How to Implement Graphene Oxide in Robotics for Enhanced Sensory Systems?

Graphene Oxide in Robotics: Background and Objectives

Graphene oxide, a derivative of graphene, has emerged as a revolutionary material with exceptional properties that hold immense potential for enhancing sensory systems in robotics. This two-dimensional carbon-based nanomaterial has garnered significant attention in the scientific community due to its unique combination of electrical, mechanical, and chemical characteristics.

The field of robotics has been evolving rapidly, with a growing emphasis on developing more sophisticated and responsive sensory systems. Traditional sensors often face limitations in terms of sensitivity, flexibility, and integration capabilities. The introduction of graphene oxide into robotic sensory systems aims to address these challenges and push the boundaries of what is possible in robotic perception and interaction.

The primary objective of implementing graphene oxide in robotics is to create highly sensitive, multifunctional, and adaptable sensory systems. These enhanced systems are expected to significantly improve a robot's ability to perceive and respond to its environment, leading to more intelligent and autonomous robotic applications across various industries.

One of the key goals is to leverage graphene oxide's exceptional electrical conductivity and large surface area to develop ultra-sensitive touch and pressure sensors. These sensors could enable robots to detect and respond to even the slightest changes in their surroundings, mimicking and potentially surpassing human tactile sensitivity.

Another crucial objective is to exploit graphene oxide's flexibility and strength to create stretchable and durable sensors that can be seamlessly integrated into robotic structures. This integration could lead to the development of "smart skins" for robots, allowing for more natural and intuitive interactions with their environment and human operators.

Furthermore, researchers aim to harness graphene oxide's unique chemical properties to develop advanced chemical and biological sensors for robotics. These sensors could enable robots to detect and analyze various substances in their environment, opening up new possibilities in fields such as environmental monitoring, healthcare, and security.

The implementation of graphene oxide in robotic sensory systems also seeks to address the challenge of energy efficiency. By utilizing graphene oxide's excellent electrical properties, researchers hope to develop low-power sensors that can operate for extended periods without frequent recharging, enhancing the overall autonomy and operational capabilities of robots.

As we explore the potential of graphene oxide in robotics, it is essential to consider the broader implications of this technology. The enhanced sensory capabilities could revolutionize human-robot interaction, enabling more intuitive and responsive robotic systems across various applications, from industrial automation to healthcare and beyond.

Market Analysis for Advanced Robotic Sensory Systems

The market for advanced robotic sensory systems is experiencing rapid growth, driven by increasing demand for more sophisticated and efficient robots across various industries. The integration of graphene oxide in robotic sensory systems represents a significant technological advancement, offering potential for enhanced performance and capabilities.

The global robotics market is projected to reach substantial value in the coming years, with a significant portion attributed to sensory systems. Industries such as manufacturing, healthcare, automotive, and logistics are primary drivers of this growth. The demand for robots with advanced sensory capabilities is particularly strong in applications requiring precise manipulation, environmental awareness, and adaptive behavior.

Graphene oxide-based sensors offer several advantages over traditional sensing technologies, including higher sensitivity, faster response times, and improved durability. These characteristics make them particularly attractive for robotics applications where real-time data processing and reliability are crucial. The market for graphene-based sensors is expected to grow significantly, with robotics being a key application area.

In the manufacturing sector, there is a growing need for robots with enhanced tactile sensing capabilities to perform delicate assembly tasks and quality control inspections. The healthcare industry is seeking robots with advanced sensory systems for minimally invasive surgeries and patient care. In the automotive sector, the development of autonomous vehicles is driving demand for sophisticated sensor technologies that can provide accurate environmental perception.

The adoption of graphene oxide in robotic sensory systems is still in its early stages, presenting significant market opportunities for companies that can successfully commercialize this technology. Early adopters are likely to gain a competitive advantage in their respective industries by offering robots with superior sensing capabilities.

However, challenges remain in scaling up production of graphene oxide-based sensors and integrating them into existing robotic platforms. The market is also influenced by factors such as regulatory requirements, particularly in sensitive applications like healthcare and autonomous vehicles.

