Graphene Oxide: Transformative Impact on Inkjet Electronics

Graphene Oxide Evolution

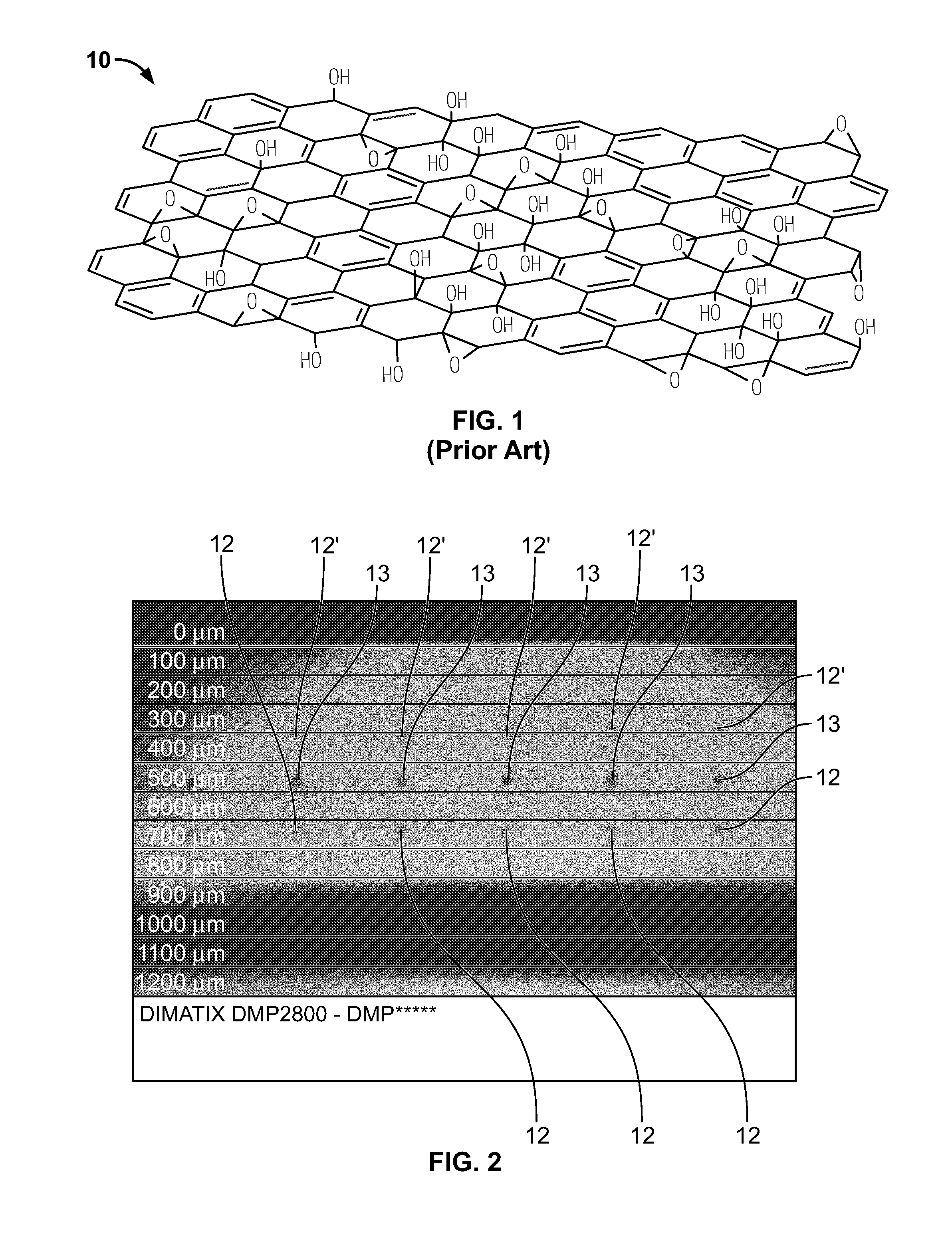

Graphene oxide has undergone a remarkable evolution since its initial discovery, transforming from a novel material to a key component in advanced electronics. The journey began with the isolation of graphene in 2004, which sparked intense research into its derivatives, including graphene oxide. Initially, graphene oxide was primarily studied for its unique structural and chemical properties, with researchers focusing on understanding its synthesis methods and characterization techniques.

