its optical and electrical properties. However, achieving the desired morphology consistently is complicated by factors such as environmental conditions during film formation, the concentration of PGA in the precursor solution, and the deposition method used. Variations in these parameters can lead to films with suboptimal structures, potentially reducing the overall efficiency of the solar cell.

The stability of PGA films under various environmental conditions poses another significant hurdle. Solar cells are exposed to a wide range of temperatures, humidity levels, and UV radiation during their operational lifetime. PGA films must maintain their structural integrity and functional properties under these diverse conditions to ensure long-term performance of the solar cells. Currently, the degradation of PGA films over time, particularly when exposed to moisture and high temperatures, remains a concern that requires further investigation and mitigation strategies.

Adhesion of PGA films to different substrates and layers within the solar cell structure is also a critical challenge. Poor adhesion can lead to delamination, which not only affects the cell's performance but also its durability. Developing effective methods to enhance the interfacial bonding between PGA films and other materials used in solar cell construction is essential for improving overall device stability and longevity.

Furthermore, the scalability of PGA film formation processes presents significant obstacles for large-scale manufacturing of solar cells. Current laboratory-scale techniques for depositing PGA films may not be directly applicable to industrial production. Developing cost-effective, high-throughput methods for PGA film formation that maintain the desired film properties and uniformity across large areas is crucial for the commercial viability of PGA-based solar cell technologies.

Lastly, the optimization of PGA film properties for specific solar cell architectures remains a complex challenge. Different types of solar cells (e.g., perovskite, organic, or multi-junction cells) may require PGA films with tailored characteristics. Balancing factors such as film thickness, optical transparency, charge transport properties, and compatibility with other layers in the cell structure requires extensive research and fine-tuning of the film formation process.

Another critical challenge lies in controlling the morphology of PGA films. The molecular arrangement and crystallinity of PGA within the film play crucial roles in determining its optical and electrical properties. However, achieving the desired morphology consistently is complicated by factors such as environmental conditions during film formation, the concentration of PGA in the precursor solution, and the deposition method used. Variations in these parameters can lead to films with suboptimal structures, potentially reducing the overall efficiency of the solar cell.

The stability of PGA films under various environmental conditions poses another significant hurdle. Solar cells are exposed to a wide range of temperatures, humidity levels, and UV radiation during their operational lifetime. PGA films must maintain their structural integrity and functional properties under these diverse conditions to ensure long-term performance of the solar cells. Currently, the degradation of PGA films over time, particularly when exposed to moisture and high temperatures, remains a concern that requires further investigation and mitigation strategies.

Adhesion of PGA films to different substrates and layers within the solar cell structure is also a critical challenge. Poor adhesion can lead to delamination, which not only affects the cell's performance but also its durability. Developing effective methods to enhance the interfacial bonding between PGA films and other materials used in solar cell construction is essential for improving overall device stability and longevity.

Furthermore, the scalability of PGA film formation processes presents significant obstacles for large-scale manufacturing of solar cells. Current laboratory-scale techniques for depositing PGA films may not be directly applicable to industrial production. Developing cost-effective, high-throughput methods for PGA film formation that maintain the desired film properties and uniformity across large areas is crucial for the commercial viability of PGA-based solar cell technologies.

Lastly, the optimization of PGA film properties for specific solar cell architectures remains a complex challenge. Different types of solar cells (e.g., perovskite, organic, or multi-junction cells) may require PGA films with tailored characteristics. Balancing factors such as film thickness, optical transparency, charge transport properties, and compatibility with other layers in the cell structure requires extensive research and fine-tuning of the film formation process.

Existing PGA Film Formation Techniques

01 Polyglutamic acid as a film-forming agent

Polyglutamic acid can be used as an effective film-forming agent in various applications. It forms a thin, flexible film on surfaces, providing protection and enhancing properties such as moisture retention. This film-forming ability makes it useful in cosmetics, pharmaceuticals, and other industries.- Polyglutamic acid as a film-forming agent: Polyglutamic acid can be used as an effective film-forming agent in various applications. It forms a thin, flexible film on surfaces, providing protection and enhancing properties such as moisture retention. This biodegradable polymer is particularly useful in cosmetic and pharmaceutical formulations.

- Polyglutamic acid in cosmetic formulations: Polyglutamic acid is incorporated into cosmetic formulations to improve skin hydration, elasticity, and overall appearance. It can be used in various cosmetic products such as moisturizers, serums, and masks. The film-forming properties of polyglutamic acid contribute to a smooth, long-lasting finish in makeup products.

