How is Graphene Oxide Made?

Graphene Oxide Synthesis Background and Objectives

Graphene oxide, a remarkable derivative of graphene, has garnered significant attention in the scientific community due to its unique properties and potential applications. The synthesis of graphene oxide represents a critical step in harnessing the power of this versatile material. The journey of graphene oxide production began with the discovery of graphene in 2004, which sparked a revolution in materials science.

The primary objective of graphene oxide synthesis is to create a scalable and efficient method for producing high-quality, atomically thin sheets of carbon with oxygen-containing functional groups. This process aims to maintain the exceptional properties of graphene while introducing new functionalities through oxidation. The development of reliable synthesis techniques is crucial for advancing graphene-based technologies across various industries.

Over the years, several methods for graphene oxide synthesis have emerged, each with its own advantages and challenges. The most widely adopted approach is the modified Hummers method, which involves the oxidation of graphite using strong oxidizing agents. This technique has undergone numerous refinements to improve yield, reduce environmental impact, and enhance the quality of the resulting graphene oxide.

The evolution of graphene oxide synthesis techniques reflects the broader trends in nanomaterial production, emphasizing sustainability, scalability, and precise control over material properties. Researchers are continuously exploring novel approaches to overcome the limitations of current methods, such as the use of environmentally friendly oxidants and the development of top-down and bottom-up synthesis strategies.

As the field progresses, the focus is shifting towards achieving better control over the degree of oxidation, reducing defects in the graphene oxide structure, and developing methods for large-scale production. These advancements are crucial for realizing the full potential of graphene oxide in applications ranging from energy storage and water purification to biomedical devices and advanced composites.

The synthesis of graphene oxide is not only a technical challenge but also a key enabler for the commercialization of graphene-based technologies. As such, research in this area is driven by both scientific curiosity and industrial demand, creating a dynamic and rapidly evolving field of study. The ongoing efforts to optimize graphene oxide production are paving the way for a new generation of advanced materials with transformative potential across multiple sectors.

Market Applications and Demand Analysis

Graphene oxide has emerged as a versatile material with a wide range of potential applications across various industries. The market demand for graphene oxide is driven by its unique properties, including high surface area, excellent mechanical strength, and exceptional electrical conductivity. These characteristics make it an attractive option for numerous sectors, particularly in advanced materials and electronics.

In the energy storage sector, graphene oxide shows significant promise for enhancing the performance of batteries and supercapacitors. The material's high surface area and conductivity contribute to improved energy density and faster charging capabilities, addressing key challenges in electric vehicle and portable electronics markets. This application alone is expected to drive substantial demand growth in the coming years as the shift towards electrification accelerates globally.

The water treatment industry represents another major market for graphene oxide. Its ability to effectively remove contaminants, including heavy metals and organic pollutants, makes it an ideal candidate for advanced filtration systems. As water scarcity becomes an increasingly pressing issue worldwide, the demand for efficient water purification technologies is projected to rise, further boosting the market for graphene oxide-based solutions.

In the biomedical field, graphene oxide's biocompatibility and functionalization potential have opened up new avenues for drug delivery systems, tissue engineering, and biosensors. The material's ability to carry and release drugs in a controlled manner has attracted significant interest from pharmaceutical companies, potentially revolutionizing targeted drug delivery approaches. This application is expected to contribute to the growing demand in the healthcare and life sciences sectors.

The electronics industry is another key driver of graphene oxide demand. Its use in flexible electronics, transparent conductive films, and next-generation semiconductors is gaining traction. As consumer electronics continue to evolve towards more flexible and efficient designs, the demand for graphene oxide in this sector is anticipated to grow substantially.

Additionally, the aerospace and automotive industries are exploring graphene oxide for lightweight composite materials. Its incorporation into polymers and other materials can lead to significant weight reduction while maintaining or improving strength, which is crucial for fuel efficiency and performance enhancement in these sectors.

The global market for graphene oxide is still in its early stages but is expected to experience rapid growth. While precise market size figures are challenging to determine due to the emerging nature of the technology, industry analysts project a compound annual growth rate (CAGR) in double digits for the next decade. This growth is driven by increasing research and development activities, expanding applications, and growing investments in graphene-based technologies across various industries.

Current Production Methods and Challenges

Graphene oxide (GO) production has evolved significantly since its discovery, with several methods now established in the scientific and industrial communities. The most widely adopted approach is the modified Hummers' method, which involves the oxidation of graphite using strong oxidizing agents such as potassium permanganate in the presence of sulfuric acid. This process effectively exfoliates graphite layers and introduces oxygen-containing functional groups, resulting in the formation of graphene oxide.

