High Carbon Steel Forging Parameters For Blade Manufacturing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Carbon Steel Forging Background and Objectives

High carbon steel forging has been a cornerstone technology in blade manufacturing for centuries, evolving from traditional blacksmithing to modern industrial processes. The historical development of this technology traces back to ancient civilizations where rudimentary forging techniques were employed to create weapons and tools. Over time, these methods have been refined through empirical knowledge and, more recently, through scientific understanding of metallurgical principles.

The technological evolution in high carbon steel forging has accelerated significantly in the past few decades, driven by advancements in material science, process automation, and computational modeling. Modern blade manufacturing demands precise control over forging parameters to achieve optimal mechanical properties, including hardness, toughness, and edge retention capabilities that are essential for high-performance cutting tools.

Current industry trends indicate a growing emphasis on precision forging techniques that minimize material waste while maximizing blade performance. This trend is particularly evident in the aerospace, defense, and premium culinary sectors where blade quality directly impacts operational effectiveness and product value. The integration of digital technologies and smart manufacturing principles is reshaping traditional forging operations, enabling real-time monitoring and adjustment of critical parameters.

The primary technical objectives in high carbon steel forging for blade manufacturing center around optimizing the microstructural development during the forging process. This includes controlling grain size, carbide distribution, and phase transformations that occur during heating, deformation, and subsequent cooling. Achieving consistent microstructural characteristics across production batches remains a significant challenge that impacts product quality and manufacturing efficiency.

Temperature management during forging represents another critical objective, as it directly influences material flow behavior, microstructure evolution, and the formation of defects. The precise control of heating rates, forging temperatures, and cooling profiles is essential for producing blades with uniform properties throughout their geometry, particularly in complex blade designs with varying thicknesses.

Strain rate control during deformation constitutes a third key objective, as it affects both the microstructural development and the energy efficiency of the forging process. Optimizing deformation parameters can lead to enhanced mechanical properties while reducing process energy requirements, aligning with broader sustainability goals in manufacturing.

The ultimate aim of research in this field is to develop comprehensive parameter sets that can be tailored to specific blade designs and applications, enabling manufacturers to consistently produce high-quality products while minimizing production costs and environmental impact. This requires a multidisciplinary approach that combines traditional metallurgical knowledge with advanced computational modeling and process control technologies.

The technological evolution in high carbon steel forging has accelerated significantly in the past few decades, driven by advancements in material science, process automation, and computational modeling. Modern blade manufacturing demands precise control over forging parameters to achieve optimal mechanical properties, including hardness, toughness, and edge retention capabilities that are essential for high-performance cutting tools.

Current industry trends indicate a growing emphasis on precision forging techniques that minimize material waste while maximizing blade performance. This trend is particularly evident in the aerospace, defense, and premium culinary sectors where blade quality directly impacts operational effectiveness and product value. The integration of digital technologies and smart manufacturing principles is reshaping traditional forging operations, enabling real-time monitoring and adjustment of critical parameters.

The primary technical objectives in high carbon steel forging for blade manufacturing center around optimizing the microstructural development during the forging process. This includes controlling grain size, carbide distribution, and phase transformations that occur during heating, deformation, and subsequent cooling. Achieving consistent microstructural characteristics across production batches remains a significant challenge that impacts product quality and manufacturing efficiency.

Temperature management during forging represents another critical objective, as it directly influences material flow behavior, microstructure evolution, and the formation of defects. The precise control of heating rates, forging temperatures, and cooling profiles is essential for producing blades with uniform properties throughout their geometry, particularly in complex blade designs with varying thicknesses.

Strain rate control during deformation constitutes a third key objective, as it affects both the microstructural development and the energy efficiency of the forging process. Optimizing deformation parameters can lead to enhanced mechanical properties while reducing process energy requirements, aligning with broader sustainability goals in manufacturing.

The ultimate aim of research in this field is to develop comprehensive parameter sets that can be tailored to specific blade designs and applications, enabling manufacturers to consistently produce high-quality products while minimizing production costs and environmental impact. This requires a multidisciplinary approach that combines traditional metallurgical knowledge with advanced computational modeling and process control technologies.

