How to Optimize Optical Clarity with Graphene Oxide?

Graphene Oxide Optics Background and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of optics, offering unique properties that have captivated researchers and industry professionals alike. The journey of GO in optics began with the isolation of graphene in 2004, which led to the exploration of its oxidized form for various applications. Over the past decade, the optical properties of GO have been extensively studied, revealing its potential for enhancing light transmission, absorption, and manipulation.

The evolution of GO in optics has been marked by significant milestones, including the development of GO-based transparent conductive films, optical sensors, and photonic devices. As research progressed, scientists discovered GO's ability to modulate its optical properties through chemical reduction and functionalization, opening up new avenues for tailored optical materials.

The primary objective in optimizing optical clarity with GO is to harness its unique characteristics while overcoming inherent challenges. Researchers aim to enhance transparency across a broad spectrum of wavelengths, minimize light scattering, and improve the material's stability under various environmental conditions. Additionally, there is a focus on developing scalable production methods to ensure the consistent quality of GO for optical applications.

One of the key goals is to leverage GO's tunable optical properties to create adaptive optical systems. This includes developing GO-based materials that can dynamically adjust their refractive index, polarization, or absorption in response to external stimuli such as electric fields or light intensity. Such advancements could revolutionize fields like adaptive optics, optical computing, and advanced display technologies.

Another critical objective is to integrate GO with existing optical materials and devices seamlessly. This involves optimizing GO's compatibility with substrates like glass, polymers, and other 2D materials to create hybrid structures with enhanced optical performance. Researchers are also exploring ways to manipulate GO's surface chemistry and structure to fine-tune its interaction with light at the nanoscale.

The pursuit of optimizing optical clarity with GO extends beyond academic research into practical applications. There is a growing interest in developing GO-based optical coatings for solar cells, anti-reflective surfaces for displays, and high-performance optical filters. These applications demand not only excellent optical properties but also durability, cost-effectiveness, and ease of integration into existing manufacturing processes.

As the field progresses, the objectives continue to evolve, with increasing emphasis on sustainability and environmental compatibility. Researchers are exploring eco-friendly methods for GO production and investigating its potential in bio-optical applications, such as biosensors and biomedical imaging. The ultimate goal is to establish GO as a versatile and indispensable material in the optics industry, capable of addressing current limitations and enabling next-generation optical technologies.

Market Analysis for Graphene Oxide Optical Applications

The market for graphene oxide optical applications is experiencing significant growth, driven by the material's unique properties and its potential to revolutionize various industries. Graphene oxide, a derivative of graphene, offers exceptional optical clarity and transparency, making it highly attractive for applications in optoelectronics, photonics, and advanced display technologies.

The global market for graphene oxide in optical applications is projected to expand rapidly in the coming years. This growth is fueled by increasing demand for high-performance optical materials in sectors such as consumer electronics, automotive, aerospace, and healthcare. The market is particularly strong in regions with advanced technological infrastructure, including North America, Europe, and Asia-Pacific.

One of the key drivers of market growth is the rising adoption of graphene oxide in transparent conductive films. These films are essential components in touchscreens, smart windows, and solar cells. The superior conductivity and transparency of graphene oxide-based films offer significant advantages over traditional materials like indium tin oxide (ITO), potentially leading to more efficient and durable devices.

The display industry represents a substantial portion of the market for graphene oxide optical applications. As manufacturers seek to develop thinner, more flexible, and energy-efficient displays, graphene oxide emerges as a promising material. Its ability to enhance optical clarity while maintaining structural integrity makes it an ideal candidate for next-generation flexible OLED displays and e-paper technologies.

In the photonics sector, graphene oxide is gaining traction for its potential in developing high-performance optical modulators, photodetectors, and lasers. The material's unique optical properties enable the creation of more compact and efficient photonic devices, which are crucial for advancing optical communication systems and data centers.

