How to Use Graphene Oxide for Thermal Conductivity Improvement?

Graphene Oxide Thermal Conductivity Background

Graphene oxide (GO) has emerged as a revolutionary material in the field of thermal management due to its exceptional thermal conductivity properties. This two-dimensional carbon-based nanomaterial is derived from graphene, which is known for its remarkable mechanical, electrical, and thermal characteristics. The exploration of GO for thermal conductivity improvement has gained significant attention in recent years, driven by the increasing demand for efficient heat dissipation in various applications.

The thermal conductivity of GO is primarily attributed to its unique structure, consisting of a single layer of carbon atoms arranged in a hexagonal lattice with oxygen-containing functional groups. These functional groups, such as hydroxyl, epoxy, and carboxyl groups, play a crucial role in modifying the thermal properties of GO. The presence of these groups allows for better interfacial interactions with other materials, making GO an excellent candidate for enhancing thermal conductivity in composite systems.

The development of GO-based thermal management solutions has been fueled by the limitations of traditional materials in addressing the growing thermal challenges in electronics, aerospace, and energy storage applications. As electronic devices become more compact and powerful, the need for efficient heat dissipation becomes increasingly critical. GO offers a promising solution to this challenge, with its ability to conduct heat more effectively than many conventional materials.

Research in this field has focused on various aspects of GO's thermal conductivity, including the effects of oxidation level, reduction processes, and functionalization techniques. Scientists have explored different methods to optimize the thermal properties of GO, such as controlling the oxygen content, creating hybrid structures with other nanomaterials, and developing novel synthesis techniques to enhance its thermal conductivity.

The potential applications of GO in thermal management are vast and diverse. From thermal interface materials in electronic packaging to thermally conductive coatings for aerospace components, GO has demonstrated its versatility in improving heat dissipation across multiple industries. The ongoing research and development in this area aim to unlock the full potential of GO, addressing challenges such as scalability, cost-effectiveness, and long-term stability in real-world applications.

As we delve deeper into the background of GO's thermal conductivity, it becomes evident that this field is at the intersection of materials science, nanotechnology, and thermal engineering. The journey to harness the thermal properties of GO has led to significant advancements in our understanding of nanoscale heat transfer mechanisms and opened up new possibilities for innovative thermal management solutions.

Market Demand Analysis

The market demand for graphene oxide in thermal conductivity improvement applications has been steadily growing, driven by the increasing need for efficient heat management solutions across various industries. As electronic devices become more compact and powerful, the challenge of dissipating heat effectively has become paramount. This has led to a surge in demand for advanced thermal management materials, with graphene oxide emerging as a promising candidate.

In the electronics sector, the miniaturization trend has intensified the need for materials that can efficiently conduct heat away from sensitive components. Graphene oxide's exceptional thermal conductivity properties make it an attractive option for manufacturers looking to enhance the performance and longevity of their products. The automotive industry has also shown significant interest in graphene oxide-based thermal management solutions, particularly for electric vehicles where battery thermal management is crucial for optimal performance and safety.

The aerospace and defense sectors have been exploring graphene oxide's potential in developing lightweight yet thermally efficient materials for aircraft and spacecraft components. The material's ability to improve thermal conductivity without adding significant weight aligns well with the industry's ongoing efforts to reduce fuel consumption and increase payload capacity.

In the energy sector, graphene oxide has garnered attention for its potential applications in improving the efficiency of solar panels and thermoelectric devices. By enhancing heat dissipation, these materials could lead to increased energy conversion rates and overall system performance.

The construction industry has also begun to recognize the value of graphene oxide in developing thermally efficient building materials. Incorporating graphene oxide into insulation materials or structural components could lead to significant improvements in energy efficiency for both residential and commercial buildings.

Market analysts predict that the global market for graphene-based thermal management materials, including graphene oxide, is poised for substantial growth in the coming years. This growth is expected to be fueled by ongoing research and development efforts, as well as increasing adoption across multiple industries. As manufacturing processes for graphene oxide continue to improve and scale up, the material is likely to become more cost-effective, further driving market expansion.

