What is Graphene Oxide?

Graphene Oxide Overview

Graphene oxide (GO) is a remarkable derivative of graphene, the two-dimensional carbon allotrope that has revolutionized materials science since its discovery in 2004. GO is produced by the oxidation of graphite, resulting in a single-layer material with oxygen-containing functional groups attached to its basal plane and edges. This oxidation process introduces sp3 hybridized carbon atoms, disrupting the sp2 bonding network of graphene and altering its electrical, mechanical, and chemical properties.

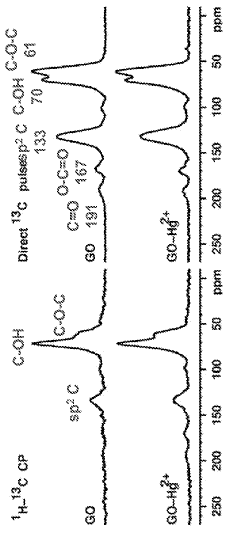

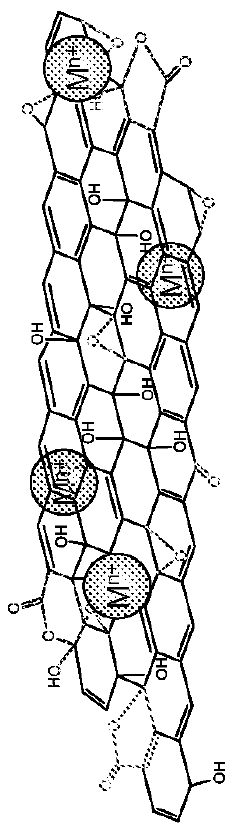

The structure of GO consists of a carbon backbone with epoxy, hydroxyl, and carboxyl groups randomly distributed across the surface. This unique composition gives GO its distinctive characteristics, including hydrophilicity, high surface area, and excellent dispersibility in water and various organic solvents. These properties make GO an attractive material for a wide range of applications, from electronics to environmental remediation.

One of the most significant features of GO is its ability to be reduced to graphene-like materials through various reduction methods. This process, known as reduction of graphene oxide (rGO), allows for the partial restoration of the sp2 carbon network, enhancing electrical conductivity and mechanical strength. The degree of reduction can be controlled, enabling the fine-tuning of GO's properties for specific applications.

GO's versatility extends to its role as a precursor for functionalized graphene materials. The oxygen-containing groups on its surface serve as reactive sites for further chemical modifications, allowing for the attachment of various molecules or nanoparticles. This adaptability makes GO an excellent platform for developing advanced composite materials, sensors, and biomedical devices.

In the field of energy storage and conversion, GO has shown promise in applications such as supercapacitors, lithium-ion batteries, and fuel cells. Its high surface area and controllable electronic properties make it an ideal candidate for electrode materials and as a support for catalysts. Additionally, GO's ability to form stable aqueous dispersions has led to its use in water purification systems, where it can effectively remove contaminants through adsorption or as a membrane material.

The biomedical sector has also embraced GO for its potential in drug delivery, tissue engineering, and biosensing. Its large surface area allows for high drug loading capacity, while its ability to be functionalized enables targeted delivery and controlled release of therapeutic agents. Furthermore, GO's unique optical properties have been exploited for bioimaging and photothermal therapy applications.

Despite its numerous advantages, challenges remain in the large-scale production and standardization of GO. The oxidation process can introduce defects and variability in the material's properties, necessitating careful control and characterization. Ongoing research focuses on developing more efficient and environmentally friendly production methods, as well as exploring new applications that leverage GO's unique characteristics.

Market Applications

Graphene oxide has emerged as a versatile material with a wide range of potential market applications across various industries. In the electronics sector, graphene oxide's exceptional electrical conductivity and flexibility make it an ideal candidate for next-generation flexible displays, touchscreens, and wearable devices. Its incorporation into electronic components could lead to faster, more efficient, and more durable products.

