Graphene Oxide: Enhancing Biodegradable Plastic Durability

Graphene Oxide in Bioplastics: Background and Objectives

The field of biodegradable plastics has gained significant attention in recent years due to growing environmental concerns and the need for sustainable alternatives to conventional plastics. However, one of the major challenges facing biodegradable plastics is their limited durability, which often restricts their practical applications. In this context, the integration of Graphene Oxide (GO) into bioplastics has emerged as a promising approach to enhance their performance and longevity.

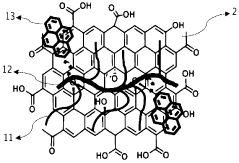

Graphene Oxide, a derivative of graphene, is a two-dimensional carbon nanomaterial with exceptional mechanical, thermal, and barrier properties. Its unique structure and characteristics make it an ideal candidate for reinforcing biodegradable plastics. The incorporation of GO into bioplastic matrices has shown potential to address several key limitations of biodegradable plastics, including poor mechanical strength, low thermal stability, and inadequate barrier properties.

The primary objective of this research is to explore and develop innovative methods for enhancing the durability of biodegradable plastics through the incorporation of Graphene Oxide. This involves investigating the fundamental interactions between GO and various biopolymer matrices, optimizing the dispersion and integration of GO within the bioplastic structure, and evaluating the resulting improvements in mechanical, thermal, and barrier properties.

Furthermore, this research aims to elucidate the mechanisms by which GO enhances the durability of biodegradable plastics. Understanding these mechanisms is crucial for developing tailored solutions and optimizing the GO-bioplastic composites for specific applications. The study will also focus on the scalability and cost-effectiveness of GO integration, addressing potential challenges in large-scale production and commercialization.

Another key objective is to assess the environmental impact and biodegradability of GO-reinforced bioplastics. While enhancing durability, it is essential to maintain the biodegradable nature of the materials, ensuring that they still offer a sustainable alternative to conventional plastics. This involves studying the degradation behavior of GO-bioplastic composites under various environmental conditions and evaluating their overall life cycle impact.

The research also aims to explore potential applications for GO-enhanced biodegradable plastics across different industries, including packaging, agriculture, and consumer goods. By identifying suitable application areas, the study seeks to bridge the gap between laboratory research and practical implementation, paving the way for the widespread adoption of these advanced materials.

Ultimately, this research endeavors to contribute to the development of next-generation biodegradable plastics that combine enhanced durability with maintained biodegradability. The successful integration of Graphene Oxide into bioplastics has the potential to revolutionize the field of sustainable materials, offering a viable solution to the global plastic waste problem while meeting the performance requirements of various industries.

Market Analysis for Durable Biodegradable Plastics

The market for durable biodegradable plastics enhanced with graphene oxide is experiencing significant growth and transformation. This innovative material addresses the critical need for environmentally friendly packaging solutions that maintain the strength and longevity required for various applications. The global biodegradable plastics market is projected to expand rapidly, driven by increasing environmental concerns and stringent regulations on single-use plastics.

Consumer awareness and demand for sustainable products are key factors fueling market growth. Major industries, including food and beverage, consumer goods, and agriculture, are actively seeking alternatives to conventional plastics. The incorporation of graphene oxide into biodegradable plastics offers a promising solution, potentially extending the shelf life and durability of these materials while maintaining their biodegradability.

The packaging sector represents the largest market segment for durable biodegradable plastics, followed by agriculture and textiles. In the packaging industry, there is a growing demand for materials that can withstand various environmental conditions while decomposing naturally after use. The food industry, in particular, is showing keen interest in these materials for extending the shelf life of perishable goods.

Geographically, Europe leads the market for durable biodegradable plastics, with stringent environmental regulations driving adoption. North America and Asia-Pacific are also witnessing rapid market growth, with countries like China and India emerging as significant players due to their large manufacturing bases and increasing environmental awareness.

The market is characterized by intense research and development activities, with companies investing heavily in improving the properties of biodegradable plastics. The integration of graphene oxide is seen as a breakthrough in enhancing the mechanical and barrier properties of these materials, potentially opening up new application areas.

