How To Standardize Hardness Testing For High Carbon Steel Batches

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Carbon Steel Hardness Testing Background and Objectives

Hardness testing for high carbon steel has evolved significantly since the early 20th century when the first standardized methods were introduced. Initially, simple indentation tests provided basic comparative measurements, but as manufacturing precision requirements increased, more sophisticated testing methodologies emerged. Today, hardness testing represents a critical quality control parameter in industries ranging from automotive and aerospace to tooling and infrastructure, where high carbon steel components must meet precise performance specifications.

The evolution of hardness testing technologies has followed industrial demands for greater accuracy, repeatability, and efficiency. From manual Rockwell testers to automated microhardness systems, the technological progression has enabled manufacturers to achieve increasingly stringent quality standards. However, this evolution has also created challenges in standardization across different production facilities, testing equipment manufacturers, and global supply chains.

Current hardness testing practices for high carbon steel batches often suffer from inconsistencies due to variations in testing procedures, equipment calibration methods, environmental conditions, and operator techniques. These inconsistencies can lead to significant quality control issues, including rejected batches, customer complaints, warranty claims, and production delays. The financial impact of these inconsistencies is estimated to cost the global steel industry billions annually in waste, rework, and lost productivity.

The primary objective of standardizing hardness testing for high carbon steel batches is to establish universally accepted protocols that ensure consistent, reliable, and comparable results across different testing environments. This standardization aims to minimize measurement uncertainties and provide a common language for hardness specifications between suppliers and customers throughout the global supply chain.

Secondary objectives include reducing testing time and costs, improving production efficiency, enhancing product quality consistency, and facilitating more accurate material property predictions based on hardness correlations. Additionally, standardization seeks to address emerging challenges related to new high carbon steel formulations with complex microstructures that may respond differently to traditional testing methods.

The scope of standardization must encompass sample preparation techniques, testing equipment specifications, calibration procedures, measurement methodologies, data analysis approaches, and reporting formats. It must also consider the unique characteristics of high carbon steels, including their sensitivity to microstructural variations, heat treatment effects, and surface conditions that can significantly influence hardness readings.

Achieving these objectives requires collaboration among steel producers, end-users, equipment manufacturers, standards organizations, and research institutions to develop comprehensive guidelines that balance technical rigor with practical implementation considerations across diverse manufacturing environments.

The evolution of hardness testing technologies has followed industrial demands for greater accuracy, repeatability, and efficiency. From manual Rockwell testers to automated microhardness systems, the technological progression has enabled manufacturers to achieve increasingly stringent quality standards. However, this evolution has also created challenges in standardization across different production facilities, testing equipment manufacturers, and global supply chains.

Current hardness testing practices for high carbon steel batches often suffer from inconsistencies due to variations in testing procedures, equipment calibration methods, environmental conditions, and operator techniques. These inconsistencies can lead to significant quality control issues, including rejected batches, customer complaints, warranty claims, and production delays. The financial impact of these inconsistencies is estimated to cost the global steel industry billions annually in waste, rework, and lost productivity.

The primary objective of standardizing hardness testing for high carbon steel batches is to establish universally accepted protocols that ensure consistent, reliable, and comparable results across different testing environments. This standardization aims to minimize measurement uncertainties and provide a common language for hardness specifications between suppliers and customers throughout the global supply chain.

Secondary objectives include reducing testing time and costs, improving production efficiency, enhancing product quality consistency, and facilitating more accurate material property predictions based on hardness correlations. Additionally, standardization seeks to address emerging challenges related to new high carbon steel formulations with complex microstructures that may respond differently to traditional testing methods.

The scope of standardization must encompass sample preparation techniques, testing equipment specifications, calibration procedures, measurement methodologies, data analysis approaches, and reporting formats. It must also consider the unique characteristics of high carbon steels, including their sensitivity to microstructural variations, heat treatment effects, and surface conditions that can significantly influence hardness readings.

Achieving these objectives requires collaboration among steel producers, end-users, equipment manufacturers, standards organizations, and research institutions to develop comprehensive guidelines that balance technical rigor with practical implementation considerations across diverse manufacturing environments.