However, challenges remain in terms of large-scale production and integration of graphene oxide into existing manufacturing processes. Overcoming these hurdles will be crucial for meeting the growing market demand and realizing the full potential of graphene oxide in thermal conductivity applications across various industries.

Current Challenges

Despite the promising potential of graphene oxide for thermal conductivity improvement, several significant challenges currently hinder its widespread application and commercialization. These challenges span across multiple domains, including material synthesis, property control, and integration into existing systems.

One of the primary obstacles is the difficulty in producing high-quality graphene oxide at scale. The synthesis process often results in inconsistent quality and properties, leading to variability in thermal conductivity performance. This lack of reproducibility poses a significant barrier to industrial adoption, as it complicates quality control and standardization efforts.

Another challenge lies in controlling the oxygen content and functional groups of graphene oxide. The presence of oxygen-containing groups, while beneficial for certain applications, can disrupt the sp2 carbon network and negatively impact thermal conductivity. Striking the right balance between oxidation levels and thermal performance remains a complex task that requires further research and optimization.

The dispersion and alignment of graphene oxide sheets within composite materials present additional hurdles. Achieving uniform dispersion and proper orientation of graphene oxide flakes is crucial for maximizing thermal conductivity enhancement. However, current methods often struggle to prevent agglomeration and ensure consistent alignment, particularly in large-scale production scenarios.

Interface thermal resistance between graphene oxide and the matrix material is another significant challenge. Poor interfacial contact can lead to phonon scattering and reduced overall thermal conductivity. Developing effective strategies to improve interfacial bonding and minimize thermal boundary resistance is essential for realizing the full potential of graphene oxide in thermal management applications.

The environmental stability and long-term performance of graphene oxide-based thermal management solutions also raise concerns. Exposure to moisture, temperature fluctuations, and mechanical stress can potentially degrade the material's properties over time. Ensuring the durability and reliability of graphene oxide-enhanced systems under various operating conditions remains a critical challenge.

Lastly, the cost-effectiveness of graphene oxide production and integration into existing thermal management solutions poses a significant barrier to widespread adoption. Current manufacturing processes are often expensive and energy-intensive, making it difficult to compete with established alternatives. Developing more economical and scalable production methods is crucial for the commercial viability of graphene oxide-based thermal conductivity improvements.

Existing GO Solutions

01 Enhancing thermal conductivity of graphene oxide

Various methods are employed to enhance the thermal conductivity of graphene oxide, including chemical reduction, functionalization, and structural modifications. These techniques aim to improve the heat transfer properties of graphene oxide for applications in thermal management and electronic devices.- Enhancing thermal conductivity of graphene oxide: Various methods are employed to enhance the thermal conductivity of graphene oxide, including chemical reduction, functionalization, and structural modifications. These techniques aim to improve the heat transfer properties of graphene oxide for applications in thermal management and energy-related fields.

- Graphene oxide composites for improved thermal conductivity: Composites incorporating graphene oxide are developed to achieve enhanced thermal conductivity. These composites often combine graphene oxide with polymers, metals, or other materials to create hybrid structures with superior heat dissipation properties for use in electronics and aerospace applications.

- Tuning graphene oxide properties for thermal applications: Researchers explore methods to tune the properties of graphene oxide, such as oxygen content, defect density, and layer thickness, to optimize its thermal conductivity. This approach allows for tailored graphene oxide materials suitable for specific thermal management requirements in various industries.

- Graphene oxide films and coatings for heat dissipation: Thin films and coatings made from graphene oxide are developed to enhance heat dissipation in electronic devices and other applications. These films can be applied to surfaces to improve thermal management and reduce hotspots in high-performance electronics.

- Measurement and characterization of graphene oxide thermal conductivity: Advanced techniques and methodologies are employed to accurately measure and characterize the thermal conductivity of graphene oxide materials. These measurements are crucial for understanding the heat transfer mechanisms and optimizing graphene oxide-based thermal management solutions.

