Graphene Oxide: Reducing Environmental Footprint in Manufacturing

Graphene Oxide Evolution

Graphene oxide has undergone a remarkable evolution since its initial discovery, marking significant milestones in the field of materials science. The journey began with the groundbreaking work on graphene by Andre Geim and Konstantin Novoselov in 2004, which laid the foundation for graphene oxide research. As scientists explored the potential of graphene, they quickly recognized the unique properties and versatility of its oxidized form.

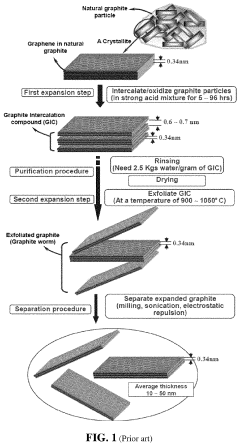

The early stages of graphene oxide evolution focused on developing efficient synthesis methods. The modified Hummers method, introduced in the late 2000s, became a pivotal technique for producing graphene oxide at scale. This breakthrough allowed researchers to explore the material's properties more extensively and opened up new avenues for applications.

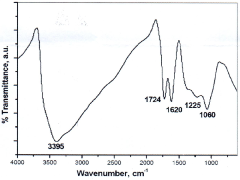

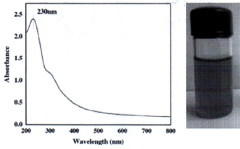

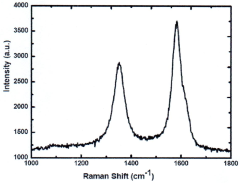

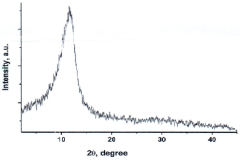

As research progressed, scientists began to uncover the complex structure and chemistry of graphene oxide. The presence of oxygen-containing functional groups on the graphene sheets was found to be crucial in determining its properties and reactivity. This understanding led to the development of various reduction techniques, enabling the fine-tuning of graphene oxide's characteristics for specific applications.

The mid-2010s saw a surge in research aimed at harnessing graphene oxide's potential in environmental applications. Its high surface area and adsorption capabilities made it an excellent candidate for water purification and contaminant removal. Concurrently, efforts to incorporate graphene oxide into composite materials gained momentum, leading to advancements in lightweight, strong, and conductive materials.

Recent years have witnessed a shift towards more sustainable and eco-friendly production methods for graphene oxide. Researchers have been exploring green synthesis techniques that reduce the use of harsh chemicals and minimize environmental impact. This aligns with the growing emphasis on reducing the environmental footprint in manufacturing processes.

The latest phase in graphene oxide evolution focuses on scalability and industrial applications. Researchers and companies are working on developing large-scale production methods that maintain product quality while reducing costs. This effort is crucial for the widespread adoption of graphene oxide in various industries, from electronics to environmental remediation.

As we look to the future, the evolution of graphene oxide continues to accelerate. Emerging trends include the development of functionalized graphene oxide for targeted applications, the exploration of its potential in energy storage and conversion, and the integration of graphene oxide into smart and responsive materials. These advancements promise to further expand the material's impact across multiple sectors, driving innovation and sustainability in manufacturing processes.

Market Demand Analysis

The market demand for graphene oxide in manufacturing processes aimed at reducing environmental footprint has been steadily growing in recent years. This surge is primarily driven by increasing environmental regulations, consumer awareness, and corporate sustainability initiatives across various industries.

In the electronics sector, graphene oxide is gaining traction as a potential replacement for traditional materials in printed circuit boards and flexible electronics. Its excellent thermal and electrical conductivity, coupled with its lightweight nature, make it an attractive option for manufacturers looking to reduce energy consumption and material waste in their production processes.

The automotive industry is another significant market for graphene oxide, particularly in the development of lightweight components and advanced batteries for electric vehicles. As automakers strive to meet stringent emissions standards and improve fuel efficiency, the demand for graphene oxide-based materials is expected to rise substantially in the coming years.

In the construction sector, graphene oxide is being explored for its potential to enhance the strength and durability of concrete while reducing the overall carbon footprint of buildings. This application aligns with the growing trend of green construction and sustainable urban development, further driving market demand.

