Graphene Oxide: Pioneering Zero-Waste Manufacturing

Graphene Oxide Background and Objectives

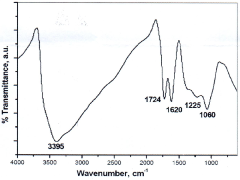

Graphene oxide, a derivative of graphene, has emerged as a revolutionary material with exceptional properties and diverse applications. Since its discovery in the early 2000s, graphene oxide has garnered significant attention in the scientific community due to its unique structure and versatile characteristics. This two-dimensional material consists of a single layer of carbon atoms arranged in a hexagonal lattice, with oxygen-containing functional groups attached to its surface.

The development of graphene oxide can be traced back to the groundbreaking work on graphene by Andre Geim and Konstantin Novoselov, who were awarded the Nobel Prize in Physics in 2010 for their pioneering research. As scientists explored the potential of graphene, they discovered that its oxidized form, graphene oxide, offered additional advantages and applications across various industries.

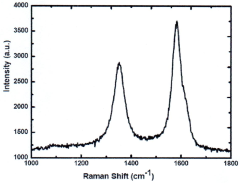

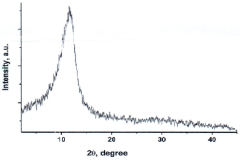

The evolution of graphene oxide technology has been marked by continuous improvements in synthesis methods, characterization techniques, and application development. Initially, the Hummers method was widely used for graphene oxide production, but researchers have since developed modified approaches to enhance yield, purity, and scalability. These advancements have paved the way for the exploration of graphene oxide in zero-waste manufacturing processes.

In the context of zero-waste manufacturing, graphene oxide presents a promising avenue for sustainable production practices. Its unique properties, such as high surface area, excellent mechanical strength, and tunable surface chemistry, make it an ideal candidate for various applications in waste reduction and resource efficiency. The primary objective of researching graphene oxide for zero-waste manufacturing is to harness its potential in developing innovative solutions that minimize environmental impact and maximize resource utilization.

Key goals of this research include exploring graphene oxide's role in enhancing material efficiency, developing recyclable and biodegradable composites, and creating advanced filtration and purification systems. Additionally, researchers aim to investigate the integration of graphene oxide in circular economy models, where waste materials can be transformed into valuable resources through innovative processes.

The pursuit of zero-waste manufacturing aligns with global sustainability initiatives and the growing demand for environmentally friendly production methods. By leveraging graphene oxide's unique properties, researchers and industry professionals seek to address critical challenges in waste management, resource conservation, and pollution reduction. This research not only aims to advance scientific understanding but also to drive practical applications that can revolutionize manufacturing processes across various sectors.

Market Demand Analysis for Zero-Waste Manufacturing

The market demand for zero-waste manufacturing technologies, particularly those involving graphene oxide, has been steadily increasing in recent years. This growth is driven by several factors, including stringent environmental regulations, consumer preferences for sustainable products, and corporate sustainability initiatives. Industries such as electronics, automotive, aerospace, and consumer goods are actively seeking innovative solutions to minimize waste and improve resource efficiency.

Graphene oxide, with its unique properties and versatility, has emerged as a promising material for zero-waste manufacturing applications. Its potential to enhance material strength, conductivity, and barrier properties while reducing overall material consumption has attracted significant attention from manufacturers and researchers alike. The global market for graphene-based products, including those utilizing graphene oxide, is projected to grow substantially in the coming years.

In the electronics industry, there is a growing demand for graphene oxide-based components that can reduce electronic waste and improve product longevity. The automotive sector is exploring graphene oxide applications in lightweight materials and energy storage systems, aligning with the industry's shift towards electric vehicles and sustainable transportation solutions. Aerospace manufacturers are investigating graphene oxide's potential to create stronger, lighter materials that can improve fuel efficiency and reduce waste in aircraft production.

