How to Improve Flame Retardance with Graphene Oxide?

Graphene Oxide FR Background and Objectives

Graphene oxide (GO) has emerged as a promising material in the field of flame retardancy due to its unique structure and properties. The development of flame retardant materials has been a critical area of research for decades, driven by the need to enhance safety in various industries, including construction, electronics, and transportation. GO, a two-dimensional carbon nanomaterial derived from graphite, has attracted significant attention for its potential to improve flame retardance in polymers and other materials.

The primary objective of incorporating GO into flame retardant systems is to enhance the overall fire resistance of materials while maintaining or improving their mechanical and physical properties. GO's layered structure, high surface area, and oxygen-containing functional groups contribute to its effectiveness as a flame retardant additive. These characteristics enable GO to create a protective barrier, reduce heat release, and promote char formation during combustion.

The evolution of GO as a flame retardant material can be traced back to the early 2000s when researchers began exploring the potential of graphene-based materials in various applications. As the synthesis and modification techniques for GO improved, its application in flame retardancy gained momentum. The past decade has witnessed a surge in research activities focused on understanding the mechanisms by which GO enhances flame retardance and developing novel GO-based flame retardant systems.

One of the key trends in this field is the functionalization of GO to further improve its flame retardant properties. By introducing specific functional groups or combining GO with other flame retardant additives, researchers aim to achieve synergistic effects that enhance overall performance. Another emerging trend is the development of GO-based nanocomposites, where GO is incorporated into polymer matrices to create materials with superior flame retardant properties.

The technical goals in this area include optimizing GO content in flame retardant formulations, improving the dispersion of GO in various matrices, and enhancing the interfacial interactions between GO and host materials. Researchers are also focusing on developing scalable and cost-effective methods for producing GO-based flame retardant materials to facilitate their commercial adoption.

As environmental concerns grow, there is an increasing emphasis on developing eco-friendly flame retardant solutions. GO, being a carbon-based material, offers potential advantages in this regard compared to traditional halogenated flame retardants. However, challenges remain in terms of ensuring the long-term stability and durability of GO-based flame retardant systems under various environmental conditions.

Market Analysis for Graphene Oxide FR Solutions

The market for graphene oxide-based flame retardant solutions is experiencing significant growth, driven by increasing safety regulations and the demand for high-performance materials across various industries. The global flame retardant market is projected to reach $10.2 billion by 2025, with a compound annual growth rate of 6.2%. Within this market, graphene oxide-based solutions are gaining traction due to their superior flame retardant properties and potential for eco-friendly formulations.

Key industries driving the demand for graphene oxide flame retardant solutions include construction, automotive, electronics, and textiles. The construction sector, in particular, is showing strong interest in these materials for improving the fire resistance of building materials, insulation, and coatings. The automotive industry is exploring graphene oxide-based flame retardants for use in interior components and electrical systems to enhance vehicle safety.

In the electronics sector, the miniaturization of devices and the increasing use of lithium-ion batteries have created a pressing need for effective flame retardant solutions. Graphene oxide-based materials offer promising applications in this area, potentially addressing both fire safety concerns and the demand for lightweight, high-performance components.

The textile industry is another significant market for graphene oxide flame retardants, with applications in protective clothing, upholstery, and industrial fabrics. The ability of graphene oxide to impart flame retardancy without compromising the fabric's comfort or flexibility is a key selling point in this sector.

Geographically, North America and Europe are currently the largest markets for advanced flame retardant solutions, including those based on graphene oxide. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by rapid industrialization, stringent safety regulations, and increasing awareness of fire safety in emerging economies like China and India.

Despite the promising outlook, challenges remain in the widespread adoption of graphene oxide flame retardant solutions. These include the relatively high production costs, scalability issues, and the need for further research to optimize performance across different applications. However, ongoing technological advancements and increasing investment in research and development are expected to address these challenges, potentially leading to more cost-effective and efficient graphene oxide-based flame retardant solutions in the near future.

Current Challenges in Graphene Oxide FR Technology

Despite the promising potential of graphene oxide (GO) in flame retardant applications, several significant challenges persist in its development and implementation. One of the primary obstacles is the difficulty in achieving uniform dispersion of GO within polymer matrices. The tendency of GO to agglomerate due to strong van der Waals forces between layers can lead to inconsistent flame retardant performance across the material.

Another challenge lies in maintaining the mechanical properties of the host polymer after GO incorporation. While GO can enhance flame retardancy, it may simultaneously compromise the material's strength, flexibility, or other crucial physical characteristics. Striking the right balance between flame retardance and mechanical integrity remains a complex task for researchers and engineers.

The scalability of GO production for large-scale flame retardant applications presents a significant hurdle. Current synthesis methods for high-quality GO are often limited in yield and can be costly, making it challenging to meet the demands of industrial-scale production. This economic barrier hinders the widespread adoption of GO-based flame retardant solutions in various sectors.