The water treatment industry is also showing increased interest in graphene oxide-based membranes for desalination and purification processes. These advanced membranes offer improved efficiency and reduced energy consumption compared to conventional technologies, addressing the critical need for sustainable water management solutions globally.

Packaging is another area where graphene oxide is making inroads, particularly in the development of biodegradable and recyclable materials. As companies seek alternatives to traditional plastics, graphene oxide-enhanced packaging materials offer promising solutions for reducing environmental impact while maintaining product integrity.

The textile industry is exploring graphene oxide for its potential in creating smart fabrics and environmentally friendly dyeing processes. This aligns with the growing consumer demand for sustainable fashion and the industry's efforts to reduce water consumption and chemical usage in textile production.

Despite the promising market outlook, challenges remain in scaling up production and reducing the cost of graphene oxide to make it commercially viable for widespread adoption. However, ongoing research and development efforts are expected to address these hurdles, potentially leading to a significant market expansion in the near future.

As industries continue to prioritize sustainability and environmental responsibility, the demand for graphene oxide in manufacturing processes is projected to grow substantially. This trend is likely to be further accelerated by government incentives and policies promoting green technologies and circular economy principles.

Technical Challenges

The production of graphene oxide faces several significant technical challenges that hinder its widespread adoption and environmental sustainability. One of the primary issues is the scalability of production processes. Current methods, such as the modified Hummers method, are not easily scalable to industrial levels without compromising quality or increasing environmental impact. This limitation creates a bottleneck in meeting the growing demand for graphene oxide in various applications.

Another major challenge is the use of harsh chemicals in the oxidation process. Traditional methods rely on strong oxidizing agents like potassium permanganate and sulfuric acid, which pose significant environmental and safety risks. These chemicals not only contribute to a larger carbon footprint but also generate hazardous waste that requires careful handling and disposal. Developing greener alternatives that maintain the desired properties of graphene oxide while reducing environmental impact remains a significant hurdle.

The energy-intensive nature of graphene oxide production is also a concern. The process often requires high temperatures and prolonged reaction times, leading to substantial energy consumption. This not only increases production costs but also contributes to indirect environmental impacts through increased carbon emissions from energy generation. Optimizing energy efficiency in the production process is crucial for improving the overall environmental footprint.

Quality control and consistency in large-scale production present another set of challenges. Achieving uniform oxidation levels and maintaining consistent properties across batches is difficult, especially when scaling up production. This variability can affect the performance of graphene oxide in various applications, potentially limiting its usefulness in high-precision industries.

The purification and separation of graphene oxide from reaction mixtures also pose technical difficulties. Current methods often involve multiple washing steps and centrifugation, which are time-consuming and resource-intensive. Developing more efficient separation techniques that reduce water and energy consumption while maintaining product purity is essential for improving the overall sustainability of the production process.

Lastly, the reduction of graphene oxide to graphene, often necessary for many applications, presents its own set of challenges. Common reduction methods often involve the use of toxic chemicals or high-energy processes, which can negate the environmental benefits sought in the initial production. Finding eco-friendly reduction methods that are both effective and scalable remains an important area of research in the quest to make graphene oxide production more environmentally sustainable.

Current GO Production

01 Environmental impact assessment of graphene oxide production

Methods and systems for assessing the environmental impact of graphene oxide production processes. This includes analyzing the carbon footprint, energy consumption, and resource utilization associated with various synthesis methods. The assessment helps in identifying more sustainable production techniques and optimizing the overall environmental performance of graphene oxide manufacturing.- Environmental impact assessment of graphene oxide production: Methods and systems for assessing the environmental impact of graphene oxide production processes. This includes analyzing the carbon footprint, energy consumption, and resource utilization associated with various synthesis methods. The assessment helps in identifying more sustainable production techniques and optimizing the overall environmental performance of graphene oxide manufacturing.

- Eco-friendly synthesis methods for graphene oxide: Development of environmentally friendly approaches for synthesizing graphene oxide. These methods focus on reducing the use of harmful chemicals, minimizing waste generation, and improving energy efficiency. Techniques may include green reduction processes, bio-based precursors, and sustainable oxidation methods to produce graphene oxide with a lower environmental footprint.