The packaging industry represents another significant market for graphene oxide in zero-waste manufacturing. With increasing pressure to reduce plastic waste, companies are exploring graphene oxide-enhanced biodegradable materials that offer improved barrier properties and durability. This aligns with the growing consumer demand for environmentally friendly packaging solutions.

Water treatment and environmental remediation sectors are also showing interest in graphene oxide-based technologies for waste reduction and resource recovery. The material's ability to efficiently remove contaminants and facilitate water purification processes has the potential to revolutionize waste management practices across various industries.

Despite the promising market outlook, challenges remain in scaling up graphene oxide production and integrating it into existing manufacturing processes. The cost of production and the need for specialized equipment and expertise are current barriers to widespread adoption. However, ongoing research and development efforts are focused on addressing these challenges, with the aim of making graphene oxide-based zero-waste manufacturing solutions more accessible and economically viable.

As sustainability becomes an increasingly critical factor in consumer purchasing decisions and corporate strategies, the demand for zero-waste manufacturing technologies is expected to continue its upward trajectory. This presents significant opportunities for companies investing in graphene oxide research and development, particularly those focusing on scalable, cost-effective solutions that can be readily integrated into existing manufacturing processes.

Current State and Challenges in Graphene Oxide Production

The current state of graphene oxide production is characterized by significant advancements in synthesis methods and scalability, yet it still faces several challenges in achieving zero-waste manufacturing. Traditional production methods, such as the modified Hummers method, have been widely adopted but are associated with environmental concerns due to the use of strong oxidizing agents and the generation of toxic byproducts.

Recent developments have focused on more environmentally friendly approaches, such as electrochemical exfoliation and green reduction methods. These techniques aim to reduce the environmental impact of graphene oxide production while maintaining or improving the quality of the final product. However, the scalability of these methods remains a significant challenge, limiting their widespread industrial adoption.

One of the primary obstacles in graphene oxide production is the lack of standardization in quality control and characterization methods. This inconsistency leads to variations in product quality and hinders the development of reliable applications. Additionally, the high cost of production, particularly for high-quality graphene oxide, remains a barrier to its widespread use in various industries.

The pursuit of zero-waste manufacturing in graphene oxide production faces several technical challenges. These include the efficient recovery and recycling of reagents, the minimization of water consumption, and the reduction of energy inputs. Current research efforts are focused on developing closed-loop systems that can recycle and reuse process materials, but these solutions are still in their early stages and require further optimization.

Another significant challenge is the scalability of production processes while maintaining product quality. As production volumes increase, maintaining consistent properties and purity levels becomes increasingly difficult. This issue is particularly pronounced when attempting to scale up more environmentally friendly production methods, which often struggle to match the efficiency and output of traditional techniques.

The environmental impact of graphene oxide production remains a concern, with efforts underway to develop life cycle assessments and improve the overall sustainability of the manufacturing process. This includes addressing issues such as the disposal of waste products, the use of hazardous chemicals, and the energy intensity of production methods.

In terms of geographical distribution, graphene oxide production is concentrated in regions with strong research and industrial bases, particularly in Asia, North America, and Europe. However, there is a growing trend towards the establishment of production facilities in emerging economies, driven by lower production costs and increasing demand for advanced materials in these regions.

Existing Zero-Waste Manufacturing Solutions

01 Recycling and reuse of graphene oxide waste

Methods for recycling and reusing graphene oxide waste materials, including processes for recovering and repurposing graphene oxide from industrial byproducts or end-of-life products. These techniques aim to reduce environmental impact and improve resource efficiency in graphene-based industries.- Recycling and reuse of graphene oxide waste: Methods for recycling and reusing graphene oxide waste materials, including processes for recovering and repurposing graphene oxide from industrial byproducts or discarded products. These techniques aim to reduce environmental impact and improve resource efficiency in graphene oxide production and applications.

- Treatment and disposal of graphene oxide-containing waste: Techniques for treating and safely disposing of waste materials containing graphene oxide, including methods for neutralizing or stabilizing the material to minimize environmental risks. This may involve chemical treatments, encapsulation, or specialized disposal processes to ensure proper handling of graphene oxide waste.