02 Graphene oxide composites for improved thermal conductivity

Graphene oxide is incorporated into composite materials to enhance their thermal conductivity. These composites often include polymers, metals, or ceramics, and can be used in applications such as heat sinks, thermal interface materials, and aerospace components.Expand Specific Solutions03 Measurement and characterization of graphene oxide thermal conductivity

Various techniques and methods are developed to accurately measure and characterize the thermal conductivity of graphene oxide. These include laser flash analysis, thermal bridge methods, and scanning thermal microscopy, which help in understanding and optimizing the material's thermal properties.Expand Specific Solutions04 Tuning graphene oxide thermal conductivity through defect engineering

The thermal conductivity of graphene oxide can be tuned by controlling defects and oxygen-containing functional groups. This approach involves manipulating the structure and composition of graphene oxide to achieve desired thermal properties for specific applications.Expand Specific Solutions05 Applications of graphene oxide in thermal management systems

Graphene oxide's unique thermal properties are utilized in various thermal management systems. These applications include heat spreaders, thermal interface materials, and cooling solutions for electronic devices, contributing to improved energy efficiency and device performance.Expand Specific Solutions

Key Industry Players

The thermal conductivity improvement using graphene oxide is an emerging field in advanced materials science, currently in its early development stage. The market size is growing rapidly, driven by increasing demand for high-performance thermal management solutions in electronics and energy sectors. While the technology shows great promise, its maturity level varies across applications. Companies like Toray Industries, TCL China Star Optoelectronics, and Daicel Corp are leading industrial research efforts, while academic institutions such as Shanghai University and Fudan University are contributing significant fundamental research. The involvement of diverse players, from startups like Morion NanoTech to established corporations like Goodyear Tire & Rubber Co., indicates a competitive and dynamic landscape with potential for breakthrough innovations.

Morion NanoTech

Toray Industries, Inc.

Core GO Innovations

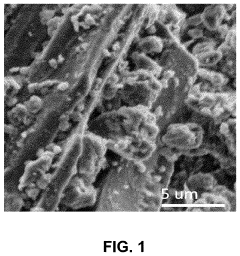

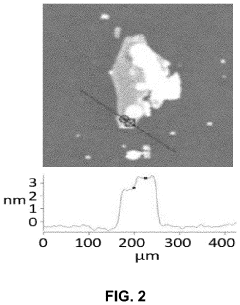

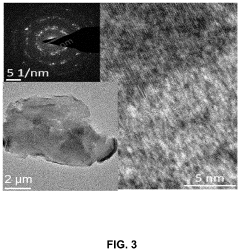

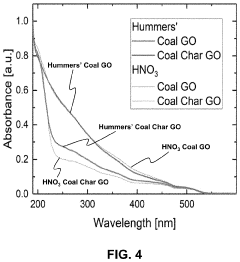

- A method involving charring and grinding of carbon-containing feedstocks, followed by treatment with a nitric acid oxidizing composition, sonicating, and annealing to produce high-quality graphene oxide with controlled particle size and enhanced electrical conductivity.

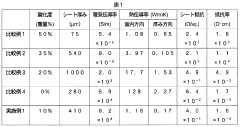

- Control thermal conductivity by partially oxidizing graphite to form graphene oxide with a specific oxygen content, followed by reduction to achieve a desired degree of oxidation, resulting in secondary graphene oxide with high electrical conductivity and low thermal conductivity.

Environmental Impact

The use of graphene oxide for thermal conductivity improvement has significant environmental implications that warrant careful consideration. While this innovative material offers promising solutions for enhancing heat transfer in various applications, its production, use, and disposal may pose potential risks to ecosystems and human health.

The manufacturing process of graphene oxide involves chemical oxidation of graphite, which can generate hazardous byproducts and consume substantial energy. This raises concerns about carbon emissions and the overall environmental footprint of large-scale production. However, ongoing research aims to develop more sustainable synthesis methods, such as electrochemical exfoliation or green reduction processes, which could mitigate these impacts.