As the technology matures and production costs decrease, the market for graphene oxide-enhanced robotic sensory systems is expected to expand rapidly. This growth will likely be accompanied by the emergence of new applications and use cases, further driving market demand and innovation in the field of advanced robotics.

Current Challenges in Robotic Sensory Technology

The field of robotic sensory technology is currently facing several significant challenges that hinder the development of more advanced and efficient systems. One of the primary issues is the limited sensitivity and accuracy of existing sensors, which often struggle to detect and interpret subtle environmental changes or complex stimuli. This limitation affects the overall performance and adaptability of robotic systems in various applications.

Another major challenge is the integration of multiple sensory modalities into a cohesive and efficient system. While robots can be equipped with various types of sensors, such as visual, auditory, and tactile, the seamless fusion of data from these different sources remains a complex task. This integration is crucial for creating a comprehensive and accurate representation of the robot's environment and enabling more sophisticated decision-making processes.

The power consumption and energy efficiency of sensory systems also pose significant challenges. As robots become more autonomous and are expected to operate for extended periods, the energy demands of their sensory systems can be a limiting factor. Developing low-power sensors and efficient data processing algorithms is essential for improving the overall performance and operational duration of robotic systems.

Miniaturization of sensory components is another area of concern. As robots are designed for increasingly diverse and specialized applications, there is a growing need for compact and lightweight sensory systems that do not compromise on performance. This challenge is particularly relevant in fields such as medical robotics and micro-robotics, where space constraints are critical.

Robustness and reliability of sensory systems in diverse and challenging environments remain ongoing issues. Sensors must be able to function accurately and consistently in various conditions, including extreme temperatures, high humidity, or dusty environments. Developing sensors that can withstand these conditions without compromising performance is a significant challenge for researchers and engineers.

The cost-effectiveness of advanced sensory systems is also a major consideration. While highly sophisticated sensors are available, their widespread adoption in robotics is often limited by their high costs. Striking a balance between performance and affordability is crucial for the broader implementation of advanced sensory technologies in robotics.

Lastly, the processing and interpretation of vast amounts of sensory data in real-time present significant computational challenges. As sensors become more advanced and collect increasingly detailed information, the ability to efficiently process this data and extract meaningful insights becomes more complex. This challenge requires advancements in both hardware and software solutions to enable rapid and accurate data analysis for real-time decision-making in robotic systems.

Existing Graphene Oxide Integration Methods for Robotics

01 Graphene oxide-based sensors for chemical detection

Graphene oxide is utilized in the development of highly sensitive and selective chemical sensors. These sensors can detect various substances, including gases, volatile organic compounds, and biomolecules. The unique properties of graphene oxide, such as its large surface area and excellent electrical conductivity, make it an ideal material for sensor applications.- Graphene oxide-based sensors for chemical detection: Graphene oxide is utilized in sensory systems for detecting various chemical substances. These sensors leverage the unique properties of graphene oxide, such as its large surface area and high sensitivity to environmental changes, to create highly responsive and accurate detection systems for gases, ions, and other chemical compounds.

- Graphene oxide-based biosensors: Graphene oxide is employed in the development of biosensors for detecting biological molecules and processes. These biosensors can be used for applications such as disease diagnosis, monitoring of biological processes, and detection of biomolecules. The high sensitivity and biocompatibility of graphene oxide make it an ideal material for such applications.

- Graphene oxide-based electronic and optoelectronic devices: Graphene oxide is used in the fabrication of various electronic and optoelectronic devices, including sensors. These devices exploit the unique electronic properties of graphene oxide, such as its tunable bandgap and high carrier mobility, to create highly sensitive and responsive sensory systems for applications in electronics, photonics, and energy harvesting.

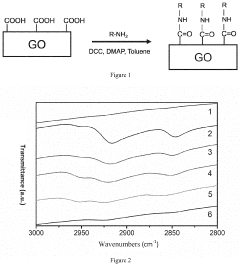

- Functionalization and modification of graphene oxide for enhanced sensing: Various methods are employed to functionalize and modify graphene oxide to enhance its sensing capabilities. These modifications can include doping, surface functionalization, and creation of composite materials. Such modifications aim to improve the selectivity, sensitivity, and stability of graphene oxide-based sensory systems for specific applications.