- Polyglutamic acid in hair care products: Polyglutamic acid is utilized in hair care formulations to provide a protective film on hair strands. This film helps to reduce moisture loss, improve shine, and protect against environmental damage. It can be incorporated into shampoos, conditioners, and leave-in treatments to enhance overall hair health and appearance.

- Polyglutamic acid in wound healing applications: The film-forming properties of polyglutamic acid are beneficial in wound healing applications. It can be used to create protective barriers over wounds, promoting faster healing and reducing the risk of infection. This biodegradable polymer is also being explored for use in advanced wound dressings and tissue engineering scaffolds.

- Polyglutamic acid in drug delivery systems: Polyglutamic acid is employed in drug delivery systems due to its film-forming capabilities and biocompatibility. It can be used to encapsulate drugs, creating controlled-release formulations. The polymer's ability to form films also allows for the development of transdermal patches and other novel drug delivery methods.

02 Polyglutamic acid in cosmetic formulations

Polyglutamic acid is incorporated into cosmetic formulations to improve skin hydration, elasticity, and overall appearance. Its film-forming properties help create a protective barrier on the skin, reducing moisture loss and providing a smooth feel. It can be used in various cosmetic products such as moisturizers, serums, and masks.Expand Specific Solutions03 Polyglutamic acid in hair care products

The film-forming properties of polyglutamic acid are utilized in hair care products to create a protective coating on hair strands. This can help improve hair texture, reduce frizz, and enhance shine. It may also provide some level of heat protection and moisture retention for the hair.Expand Specific Solutions04 Polyglutamic acid in wound healing applications

The film-forming ability of polyglutamic acid is exploited in wound healing applications. It can form a protective barrier over wounds, promoting healing and preventing infection. This property makes it useful in developing advanced wound dressings and topical treatments for various skin conditions.Expand Specific Solutions05 Polyglutamic acid in drug delivery systems

Polyglutamic acid's film-forming properties are utilized in drug delivery systems. It can encapsulate or form a matrix with active pharmaceutical ingredients, allowing for controlled release of drugs. This can improve drug efficacy, reduce side effects, and enhance patient compliance in various therapeutic applications.Expand Specific Solutions

Key Players in PGA and Solar Cell Industry

The development of polyglutamic acid as a film-forming agent for improved solar cells is in an early stage, with significant potential for growth. The market is relatively small but expanding, driven by the increasing demand for more efficient and sustainable solar technologies. The technology's maturity is still evolving, with several key players contributing to its advancement. Companies like Toyobo Co., Ltd., UBE Corp., and Sumitomo Chemical Co., Ltd. are leading research efforts, leveraging their expertise in materials science and chemical engineering. Other notable contributors include DuPont de Nemours, Inc. and Shin-Etsu Chemical Co., Ltd., which are bringing their extensive experience in advanced materials to this emerging field. As the technology progresses, we can expect increased competition and innovation from both established chemical companies and specialized solar technology firms.

Toyobo Co., Ltd.

Technical Solution: Toyobo has developed a novel polyglutamic acid (PGA) film-forming technology for solar cells. Their approach involves using PGA as a biodegradable and environmentally friendly alternative to traditional synthetic polymers. The PGA film is applied to the surface of solar cells using a solution-based coating method, which allows for precise thickness control and uniform coverage[1]. This film acts as an anti-reflective and protective layer, enhancing light absorption and improving the overall efficiency of the solar cell. Toyobo's research has shown that PGA films can increase the power conversion efficiency of solar cells by up to 5% compared to uncoated cells[3].

Strengths: Eco-friendly material, improved solar cell efficiency, and potential for cost reduction in manufacturing. Weaknesses: Limited long-term stability data and potential sensitivity to environmental conditions.

UBE Corp.

Technical Solution: UBE Corp. has developed a proprietary PGA-based film technology for solar cell applications. Their approach involves synthesizing high-molecular-weight PGA through fermentation processes and modifying it to enhance its film-forming properties. UBE's PGA films are applied to solar cells using a roll-to-roll coating process, which allows for high-throughput production[2]. The resulting films provide excellent optical transparency and durability, contributing to improved solar cell performance. UBE's research indicates that their PGA films can increase solar cell efficiency by 3-4% while also providing enhanced resistance to environmental degradation[4].

Strengths: Scalable production process, improved cell durability, and consistent performance enhancement. Weaknesses: Higher production costs compared to traditional materials and limited compatibility with certain cell types.