As research progressed, the potential applications of graphene oxide in electronics became increasingly apparent. The material's exceptional electrical and thermal conductivity, combined with its flexibility and transparency, made it an ideal candidate for next-generation electronic devices. The evolution of graphene oxide in inkjet electronics can be traced through several key stages.

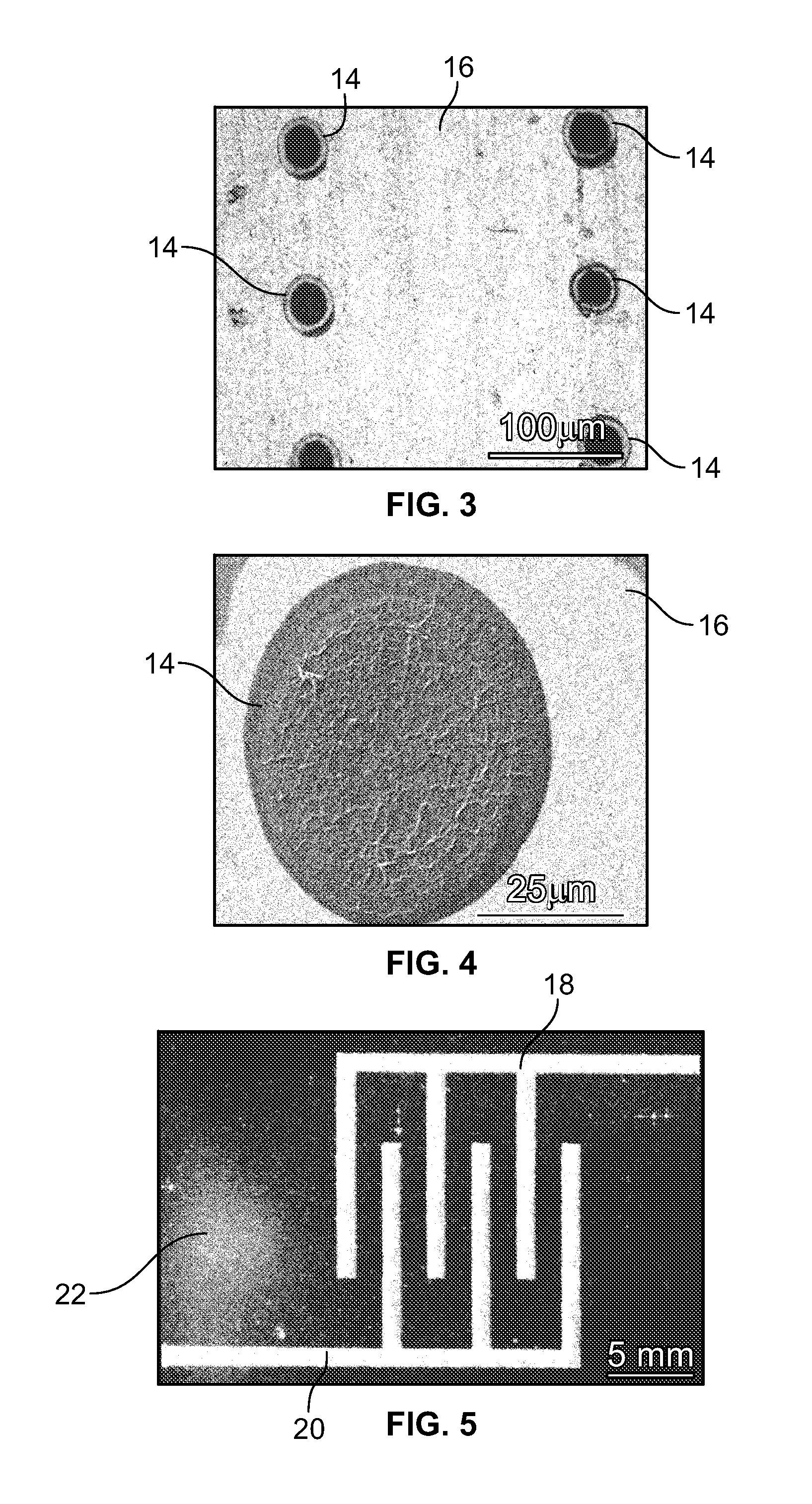

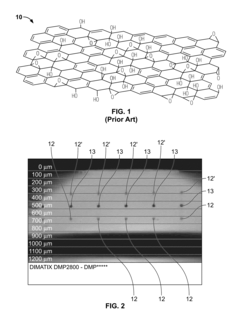

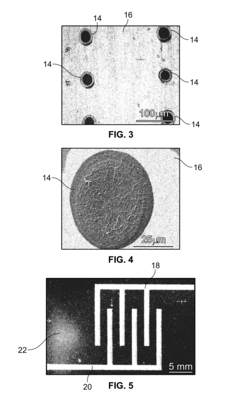

In the early stages, researchers focused on developing stable graphene oxide dispersions suitable for inkjet printing. This involved overcoming challenges related to viscosity, surface tension, and particle size distribution. As printing techniques improved, attention shifted towards optimizing the electrical properties of printed graphene oxide films. This led to the development of various reduction methods, including thermal, chemical, and photonic approaches, to convert graphene oxide into reduced graphene oxide with enhanced conductivity.

The next phase of evolution saw the integration of graphene oxide into functional electronic devices. Researchers began exploring its use in transparent conductive films, flexible electrodes, and sensors. The material's ability to form uniform, thin films through inkjet printing opened up new possibilities for large-area electronics and wearable devices.

Recent advancements have focused on enhancing the performance and stability of graphene oxide-based electronic components. This includes the development of hybrid inks combining graphene oxide with other nanomaterials, such as metal nanoparticles or carbon nanotubes, to create composite materials with tailored properties. Additionally, researchers have made significant progress in improving the environmental stability of printed graphene oxide devices, addressing issues related to humidity sensitivity and long-term performance.

The latest frontier in graphene oxide evolution for inkjet electronics involves its application in emerging fields such as flexible energy storage devices, bioelectronics, and smart packaging. Researchers are exploring ways to leverage the material's unique properties to create multifunctional devices that can sense, compute, and communicate. This ongoing evolution continues to push the boundaries of what is possible in printed electronics, promising a future where flexible, lightweight, and high-performance electronic devices become commonplace.