- Graphene oxide waste as a resource for new materials: Innovative approaches to utilizing graphene oxide waste as a raw material for creating new products or materials. This includes processes for transforming waste into valuable resources for various applications, such as composites, coatings, or energy storage materials.

- Environmental impact assessment of graphene oxide waste: Studies and methodologies for evaluating the environmental impact of graphene oxide waste, including its potential effects on ecosystems, water sources, and human health. This research aims to inform better waste management practices and regulatory guidelines for handling graphene oxide materials.

- Graphene oxide waste reduction in manufacturing processes: Strategies and technologies for minimizing graphene oxide waste generation during production and manufacturing processes. This includes optimizing synthesis methods, improving material efficiency, and developing closed-loop systems to reduce the overall amount of waste produced in graphene oxide-related industries.

02 Treatment and disposal of graphene oxide-containing wastewater

Techniques for treating and safely disposing of wastewater containing graphene oxide particles. This includes filtration, chemical treatment, and other purification methods to remove graphene oxide from industrial effluents before release into the environment.Expand Specific Solutions03 Conversion of graphene oxide waste into useful materials

Processes for transforming graphene oxide waste into valuable materials or products. This may involve chemical modification, thermal treatment, or incorporation into composites to create new materials with enhanced properties or applications.Expand Specific Solutions04 Environmental impact assessment and mitigation of graphene oxide waste

Studies and methods for evaluating the environmental impact of graphene oxide waste and developing strategies to mitigate potential risks. This includes toxicity assessments, biodegradation studies, and the development of eco-friendly disposal methods.Expand Specific Solutions05 Recovery of graphene oxide from composite materials

Techniques for extracting and recovering graphene oxide from composite materials or products at the end of their lifecycle. This involves separation processes, chemical treatments, and purification methods to isolate graphene oxide for potential reuse or proper disposal.Expand Specific Solutions

Key Players in Graphene Oxide Research and Industry

The research on graphene oxide for zero-waste manufacturing is in its early stages, with significant potential for growth. The market size is expanding rapidly, driven by increasing demand for sustainable manufacturing processes. Technologically, it's still evolving, with varying levels of maturity among key players. Companies like China Petroleum & Chemical Corp. and Nanotek Instruments, Inc. are leading in industrial applications, while academic institutions such as Tianjin University and Beihang University are advancing fundamental research. Global Graphene Group, Inc. and The Sixth Element (Changzhou) Materials Technology Co., Ltd. are emerging as innovative players in commercialization. The competitive landscape is diverse, with collaborations between industry and academia driving progress towards scalable, zero-waste graphene oxide production methods.

Nanotek Instruments, Inc.

Global Graphene Group, Inc.

Core Innovations in Graphene Oxide Synthesis

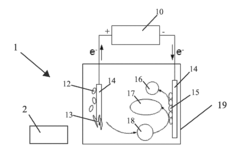

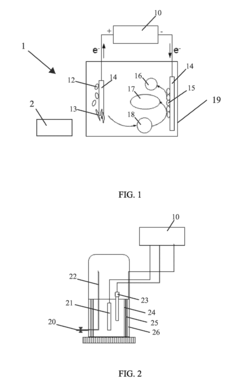

- A bioelectrochemical system using a graphite-containing anode, a conductive cathode, and a microbial population to produce graphene oxide and hydrogen gas under ambient conditions, eliminating the need for hazardous chemicals and enabling efficient production through bioelectrochemical reactions.

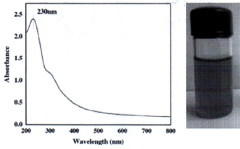

- A method involving the conversion of sugarcane bagasse into graphene oxide through heating in a controlled atmosphere and subsequent oxidation with nitric acid, avoiding the use of flake graphite and hazardous agents, while utilizing a renewable and inexpensive carbon source.

Environmental Impact Assessment

The environmental impact assessment of graphene oxide (GO) in zero-waste manufacturing is a critical aspect of its research and development. GO production and application processes have both positive and negative environmental implications that must be carefully evaluated.