The energy industry has shown significant interest in graphene oxide for its potential to enhance energy storage and conversion technologies. It is being explored for use in supercapacitors, lithium-ion batteries, and solar cells, where it can improve energy density, charge-discharge rates, and overall performance. This could revolutionize portable electronics and contribute to the advancement of renewable energy systems.

In the field of water treatment, graphene oxide's large surface area and ability to be functionalized make it an excellent material for water purification and desalination processes. Its use in filtration membranes could lead to more efficient and cost-effective water treatment solutions, addressing global water scarcity issues.

The biomedical sector is another area where graphene oxide shows promise. Its biocompatibility and ability to be functionalized with various molecules make it suitable for drug delivery systems, biosensors, and tissue engineering applications. Graphene oxide-based materials could enable targeted drug delivery, improve diagnostic tools, and enhance regenerative medicine techniques.

In the automotive and aerospace industries, graphene oxide's lightweight nature and superior mechanical properties make it an attractive material for composite reinforcement. Its incorporation into structural materials could lead to lighter, stronger, and more fuel-efficient vehicles and aircraft.

The environmental remediation sector is exploring graphene oxide for its potential in removing pollutants from air and water. Its high adsorption capacity and selectivity make it effective in capturing various contaminants, including heavy metals and organic pollutants.

Lastly, the packaging industry is investigating graphene oxide for its barrier properties and antimicrobial characteristics. Its use in food packaging could extend shelf life and improve food safety, while its application in smart packaging could enable real-time monitoring of product quality and freshness.

As research and development continue, new applications for graphene oxide are likely to emerge, potentially disrupting existing markets and creating new ones. The material's versatility and unique properties position it as a key player in driving innovation across multiple industries in the coming years.

Synthesis Challenges

The synthesis of graphene oxide presents several significant challenges that researchers and manufacturers must overcome to produce high-quality material consistently and at scale. One of the primary difficulties lies in controlling the oxidation process to achieve a uniform degree of oxidation across the graphene sheets. Over-oxidation can lead to structural damage and loss of desirable properties, while under-oxidation may result in incomplete exfoliation and poor dispersibility.

Another major challenge is the removal of residual oxidizing agents and byproducts from the final product. These impurities can significantly affect the properties and performance of graphene oxide in various applications. The purification process often involves multiple washing steps, which can be time-consuming and resource-intensive, especially when scaling up production.

The choice of starting material also plays a crucial role in the synthesis process. While graphite is the most common precursor, its quality and characteristics can vary widely depending on the source. Impurities in the starting material can lead to inconsistencies in the final product, making it difficult to achieve reproducible results across different batches.

Exfoliation of graphene oxide sheets is another critical step that poses challenges. Achieving complete exfoliation while maintaining the structural integrity of the sheets is essential for maximizing the material's surface area and properties. However, aggressive exfoliation techniques can cause fragmentation and introduce defects in the graphene oxide structure.

Scaling up the production of graphene oxide from laboratory to industrial levels presents additional hurdles. Maintaining consistent quality and properties while increasing production volume requires careful process optimization and control. Factors such as reaction kinetics, heat transfer, and mixing dynamics can behave differently at larger scales, necessitating adjustments to synthesis protocols.

Environmental and safety concerns also pose challenges in graphene oxide synthesis. The use of strong oxidizing agents and acids in traditional methods raises safety issues and environmental concerns. Developing greener, more sustainable synthesis routes that maintain product quality while reducing environmental impact is an ongoing area of research and development.

Lastly, characterization and quality control of graphene oxide present their own set of challenges. The heterogeneous nature of graphene oxide, with varying degrees of oxidation and defects, makes it difficult to establish standardized characterization methods and quality metrics. This lack of standardization can hinder comparisons between different studies and products, potentially slowing down the adoption of graphene oxide in commercial applications.