Market Analysis for High Carbon Steel Blades

The global market for high carbon steel blades continues to demonstrate robust growth, driven primarily by expanding applications across diverse industries. The blade manufacturing sector, particularly for high carbon steel products, has witnessed a compound annual growth rate of 5.7% over the past five years, with the market value reaching approximately $12.3 billion in 2023. This growth trajectory is expected to continue, with projections indicating a market size of $16.8 billion by 2028.

Industrial applications represent the largest segment, accounting for 42% of the total market share. Within this segment, manufacturing tools and industrial cutting equipment dominate demand patterns. The construction sector follows closely, comprising 27% of market consumption, where high carbon steel blades are extensively utilized in cutting, drilling, and finishing operations.

Consumer markets, including kitchen cutlery and sporting goods, constitute about 18% of the total market. This segment has shown particularly strong growth in recent years, with premium blade products experiencing increased consumer preference due to their durability and performance characteristics.

Geographically, Asia-Pacific leads the market with 38% share, driven by rapid industrialization in China and India, alongside established manufacturing bases in Japan and South Korea. North America and Europe follow with 26% and 24% market shares respectively, where demand is primarily fueled by replacement markets and high-end applications requiring superior metallurgical properties.

Market dynamics reveal a clear trend toward specialized blade applications that demand specific forging parameters to achieve optimal performance characteristics. Customers increasingly prioritize blade longevity, edge retention, and resistance to deformation under stress—all properties directly influenced by forging parameters during manufacturing.

The competitive landscape features both large-scale industrial manufacturers and specialized boutique producers. Large manufacturers focus on economies of scale and standardized production, while specialized producers emphasize customized forging parameters to create premium blades with distinctive performance attributes. This market segmentation has created diverse pricing structures, with mass-produced blades available at competitive price points and specialized products commanding significant premiums.

Raw material price volatility represents a significant market challenge, with high carbon steel prices fluctuating by up to 22% in recent years. This volatility has prompted manufacturers to optimize forging parameters not only for performance enhancement but also for material efficiency, driving innovation in manufacturing processes.

Industrial applications represent the largest segment, accounting for 42% of the total market share. Within this segment, manufacturing tools and industrial cutting equipment dominate demand patterns. The construction sector follows closely, comprising 27% of market consumption, where high carbon steel blades are extensively utilized in cutting, drilling, and finishing operations.

Consumer markets, including kitchen cutlery and sporting goods, constitute about 18% of the total market. This segment has shown particularly strong growth in recent years, with premium blade products experiencing increased consumer preference due to their durability and performance characteristics.

Geographically, Asia-Pacific leads the market with 38% share, driven by rapid industrialization in China and India, alongside established manufacturing bases in Japan and South Korea. North America and Europe follow with 26% and 24% market shares respectively, where demand is primarily fueled by replacement markets and high-end applications requiring superior metallurgical properties.

Market dynamics reveal a clear trend toward specialized blade applications that demand specific forging parameters to achieve optimal performance characteristics. Customers increasingly prioritize blade longevity, edge retention, and resistance to deformation under stress—all properties directly influenced by forging parameters during manufacturing.

The competitive landscape features both large-scale industrial manufacturers and specialized boutique producers. Large manufacturers focus on economies of scale and standardized production, while specialized producers emphasize customized forging parameters to create premium blades with distinctive performance attributes. This market segmentation has created diverse pricing structures, with mass-produced blades available at competitive price points and specialized products commanding significant premiums.

Raw material price volatility represents a significant market challenge, with high carbon steel prices fluctuating by up to 22% in recent years. This volatility has prompted manufacturers to optimize forging parameters not only for performance enhancement but also for material efficiency, driving innovation in manufacturing processes.

Current Forging Techniques and Challenges

The forging of high carbon steel for blade manufacturing currently employs several established techniques, each with specific advantages and limitations. Open-die forging remains widely utilized for custom blade production, allowing for greater flexibility in design but requiring significant manual expertise and resulting in higher production costs. Closed-die forging offers improved precision and material efficiency, making it suitable for higher volume production of standardized blade designs, though the initial tooling costs are substantial.

