Graphene Oxide: Advanced Techniques in Surface Modification

Graphene Oxide Evolution and Research Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of nanotechnology since its discovery in the early 2000s. This two-dimensional carbon-based material, derived from graphite through oxidation processes, has garnered significant attention due to its unique properties and versatile applications. The evolution of GO research has been marked by rapid advancements in synthesis methods, characterization techniques, and surface modification strategies.

The journey of GO began with the Hummers method, developed in 1958, which laid the foundation for large-scale production of graphite oxide. However, it wasn't until the early 21st century that researchers recognized the potential of exfoliating graphite oxide into single-layer GO sheets. This breakthrough opened up a new realm of possibilities in materials science and engineering.

As research progressed, scientists focused on refining production methods to enhance the quality and yield of GO. Improved versions of the Hummers method, such as the Modified Hummers method and Tour method, were developed to address issues like environmental concerns and product consistency. These advancements have been crucial in scaling up GO production for industrial applications.

The evolution of GO research has been closely tied to the development of surface modification techniques. Initially, researchers explored simple functionalization methods to alter GO's surface properties. Over time, more sophisticated approaches emerged, including covalent and non-covalent modifications, which allowed for precise tailoring of GO's characteristics to suit specific applications.

The primary research objectives in the field of GO surface modification have evolved to address several key challenges. One major goal is to enhance the dispersibility and stability of GO in various solvents, which is crucial for its integration into composite materials and coatings. Another important objective is to improve GO's electrical conductivity, as the oxidation process disrupts the sp2 carbon network, reducing its conductive properties.

Researchers are also focusing on developing methods to control the degree of oxidation and reduction of GO, allowing for fine-tuning of its properties. This has led to the emergence of reduced graphene oxide (rGO) as an important derivative, bridging the gap between GO and pristine graphene in terms of electrical and mechanical properties.

Furthermore, there is a growing emphasis on creating multifunctional GO-based materials through strategic surface modifications. This includes incorporating specific functional groups or nanoparticles to impart properties such as magnetism, photocatalytic activity, or biocompatibility. Such advancements are crucial for expanding GO's applications in fields like environmental remediation, energy storage, and biomedical engineering.

Market Demand for Modified Graphene Oxide

The market demand for modified graphene oxide has been experiencing significant growth in recent years, driven by its unique properties and diverse applications across multiple industries. This advanced material, derived from graphene oxide through various surface modification techniques, offers enhanced performance characteristics that make it highly desirable in sectors such as electronics, energy storage, biomedical, and environmental remediation.

In the electronics industry, modified graphene oxide is increasingly sought after for its potential to improve the performance of flexible electronics, transparent conductive films, and sensors. The material's excellent electrical conductivity, coupled with its ability to be tailored for specific applications through surface modification, has led to a surge in demand from manufacturers of next-generation electronic devices.

The energy storage sector represents another significant market for modified graphene oxide. With the global push towards renewable energy and electric vehicles, there is a growing need for high-performance energy storage solutions. Modified graphene oxide has shown promise in enhancing the capacity and charging speed of lithium-ion batteries, as well as improving the efficiency of supercapacitors. This has resulted in increased demand from battery manufacturers and energy companies looking to gain a competitive edge in the market.

In the biomedical field, the demand for modified graphene oxide is driven by its potential applications in drug delivery systems, tissue engineering, and biosensors. The ability to functionalize graphene oxide's surface with specific biomolecules has opened up new possibilities for targeted drug delivery and improved biocompatibility in medical implants. This has led to growing interest from pharmaceutical companies and medical device manufacturers.

Environmental remediation is another area where modified graphene oxide is gaining traction. Its high adsorption capacity and ability to be tailored for specific pollutants make it an attractive option for water and air purification applications. As global concerns about environmental pollution continue to rise, there is an increasing demand for effective and sustainable remediation solutions, further driving the market for modified graphene oxide.

The market demand is also influenced by ongoing research and development efforts aimed at exploring new applications and improving existing ones. As more breakthroughs are made in surface modification techniques, the potential applications of modified graphene oxide continue to expand, creating new market opportunities and driving further demand growth.

However, it is important to note that the market for modified graphene oxide is still in its early stages, with some challenges to overcome. These include scaling up production to meet industrial demands, reducing production costs, and addressing potential environmental and health concerns. Despite these challenges, the overall market trajectory remains positive, with analysts projecting continued growth in the coming years as the material's unique properties and versatility continue to attract interest across various industries.

Current Challenges in Graphene Oxide Surface Modification

Despite significant advancements in graphene oxide (GO) surface modification techniques, several challenges persist in this field. One of the primary obstacles is achieving uniform and controlled functionalization across the entire GO surface. The heterogeneous nature of GO, with its varying oxygen-containing functional groups, makes it difficult to attain consistent surface properties.

Another major challenge lies in the scalability of surface modification processes. While many techniques work well at the laboratory scale, translating these methods to industrial-scale production remains problematic. Issues such as maintaining quality control, ensuring reproducibility, and managing costs become more pronounced as production volumes increase.