The healthcare industry is another significant market for graphene oxide optical applications. The material's biocompatibility and optical properties make it suitable for biosensing and bioimaging applications. Researchers are exploring its use in developing advanced diagnostic tools and drug delivery systems, potentially revolutionizing medical imaging and targeted therapies.

Despite the promising outlook, the market faces challenges related to scalability and cost-effectiveness in production. Overcoming these hurdles is crucial for widespread adoption across industries. As research and development efforts intensify, and manufacturing processes improve, the market for graphene oxide optical applications is expected to mature, offering substantial opportunities for innovation and commercial success.

Current Challenges in Graphene Oxide Optical Clarity

Despite the remarkable properties of graphene oxide (GO) and its potential applications in various optical devices, several challenges persist in optimizing its optical clarity. One of the primary issues is the inherent opacity of GO sheets, which can significantly reduce light transmission. This opacity is largely attributed to the presence of oxygen-containing functional groups and structural defects on the GO surface, which scatter and absorb light.

Another major challenge is the difficulty in achieving uniform and controlled deposition of GO films. The tendency of GO sheets to aggregate and form inhomogeneous layers during deposition processes can lead to inconsistent optical properties across the material. This non-uniformity not only affects the overall transparency but also impacts the refractive index and other optical characteristics of the GO-based devices.

The stability of GO under various environmental conditions poses another significant hurdle. Exposure to heat, humidity, and certain chemicals can alter the structure and composition of GO, leading to changes in its optical properties over time. This instability can result in degradation of device performance and reduced longevity, limiting the practical applications of GO in optical systems.

Furthermore, the reduction process of GO, which is often employed to enhance its electrical conductivity, can adversely affect its optical clarity. While reduction improves certain properties, it can also introduce additional defects and increase light absorption, thereby compromising the transparency of the material.

The scalability of producing optically clear GO films with consistent properties remains a challenge for industrial applications. Current methods for synthesizing and processing GO often struggle to maintain uniform quality and optical characteristics when scaled up to larger production volumes.

Lastly, the integration of GO with other materials in composite structures presents its own set of challenges. Achieving optimal interfaces between GO and other components while maintaining desired optical properties requires precise control over material interactions and processing conditions. These integration issues can limit the effectiveness of GO in complex optical systems and devices.

Addressing these challenges requires interdisciplinary approaches combining materials science, nanotechnology, and optical engineering. Innovations in synthesis methods, deposition techniques, and surface functionalization strategies are crucial for overcoming the current limitations and fully realizing the potential of GO in optical applications.

Existing Graphene Oxide Optical Clarity Solutions

01 Synthesis methods for optically clear graphene oxide

Various synthesis methods have been developed to produce graphene oxide with high optical clarity. These methods focus on controlling the oxidation process, exfoliation techniques, and purification steps to minimize impurities and defects that could affect transparency. The resulting graphene oxide sheets exhibit excellent optical properties, making them suitable for applications requiring high transparency.- Synthesis methods for optically clear graphene oxide: Various synthesis methods have been developed to produce graphene oxide with high optical clarity. These methods focus on controlling the oxidation process, exfoliation techniques, and purification steps to minimize defects and impurities that could affect transparency. The resulting graphene oxide sheets exhibit excellent optical properties, making them suitable for applications requiring high transparency.

- Characterization techniques for optical clarity: Advanced characterization techniques are employed to assess the optical clarity of graphene oxide. These include spectroscopic methods, microscopy techniques, and optical measurements to evaluate transparency, light transmission, and refractive index. Such characterization helps in optimizing the production process and ensuring consistent optical quality of graphene oxide materials.

- Surface functionalization for improved optical properties: Surface functionalization of graphene oxide can enhance its optical clarity. Various chemical modifications and treatments are applied to the graphene oxide surface to reduce light scattering, improve dispersion, and increase transparency. These functionalization methods enable the tailoring of optical properties for specific applications.

- Incorporation of graphene oxide in transparent composites: Graphene oxide is incorporated into various composite materials to create optically clear structures. These composites combine the high transparency of graphene oxide with the mechanical or functional properties of the matrix material. Applications include transparent electrodes, optical coatings, and advanced display technologies.