However, the market faces challenges such as higher production costs compared to conventional plastics and the need for specialized waste management infrastructure. Despite these hurdles, the long-term outlook remains positive, driven by technological advancements and increasing environmental consciousness.

Key market players are focusing on strategic partnerships and collaborations to accelerate product development and market penetration. The competitive landscape is dynamic, with both established chemical companies and innovative startups vying for market share. As the technology matures and production scales up, it is expected that the cost of durable biodegradable plastics will decrease, further driving market growth and adoption across various industries.

Current Challenges in Bioplastic Durability

Biodegradable plastics have emerged as a promising solution to address the global plastic pollution crisis. However, their widespread adoption faces significant challenges, primarily due to their limited durability compared to conventional plastics. This issue of durability is a critical factor hindering the broader application of bioplastics in various industries.

One of the main challenges in bioplastic durability is their susceptibility to environmental factors. Biodegradable plastics are designed to break down under specific conditions, but this characteristic often leads to premature degradation in real-world applications. Exposure to moisture, heat, and UV radiation can accelerate the degradation process, resulting in a shorter lifespan than desired for many products.

The mechanical properties of bioplastics also present a significant challenge. Many biodegradable plastics exhibit lower tensile strength, flexibility, and impact resistance compared to their petroleum-based counterparts. This limitation restricts their use in applications that require high structural integrity or resistance to physical stress, such as in packaging or automotive components.

Another hurdle is the variability in degradation rates. Depending on the specific composition and environmental conditions, biodegradable plastics can degrade at vastly different rates. This inconsistency makes it difficult to predict product lifespans and ensure proper disposal, potentially leading to unintended environmental consequences if not managed correctly.

The cost factor associated with enhancing bioplastic durability is also a significant challenge. Improving the durability often requires additional processing steps or the incorporation of specialized additives, which can substantially increase production costs. This economic barrier makes it challenging for biodegradable plastics to compete with traditional plastics in many market segments.

Furthermore, there is a delicate balance between enhancing durability and maintaining biodegradability. Efforts to improve the longevity of bioplastics must not compromise their ability to decompose naturally at the end of their lifecycle. This balance is crucial to ensure that the environmental benefits of biodegradable plastics are not negated by attempts to enhance their durability.

The lack of standardized testing methods for bioplastic durability also poses a challenge. Different industries and applications have varying requirements for durability, and the absence of universally accepted testing protocols makes it difficult to compare and validate the performance of different bioplastic formulations across diverse use cases.

Existing GO-Bioplastic Composite Solutions

01 Chemical modification of graphene oxide

Chemical modification techniques can be applied to graphene oxide to enhance its durability. These methods involve altering the surface chemistry of graphene oxide, which can improve its stability and resistance to degradation. Various chemical treatments and functionalization processes can be used to achieve this, resulting in more durable graphene oxide materials for different applications.- Chemical modification of graphene oxide: Chemical modification techniques can be applied to graphene oxide to enhance its durability. These methods involve altering the surface chemistry of graphene oxide, which can improve its stability and resistance to degradation. Various chemical treatments and functionalization processes can be used to achieve this, resulting in more durable graphene oxide materials for different applications.

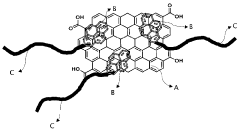

- Composite materials with graphene oxide: Incorporating graphene oxide into composite materials can significantly improve its durability. By combining graphene oxide with other materials such as polymers or metals, the resulting composites can exhibit enhanced mechanical strength, thermal stability, and resistance to environmental factors. This approach allows for the creation of more robust and long-lasting graphene oxide-based materials.

- Structural reinforcement of graphene oxide: Structural reinforcement techniques can be employed to enhance the durability of graphene oxide. These methods focus on improving the physical structure of graphene oxide, such as increasing its thickness, creating multi-layer structures, or introducing additional support materials. By strengthening the overall structure, the durability and resistance to mechanical stress can be significantly improved.

- Surface coating and encapsulation: Applying protective coatings or encapsulating graphene oxide can enhance its durability. These techniques involve creating a barrier layer around the graphene oxide, shielding it from environmental factors that could cause degradation. Various coating materials and encapsulation methods can be used to provide protection while maintaining the desirable properties of graphene oxide.