Market Requirements for Standardized Hardness Testing

The global market for standardized hardness testing in high carbon steel manufacturing has experienced significant growth, driven by increasing quality control requirements across automotive, aerospace, and industrial equipment sectors. Current market analysis indicates that manufacturers are facing escalating pressure to ensure batch-to-batch consistency in high carbon steel production, with hardness variations directly impacting product performance and safety.

Industry surveys reveal that approximately 78% of high carbon steel manufacturers cite inconsistent hardness testing methodologies as a major challenge affecting product quality and customer satisfaction. This inconsistency leads to rejection rates averaging between 5-7% in precision manufacturing applications, representing substantial financial losses across the supply chain.

The demand for standardized testing protocols is particularly acute in automotive manufacturing, where high carbon steel components must meet stringent safety and performance specifications. Tier 1 automotive suppliers report that harmonized hardness testing could reduce quality-related disputes by up to 40% and decrease validation testing time by nearly 30%.

Geographical market analysis shows varying levels of standardization adoption, with European manufacturers generally adhering to more consistent testing protocols than their counterparts in developing markets. This disparity creates challenges for global supply chains and international trade in high carbon steel products.

End-users across industries are increasingly demanding comprehensive material certification that includes standardized hardness data. This trend is reflected in recent procurement policies of major OEMs, which now commonly specify not only the required hardness values but also the exact testing methodology to be employed.

The testing equipment market has responded with advanced solutions featuring automated documentation and traceability features. However, customer feedback indicates persistent concerns regarding calibration consistency and result interpretation across different testing platforms and operator skill levels.

Market research identifies a clear correlation between standardized testing implementation and reduced warranty claims, with manufacturers employing rigorous standardized protocols reporting up to 25% fewer field failures related to material hardness issues. This translates to significant cost savings and enhanced brand reputation.

The economic value proposition for standardization is compelling, with industry analysts estimating that comprehensive standardization of hardness testing could save the high carbon steel industry millions annually through reduced scrap, rework, and customer claims. Furthermore, standardization facilitates more efficient material utilization and process optimization, contributing to sustainability goals increasingly valued by market stakeholders.

Industry surveys reveal that approximately 78% of high carbon steel manufacturers cite inconsistent hardness testing methodologies as a major challenge affecting product quality and customer satisfaction. This inconsistency leads to rejection rates averaging between 5-7% in precision manufacturing applications, representing substantial financial losses across the supply chain.

The demand for standardized testing protocols is particularly acute in automotive manufacturing, where high carbon steel components must meet stringent safety and performance specifications. Tier 1 automotive suppliers report that harmonized hardness testing could reduce quality-related disputes by up to 40% and decrease validation testing time by nearly 30%.

Geographical market analysis shows varying levels of standardization adoption, with European manufacturers generally adhering to more consistent testing protocols than their counterparts in developing markets. This disparity creates challenges for global supply chains and international trade in high carbon steel products.

End-users across industries are increasingly demanding comprehensive material certification that includes standardized hardness data. This trend is reflected in recent procurement policies of major OEMs, which now commonly specify not only the required hardness values but also the exact testing methodology to be employed.

The testing equipment market has responded with advanced solutions featuring automated documentation and traceability features. However, customer feedback indicates persistent concerns regarding calibration consistency and result interpretation across different testing platforms and operator skill levels.

Market research identifies a clear correlation between standardized testing implementation and reduced warranty claims, with manufacturers employing rigorous standardized protocols reporting up to 25% fewer field failures related to material hardness issues. This translates to significant cost savings and enhanced brand reputation.

The economic value proposition for standardization is compelling, with industry analysts estimating that comprehensive standardization of hardness testing could save the high carbon steel industry millions annually through reduced scrap, rework, and customer claims. Furthermore, standardization facilitates more efficient material utilization and process optimization, contributing to sustainability goals increasingly valued by market stakeholders.

Current Challenges in High Carbon Steel Hardness Measurement

Despite significant advancements in metallurgical testing, the hardness measurement of high carbon steel batches continues to present numerous challenges for manufacturers and quality control departments. One of the primary difficulties lies in the inherent material variability across different production batches. High carbon steel, containing 0.55% to 2.1% carbon content, exhibits microstructural heterogeneity that can significantly affect hardness readings even within the same batch.