- Life cycle analysis of graphene oxide-based products: Comprehensive life cycle assessments of products incorporating graphene oxide, from raw material extraction to end-of-life disposal. This analysis considers the environmental impacts throughout the entire product lifecycle, including production, use phase, and recycling or disposal. The goal is to identify opportunities for reducing the overall environmental footprint of graphene oxide applications.

- Recycling and waste management of graphene oxide materials: Strategies and technologies for recycling and managing waste from graphene oxide production and applications. This includes developing efficient recovery processes, exploring circular economy approaches, and finding ways to repurpose or safely dispose of graphene oxide-containing materials. The aim is to minimize environmental impact and promote sustainable resource management.

- Environmental applications of graphene oxide: Utilization of graphene oxide in environmental remediation and protection applications. This includes using graphene oxide for water purification, air filtration, and contaminant removal. While these applications aim to address environmental issues, the analysis also considers the potential environmental impacts of using graphene oxide in these contexts, ensuring a net positive environmental effect.

02 Eco-friendly synthesis methods for graphene oxide

Development of environmentally friendly approaches for synthesizing graphene oxide. These methods focus on reducing the use of harsh chemicals, minimizing waste generation, and lowering energy consumption during the production process. The aim is to create more sustainable and greener alternatives to traditional graphene oxide synthesis techniques.Expand Specific Solutions03 Recycling and waste management of graphene oxide

Strategies and technologies for recycling graphene oxide and managing associated waste products. This includes methods for recovering and reusing graphene oxide from various applications, as well as techniques for treating and disposing of waste materials generated during production and use. The goal is to minimize the environmental impact and promote circular economy principles in the graphene oxide lifecycle.Expand Specific Solutions04 Life cycle analysis of graphene oxide-based products

Comprehensive life cycle assessments of products and applications incorporating graphene oxide. These analyses consider the environmental impacts from raw material extraction, production, use phase, and end-of-life disposal. The studies help in understanding the overall environmental footprint of graphene oxide-based technologies and identifying areas for improvement in sustainability.Expand Specific Solutions05 Environmental remediation applications of graphene oxide

Exploration of graphene oxide's potential in environmental remediation and pollution control. This includes its use in water purification, air filtration, and soil decontamination. While these applications aim to address environmental issues, the analysis also considers the potential environmental impacts of using graphene oxide in these remediation processes.Expand Specific Solutions

Key Industry Players

The graphene oxide manufacturing industry is in a growth phase, with increasing market size driven by environmental concerns and technological advancements. The global market for graphene oxide is expanding rapidly, fueled by its potential to reduce environmental footprints in various applications. Technologically, the field is progressing from early-stage research to more mature industrial applications. Companies like ArcelorMittal SA and Tata Steel Ltd. are exploring graphene oxide's potential in steel manufacturing, while research institutions such as the Sichuan Institute of Graphene Industrial Technology and the Indian Institutes of Technology are advancing fundamental knowledge. Specialized firms like The Sixth Element Materials Technology Co., Ltd. and Global Graphene Group, Inc. are developing innovative production methods, indicating a competitive landscape with diverse players from both industry and academia.

ArcelorMittal SA

Tata Steel Ltd.

Eco-friendly Innovations

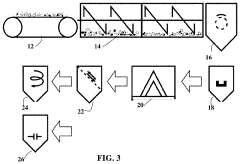

- A method involving mechanical agitation of graphitic material with a solid carrier and optional oxidizing liquid in an energy impacting device to peel off graphene layers, which are then oxidized and separated, reducing chemical usage and processing time while minimizing environmental impact.

- A method involving the conversion of sugarcane bagasse into graphene oxide through heating in a controlled atmosphere and subsequent oxidation with nitric acid, avoiding the use of flake graphite and hazardous agents, while utilizing a renewable and inexpensive carbon source.

Environmental Regulations

Environmental regulations play a crucial role in shaping the manufacturing processes and adoption of new materials like graphene oxide. As industries strive to reduce their environmental footprint, regulatory frameworks have evolved to address the potential impacts of nanomaterials on human health and the environment.