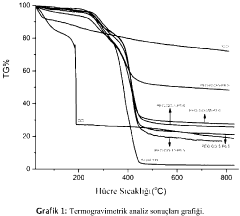

- Thermal and environmental stability enhancement: Improving the thermal and environmental stability of graphene oxide is crucial for enhancing its overall durability. This can be achieved through various methods such as heat treatment, controlled oxidation, or the introduction of stabilizing agents. These techniques aim to make graphene oxide more resistant to temperature fluctuations, humidity, and other environmental factors that could compromise its long-term performance.

02 Composite materials with graphene oxide

Incorporating graphene oxide into composite materials can significantly improve its durability. By combining graphene oxide with other materials such as polymers or metals, the resulting composites can exhibit enhanced mechanical strength, thermal stability, and resistance to environmental factors. This approach allows for the creation of more robust and long-lasting graphene oxide-based products.Expand Specific Solutions03 Structural reinforcement of graphene oxide

Structural reinforcement techniques can be employed to improve the durability of graphene oxide. These methods focus on strengthening the internal structure of graphene oxide sheets or particles, which can include processes like controlled reduction, layer stacking, or the introduction of additional support materials. Such reinforcement can lead to increased mechanical strength and resistance to degradation.Expand Specific Solutions04 Protective coatings for graphene oxide

Applying protective coatings to graphene oxide can significantly enhance its durability. These coatings can shield the graphene oxide from environmental factors such as moisture, oxidation, or chemical exposure. Various types of coatings, including polymers, ceramics, or other nanomaterials, can be used to create a barrier that prolongs the lifespan and maintains the properties of graphene oxide.Expand Specific Solutions05 Durability testing and characterization methods

Developing and implementing effective durability testing and characterization methods is crucial for assessing and improving graphene oxide durability. These techniques can include accelerated aging tests, mechanical stress evaluations, and chemical resistance assessments. By accurately measuring and analyzing the durability of graphene oxide under various conditions, researchers can identify weaknesses and develop targeted strategies for enhancement.Expand Specific Solutions

Key Players in Graphene-Enhanced Bioplastics

The research on enhancing biodegradable plastic durability using Graphene Oxide is in its early development stage, with growing market potential due to increasing environmental concerns. The global biodegradable plastics market is expanding rapidly, driven by regulatory pressures and consumer demand for sustainable materials. Technologically, the field is still evolving, with various companies and research institutions exploring different approaches. Key players like DSM IP Assets BV, Tsinghua University, and William Marsh Rice University are at the forefront of this research, leveraging their expertise in materials science and nanotechnology. Other notable contributors include Centre National de la Recherche Scientifique and Zhejiang University, indicating a global effort to advance this technology. The involvement of both academic institutions and industry leaders suggests a collaborative approach to overcoming the challenges in enhancing biodegradable plastic durability.

DSM IP Assets BV

Kingfa Sci. & Tech. Co., Ltd.

Core Innovations in GO-Bioplastic Integration

- A biodegradable graphene oxide biocomposite fibrous membrane is developed, comprising an outer layer of graphene oxide-biodegradable polymer nanofibers and an inner layer of sodium alginate/polyvinyl alcohol nanocomposite fibers, prepared through coaxial electrospinning, which enhances mechanical properties, porosity, and biocompatibility.

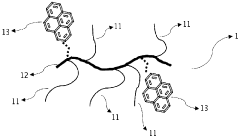

- A method involving the synthesis of a graft copolymer containing PEG and pyrene groups is used to coat graphene oxide, allowing controlled attachment and reduction, enhancing biocompatibility and solubility, and preserving electrical and thermal properties.

Environmental Impact Assessment

The integration of Graphene Oxide (GO) into biodegradable plastics to enhance their durability presents both opportunities and challenges from an environmental perspective. This assessment aims to evaluate the potential impacts of this technology on ecosystems, waste management systems, and overall environmental sustainability.

One of the primary environmental benefits of enhancing biodegradable plastic durability with GO is the potential reduction in plastic waste accumulation. By extending the useful life of biodegradable plastics, fewer products may need to be manufactured and disposed of over time, potentially decreasing the overall environmental footprint of plastic production and waste management.