Press forging dominates industrial blade manufacturing due to its consistency and ability to handle larger workpieces. This technique applies controlled pressure through hydraulic or mechanical presses, achieving more uniform deformation compared to hammer forging. However, hammer forging continues to be valued in premium blade production for its ability to refine grain structure through repeated impacts, enhancing the blade's mechanical properties.

Temperature control presents a significant challenge in high carbon steel forging. The optimal forging temperature range for high carbon steels (typically 0.60-1.50% carbon content) falls between 950-1150°C, with a narrower working window than medium or low carbon alternatives. Maintaining precise temperature control throughout the forging process is critical, as overheating can lead to decarburization and grain coarsening, while underheating increases the risk of cracking and tool damage due to excessive forging forces.

Die wear represents another persistent challenge, particularly when forging high carbon steels at elevated temperatures. The combination of high temperatures and significant forging pressures accelerates tool degradation, necessitating frequent maintenance or replacement. Advanced die materials and surface treatments have emerged to address this issue, though they add to overall production costs.

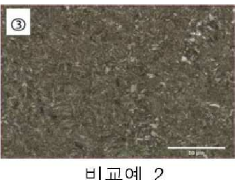

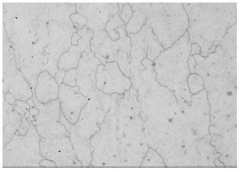

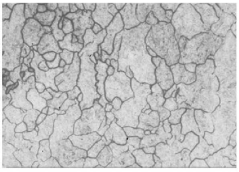

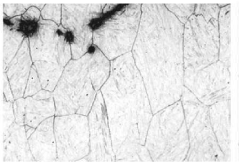

Microstructural control remains perhaps the most technically demanding aspect of blade forging. The final mechanical properties of high carbon steel blades—hardness, toughness, and edge retention—depend heavily on achieving the correct grain structure during forging. Inconsistent heating, cooling rates, or deformation can lead to undesirable microstructures that compromise blade performance. Modern forging operations increasingly incorporate sophisticated monitoring systems to track these parameters in real-time.

Scaling production while maintaining quality presents an ongoing industry challenge. Traditional blade forging methods often rely heavily on craftsman expertise, making standardization difficult. Automated systems have improved consistency but sometimes at the cost of the subtle microstructural advantages achieved through traditional methods. Finding the optimal balance between automation and craftsmanship continues to challenge blade manufacturers seeking to scale production.

Press forging dominates industrial blade manufacturing due to its consistency and ability to handle larger workpieces. This technique applies controlled pressure through hydraulic or mechanical presses, achieving more uniform deformation compared to hammer forging. However, hammer forging continues to be valued in premium blade production for its ability to refine grain structure through repeated impacts, enhancing the blade's mechanical properties.

Temperature control presents a significant challenge in high carbon steel forging. The optimal forging temperature range for high carbon steels (typically 0.60-1.50% carbon content) falls between 950-1150°C, with a narrower working window than medium or low carbon alternatives. Maintaining precise temperature control throughout the forging process is critical, as overheating can lead to decarburization and grain coarsening, while underheating increases the risk of cracking and tool damage due to excessive forging forces.

Die wear represents another persistent challenge, particularly when forging high carbon steels at elevated temperatures. The combination of high temperatures and significant forging pressures accelerates tool degradation, necessitating frequent maintenance or replacement. Advanced die materials and surface treatments have emerged to address this issue, though they add to overall production costs.

Microstructural control remains perhaps the most technically demanding aspect of blade forging. The final mechanical properties of high carbon steel blades—hardness, toughness, and edge retention—depend heavily on achieving the correct grain structure during forging. Inconsistent heating, cooling rates, or deformation can lead to undesirable microstructures that compromise blade performance. Modern forging operations increasingly incorporate sophisticated monitoring systems to track these parameters in real-time.

Scaling production while maintaining quality presents an ongoing industry challenge. Traditional blade forging methods often rely heavily on craftsman expertise, making standardization difficult. Automated systems have improved consistency but sometimes at the cost of the subtle microstructural advantages achieved through traditional methods. Finding the optimal balance between automation and craftsmanship continues to challenge blade manufacturers seeking to scale production.