- Graphene oxide-based flexible and wearable sensors: Graphene oxide is utilized in the development of flexible and wearable sensory systems. These sensors leverage the mechanical flexibility and durability of graphene oxide to create devices that can be integrated into clothing, skin patches, or other wearable items for continuous monitoring of various parameters such as physiological signals, environmental conditions, or chemical exposures.

02 Graphene oxide-based biosensors

Graphene oxide is employed in the creation of biosensors for detecting biological molecules and pathogens. These biosensors offer high sensitivity and specificity for various biomarkers, proteins, and nucleic acids. The functionalization of graphene oxide with biomolecules enables the development of advanced diagnostic tools for medical and environmental applications.Expand Specific Solutions03 Graphene oxide-based environmental sensors

Graphene oxide is used in the development of sensors for environmental monitoring. These sensors can detect pollutants, heavy metals, and other contaminants in air, water, and soil. The high surface area and adsorption properties of graphene oxide make it an effective material for capturing and detecting environmental pollutants.Expand Specific Solutions04 Graphene oxide-based electronic and optoelectronic devices

Graphene oxide is utilized in the fabrication of electronic and optoelectronic devices for sensing applications. These devices include field-effect transistors, photodetectors, and electrochemical sensors. The tunable electronic properties of graphene oxide enable the development of highly sensitive and responsive sensing platforms.Expand Specific Solutions05 Graphene oxide-based wearable and flexible sensors

Graphene oxide is employed in the development of wearable and flexible sensors for various applications. These sensors can be integrated into textiles, skin patches, and other flexible substrates for monitoring physiological parameters, environmental conditions, and motion. The mechanical flexibility and electrical properties of graphene oxide make it suitable for creating conformable and stretchable sensing devices.Expand Specific Solutions

Key Players in Graphene Oxide and Robotics Industries

The implementation of graphene oxide in robotics for enhanced sensory systems is an emerging field in its early stages of development. The market size is growing but still relatively small, with significant potential for expansion as the technology matures. Currently, the technology readiness level is moderate, with ongoing research and development efforts. Leading institutions like Massachusetts Institute of Technology, The University of Manchester, and Nanjing Tech University are at the forefront of this research. Companies such as Flextrapower, Inc. and DiChuang (Suzhou) New Material Technology Co., Ltd. are also making strides in commercializing graphene oxide applications for robotics. The competitive landscape is characterized by a mix of academic institutions and innovative startups, with increasing interest from established technology firms.

Technical University of Denmark

Massachusetts Institute of Technology

Innovative Graphene Oxide Sensory Applications in Robotics

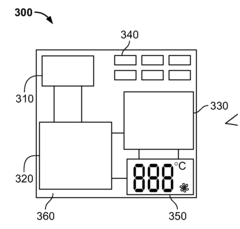

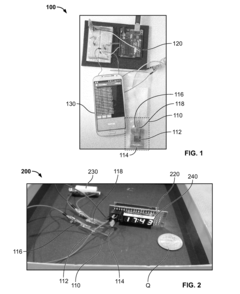

- The development of an electronic device featuring an array of chemically sensitive sensors made from functionalized graphene oxide, combined with pattern recognition algorithms like artificial neural networks and principal component analysis, which utilizes carbodiimide crosslinker chemistry for functionalization and reduction of graphene oxide to enhance sensing capabilities and reduce production costs.

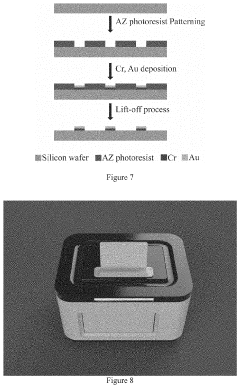

- The development of graphene oxide sensors integrated with flexible substrates, capable of measuring electrical resistance to determine conditions like temperature and pressure, utilizing negative temperature coefficient (NTC) behavior for temperature sensing and piezoresistive properties for pressure sensing, fabricated using inkjet printing and subsequent reduction techniques.