- Reduction methods for tuning optical properties: Controlled reduction of graphene oxide allows for fine-tuning of its optical properties. Various reduction methods, including chemical, thermal, and electrochemical approaches, are used to adjust the degree of oxidation and consequently the optical clarity. This enables the production of graphene-based materials with tailored transparency for specific optical applications.

02 Characterization techniques for optical clarity

Advanced characterization techniques are employed to assess the optical clarity of graphene oxide. These include spectroscopic methods, microscopy techniques, and optical measurements to determine transparency, light transmission, and refractive index. Such characterization helps in optimizing the production process and ensuring consistent optical quality of graphene oxide materials.Expand Specific Solutions03 Surface modification for enhanced optical properties

Surface modification techniques are applied to graphene oxide to enhance its optical properties. These methods involve functionalization with various chemical groups, doping with other elements, or creating hybrid structures. Such modifications can improve transparency, reduce light scattering, and tailor the optical response of graphene oxide for specific applications.Expand Specific Solutions04 Applications utilizing graphene oxide's optical clarity

The high optical clarity of graphene oxide is exploited in various applications. These include transparent electrodes for displays and solar cells, optical coatings, sensors, and optoelectronic devices. The material's unique combination of transparency and conductivity makes it particularly valuable in fields requiring both optical and electrical performance.Expand Specific Solutions05 Scalable production of optically clear graphene oxide

Efforts are focused on developing scalable production methods for optically clear graphene oxide. These approaches aim to maintain high optical quality while increasing production volume, addressing challenges such as batch consistency, process efficiency, and cost-effectiveness. Scalable production is crucial for the widespread adoption of graphene oxide in various optical applications.Expand Specific Solutions

Key Players in Graphene Oxide Optics Industry

The optimization of optical clarity with graphene oxide is an emerging field in advanced materials science, currently in its early development stage. The market for this technology is growing, driven by applications in optoelectronics, displays, and photovoltaics. While the market size is still relatively small, it shows significant potential for expansion. The technology's maturity is progressing rapidly, with key players like Northwestern University, Zhejiang University, and Toray Industries leading research efforts. Companies such as LG Display Co., Ltd. and Lumileds Holding BV are exploring practical applications, indicating a transition from laboratory research to industrial implementation. The competitive landscape is characterized by a mix of academic institutions and industry leaders, suggesting a collaborative approach to advancing this technology.

Northwestern University

Toray Industries, Inc.

Core Innovations in Graphene Oxide Optics

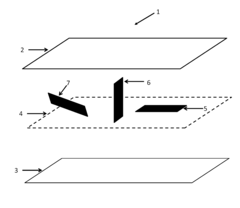

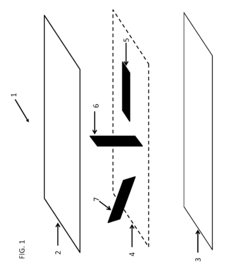

- A free-standing film composed of stacked graphene oxide nanosheets, oriented parallel and perpendicular to the surface, doped with acids or metal salts, integrated with flexible or conductive substrates, which effectively absorbs and reflects electromagnetic radiation from 1 GHz to 12 GHz, providing enhanced shielding effectiveness.

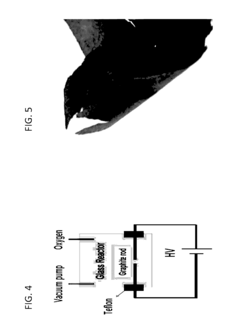

- A method involving sequential ion exchange purification using a hydrogen cation exchange resin and a hydroxide anion exchange resin, followed by salting-out washing and deep purification through electrodeionization, to effectively remove impurities and achieve high-purity graphene oxide.

Environmental Impact of Graphene Oxide Production

The production of graphene oxide, while promising for various applications including optical clarity optimization, carries significant environmental implications that warrant careful consideration. The synthesis process typically involves the oxidation of graphite using strong oxidizing agents, which can lead to the generation of hazardous waste and potentially harmful byproducts. One of the primary environmental concerns is the release of toxic chemicals, such as sulfuric acid and potassium permanganate, used in the widely adopted Hummers method.