On the positive side, GO's potential in zero-waste manufacturing could significantly reduce industrial waste and resource consumption. Its unique properties allow for more efficient material use, potentially decreasing the overall environmental footprint of manufacturing processes. GO-based materials can enhance product durability and recyclability, contributing to a circular economy approach.

However, the production of GO itself raises environmental concerns. The most common method, the modified Hummers' method, involves the use of strong oxidizing agents and acids, which can generate hazardous waste. The disposal or treatment of these chemical byproducts requires careful management to prevent environmental contamination.

Water usage in GO production is another significant factor. The synthesis and purification processes often require large volumes of water, which may strain local water resources. Additionally, the potential release of GO nanoparticles into aquatic environments during manufacturing or product use poses ecological risks that are not yet fully understood.

Energy consumption in GO production is also a consideration. While the energy requirements for GO synthesis are generally lower than those for pristine graphene, scaling up production for industrial use could lead to increased energy demands and associated carbon emissions.

The lifecycle assessment of GO-based products in zero-waste manufacturing is crucial. While these products may offer environmental benefits during use and end-of-life stages, the production phase's environmental impact must be carefully balanced against these advantages.

Occupational and public health impacts are also part of the environmental assessment. The potential inhalation of GO nanoparticles during manufacturing processes necessitates stringent safety measures to protect workers and prevent environmental release.

Research into more environmentally friendly GO production methods is ongoing. Green synthesis approaches using renewable resources and less harmful chemicals are being explored to mitigate the environmental impact of GO production.

In conclusion, while GO holds promise for zero-waste manufacturing, its environmental impact is complex and multifaceted. Comprehensive lifecycle assessments and continued research into sustainable production methods are essential to fully realize GO's potential in environmentally responsible manufacturing practices.

Regulatory Framework for Nanomaterials in Manufacturing

The regulatory framework for nanomaterials in manufacturing is a critical aspect of the research on graphene oxide for zero-waste manufacturing. As the use of graphene oxide and other nanomaterials in industrial processes continues to grow, governments and regulatory bodies worldwide have been developing guidelines and regulations to ensure their safe and responsible use.

In the United States, the Environmental Protection Agency (EPA) plays a key role in regulating nanomaterials under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices for new nanomaterials, including graphene oxide, and conducts risk assessments to evaluate potential environmental and health impacts. Additionally, the Occupational Safety and Health Administration (OSHA) has established guidelines for worker safety when handling nanomaterials in manufacturing settings.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to nanomaterials, including graphene oxide. Under REACH, manufacturers must register nanomaterials and provide safety data before they can be produced or imported in significant quantities. The European Chemicals Agency (ECHA) has also developed specific guidance for the safety assessment of nanomaterials.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for nanomaterials. Japan's Ministry of Economy, Trade, and Industry (METI) has implemented voluntary reporting schemes for manufacturers using nanomaterials, while South Korea has introduced mandatory registration requirements under its Act on the Registration and Evaluation of Chemicals.

International organizations, such as the Organization for Economic Co-operation and Development (OECD), have been working to harmonize regulatory approaches for nanomaterials across different countries. The OECD has developed guidelines for the testing and assessment of manufactured nanomaterials, which serve as a reference for many national regulatory frameworks.

As research on graphene oxide for zero-waste manufacturing progresses, manufacturers must navigate these regulatory landscapes to ensure compliance. This includes conducting thorough safety assessments, implementing appropriate risk management measures, and providing transparent information about the use of graphene oxide in their processes. The evolving nature of nanomaterial regulations also necessitates ongoing monitoring and adaptation to new requirements as they emerge.

Furthermore, the development of industry-specific standards and best practices for the use of graphene oxide in zero-waste manufacturing is crucial. Organizations such as the International Organization for Standardization (ISO) have been working on developing standards for the characterization and measurement of nanomaterials, which can support regulatory compliance and promote consistency in manufacturing processes.