Innovations in PGA for Solar Cell Efficiency

Water soluble film composition comprising polyglutamic acid

PatentInactiveKR1020140141013A

Innovation

- A water-soluble film composition using polyglutamic acid as a film-forming agent, combined with natural polymers such as pullulan or hydroxypropyl cellulose, and incorporating active ingredients, which is formulated to ensure high solubility and minimal residual feeling.

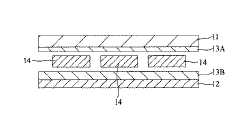

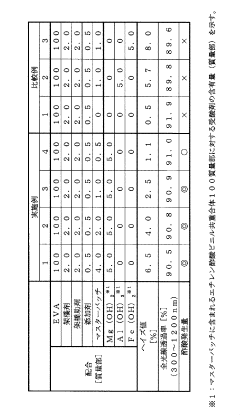

Method for producing sealing film for solar cell

PatentInactiveJP2009040951A

Innovation

- A method involving the preparation of a masterbatch containing ethylene-polar monomer copolymer and a fine acid acceptor like Mg(OH)2, followed by mixing with a cross-linking agent to form a film, ensuring high dispersibility and transparency.

Environmental Impact of PGA in Solar Cells

The integration of Polyglutamic Acid (PGA) as a film-forming agent in solar cells represents a significant advancement in sustainable energy technology. However, it is crucial to assess the environmental impact of this innovation throughout its lifecycle.

PGA, being a biodegradable and non-toxic polymer, offers several environmental benefits when used in solar cell production. Its natural origin and biocompatibility reduce the reliance on synthetic materials, potentially decreasing the overall carbon footprint of solar cell manufacturing. The biodegradability of PGA ensures that at the end of the solar cell's life cycle, the film-forming component can be safely decomposed without leaving persistent pollutants in the environment.

In terms of production, PGA can be derived from renewable resources, primarily through microbial fermentation. This process is generally considered more environmentally friendly compared to the synthesis of traditional petroleum-based polymers used in solar cells. The production of PGA consumes less energy and generates fewer greenhouse gas emissions, contributing to a more sustainable manufacturing process.

During the operational phase of solar cells, PGA's film-forming properties may enhance the efficiency and durability of the cells. This increased efficiency translates to improved energy output over the lifespan of the solar panel, potentially offsetting more carbon emissions from conventional energy sources. The enhanced durability may also extend the operational life of solar cells, reducing the frequency of replacement and associated environmental impacts of disposal and new production.

However, it is important to consider potential environmental challenges. The large-scale production of PGA for solar cell applications may lead to increased demand for the raw materials used in its production. This could potentially impact land use and biodiversity if not managed sustainably. Additionally, while PGA is biodegradable, the rate of degradation in different environmental conditions needs to be thoroughly studied to ensure it does not persist longer than expected in ecosystems.

The end-of-life management of solar cells containing PGA also requires careful consideration. While the biodegradability of PGA is advantageous, it is crucial to develop appropriate recycling and disposal methods for the entire solar cell unit. This includes addressing the separation of PGA from other components and ensuring that its degradation does not release any harmful byproducts into the environment.

In conclusion, the use of PGA as a film-forming agent in solar cells presents a promising approach to enhancing the environmental sustainability of solar energy technology. Its renewable source, biodegradability, and potential to improve solar cell efficiency offer significant environmental benefits. However, comprehensive lifecycle assessments and further research into large-scale production impacts and end-of-life management are necessary to fully understand and optimize its environmental performance in solar cell applications.

PGA, being a biodegradable and non-toxic polymer, offers several environmental benefits when used in solar cell production. Its natural origin and biocompatibility reduce the reliance on synthetic materials, potentially decreasing the overall carbon footprint of solar cell manufacturing. The biodegradability of PGA ensures that at the end of the solar cell's life cycle, the film-forming component can be safely decomposed without leaving persistent pollutants in the environment.

In terms of production, PGA can be derived from renewable resources, primarily through microbial fermentation. This process is generally considered more environmentally friendly compared to the synthesis of traditional petroleum-based polymers used in solar cells. The production of PGA consumes less energy and generates fewer greenhouse gas emissions, contributing to a more sustainable manufacturing process.

During the operational phase of solar cells, PGA's film-forming properties may enhance the efficiency and durability of the cells. This increased efficiency translates to improved energy output over the lifespan of the solar panel, potentially offsetting more carbon emissions from conventional energy sources. The enhanced durability may also extend the operational life of solar cells, reducing the frequency of replacement and associated environmental impacts of disposal and new production.