These chemicals, if not properly managed, can contaminate water sources and soil, posing risks to ecosystems and human health. Moreover, the production process often requires high energy inputs, contributing to increased carbon emissions and exacerbating climate change concerns. The disposal of waste materials from graphene oxide production, including acidic solutions and metal contaminants, presents another environmental challenge that needs to be addressed through proper waste management protocols.

Air pollution is another potential issue associated with graphene oxide production. The fine particulate matter generated during the manufacturing process can become airborne, potentially affecting air quality in surrounding areas. This raises concerns about respiratory health for both workers and nearby communities. Additionally, the potential for nanoparticle release into the environment during production or handling of graphene oxide materials presents a relatively new and not fully understood ecological risk.

Water consumption is a significant factor in graphene oxide production, with large volumes required for synthesis and purification processes. This high water demand can strain local water resources, particularly in water-scarce regions. Furthermore, the wastewater generated often contains residual chemicals and nanomaterials, necessitating advanced treatment methods to prevent environmental contamination.

To mitigate these environmental impacts, researchers and manufacturers are exploring more sustainable production methods. Green synthesis approaches, utilizing environmentally friendly reducing agents and milder reaction conditions, are being developed to minimize the use of harsh chemicals and reduce waste generation. Recycling and recovery of reagents and solvents are also being investigated to create more closed-loop production systems, reducing overall resource consumption and waste output.

As the demand for graphene oxide in optical clarity applications grows, it becomes increasingly crucial to address these environmental concerns. Implementing life cycle assessments, developing cleaner production technologies, and establishing robust environmental management systems are essential steps towards ensuring the sustainable production of graphene oxide. Balancing the technological benefits with environmental stewardship will be key to the responsible development and application of this innovative material in optimizing optical clarity.

Scalability of Graphene Oxide Optical Technologies

The scalability of graphene oxide optical technologies is a critical factor in their widespread adoption and commercial viability. As research progresses, several key aspects have emerged that influence the potential for large-scale implementation of these technologies.

One of the primary considerations is the production capacity of high-quality graphene oxide. Current methods, such as modified Hummers' method, have been optimized for laboratory-scale synthesis. However, transitioning to industrial-scale production while maintaining consistent quality and optical properties presents significant challenges. Efforts are underway to develop continuous flow reactors and automated processes that can increase output without compromising the material's optical clarity.

The integration of graphene oxide into existing manufacturing processes for optical devices is another crucial aspect of scalability. Techniques such as spin coating, spray coating, and roll-to-roll processing have shown promise in depositing uniform layers of graphene oxide on various substrates. The challenge lies in adapting these methods to accommodate the unique properties of graphene oxide while ensuring compatibility with large-scale production equipment.

Cost-effectiveness is a major factor in the scalability of any technology. For graphene oxide optical technologies to be commercially viable, the production costs must be competitive with existing solutions. This involves optimizing raw material sourcing, reducing energy consumption during synthesis, and minimizing waste. Additionally, the development of recycling processes for graphene oxide-based devices could further improve the economic feasibility of large-scale adoption.

The stability and longevity of graphene oxide in optical applications are also critical for scalability. Research is ongoing to enhance the resistance of graphene oxide to environmental factors such as humidity, temperature fluctuations, and UV exposure. Improving the long-term performance of graphene oxide-based optical devices is essential for their integration into consumer products and industrial applications.

Standardization of graphene oxide production and characterization methods is another key factor in scaling up these technologies. Establishing industry-wide standards for optical clarity, thickness uniformity, and other relevant properties will facilitate quality control and enable more efficient collaboration between research institutions and commercial entities.

As the field advances, addressing these scalability challenges will be crucial in realizing the full potential of graphene oxide optical technologies across various industries, from telecommunications to biomedical imaging and beyond.