Another common technique is the Brodie method, which utilizes a mixture of potassium chlorate and nitric acid to oxidize graphite. While less popular than the Hummers' method, it still finds applications in certain research contexts. The Staudenmaier method, an improvement on the Brodie method, incorporates sulfuric acid into the reaction mixture, enhancing the oxidation process and yield.

Recent advancements have led to the development of more environmentally friendly and scalable production methods. These include electrochemical exfoliation, which uses an electric current to separate graphite layers in an electrolyte solution, and the Tour method, which employs a mixture of H2SO4 and H3PO4 with KMnO4 to achieve a higher degree of oxidation with reduced toxic gas evolution.

Despite these advancements, several challenges persist in the large-scale production of graphene oxide. One major issue is the lack of standardization in production processes, leading to variations in GO quality and properties across different batches and manufacturers. This inconsistency can significantly impact the performance of GO-based materials and devices, hindering their widespread adoption in industrial applications.

Another significant challenge is the environmental impact of traditional production methods. The use of strong acids and oxidizing agents generates hazardous waste and potentially toxic byproducts, necessitating careful handling and disposal procedures. This not only increases production costs but also raises concerns about the sustainability of GO manufacturing processes.

Scalability remains a critical hurdle in GO production. While laboratory-scale synthesis is well-established, transitioning to industrial-scale production while maintaining product quality and consistency is complex. Issues such as heat management, uniform oxidation, and efficient separation of the final product from the reaction mixture become more pronounced at larger scales.

The energy-intensive nature of GO production also presents a challenge, particularly in the context of sustainability and cost-effectiveness. The high temperatures and long reaction times required in some methods contribute significantly to the overall energy consumption and production costs.

Addressing these challenges is crucial for the widespread adoption of graphene oxide in various applications. Ongoing research focuses on developing more efficient, environmentally friendly, and scalable production methods, as well as improving the consistency and quality control of GO products. These efforts are essential for realizing the full potential of graphene oxide in fields ranging from electronics to environmental remediation.

Existing Graphene Oxide Production Processes

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in energy storage devices: Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.

- Functionalization and modification of graphene oxide: Techniques for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. This includes chemical modifications, doping, and the creation of composite materials with graphene oxide.

- Graphene oxide in environmental applications: The use of graphene oxide in environmental applications is investigated, including water purification, pollutant removal, and environmental sensing. Its high adsorption capacity and large surface area make it an effective material for these purposes.

- Characterization and analysis of graphene oxide: Methods for characterizing and analyzing graphene oxide are developed, including spectroscopic techniques, microscopy, and other analytical tools. These approaches help in understanding the structure, properties, and quality of graphene oxide materials.

02 Applications of graphene oxide in energy storage devices

Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and surface modifications to improve its performance in different fields.Expand Specific Solutions04 Graphene oxide-based composites and nanocomposites

The development of graphene oxide-based composites and nanocomposites is described, combining graphene oxide with other materials to create hybrid structures with enhanced properties. These composites find applications in various fields, including electronics, sensors, and structural materials.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic techniques, microscopy, and other analytical tools to understand the material's composition, morphology, and behavior.Expand Specific Solutions

Key Players in Graphene Oxide Manufacturing

The graphene oxide production market is in a growth phase, driven by increasing applications in electronics, energy storage, and composites. The global market size is projected to expand significantly, with estimates ranging from $200-300 million by 2025. Technologically, the field is advancing rapidly, with various production methods being refined. Key players like Beihang University, Tianjin University, and The University of Manchester are at the forefront of research, while companies such as Cabot Corp. and Nissan Chemical Corp. are commercializing production processes. The involvement of diverse institutions and corporations indicates a competitive landscape with ongoing innovation in scalable and cost-effective manufacturing techniques.

The Sixth Element (Changzhou) Materials Technology Co., Ltd.

Cabot Corp.

Innovative Approaches in Graphene Oxide Synthesis

- A method involving washing crude graphene oxide with a dilute acidic solution, followed by redispersion in an aqueous solution and optional mild sonication, to produce larger sized graphene oxide platelets, flakes, or sheets, which can be filtered and centrifuged to achieve desired particle sizes and surface areas.

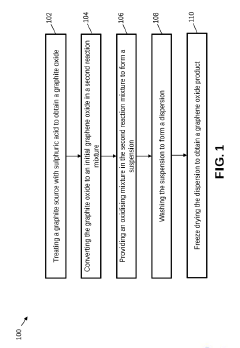

- A process involving treating graphite with sulphuric acid at -10°C to 10°C, followed by adding potassium permanganate at room temperature with mechanical agitation, then using hydrogen peroxide in an oxidizing mixture, and subsequent washing and freeze drying to produce graphene oxide with minimal impurities and optimal oxygen-to-carbon ratio.