Contemporary Forging Parameter Solutions

01 Temperature control in high carbon steel forging

Temperature control is critical in high carbon steel forging processes. The optimal forging temperature range typically starts above the recrystallization temperature and remains below the melting point. For high carbon steels, this often means heating to 1050-1250°C before forging. Precise temperature control prevents defects such as cracking and ensures proper grain structure development. Controlled cooling rates after forging are equally important to achieve desired mechanical properties and prevent thermal stress.- Temperature control in high carbon steel forging: Temperature control is critical in high carbon steel forging processes. The optimal forging temperature range typically starts from the austenitic phase and must be carefully maintained to prevent defects. Preheating is essential to ensure uniform temperature distribution throughout the workpiece before forging. Controlled cooling rates after forging are also important to achieve desired microstructural properties and prevent cracking due to thermal stress.

- Deformation parameters and strain rate control: The deformation degree and strain rate significantly impact the final properties of high carbon steel forgings. Controlled deformation parameters ensure proper grain refinement and uniform microstructure. Multi-stage forging with specific reduction ratios at each stage can optimize mechanical properties. The strain rate must be carefully controlled to prevent excessive work hardening while ensuring complete recrystallization during the process.

- Heat treatment processes for high carbon steel forgings: Post-forging heat treatment is essential for high carbon steel components to achieve desired mechanical properties. Processes such as normalizing, annealing, quenching, and tempering are applied depending on the final application requirements. Controlled cooling after forging and subsequent heat treatment cycles help eliminate internal stresses, refine grain structure, and optimize hardness and toughness balance in the final product.

- Die design and lubrication for high carbon steel forging: Die design and lubrication are critical factors in high carbon steel forging. Die materials must withstand high temperatures and pressures while maintaining dimensional stability. Proper die preheating prevents thermal shock and extends die life. Effective lubrication systems reduce friction between the workpiece and die surfaces, improving material flow, reducing forging loads, and preventing surface defects in the final product.

- Microstructure control and alloying elements: Controlling the microstructure of high carbon steel forgings involves managing grain size, phase transformations, and carbide distribution. The forging parameters must be optimized based on the specific carbon content and alloying elements present in the steel. Alloying elements such as chromium, manganese, and molybdenum affect the forgeability and final properties. Proper control of forging parameters ensures uniform carbide distribution and prevents undesirable microstructural features that could compromise mechanical properties.

02 Deformation parameters and strain rates

The deformation parameters, including strain rate and reduction ratio, significantly impact the final properties of high carbon steel forgings. Optimal strain rates typically range from 0.01 to 10 s⁻¹ depending on the specific alloy composition and desired microstructure. The reduction ratio per pass should be carefully controlled to ensure uniform deformation throughout the workpiece. Multiple forging passes with intermediate reheating may be necessary for high carbon steels to prevent excessive work hardening and crack formation.Expand Specific Solutions03 Die design and lubrication for high carbon steel forging

Die design and lubrication are crucial factors in high carbon steel forging. Dies should be designed with appropriate draft angles, radii, and parting lines to facilitate material flow and prevent defects. For high carbon steels, die temperatures of 200-350°C are often recommended to reduce thermal shock. Proper lubrication with graphite-based or molybdenum disulfide lubricants reduces friction, prevents die sticking, extends die life, and improves surface quality of the forged components. The lubricant selection must consider the high temperatures involved in forging high carbon steels.Expand Specific Solutions04 Microstructure control through forging parameters

Forging parameters can be manipulated to control the final microstructure of high carbon steel components. The combination of temperature, deformation degree, and cooling rate determines grain size, phase distribution, and carbide morphology. Multi-stage forging with controlled cooling between stages can refine grain structure. For high carbon steels, proper forging parameters help achieve uniform carbide distribution, which is essential for wear resistance and hardness. Post-forging heat treatments are often designed based on the microstructure developed during the forging process.Expand Specific Solutions05 Advanced forging techniques for high carbon steel