Market Demand Analysis

The market demand for graphene oxide in inkjet electronics has been experiencing significant growth, driven by the increasing need for flexible, lightweight, and high-performance electronic devices. As consumer electronics continue to evolve towards more portable and wearable forms, graphene oxide's unique properties make it an attractive material for inkjet-printed electronics.

The global market for printed electronics is projected to expand rapidly, with graphene oxide playing a crucial role in this growth. The automotive industry, in particular, has shown a strong interest in graphene oxide-based inkjet electronics for applications such as touch screens, sensors, and flexible displays in vehicle interiors. This sector alone is expected to contribute substantially to the market demand for graphene oxide in inkjet electronics.

In the consumer electronics sector, the demand for graphene oxide is being fueled by the development of next-generation smartphones, tablets, and wearable devices. Manufacturers are exploring the use of graphene oxide inks to create flexible, transparent, and highly conductive components, which could revolutionize the design and functionality of these devices.

The healthcare industry is another significant driver of market demand for graphene oxide in inkjet electronics. The material's potential applications in biosensors, drug delivery systems, and wearable health monitoring devices have attracted considerable attention from medical technology companies and research institutions. This sector is expected to contribute to the long-term growth of the graphene oxide market.

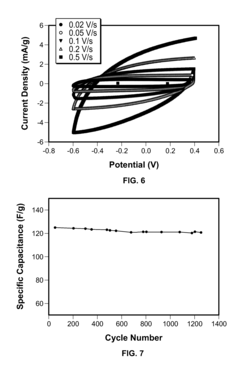

Energy storage and generation represent another promising area for graphene oxide-based inkjet electronics. The material's high conductivity and large surface area make it ideal for use in printed supercapacitors, solar cells, and batteries. As the renewable energy sector continues to expand, the demand for graphene oxide in these applications is likely to increase substantially.

The aerospace and defense industries are also showing interest in graphene oxide for inkjet-printed electronics. The material's lightweight nature and exceptional mechanical properties make it suitable for use in aircraft components, sensors, and communication systems. This sector's demand is expected to grow as more research and development efforts focus on integrating graphene oxide into advanced aerospace technologies.