Current GO Prep Methods

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in energy storage devices: Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.

- Functionalization and modification of graphene oxide: Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and composite formation with other materials.

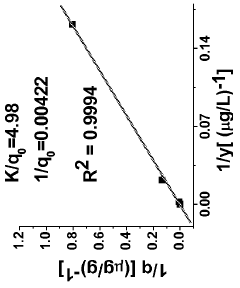

- Graphene oxide in environmental applications: Graphene oxide is used in environmental applications such as water purification, pollutant removal, and environmental sensing. Its high adsorption capacity and chemical properties make it effective for removing contaminants from water and air.

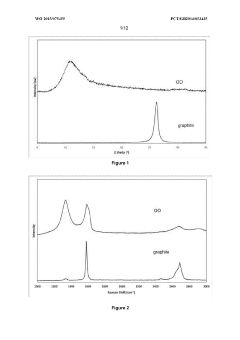

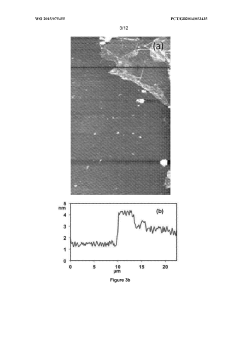

- Characterization and analysis techniques for graphene oxide: Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic techniques, microscopy, and other analytical tools to determine the quality, composition, and characteristics of graphene oxide materials.

02 Applications of graphene oxide in energy storage devices

Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and composite formation with other materials.Expand Specific Solutions04 Graphene oxide in environmental applications

Graphene oxide is used in environmental applications such as water purification, pollutant removal, and environmental sensing. Its high adsorption capacity and large surface area make it an effective material for these purposes.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic techniques, microscopy, and other analytical tools to understand its composition and behavior.Expand Specific Solutions

Key GO Manufacturers

The graphene oxide market is in a growth phase, driven by increasing research and industrial applications. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, graphene oxide is advancing from research to commercial applications, with varying levels of maturity across sectors. Key players like Northwestern University, The University of Manchester, and Tsinghua University are leading academic research, while companies such as China Petroleum & Chemical Corp. and Nitto Denko Corp. are focusing on industrial applications. The technology's development is characterized by a mix of academic institutions and commercial entities collaborating to overcome production challenges and expand practical applications.

Northwestern University

China Petroleum & Chemical Corp.

GO Characterization

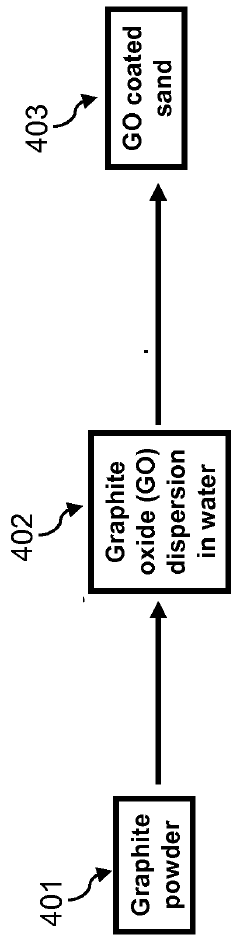

- Graphite oxide is coated onto particulate materials like sand using a low-temperature process, incorporating covalently attached thiol groups to enhance adsorption capacity and hydrophilicity, creating a 'core-shell' structure that increases retention of heavy metals and organics without compromising conductivity.

- An electrochemical method using organic anions, non-oxidant polyatomic anions, and less acidic electrolyte conditions to intercalate and exfoliate graphite, reducing mechanical and oxidative stress, allowing for the production of graphene oxide with controlled thickness and high yields without the need for harsh chemicals or high temperatures.

Environmental Impact

Graphene oxide (GO) has garnered significant attention in the scientific community due to its unique properties and potential applications. However, its environmental impact is a crucial aspect that requires careful consideration. The production, use, and disposal of GO can have both positive and negative effects on the environment.