However, the introduction of GO into biodegradable plastics raises concerns about the fate of these materials in natural environments. While the enhanced durability may prevent premature degradation and reduce litter, it could also prolong the presence of plastic particles in ecosystems if not properly managed at the end of their life cycle. This necessitates careful consideration of disposal methods and recycling processes to ensure that the benefits of increased durability do not compromise the ultimate biodegradability of the material.

The production of GO itself must also be scrutinized for its environmental impact. The synthesis of GO typically involves chemical processes that may generate hazardous waste or consume significant energy. As such, a comprehensive life cycle assessment is crucial to determine whether the environmental benefits of enhanced durability outweigh the potential negative impacts of GO production and incorporation into plastics.

Water systems are of particular concern when assessing the environmental impact of GO-enhanced biodegradable plastics. The potential leaching of GO nanoparticles into aquatic environments could have unforeseen consequences on marine and freshwater ecosystems. Research is needed to understand the long-term effects of GO exposure on aquatic organisms and the potential for bioaccumulation in food chains.

From an air quality perspective, the use of GO in biodegradable plastics may have mixed effects. While the extended lifespan of products could reduce the need for incineration of plastic waste, thus potentially decreasing air pollution, the production of GO and its incorporation into plastics may involve processes that emit greenhouse gases or other air pollutants. A thorough analysis of these trade-offs is essential for a complete environmental impact assessment.

Soil health is another critical factor to consider. As biodegradable plastics enhanced with GO decompose, the interaction between GO particles and soil microorganisms, plants, and other soil components must be carefully studied. The potential for GO to alter soil chemistry or impact soil biodiversity could have far-reaching consequences for agricultural systems and natural habitats.

In conclusion, while the enhancement of biodegradable plastic durability using GO shows promise for reducing plastic waste, a comprehensive environmental impact assessment is crucial. This assessment must balance the benefits of extended product life against the potential risks associated with GO production, use, and disposal. Ongoing research and monitoring will be essential to ensure that this technological advancement aligns with broader environmental sustainability goals.

Regulatory Framework for Bioplastic Materials

The regulatory framework for bioplastic materials is a complex and evolving landscape that plays a crucial role in shaping the development, production, and use of biodegradable plastics enhanced with graphene oxide. As the demand for sustainable alternatives to traditional plastics grows, governments and international organizations are establishing guidelines and standards to ensure the safety, efficacy, and environmental impact of these innovative materials.

At the forefront of bioplastic regulation is the European Union, which has implemented the European Standard EN 13432 for biodegradable and compostable packaging. This standard sets specific criteria for the biodegradability, disintegration, and eco-toxicity of bioplastic materials. The inclusion of graphene oxide in biodegradable plastics necessitates careful consideration of these existing regulations to ensure compliance and market acceptance.

In the United States, the Federal Trade Commission (FTC) has issued guidelines on environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims, which becomes particularly relevant when incorporating novel materials like graphene oxide into bioplastics.

The International Organization for Standardization (ISO) has also developed standards relevant to bioplastics, such as ISO 17088 for compostable plastics. These international standards provide a framework for testing and certifying the biodegradability and compostability of plastic materials, including those enhanced with graphene oxide.

As research on enhancing biodegradable plastic durability using graphene oxide progresses, regulatory bodies are likely to adapt their frameworks to address the unique properties and potential environmental impacts of these advanced materials. This may include the development of new testing protocols to assess the long-term durability and eventual biodegradation of graphene oxide-enhanced bioplastics.

Regulatory considerations also extend to the production and handling of graphene oxide itself. Occupational safety and health regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, may apply to the manufacturing processes involving graphene oxide. Additionally, the potential for nanoparticle release during the lifecycle of graphene oxide-enhanced bioplastics may necessitate specific regulations addressing nanomaterial safety and environmental impact.

As the field of biodegradable plastics continues to evolve, it is crucial for researchers and manufacturers to stay informed about the latest regulatory developments and actively engage with regulatory bodies to ensure that innovative solutions, such as graphene oxide-enhanced bioplastics, can be safely and effectively brought to market while meeting all necessary environmental and safety standards.