Testing methodology inconsistencies represent another major challenge. Various hardness testing methods—Rockwell, Brinell, Vickers, and microhardness testing—each employ different principles and yield results in different scales. This lack of standardization makes cross-comparison between facilities or even between different production lines within the same facility problematic, hampering quality assurance efforts.

Environmental factors further complicate hardness measurements. Temperature fluctuations, humidity levels, and vibrations in testing environments can introduce significant measurement errors. Many facilities lack properly controlled testing environments, leading to inconsistent results that may not accurately reflect the true material properties.

Calibration issues present persistent problems in industrial settings. Testing equipment requires regular calibration against certified reference blocks, but maintenance schedules and calibration procedures often vary between facilities. Improper or infrequent calibration leads to systematic errors that may go undetected for extended periods, potentially affecting entire production runs.

Sample preparation inconsistencies significantly impact measurement accuracy. Surface finish quality, sample flatness, and cleanliness all influence hardness readings. The lack of standardized sample preparation protocols across the industry means that identical materials may yield different hardness values depending on preparation techniques.

Operator variability introduces another layer of complexity. Different technicians may apply varying levels of force, hold times, or interpretation methods when conducting manual hardness tests. Even with automated systems, operator-dependent factors such as sample positioning can influence results.

Data interpretation and statistical analysis challenges further complicate standardization efforts. There is limited consensus on appropriate statistical methods for analyzing hardness data, determining acceptable variation ranges, or establishing correlation between laboratory tests and actual performance requirements.

Emerging technologies like portable hardness testers, while offering convenience, introduce additional standardization challenges due to their different operating principles and varying degrees of accuracy compared to traditional bench-top equipment.

Testing methodology inconsistencies represent another major challenge. Various hardness testing methods—Rockwell, Brinell, Vickers, and microhardness testing—each employ different principles and yield results in different scales. This lack of standardization makes cross-comparison between facilities or even between different production lines within the same facility problematic, hampering quality assurance efforts.

Environmental factors further complicate hardness measurements. Temperature fluctuations, humidity levels, and vibrations in testing environments can introduce significant measurement errors. Many facilities lack properly controlled testing environments, leading to inconsistent results that may not accurately reflect the true material properties.

Calibration issues present persistent problems in industrial settings. Testing equipment requires regular calibration against certified reference blocks, but maintenance schedules and calibration procedures often vary between facilities. Improper or infrequent calibration leads to systematic errors that may go undetected for extended periods, potentially affecting entire production runs.

Sample preparation inconsistencies significantly impact measurement accuracy. Surface finish quality, sample flatness, and cleanliness all influence hardness readings. The lack of standardized sample preparation protocols across the industry means that identical materials may yield different hardness values depending on preparation techniques.

Operator variability introduces another layer of complexity. Different technicians may apply varying levels of force, hold times, or interpretation methods when conducting manual hardness tests. Even with automated systems, operator-dependent factors such as sample positioning can influence results.

Data interpretation and statistical analysis challenges further complicate standardization efforts. There is limited consensus on appropriate statistical methods for analyzing hardness data, determining acceptable variation ranges, or establishing correlation between laboratory tests and actual performance requirements.

Emerging technologies like portable hardness testers, while offering convenience, introduce additional standardization challenges due to their different operating principles and varying degrees of accuracy compared to traditional bench-top equipment.

Established Hardness Testing Protocols for High Carbon Steel

01 Hardness testing methods for high carbon steel

Various methods are employed for testing the hardness of high carbon steel, including Rockwell, Brinell, and Vickers hardness tests. These methods involve applying a specific load to the steel surface using different indenters and measuring the resulting indentation. The choice of method depends on the steel's thickness, surface condition, and the required precision of measurement. These standardized testing procedures help ensure consistent quality control in high carbon steel production.- Hardness testing methods for high carbon steel: Various methods are employed to test the hardness of high carbon steel, including Rockwell, Brinell, and Vickers hardness tests. These methods involve applying a specific load to the steel surface using different indenters and measuring the resulting indentation. The choice of method depends on the steel thickness, surface condition, and required precision. These standardized testing procedures ensure consistent and reliable hardness measurements across different manufacturing processes.