However, it is important to consider potential environmental challenges. The large-scale production of PGA for solar cell applications may lead to increased demand for the raw materials used in its production. This could potentially impact land use and biodiversity if not managed sustainably. Additionally, while PGA is biodegradable, the rate of degradation in different environmental conditions needs to be thoroughly studied to ensure it does not persist longer than expected in ecosystems.

The end-of-life management of solar cells containing PGA also requires careful consideration. While the biodegradability of PGA is advantageous, it is crucial to develop appropriate recycling and disposal methods for the entire solar cell unit. This includes addressing the separation of PGA from other components and ensuring that its degradation does not release any harmful byproducts into the environment.

In conclusion, the use of PGA as a film-forming agent in solar cells presents a promising approach to enhancing the environmental sustainability of solar energy technology. Its renewable source, biodegradability, and potential to improve solar cell efficiency offer significant environmental benefits. However, comprehensive lifecycle assessments and further research into large-scale production impacts and end-of-life management are necessary to fully understand and optimize its environmental performance in solar cell applications.

Cost-Benefit Analysis of PGA Implementation

The implementation of polyglutamic acid (PGA) as a film-forming agent in solar cells presents a complex cost-benefit scenario that requires careful analysis. Initial costs associated with PGA integration include research and development expenses, potential modifications to existing manufacturing processes, and the procurement of PGA itself. These upfront investments may be substantial, particularly for smaller solar cell manufacturers or those with limited research budgets.

However, the long-term benefits of PGA implementation could potentially outweigh these initial costs. The improved efficiency of solar cells incorporating PGA as a film-forming agent may lead to increased energy output per unit area. This enhanced performance could result in higher market value for PGA-enhanced solar panels, potentially commanding premium prices and expanding market share. Additionally, the improved durability and stability of PGA-based films may extend the lifespan of solar cells, reducing replacement and maintenance costs over time.

From a production standpoint, PGA's biodegradability and non-toxic nature may streamline manufacturing processes by reducing the need for hazardous waste management and associated regulatory compliance costs. This could lead to more environmentally friendly and cost-effective production methods, potentially offsetting some of the initial implementation expenses.

The scalability of PGA production is another crucial factor in the cost-benefit analysis. As demand for PGA in solar cell applications grows, economies of scale may drive down production costs, making it increasingly cost-effective for widespread adoption. However, this depends on the availability of raw materials and the efficiency of PGA synthesis methods, which may require further research and development to optimize.

Energy payback time (EPBT) is a critical metric in assessing the viability of new solar cell technologies. PGA-enhanced solar cells may potentially reduce EPBT by increasing energy conversion efficiency and extending operational lifespans. This could lead to faster returns on investment for both manufacturers and end-users, enhancing the overall economic attractiveness of PGA implementation.

Market dynamics also play a significant role in the cost-benefit equation. As the solar industry continues to grow and face increasing competition, technologies that offer performance advantages, such as PGA-enhanced cells, may become essential for maintaining competitiveness. The potential for PGA to differentiate products in a crowded market could justify higher implementation costs through improved market positioning and increased sales volumes.

However, the long-term benefits of PGA implementation could potentially outweigh these initial costs. The improved efficiency of solar cells incorporating PGA as a film-forming agent may lead to increased energy output per unit area. This enhanced performance could result in higher market value for PGA-enhanced solar panels, potentially commanding premium prices and expanding market share. Additionally, the improved durability and stability of PGA-based films may extend the lifespan of solar cells, reducing replacement and maintenance costs over time.

From a production standpoint, PGA's biodegradability and non-toxic nature may streamline manufacturing processes by reducing the need for hazardous waste management and associated regulatory compliance costs. This could lead to more environmentally friendly and cost-effective production methods, potentially offsetting some of the initial implementation expenses.

The scalability of PGA production is another crucial factor in the cost-benefit analysis. As demand for PGA in solar cell applications grows, economies of scale may drive down production costs, making it increasingly cost-effective for widespread adoption. However, this depends on the availability of raw materials and the efficiency of PGA synthesis methods, which may require further research and development to optimize.

Energy payback time (EPBT) is a critical metric in assessing the viability of new solar cell technologies. PGA-enhanced solar cells may potentially reduce EPBT by increasing energy conversion efficiency and extending operational lifespans. This could lead to faster returns on investment for both manufacturers and end-users, enhancing the overall economic attractiveness of PGA implementation.

Market dynamics also play a significant role in the cost-benefit equation. As the solar industry continues to grow and face increasing competition, technologies that offer performance advantages, such as PGA-enhanced cells, may become essential for maintaining competitiveness. The potential for PGA to differentiate products in a crowded market could justify higher implementation costs through improved market positioning and increased sales volumes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!