One of the primary environmental concerns associated with GO is its potential toxicity to aquatic ecosystems. Studies have shown that GO can accumulate in water bodies and interact with various organisms, potentially causing harm to aquatic life. The small size of GO particles allows them to penetrate cell membranes, potentially leading to oxidative stress and cellular damage in marine organisms. This raises concerns about the long-term effects on biodiversity and ecosystem balance in aquatic environments.

On the other hand, GO has shown promise in environmental remediation applications. Its high surface area and adsorption capacity make it an effective material for removing pollutants from water and air. GO-based materials have been successfully used to remove heavy metals, organic contaminants, and even radioactive elements from contaminated water sources. This potential for environmental cleanup could contribute positively to ecosystem restoration efforts.

The production of GO also has environmental implications. The synthesis process often involves the use of strong oxidizing agents and acids, which can generate hazardous waste if not properly managed. However, researchers are actively developing more environmentally friendly production methods, such as electrochemical exfoliation and green reduction techniques, to minimize the environmental footprint of GO manufacturing.

Another aspect to consider is the potential for GO to act as a carrier for other pollutants in the environment. Due to its high adsorption capacity, GO can potentially accumulate and transport contaminants over long distances, affecting ecosystems far from the original source of pollution. This phenomenon requires further investigation to fully understand its implications for environmental health.

The biodegradability of GO is another important factor in assessing its environmental impact. While some studies suggest that GO can be degraded by certain microorganisms, the rate and extent of degradation can vary depending on environmental conditions. The persistence of GO in the environment could lead to long-term accumulation and potential ecological consequences.

In conclusion, the environmental impact of graphene oxide is complex and multifaceted. While it offers promising solutions for environmental remediation, concerns about its potential toxicity and long-term effects on ecosystems remain. Continued research and development of sustainable production methods and proper waste management strategies are essential to harness the benefits of GO while minimizing its environmental risks.

Regulatory Framework

The regulatory framework surrounding graphene oxide is still evolving due to its relatively recent emergence as a material of interest. Currently, there is no unified global regulatory approach specifically tailored to graphene oxide. Instead, it falls under broader regulations for nanomaterials and chemical substances.

In the European Union, graphene oxide is subject to the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers are required to register substances produced or imported in quantities of one tonne or more per year. This includes providing safety data and risk assessments for the material.

The United States Environmental Protection Agency (EPA) regulates graphene oxide under the Toxic Substances Control Act (TSCA). Manufacturers and importers must submit a Pre-Manufacture Notice (PMN) to the EPA before producing or importing new chemical substances, including nanomaterials like graphene oxide.

In Canada, graphene oxide falls under the purview of the Canadian Environmental Protection Act (CEPA). The New Substances Notification Regulations require manufacturers and importers to provide information on new substances, including nanomaterials, before they are introduced into the Canadian market.

Occupational safety regulations also apply to the handling and use of graphene oxide in workplace settings. In the United States, the Occupational Safety and Health Administration (OSHA) has established guidelines for working with nanomaterials, which include recommendations for exposure controls and personal protective equipment.

The lack of specific regulations for graphene oxide has led to calls for more targeted regulatory frameworks. Some experts argue that the unique properties of graphene-based materials necessitate specialized regulations to address potential environmental and health risks. As research on the long-term effects of graphene oxide exposure continues, it is likely that regulatory bodies will develop more specific guidelines and standards.

International collaboration is also emerging in the regulatory landscape. The Organization for Economic Co-operation and Development (OECD) has established a Working Party on Manufactured Nanomaterials to promote international cooperation on the safety of nanomaterials, including graphene-based materials.

As the applications of graphene oxide expand, regulatory bodies are likely to refine their approaches. This may include developing standardized testing methods, establishing exposure limits, and creating more comprehensive risk assessment protocols specific to graphene oxide and related materials.