Despite the promising market outlook, challenges such as high production costs and the need for standardization in quality and performance still exist. However, ongoing research and development efforts are addressing these issues, which is likely to further boost market demand as solutions are found. As manufacturing processes improve and economies of scale are achieved, the adoption of graphene oxide in inkjet electronics is expected to accelerate across various industries, driving market growth in the coming years.

Technical Challenges

Despite the promising potential of graphene oxide in inkjet electronics, several significant technical challenges persist in its widespread adoption and implementation. One of the primary obstacles is the difficulty in achieving consistent and uniform dispersion of graphene oxide in ink formulations. The tendency of graphene oxide flakes to aggregate and form clumps can lead to clogging of printer nozzles and uneven deposition, compromising the quality and performance of printed electronic components.

Another critical challenge lies in controlling the electrical properties of graphene oxide-based inks. The oxidation level of graphene oxide significantly impacts its conductivity, and achieving precise control over this parameter during ink preparation and printing processes remains a complex task. This variability in electrical properties can result in inconsistent performance of printed devices, hindering their reliability and reproducibility.

The stability of graphene oxide inks over time presents an additional hurdle. Graphene oxide suspensions may undergo sedimentation or chemical changes during storage, affecting their printability and the characteristics of the resulting printed structures. Developing formulations that maintain long-term stability without compromising performance is crucial for the commercial viability of graphene oxide-based inkjet electronics.

Furthermore, the interaction between graphene oxide inks and various substrate materials poses challenges in terms of adhesion and compatibility. Ensuring strong adhesion of printed graphene oxide layers to different substrates while maintaining the desired electrical and mechanical properties requires careful optimization of ink compositions and printing parameters.

The reduction process of graphene oxide to restore its conductive properties after printing is another area of technical complexity. Achieving efficient and uniform reduction without damaging the substrate or other components of the printed device demands precise control over reduction methods, whether thermal, chemical, or photonic.

Scalability and cost-effectiveness of graphene oxide production for large-scale inkjet printing applications remain significant challenges. Current synthesis methods may not be suitable for industrial-scale production, and the high cost of high-quality graphene oxide materials can limit their adoption in commercial electronic manufacturing processes.

Lastly, the environmental stability of printed graphene oxide structures presents ongoing challenges. Exposure to humidity, temperature fluctuations, and other environmental factors can affect the performance and longevity of graphene oxide-based electronic components. Developing effective encapsulation techniques or enhancing the inherent stability of graphene oxide materials is crucial for ensuring the reliability of printed devices in real-world applications.

Current GO Solutions

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in electronics and energy storage: Graphene oxide is utilized in electronic devices and energy storage systems due to its unique properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.

- Functionalization and modification of graphene oxide: Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its performance in various fields.

- Graphene oxide-based composites and materials: The development of composite materials incorporating graphene oxide is described. These composites combine the properties of graphene oxide with other materials to create novel structures with enhanced mechanical, thermal, or electrical properties for various applications.

- Characterization and analysis techniques for graphene oxide: Various methods and techniques for characterizing and analyzing graphene oxide are presented. These include spectroscopic, microscopic, and other analytical approaches to determine the structure, composition, and properties of graphene oxide materials.

02 Applications of graphene oxide in electronics and energy storage

Graphene oxide is utilized in electronic devices and energy storage systems due to its unique properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its performance in various fields.Expand Specific Solutions04 Graphene oxide-based composites and materials

The development of graphene oxide-based composites and materials is described, combining graphene oxide with other substances to create novel materials with enhanced properties for applications in various industries.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various methods and techniques for characterizing and analyzing graphene oxide are presented, including spectroscopic, microscopic, and other analytical approaches to determine its structure, properties, and quality.Expand Specific Solutions

Key Industry Players

The graphene oxide market for inkjet electronics is in a growth phase, with increasing research and commercial interest. The market size is expanding rapidly, driven by the material's unique properties and potential applications in flexible electronics, sensors, and energy storage devices. Technologically, graphene oxide is advancing from lab-scale to industrial production, with varying levels of maturity across applications. Companies like Global Graphene Group, Inc. and Lumileds Holding BV are at the forefront of commercialization, while academic institutions such as Northwestern University and Rice University continue to push the boundaries of research. The involvement of major players like IBM and national research institutions indicates the technology's strategic importance and potential for transformative impact in the electronics industry.