The European Union has been at the forefront of regulating nanomaterials, including graphene oxide, through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. Under REACH, manufacturers and importers are required to register nanomaterials and provide safety data when production volumes exceed one tonne per year. This has significant implications for graphene oxide production, as companies must invest in comprehensive safety assessments and risk management strategies.

In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials under the Toxic Substances Control Act (TSCA). The EPA has implemented specific reporting and recordkeeping requirements for nanoscale materials, including graphene oxide. Manufacturers must notify the EPA before producing or importing new nanoscale materials, providing detailed information on the material's characteristics, production methods, and potential environmental impacts.

China, a major player in graphene production, has also introduced regulations to manage the environmental risks associated with nanomaterials. The Ministry of Ecology and Environment has issued guidelines for the environmental management of nanomaterials, emphasizing the need for risk assessment and pollution control measures in manufacturing processes.

International organizations, such as the Organization for Economic Co-operation and Development (OECD), have developed guidelines for testing the safety of manufactured nanomaterials. These guidelines provide a standardized approach for assessing the potential environmental and health impacts of materials like graphene oxide, facilitating international cooperation and data sharing.

As the understanding of graphene oxide's environmental impacts grows, regulations are likely to become more specific and stringent. Manufacturers are increasingly required to demonstrate the sustainability of their production processes, including water usage, energy consumption, and waste management. This regulatory pressure is driving innovation in cleaner production methods for graphene oxide.

The implementation of these regulations has led to increased research and development efforts focused on green synthesis methods for graphene oxide. Companies are exploring alternatives to traditional chemical reduction processes, such as electrochemical exfoliation and microbial reduction, which have the potential to significantly reduce the environmental footprint of graphene oxide production.

Compliance with environmental regulations is becoming a key factor in the competitiveness of graphene oxide manufacturers. Those able to develop and implement environmentally friendly production processes are likely to gain a significant advantage in the market, as customers increasingly prioritize sustainability in their supply chains.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of graphene oxide manufacturing processes. This comprehensive approach examines the entire lifecycle of graphene oxide production, from raw material extraction to disposal or recycling. The assessment typically covers energy consumption, water usage, greenhouse gas emissions, and waste generation at each stage of production.

In the context of graphene oxide manufacturing, LCA reveals significant environmental challenges. The production process often involves energy-intensive steps, such as chemical oxidation and exfoliation of graphite. These processes contribute to high carbon emissions and substantial energy consumption. Additionally, the use of strong oxidizing agents and acids in the synthesis of graphene oxide raises concerns about potential environmental contamination and worker safety.

Water usage is another critical factor in the LCA of graphene oxide production. The manufacturing process requires large volumes of water for synthesis, purification, and cleaning steps. This high water demand can strain local water resources, particularly in water-scarce regions. Furthermore, the wastewater generated during production may contain toxic chemicals and nanomaterials, necessitating careful treatment and disposal to prevent environmental pollution.

The LCA also considers the sourcing of raw materials, primarily graphite. The environmental impact of graphite mining, including land use changes, biodiversity loss, and potential soil and water contamination, must be factored into the overall assessment. Transportation of raw materials and finished products contributes to the carbon footprint of graphene oxide manufacturing as well.

End-of-life considerations are equally important in the LCA. The disposal or recycling of graphene oxide and related waste products presents unique challenges due to the nanomaterial's properties. Proper handling and disposal methods must be developed to prevent potential environmental and health risks associated with the release of nanomaterials into ecosystems.

To reduce the environmental footprint of graphene oxide manufacturing, several strategies can be implemented based on LCA findings. These include optimizing production processes to improve energy efficiency, developing greener synthesis methods that use less harmful chemicals, implementing closed-loop water recycling systems, and exploring sustainable sourcing of raw materials. Additionally, research into effective recycling and safe disposal methods for graphene oxide products and waste is essential for minimizing long-term environmental impacts.

By conducting thorough Life Cycle Assessments, manufacturers can identify hotspots in the production process where environmental impacts are most significant. This information is invaluable for guiding research and development efforts towards more sustainable manufacturing practices, ultimately contributing to the reduction of the overall environmental footprint of graphene oxide production.