- Heat treatment effects on high carbon steel hardness: Heat treatment processes significantly influence the hardness of high carbon steel. Techniques such as quenching, tempering, annealing, and normalizing can be applied to achieve specific hardness levels. The cooling rate during quenching particularly affects the martensitic transformation, which is crucial for hardness development. Controlled tempering after quenching allows for precise adjustment of hardness while maintaining adequate toughness for various applications.

- Correlation between microstructure and hardness in high carbon steel: The microstructure of high carbon steel directly correlates with its hardness properties. Factors such as grain size, phase distribution, carbide precipitation, and dislocation density influence the measured hardness values. Martensitic structures typically yield the highest hardness, while pearlitic and ferritic structures result in lower hardness values. Advanced microscopy techniques combined with hardness testing provide insights into the relationship between microstructural features and mechanical properties.

- Automated and non-destructive hardness testing systems: Modern automated and non-destructive testing systems have been developed for efficient hardness evaluation of high carbon steel components. These systems utilize technologies such as ultrasonic contact impedance, rebound hardness testing, and optical imaging to assess hardness without damaging the tested parts. Automated systems offer advantages including higher testing speed, improved repeatability, and the ability to map hardness distribution across complex geometries, which is particularly valuable for quality control in mass production.

- Hardness testing for high carbon steel in specialized applications: Specialized hardness testing approaches have been developed for high carbon steel used in specific applications such as tools, bearings, and automotive components. These methods account for factors like surface treatments, coatings, and complex geometries that may affect hardness measurements. Micro and nano-hardness testing techniques allow for evaluation of localized properties in heterogeneous microstructures or thin surface layers, providing critical data for performance prediction in demanding service conditions.

02 Heat treatment effects on high carbon steel hardness

Heat treatment processes significantly influence the hardness properties of high carbon steel. Techniques such as quenching, tempering, annealing, and normalizing can be applied to achieve specific hardness levels. The cooling rate during quenching and the tempering temperature are critical factors that determine the final hardness. Proper heat treatment can optimize the balance between hardness and toughness, enhancing the steel's performance for specific applications.Expand Specific Solutions03 Microstructural analysis and hardness correlation

The microstructure of high carbon steel directly correlates with its hardness properties. Analysis techniques such as metallography, scanning electron microscopy, and X-ray diffraction are used to examine the steel's microstructure and relate it to hardness measurements. The presence and distribution of phases like martensite, pearlite, and cementite significantly affect hardness. Understanding this correlation helps in predicting and controlling the mechanical properties of high carbon steel products.Expand Specific Solutions04 Advanced hardness testing equipment and automation

Modern hardness testing of high carbon steel employs advanced equipment and automated systems. Digital hardness testers with computerized data acquisition capabilities allow for precise and repeatable measurements. Automated testing lines can perform multiple hardness tests across steel samples, generating comprehensive hardness profiles. These systems often include features for statistical analysis, quality control reporting, and integration with manufacturing execution systems, improving efficiency and reliability in hardness testing.Expand Specific Solutions05 Hardness testing for specialized high carbon steel applications

Specialized hardness testing approaches are developed for high carbon steel used in specific applications such as tools, bearings, and automotive components. These testing protocols consider the unique requirements of each application, including surface hardness, core hardness, and hardness gradients. Non-destructive testing methods may be employed for finished products, while micro-hardness testing can evaluate localized properties. These specialized approaches ensure that high carbon steel components meet the performance requirements of their intended applications.Expand Specific Solutions

Leading Organizations and Manufacturers in Hardness Testing

The high carbon steel hardness testing standardization market is in a growth phase, with increasing demand driven by automotive, aerospace, and manufacturing sectors requiring precise quality control. Major players like NIPPON STEEL, JFE Steel, POSCO Holdings, and Angang Steel are leading technological advancements in this field. These companies have developed sophisticated hardness testing protocols and equipment calibration methods specifically for high carbon steel applications. The market is characterized by a moderate level of technological maturity, with established testing methods (Rockwell, Brinell, Vickers) being continuously refined by companies such as Schaeffler Technologies and voestalpine BÖHLER Edelstahl. Research institutions like Zhejiang University of Technology and China Special Equipment Inspection & Research Institute are collaborating with industry to develop next-generation standardization approaches addressing batch-to-batch variability challenges.