Global Graphene Group, Inc.

Hubei Highland Graphene Technology Co., Ltd.

GO Innovations Review

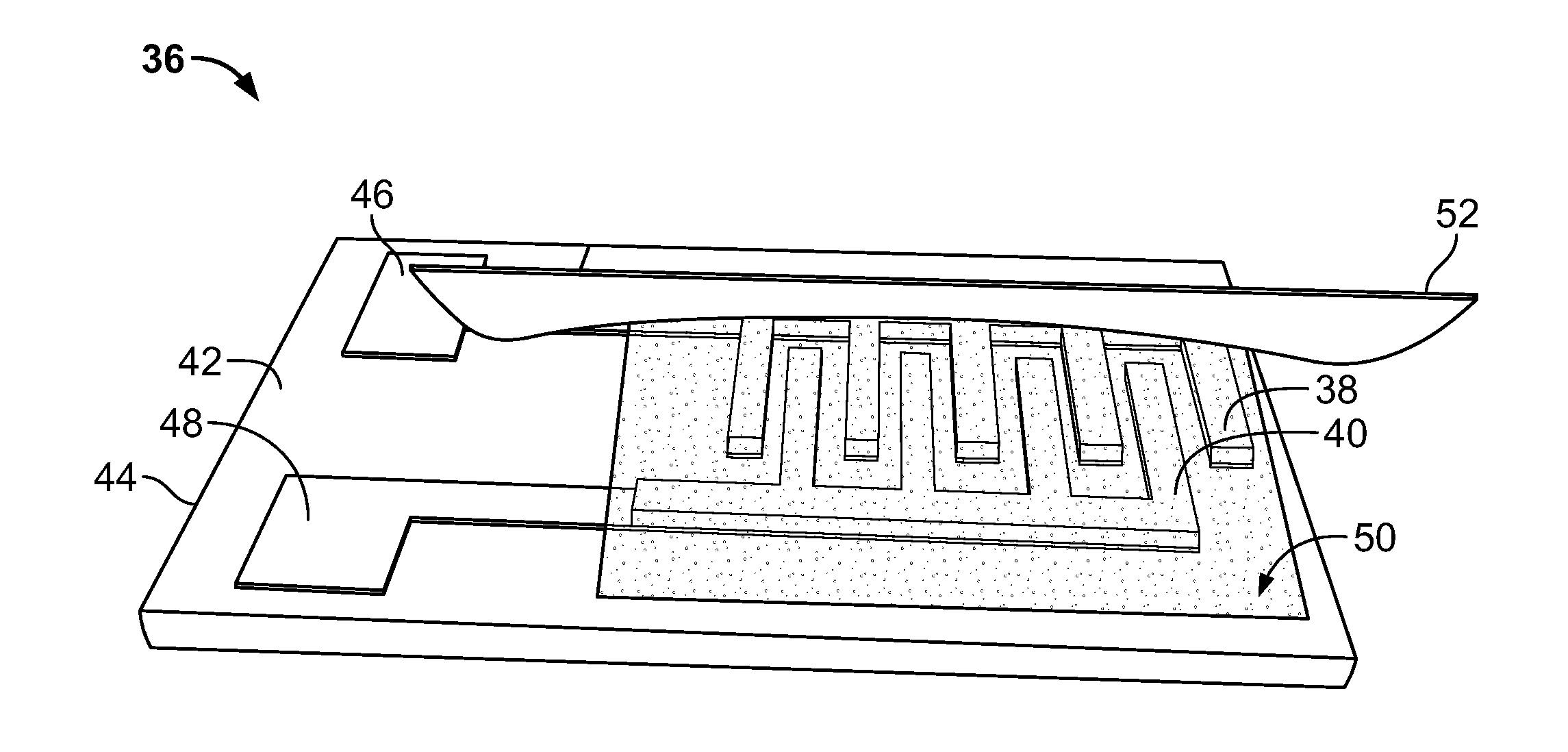

- Inkjet-printed graphene electrodes are fabricated using a water-based graphene oxide ink, which is thermally or photothermally reduced to enhance conductivity, and can be tailored with nanoparticles for improved electrical properties and porosity, enabling flexible and scalable energy storage devices.