Furthermore, the long-term stability and durability of GO-enhanced flame retardant materials under diverse environmental conditions are not yet fully understood. Factors such as humidity, temperature fluctuations, and UV exposure may affect the performance and longevity of GO-based flame retardant systems over time.

The environmental impact and potential toxicity of GO nanoparticles also raise concerns. While GO is generally considered less harmful than many traditional flame retardants, its long-term effects on ecosystems and human health require further investigation. This uncertainty poses challenges in regulatory compliance and public acceptance of GO-based flame retardant products.

Additionally, the optimization of GO's flame retardant mechanisms in different polymer systems remains a complex task. The interactions between GO and various polymer matrices can vary significantly, necessitating tailored approaches for each material combination. This complexity makes it difficult to develop a one-size-fits-all solution for GO-based flame retardants.

Lastly, the integration of GO into existing manufacturing processes without significant modifications or investments poses a challenge for many industries. Adapting current production lines to incorporate GO-based flame retardants efficiently and cost-effectively requires innovative engineering solutions and potentially substantial capital expenditure.

Existing Graphene Oxide FR Mechanisms

01 Graphene oxide-based flame retardant composites

Graphene oxide is incorporated into various polymer matrices to create flame retardant composites. These composites exhibit improved thermal stability and reduced flammability due to the barrier effect of graphene oxide layers. The synergistic effect between graphene oxide and other flame retardant additives enhances overall fire resistance.- Graphene oxide-based flame retardant composites: Graphene oxide is incorporated into various polymer matrices to create flame retardant composites. These composites exhibit improved thermal stability and reduced flammability due to the barrier effect of graphene oxide layers. The synergistic effect between graphene oxide and other flame retardant additives enhances overall fire resistance.

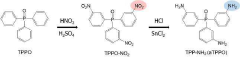

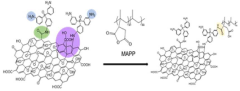

- Surface modification of graphene oxide for flame retardancy: Chemical modification of graphene oxide surfaces is employed to enhance its flame retardant properties. This includes functionalization with flame retardant groups or coupling with other fire-resistant materials. Modified graphene oxide shows improved dispersion in polymer matrices and more effective flame retardancy.

- Graphene oxide-based intumescent flame retardant systems: Graphene oxide is used in intumescent flame retardant systems, where it acts as a carbonization agent. During combustion, it forms a protective char layer that insulates the underlying material from heat and oxygen. This approach is particularly effective in enhancing the fire resistance of various polymers and coatings.

- Nanocomposites with graphene oxide for flame retardancy: Nanocomposites incorporating graphene oxide are developed for enhanced flame retardancy. The nanoscale dispersion of graphene oxide in the polymer matrix creates a tortuous path for heat and gas diffusion, effectively improving fire resistance. These nanocomposites often exhibit synergistic effects with other flame retardant additives.

- Graphene oxide-based coatings for flame retardance: Flame retardant coatings containing graphene oxide are developed for various substrates. These coatings form a protective barrier against fire, reducing heat transfer and oxygen permeation. The high aspect ratio and thermal conductivity of graphene oxide contribute to the effectiveness of these fire-resistant coatings.

02 Surface modification of graphene oxide for flame retardancy

Chemical modification of graphene oxide surfaces enhances its flame retardant properties. Techniques include functionalization with phosphorus-containing compounds, nitrogen-rich molecules, or metal oxides. These modifications improve the dispersion of graphene oxide in polymer matrices and increase its flame retardant efficiency.Expand Specific Solutions03 Graphene oxide-based intumescent flame retardant systems

Graphene oxide is used in intumescent flame retardant systems, where it acts as a carbonization agent. When exposed to heat, these systems form an expanded carbonaceous char layer that insulates the underlying material from fire. The incorporation of graphene oxide enhances char formation and improves the overall flame retardant performance.Expand Specific Solutions04 Graphene oxide flame retardant coatings and films

Graphene oxide is utilized in the development of flame retardant coatings and films for various substrates. These coatings form a protective barrier that prevents the spread of fire and reduces heat release. The high aspect ratio and thermal conductivity of graphene oxide contribute to its effectiveness in such applications.Expand Specific Solutions05 Synergistic effects of graphene oxide with other flame retardants

Graphene oxide is combined with traditional flame retardants to achieve synergistic effects. These combinations often result in improved flame retardancy at lower overall additive loadings. The synergy between graphene oxide and other flame retardants can lead to enhanced char formation, reduced heat release, and improved mechanical properties of the final material.Expand Specific Solutions

Key Players in Graphene Oxide FR Industry

The flame retardance improvement using graphene oxide is an emerging field in advanced materials, currently in its early development stage. The market for flame-retardant materials is growing, driven by stringent safety regulations across industries. While the technology shows promise, its maturity varies among key players. Companies like Dow Global Technologies LLC and LG Electronics, Inc. are at the forefront, leveraging their R&D capabilities to develop commercial applications. Academic institutions such as the University of Science & Technology of China and Sichuan University are contributing significant research. The involvement of diverse entities, from chemical companies to electronics manufacturers, indicates the technology's broad potential applications and competitive landscape.