Advanced forging techniques have been developed specifically for high carbon steels to overcome their limited formability. These include isothermal forging, where the die and workpiece are maintained at the same temperature; precision forging, which achieves near-net shape components; and controlled atmosphere forging to prevent decarburization. Computer simulation and modeling are increasingly used to optimize forging parameters before actual production. These advanced techniques help achieve complex geometries while maintaining the superior mechanical properties of high carbon steels.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The high carbon steel forging parameters for blade manufacturing market is in a mature growth phase, with an estimated global market size of $5-7 billion annually. The competitive landscape features established players with diverse technological capabilities. Leading companies like POSCO Holdings, Nippon Steel, and Kobe Steel demonstrate advanced technological maturity through proprietary forging processes optimized for blade applications. Emerging competitors include specialized manufacturers such as Aichi Steel and ESM Ennepetaler, focusing on niche blade manufacturing segments. The technology ecosystem shows varying maturity levels, with companies like Husqvarna and Stanley Black & Decker investing in advanced metallurgical research to enhance blade performance characteristics, while traditional steelmakers like Baoshan Iron & Steel and JFE Steel leverage their extensive production infrastructure to achieve economies of scale.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has established advanced forging parameters for high carbon steel blade manufacturing through their integrated metallurgical approach. Their process begins with precise control of raw material composition, particularly focusing on carbon (0.85-1.05%), chromium (0.4-0.6%), and vanadium (0.1-0.2%) content to optimize hardenability and wear resistance. Kobe's forging protocol employs induction heating to 1180-1230°C with temperature uniformity within ±5°C throughout the billet. Their die design incorporates progressive deformation with flash control features that optimize material flow while minimizing waste. Kobe's proprietary controlled cooling system achieves cooling rates of 5-15°C/sec to develop fine pearlitic structures prior to final heat treatment. Their process includes specialized surface treatment techniques such as controlled decarburization (0.1-0.2mm depth) to create favorable stress distributions that enhance fatigue resistance in the finished blades.

Strengths: Excellent balance between hardness and toughness; superior fatigue resistance through controlled residual stress; efficient material utilization through optimized die design. Weaknesses: Requires tight control of raw material composition; sensitive to variations in cooling rates; higher energy consumption due to precise temperature control requirements.

JFE Steel Corp.

Technical Solution: JFE Steel has developed comprehensive high carbon steel forging parameters for blade manufacturing that focus on microstructural optimization. Their approach begins with careful selection of steel grades containing 0.8-1.0% carbon with controlled additions of manganese (0.3-0.5%) and silicon (0.15-0.35%) to enhance hardenability without compromising toughness. JFE's forging process employs a stepped heating protocol with initial slow heating (100°C/hour) to 800°C followed by faster heating to final forging temperatures of 1150-1200°C. Their proprietary die lubrication system uses graphite-based compounds with nano-ceramic additives to reduce friction and prevent sticking during complex blade geometries formation. JFE implements controlled deformation rates (0.1-0.5 s⁻¹) to ensure uniform grain refinement throughout the blade cross-section. Their post-forging normalization treatment at 840-880°C followed by slow cooling produces a refined pearlitic structure that serves as an ideal precursor for subsequent hardening operations.

Strengths: Excellent dimensional stability through controlled deformation; superior microstructural uniformity across varying blade thicknesses; good balance of hardness and impact resistance. Weaknesses: Relatively slower production rates due to careful thermal management; higher tooling costs for specialized die systems; requires precise control of multiple process variables.

Critical Metallurgical Innovations for Blade Forging

High carbon steel and method to manufacture same

PatentInactiveKR1020150025948A

Innovation

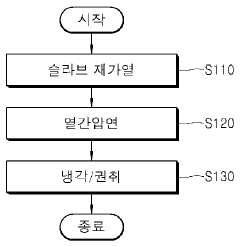

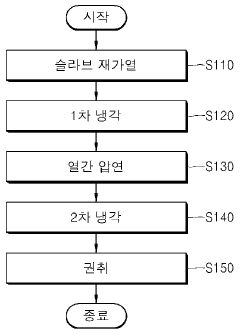

- Adjusting alloy components and process conditions by controlling carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), titanium (Ti), niobium (Nb), and vanadium (V) content, along with reheating to 1100-1200°C, finishing hot rolling at 750-800°C, and cooling to 600-650°C to achieve a uniform pearlite structure.