NIPPON STEEL CORP.

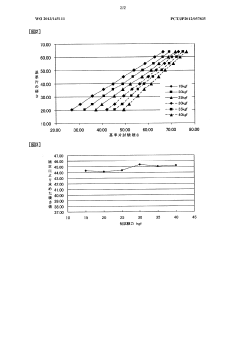

Technical Solution: Nippon Steel has developed a comprehensive hardness testing standardization protocol specifically for high carbon steel that combines multiple testing methods for enhanced accuracy. Their approach integrates automated Rockwell C scale testing with statistical process control (SPC) to ensure batch consistency. The company employs specialized calibration blocks manufactured from the same high carbon steel grades they produce, eliminating material-specific variations that often occur when using generic calibration standards. Their protocol includes precise temperature control during testing (23±1°C) and utilizes advanced surface preparation techniques to minimize the effects of decarburization on hardness readings. Nippon Steel's method also incorporates correlation factors between different hardness scales (HRC, HV, HB) specifically calibrated for high carbon steel compositions, allowing for standardized reporting regardless of the testing method used.

Strengths: Superior repeatability across different testing locations and equipment; comprehensive statistical analysis capabilities for large batch testing; excellent correlation between laboratory and production floor testing results. Weaknesses: Requires significant investment in specialized equipment and training; protocol complexity may increase testing time compared to simpler methods.

JFE Steel Corp.

Technical Solution: JFE Steel has pioneered an automated hardness mapping system specifically designed for high carbon steel quality control. Their technology employs multiple indentation points across steel samples using a modified Vickers testing methodology with specialized diamond indenters designed to minimize work hardening effects during testing. The system incorporates real-time digital imaging analysis to precisely measure indentation dimensions without operator bias. JFE's approach includes proprietary algorithms that account for microstructural variations in high carbon steels, particularly addressing the challenges posed by carbide distributions that can skew traditional hardness measurements. Their standardization protocol includes specific sample preparation guidelines with controlled cooling rates after sectioning to prevent heat-affected zone formation that could alter hardness readings. The system generates comprehensive hardness distribution maps that identify potential inconsistencies within and between batches.

Strengths: High throughput capability suitable for production environments; excellent spatial resolution of hardness variations within samples; automated documentation for quality assurance purposes. Weaknesses: Higher initial implementation cost compared to conventional methods; requires specialized maintenance and calibration procedures.

Critical Technologies in Precision Hardness Measurement

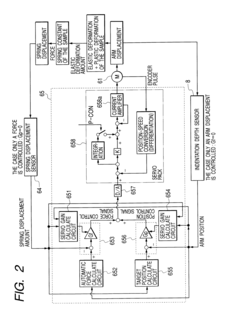

Hardness testing device and hardness testing method

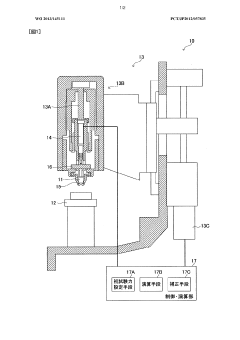

PatentWO2013145111A1

Innovation

- A hardness tester and method that allows for arbitrary adjustment of the initial test force, enabling the indenter to penetrate through surface layers, with a correction mechanism to account for deviations in hardness calculations based on the Rockwell hardness formula, using a depth detection system and control unit to calculate hardness from the difference in indenter penetration depths before and after applying the initial and final forces.

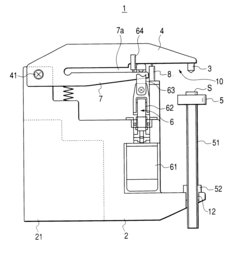

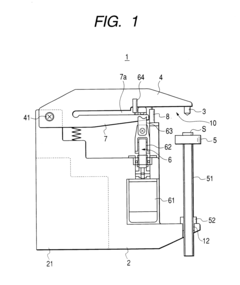

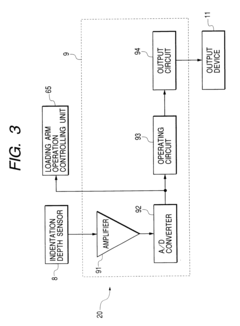

Impression forming mechanism and method, and hardness testing apparatus and method

PatentInactiveUS6725708B2

Innovation

- The implementation of an impact reducing unit that controls the movement of the sample and indentor in the same direction during contact, along with a force controlling unit and distance sensing unit, and the use of an electromagnetic brake with current inversion for demagnetization.