In terms of application, graphene oxide's ability to improve thermal conductivity can lead to more energy-efficient systems, potentially reducing overall energy consumption and associated greenhouse gas emissions. This is particularly relevant in electronics cooling, heat exchangers, and thermal management systems, where enhanced heat dissipation can result in lower power requirements and extended device lifespans.

The nanoscale nature of graphene oxide particles raises questions about their potential release into the environment during product use or disposal. Studies have shown that these nanoparticles can interact with living organisms and ecosystems in complex ways. While some research suggests potential toxicity to aquatic life and soil microorganisms, the long-term ecological effects remain uncertain and require further investigation.

End-of-life considerations for graphene oxide-enhanced products present both challenges and opportunities. The material's durability may extend product lifespans, reducing waste generation. However, the difficulty in separating graphene oxide from composite materials could complicate recycling processes. Developing effective recycling and disposal methods for graphene oxide-containing products is crucial to minimize environmental contamination and resource depletion.

Regulatory frameworks and safety guidelines for handling and disposing of graphene oxide are still evolving. As the material gains wider adoption, it is essential to establish comprehensive environmental impact assessments and life cycle analyses to guide responsible development and use. This includes evaluating potential bioaccumulation, persistence in the environment, and strategies for mitigating any adverse effects.

In conclusion, while graphene oxide offers significant potential for improving thermal conductivity and energy efficiency, its environmental impact must be carefully managed. Balancing the benefits of enhanced thermal performance with responsible production, use, and disposal practices is crucial for ensuring the sustainable development of this promising material.

Scalability and Cost

The scalability and cost considerations of using graphene oxide for thermal conductivity improvement are crucial factors in determining its widespread adoption and commercial viability. While graphene oxide exhibits exceptional thermal properties, scaling up its production and application presents significant challenges.

Current manufacturing processes for graphene oxide are primarily laboratory-scale, limiting its availability for large-scale industrial applications. The most common method, the modified Hummers' method, involves the oxidation of graphite using strong oxidizing agents. This process, while effective, is not easily scalable due to safety concerns and the need for precise control over reaction conditions. Efforts to develop more scalable production methods, such as electrochemical exfoliation and plasma-assisted techniques, are ongoing but have not yet reached industrial-scale implementation.

The cost of producing high-quality graphene oxide remains a major hurdle for its widespread use in thermal management applications. The raw materials, particularly high-purity graphite, contribute significantly to the overall cost. Additionally, the multi-step production process, involving oxidation, exfoliation, and purification, adds to the expense. As of now, the price of graphene oxide is prohibitively high for many potential applications, especially when compared to traditional thermal management materials like copper or aluminum.

Incorporating graphene oxide into existing materials or products for thermal conductivity improvement also presents scalability challenges. The uniform dispersion of graphene oxide in polymer matrices or other host materials is critical for achieving optimal thermal performance. However, achieving this uniformity at large scales is technically challenging and often requires specialized equipment and processes, further adding to the cost.

Environmental and safety considerations also impact the scalability and cost of graphene oxide production. The use of strong acids and oxidizing agents in the production process necessitates stringent safety measures and waste management protocols. Developing more environmentally friendly and safer production methods is an active area of research but may initially increase production costs.

Despite these challenges, ongoing research and development efforts are focused on improving the scalability and reducing the cost of graphene oxide production. Advances in continuous flow reactors, automated exfoliation processes, and more efficient purification techniques show promise for increasing production volumes while potentially reducing costs. Additionally, the development of graphene oxide composites and hybrid materials may offer a more cost-effective approach to leveraging its thermal properties in practical applications.

As the technology matures and production scales up, economies of scale are expected to gradually reduce the cost of graphene oxide. However, significant improvements in manufacturing efficiency and yield are still needed to make graphene oxide economically viable for widespread use in thermal management applications. The future adoption of graphene oxide in thermal conductivity improvement will largely depend on overcoming these scalability and cost challenges.