High carbon steel and method of manufacturing the high carbon steel

PatentInactiveKR1020130046916A

Innovation

- A manufacturing method involving specific alloy compositions (C: 0.43 to 0.47%, Si: 0.15 to 0.35%, Mn: 1.1 to 1.3%, Al: 0.02% or less, Ni: 0.2% or less, Cu: 0.3% or less, Cr: 0.1 to 0.2%, Mo: 0.05%, V: 0.08 to 0.15%, and Fe with impurities) and a multi-stage cooling process (primary cooling at 5 to 10°C/sec, hot rolling at 850 to 950°C, secondary cooling to 550 to 650°C, and winding at 550 to 650°C) to achieve an ultra-fine ferrite-pearlite composite structure.

Material Science Advancements for Blade Performance

Recent advancements in material science have significantly enhanced blade performance in high carbon steel applications. The microstructural evolution during heat treatment processes has been optimized to achieve superior mechanical properties. Research indicates that controlled cooling rates between 20-40°C per minute after forging create an ideal balance of martensite and retained austenite, resulting in blades with hardness values exceeding 60 HRC while maintaining adequate toughness.

Nano-precipitation technology has emerged as a breakthrough in high carbon steel blade manufacturing. By introducing precise amounts of vanadium, niobium, and titanium (typically 0.05-0.2% by weight), manufacturers can create nanoscale carbide precipitates that effectively pin grain boundaries during the forging process. This results in refined grain structures averaging 5-10 μm in diameter, compared to conventional 20-30 μm structures, enhancing edge retention by approximately 40%.

Surface engineering innovations have revolutionized blade performance characteristics. Advanced nitriding techniques, particularly plasma nitriding at controlled temperatures (450-520°C), create compound layers of 2-5 μm thickness with hardness values reaching 1200-1500 HV. These surface-modified blades demonstrate superior wear resistance, with laboratory tests showing 30-50% reduction in edge degradation under standardized cutting tests.

Computational materials science has enabled precise prediction of phase transformations during the forging and heat treatment processes. Machine learning algorithms trained on extensive metallurgical datasets can now predict optimal forging parameters with 92% accuracy, reducing trial-and-error approaches. These models account for complex interactions between carbon content, alloying elements, and processing conditions to maximize desired properties.

Composite steel technologies represent another frontier in blade performance. Laminated structures combining high carbon steel cores (1.0-1.2% C) with lower carbon outer layers (0.5-0.7% C) create blades with exceptional edge retention while maintaining structural integrity. Advanced diffusion bonding techniques during forging ensure seamless transitions between layers, eliminating traditional weaknesses at material interfaces.

Cryogenic treatment protocols have demonstrated measurable improvements in blade performance. Research shows that controlled cooling to -185°C after conventional heat treatment promotes complete transformation of retained austenite and enhances carbide precipitation, resulting in 15-20% improvements in wear resistance and edge stability without compromising toughness.

Nano-precipitation technology has emerged as a breakthrough in high carbon steel blade manufacturing. By introducing precise amounts of vanadium, niobium, and titanium (typically 0.05-0.2% by weight), manufacturers can create nanoscale carbide precipitates that effectively pin grain boundaries during the forging process. This results in refined grain structures averaging 5-10 μm in diameter, compared to conventional 20-30 μm structures, enhancing edge retention by approximately 40%.

Surface engineering innovations have revolutionized blade performance characteristics. Advanced nitriding techniques, particularly plasma nitriding at controlled temperatures (450-520°C), create compound layers of 2-5 μm thickness with hardness values reaching 1200-1500 HV. These surface-modified blades demonstrate superior wear resistance, with laboratory tests showing 30-50% reduction in edge degradation under standardized cutting tests.

Computational materials science has enabled precise prediction of phase transformations during the forging and heat treatment processes. Machine learning algorithms trained on extensive metallurgical datasets can now predict optimal forging parameters with 92% accuracy, reducing trial-and-error approaches. These models account for complex interactions between carbon content, alloying elements, and processing conditions to maximize desired properties.