The stability of modified GO surfaces presents another significant hurdle. Many surface modifications are susceptible to environmental factors such as pH, temperature, and mechanical stress, leading to degradation or loss of functionality over time. This instability can limit the long-term effectiveness and applicability of modified GO in various applications.

Characterization of modified GO surfaces also poses challenges. Existing analytical techniques often struggle to provide comprehensive information about the nature and distribution of surface modifications, particularly at the nanoscale. This limitation hampers our ability to fully understand and optimize the modification processes.

The environmental impact of GO surface modification techniques is an emerging concern. Many current methods rely on hazardous chemicals or energy-intensive processes, raising questions about their sustainability and potential ecological consequences. Developing greener, more environmentally friendly modification techniques remains a significant challenge.

Achieving precise control over the degree of functionalization is another ongoing issue. Overmodification can lead to a loss of GO's intrinsic properties, while insufficient modification may not yield the desired surface characteristics. Striking the right balance requires fine-tuning of reaction conditions, which can be challenging to achieve consistently.

Lastly, the integration of modified GO into complex systems or devices presents its own set of challenges. Issues such as compatibility with other materials, maintaining functionality during integration processes, and ensuring uniform performance across different batches of modified GO continue to pose difficulties for researchers and engineers in the field.

State-of-the-Art Surface Modification Methods

01 Surface modification of graphene oxide

Various methods are employed to modify the surface of graphene oxide, enhancing its properties and expanding its applications. These modifications can include chemical functionalization, doping, or the introduction of specific functional groups to tailor the material's characteristics for specific uses.- Surface modification of graphene oxide: Various methods are employed to modify the surface of graphene oxide, enhancing its properties and expanding its applications. These modifications can include chemical functionalization, doping, or the introduction of specific functional groups to tailor the material's characteristics for specific uses.

- Graphene oxide-based composites: Graphene oxide is used to create composite materials by combining it with other substances such as polymers, metals, or ceramics. These composites often exhibit enhanced mechanical, electrical, or thermal properties, making them suitable for a wide range of applications in various industries.

- Reduction of graphene oxide: Techniques for reducing graphene oxide to produce reduced graphene oxide (rGO) or graphene-like materials are developed. These methods aim to restore the sp2 carbon network and improve electrical conductivity while maintaining some of the advantageous properties of graphene oxide.

- Graphene oxide for energy storage applications: Graphene oxide and its derivatives are utilized in energy storage devices such as supercapacitors and batteries. The material's high surface area and unique properties make it an attractive candidate for improving the performance and efficiency of these energy storage systems.

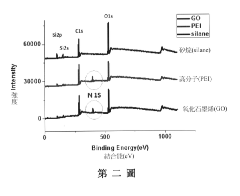

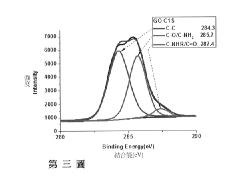

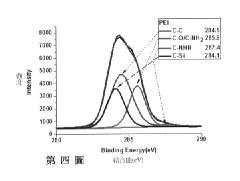

- Characterization and analysis of graphene oxide surfaces: Advanced techniques and methods are developed for characterizing and analyzing the surface properties of graphene oxide. These include spectroscopic, microscopic, and other analytical approaches to better understand the material's structure, composition, and behavior at the surface level.

02 Graphene oxide-based composites

Graphene oxide is used to create composite materials by combining it with other substances such as polymers, metals, or ceramics. These composites often exhibit enhanced mechanical, electrical, or thermal properties, making them suitable for a wide range of applications in various industries.Expand Specific Solutions03 Reduction of graphene oxide

Techniques for reducing graphene oxide to produce reduced graphene oxide (rGO) or graphene-like materials are developed. These methods aim to restore the sp2 carbon network and improve the electrical and mechanical properties of the material while maintaining some of the advantageous features of graphene oxide.Expand Specific Solutions04 Graphene oxide for energy storage applications

Graphene oxide and its derivatives are utilized in energy storage devices such as supercapacitors and batteries. The high surface area and unique properties of graphene oxide make it an attractive material for improving the performance and efficiency of these energy storage systems.Expand Specific Solutions05 Graphene oxide in environmental applications

The surface properties of graphene oxide are exploited for environmental applications such as water purification, gas sensing, and pollutant removal. The material's high adsorption capacity and ability to be functionalized make it effective for capturing various contaminants and pollutants from air and water.Expand Specific Solutions

Key Players in Graphene Oxide Research and Industry

The field of Graphene Oxide surface modification is in a rapidly evolving phase, characterized by intense research and development activities. The market for this technology is expanding, driven by its potential applications in various industries such as electronics, energy storage, and biomedical devices. While the technology is still maturing, significant progress has been made by key players. Universities like William Marsh Rice University, Sichuan University, and Beihang University are at the forefront of academic research, while companies such as Paragraf Ltd. and Empire Technology Development LLC are leading commercial development. The involvement of diverse institutions, from academic to industrial, indicates a competitive landscape with opportunities for both fundamental research and practical applications.

Paragraf Ltd.