LG Electronics, Inc.

Dow Global Technologies LLC

Innovative Graphene Oxide FR Approaches

- A polymer composite incorporating nanographene with specific organic polymers and optional metal hydrate fillers, designed to enhance flame retardancy through the formation of intumescent chars and synergistic interaction with gas and endothermic flame retardants, ensuring non-toxicity, halogen-free, and improved smoke and toxic gas liberation characteristics.

- A graphene oxide filler modified with a phosphorus-based flame retardant and a compatibilizer, such as maleic anhydride-grafted polypropylene, is used to enhance compatibility and dispersibility, allowing for improved flame retardancy and mechanical properties with reduced filler content.

Environmental Impact of Graphene Oxide FR

The environmental impact of graphene oxide (GO) as a flame retardant (FR) is a critical consideration in its application and development. GO has shown promising potential in enhancing flame retardance, but its environmental implications must be carefully evaluated.

GO's production process involves the oxidation of graphite, which can generate hazardous byproducts and consume significant energy. However, recent advancements in green synthesis methods have reduced the environmental footprint of GO production. These eco-friendly approaches utilize less toxic reagents and more sustainable processes, minimizing waste generation and energy consumption.

The release of GO into the environment during the lifecycle of flame-retardant products is a concern that requires attention. Studies have shown that GO can persist in aquatic environments and potentially impact ecosystems. Its small particle size allows for easy dispersion in water bodies, potentially affecting aquatic organisms. However, the extent of these effects is still under investigation, and more long-term studies are needed to fully understand the ecological consequences.

On the positive side, the use of GO as a flame retardant can lead to a reduction in the use of traditional halogenated flame retardants, which are known to have significant negative environmental impacts. GO-based flame retardants can potentially replace these harmful substances, contributing to a decrease in persistent organic pollutants in the environment.

The end-of-life management of GO-containing products is another crucial aspect to consider. While GO is not inherently toxic, its nano-scale dimensions pose challenges for recycling and disposal. Proper waste management protocols need to be developed to prevent the uncontrolled release of GO into the environment during product disposal or recycling processes.

Research into the biodegradability of GO is ongoing, with some studies suggesting that certain microorganisms can degrade GO under specific conditions. This potential for biodegradation could mitigate long-term environmental accumulation concerns, but more research is needed to fully understand and optimize this process.

The use of GO in flame retardants may also contribute to improved energy efficiency in buildings and vehicles by reducing the need for additional insulation materials. This indirect environmental benefit should be considered when evaluating the overall environmental impact of GO-based flame retardants.

Standardization and Testing Methods for GO FR

Standardization and testing methods play a crucial role in evaluating and ensuring the effectiveness of graphene oxide (GO) as a flame retardant (FR) additive. The development of reliable and consistent testing protocols is essential for comparing different GO-based flame retardant solutions and assessing their performance across various applications.

One of the primary standardization efforts focuses on the characterization of GO itself. This includes establishing methods to measure key properties such as oxygen content, lateral size distribution, and number of layers. These characteristics significantly influence the flame retardant properties of GO and must be accurately determined to ensure consistency in FR performance.

Thermal stability testing is a fundamental aspect of evaluating GO-based flame retardants. Thermogravimetric analysis (TGA) is widely used to assess the decomposition behavior and thermal stability of GO-FR composites. Standardized TGA protocols help in comparing the onset temperature of degradation, char yield, and overall thermal resistance of different GO-FR formulations.

Flammability tests form the core of FR performance evaluation. The limiting oxygen index (LOI) test, which measures the minimum oxygen concentration required to support combustion, is a commonly used method for assessing flame retardancy. Standardization of LOI testing for GO-FR materials ensures consistent and comparable results across different research groups and industries.

Cone calorimetry has emerged as a powerful tool for evaluating the fire behavior of GO-FR composites. This method provides valuable data on heat release rate, time to ignition, and smoke production. Efforts are underway to develop standardized cone calorimetry protocols specifically tailored for GO-based flame retardants, considering their unique properties and mechanisms of action.

The UL-94 vertical burning test is another widely recognized method for classifying the flammability of materials. Adapting and standardizing this test for GO-FR composites is crucial for their acceptance in various industries, particularly in electronics and construction materials.

Smoke density and toxicity testing are becoming increasingly important in flame retardant evaluation. Standardized methods for assessing the smoke production and potential toxic emissions from GO-FR materials during combustion are being developed to address safety concerns in real-world fire scenarios.

Durability and aging tests are essential for understanding the long-term performance of GO-FR composites. Standardized protocols for accelerated aging, weathering, and repeated flame exposure are being established to ensure the reliability and consistency of GO-FR solutions over time.

As research in GO-based flame retardants continues to advance, there is a growing need for international collaboration in developing and harmonizing testing standards. Organizations such as ISO, ASTM, and national standards bodies are working towards creating comprehensive testing frameworks that address the unique properties and applications of GO-FR materials.