Environmental Impact of Graphene Oxide in Robotics

The implementation of graphene oxide in robotics for enhanced sensory systems raises important environmental considerations. As this innovative material becomes more prevalent in robotic applications, it is crucial to assess its potential impact on ecosystems and human health.

Graphene oxide production processes can generate hazardous waste and consume significant energy resources. The synthesis often involves strong oxidizing agents and acids, which may lead to the release of harmful chemicals if not properly managed. Furthermore, the energy-intensive nature of graphene oxide production contributes to carbon emissions, potentially offsetting some of the material's environmental benefits in robotics.

The disposal of graphene oxide-enhanced robotic systems at the end of their lifecycle presents another environmental challenge. As these robots become obsolete or damaged, proper recycling and disposal methods must be developed to prevent the release of graphene oxide nanoparticles into the environment. These nanoparticles could potentially accumulate in soil and water systems, with unknown long-term effects on flora and fauna.

However, the use of graphene oxide in robotics also offers potential environmental benefits. Enhanced sensory systems in robots could lead to more efficient and precise operations, reducing energy consumption and waste in various industries. For instance, agricultural robots with improved sensors could optimize pesticide and fertilizer use, minimizing chemical runoff into waterways.

The durability and lightweight properties of graphene oxide may extend the lifespan of robotic systems, reducing the frequency of replacements and associated electronic waste. Additionally, the material's excellent conductivity could improve energy efficiency in robotic systems, potentially lowering their overall environmental footprint during operation.

It is essential to consider the potential for graphene oxide nanoparticles to be released into the environment during the robot's operational life. Wear and tear, as well as exposure to environmental factors, could lead to the shedding of these particles. Research is needed to understand the potential bioaccumulation and toxicity of graphene oxide in various ecosystems.

As the field progresses, it is crucial to develop sustainable production methods for graphene oxide and establish comprehensive lifecycle assessments for graphene oxide-enhanced robotic systems. This approach will help mitigate potential environmental risks while maximizing the benefits of this innovative material in robotics.

Standardization and Safety Protocols for Graphene-Based Robotics

As the implementation of graphene oxide in robotics for enhanced sensory systems continues to advance, it is crucial to establish standardization and safety protocols for graphene-based robotics. These protocols are essential to ensure consistent quality, reliability, and safety across the industry.

Standardization efforts should focus on developing uniform methods for characterizing graphene oxide materials used in robotic applications. This includes establishing standard testing procedures for assessing the purity, thickness, and surface properties of graphene oxide sheets. Additionally, standardized protocols for integrating graphene oxide into various robotic components, such as sensors and actuators, should be developed to ensure reproducibility and compatibility across different systems.

Safety protocols for graphene-based robotics must address potential risks associated with the use of nanomaterials. This includes guidelines for handling and processing graphene oxide to minimize exposure risks for workers involved in manufacturing and maintenance. Proper disposal methods for graphene-containing components should also be established to prevent environmental contamination.

Electromagnetic compatibility (EMC) standards specific to graphene-based electronic components in robotics should be developed. These standards would ensure that graphene-enhanced sensors and circuits do not interfere with other electronic systems or cause unintended electromagnetic emissions.

Durability and reliability testing protocols should be established to evaluate the long-term performance of graphene-enhanced robotic systems under various environmental conditions. This includes assessing the stability of graphene oxide coatings and their resistance to degradation over time.

Biocompatibility standards are crucial for robotics applications that may involve human interaction or medical use. These standards should address potential toxicity concerns and ensure that graphene-based components do not pose health risks during normal operation or in case of system failure.

Cybersecurity protocols specific to graphene-enhanced sensory systems in robotics should be developed. As these systems may offer improved data collection and processing capabilities, it is essential to establish guidelines for securing sensitive information and preventing unauthorized access or manipulation of robotic systems.

Collaboration between industry leaders, research institutions, and regulatory bodies is necessary to develop comprehensive and widely accepted standards. This cooperation will facilitate the creation of a robust framework that supports innovation while ensuring safety and reliability in graphene-based robotics.