Beneq Group Oy

Breakthrough Patents in Graphene Oxide Functionalization

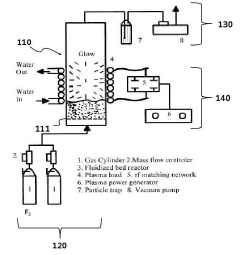

- A method using a fluidized bed reactor to inject graphene particles and a fluorine-containing gas, followed by RF glow discharge plasma treatment, enhances contact and uniformity, allowing for controlled band gap formation without damaging the graphene structure.

- Sequential wet processing steps for modifying reduced graphene oxide onto high aspect ratio substrate holes.

- Integration of multiple surface modification techniques including silane self-assembly, polymer grafting, and metal ion/atom intercalation.

- Combination of reduced graphene oxide modification with electroplating of conductive metal plugs.

Environmental Impact of Graphene Oxide Production

The production of graphene oxide (GO) has raised significant environmental concerns due to its potential impact on ecosystems and human health. The synthesis process of GO typically involves the oxidation of graphite using strong oxidizing agents, such as potassium permanganate and sulfuric acid, which can lead to the generation of hazardous waste and toxic byproducts. These chemicals, if not properly managed, can contaminate water sources and soil, posing risks to aquatic life and terrestrial ecosystems.

One of the primary environmental concerns is the release of heavy metals during GO production. The oxidation process can mobilize metal impurities present in graphite, potentially leading to the contamination of water bodies. Additionally, the use of strong acids in the synthesis can result in the generation of acidic waste streams, which may alter the pH of aquatic environments if not adequately treated before disposal.

The production of GO also consumes significant amounts of energy and water, contributing to resource depletion and greenhouse gas emissions. The high-temperature processes involved in GO synthesis and subsequent purification steps require substantial energy inputs, often derived from fossil fuel sources. This energy consumption indirectly contributes to climate change and air pollution.

Nanoparticle emissions during GO production and handling pose another environmental challenge. The fine particulate nature of GO raises concerns about its potential to become airborne, leading to inhalation risks for workers and nearby communities. These nanoparticles may also enter aquatic systems, where their behavior and impact on organisms are not yet fully understood.

Efforts to mitigate the environmental impact of GO production have led to the development of greener synthesis methods. These include the use of less toxic oxidizing agents, such as hydrogen peroxide, and the exploration of electrochemical exfoliation techniques that reduce the need for harsh chemicals. Researchers are also investigating ways to recycle and reuse process chemicals, minimizing waste generation and resource consumption.

The lifecycle assessment of GO production has become an important area of study, aiming to quantify the environmental footprint from raw material extraction to final disposal. This holistic approach helps identify hotspots in the production process where environmental interventions can be most effective. Implementing closed-loop systems and adopting principles of green chemistry in GO synthesis are promising strategies to reduce its environmental impact.

As the demand for GO continues to grow, addressing these environmental concerns becomes increasingly crucial. Regulatory frameworks and industry standards are being developed to ensure responsible production practices and proper waste management. Balancing the technological benefits of GO with environmental sustainability remains a key challenge for researchers and manufacturers in this field.

Scalability and Commercialization Prospects

The scalability and commercialization prospects for graphene oxide surface modification techniques are promising, yet face several challenges. The potential for large-scale production of modified graphene oxide materials has attracted significant attention from both industry and academia. Current research indicates that some surface modification methods, such as chemical functionalization and plasma treatment, can be adapted for industrial-scale processes.

However, the transition from laboratory-scale to commercial production presents hurdles. One major challenge is maintaining consistent quality and uniformity of surface modification across large batches. This is particularly crucial for applications in electronics and biomedical fields, where precise control over surface properties is essential. Researchers are exploring automated and continuous flow processes to address this issue, which could potentially improve scalability and reproducibility.

Cost-effectiveness is another critical factor in commercialization. While graphene oxide itself has become more affordable due to improved production methods, some advanced surface modification techniques still involve expensive reagents or equipment. This has led to a focus on developing more economical modification processes, such as using green chemistry approaches or optimizing existing methods to reduce material waste.

The market potential for modified graphene oxide is diverse, spanning sectors such as energy storage, water purification, and advanced composites. This broad applicability is driving investment in scalable production technologies. Several start-ups and established companies are now piloting industrial-scale facilities for producing surface-modified graphene oxide, indicating growing commercial interest.

Regulatory considerations also play a crucial role in commercialization prospects. As nanomaterials, modified graphene oxide products must navigate complex safety and environmental regulations. This has spurred research into eco-friendly modification techniques and comprehensive toxicology studies to facilitate regulatory approval and market acceptance.

Collaboration between academic institutions and industry partners is accelerating the development of scalable processes. These partnerships are focusing on bridging the gap between laboratory discoveries and industrial implementation, often through the establishment of pilot plants and technology transfer initiatives. Such collaborations are essential for overcoming technical barriers and reducing the time-to-market for new graphene oxide-based products.

In conclusion, while challenges remain, the scalability and commercialization prospects for advanced graphene oxide surface modification techniques are generally positive. Continued advancements in process engineering, cost reduction strategies, and regulatory compliance are likely to pave the way for wider industrial adoption in the coming years.