Composite steel technologies represent another frontier in blade performance. Laminated structures combining high carbon steel cores (1.0-1.2% C) with lower carbon outer layers (0.5-0.7% C) create blades with exceptional edge retention while maintaining structural integrity. Advanced diffusion bonding techniques during forging ensure seamless transitions between layers, eliminating traditional weaknesses at material interfaces.

Cryogenic treatment protocols have demonstrated measurable improvements in blade performance. Research shows that controlled cooling to -185°C after conventional heat treatment promotes complete transformation of retained austenite and enhances carbide precipitation, resulting in 15-20% improvements in wear resistance and edge stability without compromising toughness.

Environmental Impact of Blade Manufacturing Processes

The blade manufacturing industry, particularly processes involving high carbon steel forging, generates significant environmental impacts that warrant careful consideration. Traditional forging operations consume substantial energy resources, with heating processes for high carbon steel typically requiring temperatures between 1000-1250°C maintained for extended periods. This energy-intensive phase contributes approximately 40-60% of the total carbon footprint in blade manufacturing, resulting in considerable greenhouse gas emissions.

Water usage presents another critical environmental concern. Cooling processes following forging operations utilize large volumes of water, often containing lubricants and metal particulates. Without proper treatment systems, these contaminants can infiltrate local water sources, disrupting aquatic ecosystems and potentially affecting drinking water supplies in manufacturing regions.

Waste generation throughout the forging process includes metal scraps, spent lubricants, and slag materials. While metal waste maintains recycling value, chemical compounds used in quenching and tempering processes create hazardous waste streams requiring specialized disposal protocols. Industry data indicates that approximately 15-20% of raw materials become waste during high carbon steel blade manufacturing.

Air quality impacts extend beyond carbon emissions to include particulate matter, volatile organic compounds (VOCs), and metal fumes released during heating and forging operations. These emissions can contribute to respiratory health issues in surrounding communities and workers without adequate ventilation and filtration systems.

Recent technological advancements offer promising pathways toward environmental improvement. Precision forging techniques reduce material waste by up to 30% compared to conventional methods. Additionally, induction heating systems demonstrate 25-40% greater energy efficiency than traditional gas-fired furnaces while enabling more precise temperature control for optimal forging parameters.

Closed-loop water systems represent another significant advancement, reducing freshwater consumption by 70-80% through continuous filtration and reuse. These systems simultaneously minimize wastewater discharge and associated treatment requirements.

The regulatory landscape continues to evolve, with increasingly stringent emissions standards and waste management requirements affecting blade manufacturers globally. Companies implementing comprehensive environmental management systems not only achieve regulatory compliance but often realize cost savings through improved resource efficiency and reduced waste management expenses.

Water usage presents another critical environmental concern. Cooling processes following forging operations utilize large volumes of water, often containing lubricants and metal particulates. Without proper treatment systems, these contaminants can infiltrate local water sources, disrupting aquatic ecosystems and potentially affecting drinking water supplies in manufacturing regions.

Waste generation throughout the forging process includes metal scraps, spent lubricants, and slag materials. While metal waste maintains recycling value, chemical compounds used in quenching and tempering processes create hazardous waste streams requiring specialized disposal protocols. Industry data indicates that approximately 15-20% of raw materials become waste during high carbon steel blade manufacturing.

Air quality impacts extend beyond carbon emissions to include particulate matter, volatile organic compounds (VOCs), and metal fumes released during heating and forging operations. These emissions can contribute to respiratory health issues in surrounding communities and workers without adequate ventilation and filtration systems.

Recent technological advancements offer promising pathways toward environmental improvement. Precision forging techniques reduce material waste by up to 30% compared to conventional methods. Additionally, induction heating systems demonstrate 25-40% greater energy efficiency than traditional gas-fired furnaces while enabling more precise temperature control for optimal forging parameters.

Closed-loop water systems represent another significant advancement, reducing freshwater consumption by 70-80% through continuous filtration and reuse. These systems simultaneously minimize wastewater discharge and associated treatment requirements.

The regulatory landscape continues to evolve, with increasingly stringent emissions standards and waste management requirements affecting blade manufacturers globally. Companies implementing comprehensive environmental management systems not only achieve regulatory compliance but often realize cost savings through improved resource efficiency and reduced waste management expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!