- Inkjet-printed graphene electrodes are fabricated using stable graphene oxide inks, which are thermally or photothermally reduced to enhance conductivity, and can be tailored with nanoparticles for improved electrical properties and dispersion, allowing for flexible and high-performance energy storage devices.

Environmental Impact

The integration of graphene oxide in inkjet electronics presents both opportunities and challenges from an environmental perspective. While this innovative material offers potential benefits in terms of resource efficiency and device performance, its production and disposal raise important environmental considerations.

Graphene oxide's unique properties allow for the creation of thinner, more efficient electronic components, potentially reducing the overall material consumption in electronics manufacturing. This could lead to a decrease in electronic waste generation, as devices become more compact and durable. Additionally, the improved conductivity and thermal properties of graphene oxide-based inks may result in more energy-efficient electronic devices, contributing to reduced power consumption and associated carbon emissions during product use.

However, the production of graphene oxide involves chemical processes that may have environmental implications. The use of strong oxidizing agents and acids in its synthesis can generate hazardous waste streams if not properly managed. Ensuring proper treatment and disposal of these byproducts is crucial to mitigate potential environmental contamination. Furthermore, the long-term environmental fate and potential ecotoxicological impacts of graphene oxide nanoparticles released into the environment during production or disposal remain areas of ongoing research and concern.

The recyclability and end-of-life management of graphene oxide-containing electronics also warrant careful consideration. While the material's stability may enhance product longevity, it could pose challenges for conventional recycling processes. Developing specialized recycling techniques to recover and reuse graphene oxide from discarded electronics will be essential to minimize its environmental footprint and promote a circular economy approach in the electronics industry.

As the adoption of graphene oxide in inkjet electronics grows, it is imperative to conduct comprehensive life cycle assessments to fully understand its environmental impacts across the entire product lifecycle. This includes evaluating the material's carbon footprint, water usage, and potential for environmental persistence. Such assessments will inform the development of sustainable production methods, eco-friendly product designs, and responsible disposal strategies.

Regulatory frameworks and industry standards will play a crucial role in ensuring the environmentally responsible use of graphene oxide in electronics. Establishing guidelines for safe handling, emission controls during manufacturing, and proper disposal methods will be necessary to mitigate potential environmental risks associated with this emerging technology.

Scalability Assessment

The scalability of graphene oxide (GO) in inkjet electronics is a critical factor in determining its potential for widespread adoption and commercial viability. Current production methods for GO have shown promising results in terms of scalability, with several approaches demonstrating the ability to produce high-quality GO in large quantities.

One of the most promising methods for large-scale GO production is the modified Hummers method, which has been optimized for industrial-scale synthesis. This process has been successfully scaled up to produce GO in kilogram quantities, with consistent quality and properties. The scalability of this method is further enhanced by the availability of graphite as a raw material, which is abundant and relatively inexpensive.

In terms of inkjet printing applications, the scalability of GO-based inks has been demonstrated through the development of stable, high-concentration dispersions. These inks can be formulated to meet the specific requirements of various inkjet printing systems, allowing for seamless integration into existing manufacturing processes. The ability to produce GO inks with consistent properties and performance across large batches is crucial for industrial-scale production of printed electronics.

The scalability of GO-based inkjet electronics extends beyond material production to the printing process itself. Roll-to-roll printing techniques have been successfully employed to produce large-area GO films and patterns, demonstrating the potential for high-throughput manufacturing. This approach allows for continuous production of GO-based electronic components on flexible substrates, which is particularly advantageous for applications such as wearable electronics and flexible displays.

However, challenges remain in scaling up certain aspects of GO-based inkjet electronics. The reduction process, which is often necessary to convert GO to reduced graphene oxide (rGO) for improved conductivity, can be more difficult to scale uniformly across large areas. Researchers are actively working on developing scalable reduction methods, such as photonic annealing and chemical reduction techniques, that can be integrated into high-volume production lines.

Another consideration for scalability is the environmental impact of GO production and processing. As production scales up, it becomes increasingly important to develop sustainable and eco-friendly methods for GO synthesis and waste management. Efforts are underway to optimize production processes to minimize the use of harsh chemicals and reduce energy consumption, ensuring that the scalability of GO-based inkjet electronics aligns with environmental sustainability goals.