Quality Control Implementation Strategies

Implementing effective quality control strategies for high carbon steel hardness testing requires a systematic approach that encompasses both procedural standardization and organizational alignment. The foundation of any successful implementation begins with establishing clear testing protocols that define precise testing conditions, including sample preparation requirements, temperature controls, and calibration procedures. These protocols must be documented in comprehensive standard operating procedures (SOPs) that leave minimal room for interpretation or variation between operators.

Equipment calibration represents a critical component of quality control implementation. Regular calibration schedules must be established for all hardness testing machines, with verification using certified reference materials traceable to national or international standards. The frequency of calibration should be determined based on equipment usage patterns, environmental conditions, and historical drift data to ensure consistent measurement accuracy.

Training programs constitute another essential element of implementation strategy. All personnel involved in hardness testing should undergo standardized training that covers theoretical principles, practical operation techniques, and troubleshooting procedures. Certification processes should be established to verify operator competency, with periodic refresher courses to maintain skills and address any emerging issues or technological updates.

Statistical process control (SPC) methodologies should be integrated into the quality control framework to monitor testing processes and identify trends before they result in non-conformities. Implementation of control charts for tracking hardness measurements enables real-time monitoring of process stability and capability. Establishing appropriate control limits based on product specifications and process capabilities provides objective criteria for intervention decisions.

Cross-functional collaboration represents a key success factor in implementation. Quality departments must work closely with production, engineering, and management teams to ensure alignment on testing requirements and their implications for product performance. Regular review meetings should be established to discuss testing results, address any deviations, and continuously improve the testing process.

Technology integration offers significant opportunities for enhancing implementation effectiveness. Digital data collection systems eliminate manual recording errors and enable advanced analytics. Automated testing equipment can reduce operator variability, while laboratory information management systems (LIMS) facilitate comprehensive documentation and traceability of all testing activities and results.

Performance metrics must be established to evaluate the effectiveness of hardness testing quality control. Key indicators should include measurement system analysis results, testing throughput times, detection rates for non-conforming materials, and correlation between hardness test results and final product performance. Regular audits of the testing process provide additional verification of compliance with established protocols.

Equipment calibration represents a critical component of quality control implementation. Regular calibration schedules must be established for all hardness testing machines, with verification using certified reference materials traceable to national or international standards. The frequency of calibration should be determined based on equipment usage patterns, environmental conditions, and historical drift data to ensure consistent measurement accuracy.

Training programs constitute another essential element of implementation strategy. All personnel involved in hardness testing should undergo standardized training that covers theoretical principles, practical operation techniques, and troubleshooting procedures. Certification processes should be established to verify operator competency, with periodic refresher courses to maintain skills and address any emerging issues or technological updates.

Statistical process control (SPC) methodologies should be integrated into the quality control framework to monitor testing processes and identify trends before they result in non-conformities. Implementation of control charts for tracking hardness measurements enables real-time monitoring of process stability and capability. Establishing appropriate control limits based on product specifications and process capabilities provides objective criteria for intervention decisions.

Cross-functional collaboration represents a key success factor in implementation. Quality departments must work closely with production, engineering, and management teams to ensure alignment on testing requirements and their implications for product performance. Regular review meetings should be established to discuss testing results, address any deviations, and continuously improve the testing process.

Technology integration offers significant opportunities for enhancing implementation effectiveness. Digital data collection systems eliminate manual recording errors and enable advanced analytics. Automated testing equipment can reduce operator variability, while laboratory information management systems (LIMS) facilitate comprehensive documentation and traceability of all testing activities and results.

Performance metrics must be established to evaluate the effectiveness of hardness testing quality control. Key indicators should include measurement system analysis results, testing throughput times, detection rates for non-conforming materials, and correlation between hardness test results and final product performance. Regular audits of the testing process provide additional verification of compliance with established protocols.