Environmental Impact of Graphene Oxide Manufacturing

The manufacturing of graphene oxide has significant environmental implications that warrant careful consideration. The production process typically involves the oxidation of graphite using strong oxidizing agents, which can lead to the generation of hazardous waste and potentially harmful byproducts. One of the primary environmental concerns is the release of toxic chemicals, such as sulfuric acid and potassium permanganate, which are commonly used in the Hummers method, a widely adopted technique for graphene oxide synthesis.

These chemicals, if not properly managed, can contaminate water sources and soil, posing risks to ecosystems and human health. The production process also consumes substantial amounts of water and energy, contributing to resource depletion and increased carbon footprint. Furthermore, the disposal of acidic waste and unreacted materials presents additional environmental challenges, requiring specialized treatment and disposal methods to prevent ecological damage.

Air pollution is another potential issue associated with graphene oxide manufacturing. The process may release fine particulate matter and volatile organic compounds (VOCs) into the atmosphere, which can have adverse effects on air quality and contribute to respiratory problems in nearby communities. Additionally, the production of graphene oxide often involves high-temperature reactions, leading to increased energy consumption and associated greenhouse gas emissions.

However, it is important to note that ongoing research and development efforts are focused on improving the environmental sustainability of graphene oxide production. Green synthesis methods, such as electrochemical exfoliation and biomass-derived precursors, are being explored to reduce the environmental impact. These alternative approaches aim to minimize the use of harsh chemicals, decrease energy consumption, and lower waste generation.

The lifecycle assessment of graphene oxide production is crucial for understanding its overall environmental footprint. This includes considering the sourcing of raw materials, manufacturing processes, transportation, and end-of-life disposal or recycling. As the demand for graphene oxide grows in various applications, including electronics, energy storage, and water treatment, the importance of developing environmentally friendly production methods becomes increasingly critical.

Regulatory bodies and industry stakeholders are working towards establishing guidelines and best practices for sustainable graphene oxide manufacturing. This includes implementing closed-loop systems for chemical recycling, adopting cleaner production technologies, and optimizing process efficiency to reduce resource consumption and waste generation. By addressing these environmental concerns, the graphene oxide industry can strive towards more sustainable production practices, aligning with global efforts to mitigate climate change and protect ecosystems.

Scalability and Cost-Effectiveness Analysis

The scalability and cost-effectiveness of graphene oxide production are critical factors in its widespread adoption and commercial viability. Current manufacturing processes face significant challenges in scaling up to meet industrial demands while maintaining economic feasibility.

Large-scale production of graphene oxide primarily relies on modified Hummers' method, which involves the oxidation of graphite using strong oxidizing agents. While this method is effective for small-scale production, it encounters several obstacles when scaled up. The exothermic nature of the reaction and the generation of toxic gases pose safety concerns in large-scale operations. Additionally, the process requires substantial amounts of strong acids and oxidizing agents, leading to increased production costs and environmental issues.

To address these challenges, researchers are exploring alternative production methods that offer improved scalability and cost-effectiveness. One promising approach is the electrochemical exfoliation of graphite, which allows for continuous production and reduces the need for harsh chemicals. This method has shown potential for scaling up while maintaining product quality, but further optimization is required to enhance yield and reduce energy consumption.

Another avenue for improving scalability is the development of automated and continuous production systems. These systems aim to streamline the manufacturing process, reduce manual handling, and increase throughput. However, the initial investment in such equipment can be substantial, necessitating a careful cost-benefit analysis for implementation.

The cost-effectiveness of graphene oxide production is heavily influenced by raw material costs, energy consumption, and waste management. Efforts to reduce expenses focus on optimizing reagent usage, improving energy efficiency, and developing recycling processes for byproducts. Some researchers are investigating the use of renewable precursors and green chemistry principles to further enhance sustainability and reduce production costs.

As demand for graphene oxide continues to grow, economies of scale are expected to play a significant role in improving cost-effectiveness. Increased production volumes can lead to reduced per-unit costs through bulk purchasing of raw materials and more efficient use of equipment and labor. However, achieving these economies of scale requires substantial market demand and investment in production infrastructure.

In conclusion, while challenges remain in scaling up graphene oxide production cost-effectively, ongoing research and technological advancements are paving the way for more efficient and economical manufacturing processes. The successful development of scalable and cost-effective production methods will be crucial in unlocking the full potential of graphene oxide across various industries.