International Standards Compliance and Certification

Compliance with international standards is a critical aspect of hardness testing for high carbon steel batches, ensuring consistency, reliability, and global acceptance of test results. The primary standards governing hardness testing include ISO 6508 for Rockwell hardness, ISO 6506 for Brinell hardness, and ISO 6507 for Vickers hardness testing. These standards provide detailed specifications for testing equipment, procedures, calibration requirements, and result interpretation, forming the foundation for standardized hardness testing across different regions and industries.

The American Society for Testing and Materials (ASTM) offers complementary standards such as ASTM E18, E10, and E92, which are widely recognized in North America and beyond. For high carbon steel specifically, ASTM A370 provides standard test methods and definitions for mechanical testing of steel products, including hardness testing protocols tailored to different carbon content levels.

Certification of testing equipment and personnel represents another crucial dimension of international compliance. Equipment certification typically involves regular calibration against certified reference blocks traceable to national or international standards. Organizations like the United Kingdom Accreditation Service (UKAS) and the National Institute of Standards and Technology (NIST) provide calibration services and reference materials that ensure traceability to international measurement standards.

Personnel certification programs, such as those offered by the American Society for Nondestructive Testing (ASNT), ensure that operators possess the necessary skills and knowledge to perform hardness tests according to international standards. These certifications typically require theoretical knowledge assessment, practical demonstrations, and periodic recertification to maintain competency.

The International Laboratory Accreditation Cooperation (ILAC) facilitates mutual recognition arrangements between accreditation bodies, enabling test results from accredited laboratories to be accepted internationally. For manufacturers of high carbon steel, obtaining ISO/IEC 17025 accreditation for their testing laboratories demonstrates technical competence and compliance with internationally recognized quality management systems.

Regional variations in standards implementation present challenges for global manufacturers. While harmonization efforts have reduced discrepancies between major standards like ISO and ASTM, subtle differences remain in areas such as sample preparation requirements, force application parameters, and measurement uncertainty calculations. Companies operating across multiple markets must navigate these variations carefully, often by implementing the most stringent requirements across their entire testing program.

Digital certification systems are emerging as a solution for streamlining compliance documentation. These systems provide secure, tamper-evident records of test results, calibration histories, and operator qualifications, facilitating faster verification during audits and customer qualification processes.

The American Society for Testing and Materials (ASTM) offers complementary standards such as ASTM E18, E10, and E92, which are widely recognized in North America and beyond. For high carbon steel specifically, ASTM A370 provides standard test methods and definitions for mechanical testing of steel products, including hardness testing protocols tailored to different carbon content levels.

Certification of testing equipment and personnel represents another crucial dimension of international compliance. Equipment certification typically involves regular calibration against certified reference blocks traceable to national or international standards. Organizations like the United Kingdom Accreditation Service (UKAS) and the National Institute of Standards and Technology (NIST) provide calibration services and reference materials that ensure traceability to international measurement standards.

Personnel certification programs, such as those offered by the American Society for Nondestructive Testing (ASNT), ensure that operators possess the necessary skills and knowledge to perform hardness tests according to international standards. These certifications typically require theoretical knowledge assessment, practical demonstrations, and periodic recertification to maintain competency.

The International Laboratory Accreditation Cooperation (ILAC) facilitates mutual recognition arrangements between accreditation bodies, enabling test results from accredited laboratories to be accepted internationally. For manufacturers of high carbon steel, obtaining ISO/IEC 17025 accreditation for their testing laboratories demonstrates technical competence and compliance with internationally recognized quality management systems.

Regional variations in standards implementation present challenges for global manufacturers. While harmonization efforts have reduced discrepancies between major standards like ISO and ASTM, subtle differences remain in areas such as sample preparation requirements, force application parameters, and measurement uncertainty calculations. Companies operating across multiple markets must navigate these variations carefully, often by implementing the most stringent requirements across their entire testing program.

Digital certification systems are emerging as a solution for streamlining compliance documentation. These systems provide secure, tamper-evident records of test results, calibration histories, and operator qualifications, facilitating faster verification during audits and customer qualification processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!