How To Prevent Quench Cracking In High Carbon Steel Parts

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Carbon Steel Quenching Background and Objectives

High carbon steel, containing carbon content typically between 0.60% and 1.00%, has been a cornerstone material in manufacturing industries for decades due to its exceptional hardness and wear resistance properties. The quenching process, which involves rapid cooling of heated steel to achieve desired mechanical properties, dates back to ancient metallurgical practices but has evolved significantly with modern industrial applications.

The evolution of quenching technology has progressed from primitive water immersion methods to sophisticated controlled cooling systems. Historical developments in the early 20th century established fundamental principles of martensite formation during quenching, while the post-World War II era saw significant advancements in understanding the metallurgical transformations occurring during this critical process.

Recent technological trends in high carbon steel quenching include computer-controlled cooling systems, vacuum quenching technologies, and the integration of simulation software to predict and prevent quench cracking phenomena. The industry has gradually shifted from traditional oil quenching to more environmentally friendly alternatives, including polymer quenchants and gas quenching methods.

Quench cracking remains one of the most persistent challenges in high carbon steel heat treatment, resulting in significant material waste and production inefficiencies. This phenomenon occurs when thermal stresses and transformation stresses during rapid cooling exceed the material's ultimate strength, leading to catastrophic failure. The economic impact of quench cracking is substantial, with estimates suggesting that it accounts for 4-8% of total production losses in precision steel manufacturing.

The primary technical objective of this research is to develop comprehensive strategies to prevent quench cracking in high carbon steel components while maintaining optimal mechanical properties. Specifically, we aim to identify critical process parameters that influence crack formation, evaluate alternative quenching media and techniques, and establish predictive models for quench crack susceptibility.

Secondary objectives include quantifying the relationship between steel composition variations and quench crack sensitivity, developing non-destructive testing methodologies for early crack detection, and formulating industry-specific best practices for different high carbon steel applications ranging from automotive components to precision cutting tools.

The long-term technological goal is to establish a unified framework for quench crack prevention that integrates material science principles, process engineering innovations, and computational modeling to achieve zero-defect manufacturing of high carbon steel components across diverse industrial applications.

The evolution of quenching technology has progressed from primitive water immersion methods to sophisticated controlled cooling systems. Historical developments in the early 20th century established fundamental principles of martensite formation during quenching, while the post-World War II era saw significant advancements in understanding the metallurgical transformations occurring during this critical process.

Recent technological trends in high carbon steel quenching include computer-controlled cooling systems, vacuum quenching technologies, and the integration of simulation software to predict and prevent quench cracking phenomena. The industry has gradually shifted from traditional oil quenching to more environmentally friendly alternatives, including polymer quenchants and gas quenching methods.

Quench cracking remains one of the most persistent challenges in high carbon steel heat treatment, resulting in significant material waste and production inefficiencies. This phenomenon occurs when thermal stresses and transformation stresses during rapid cooling exceed the material's ultimate strength, leading to catastrophic failure. The economic impact of quench cracking is substantial, with estimates suggesting that it accounts for 4-8% of total production losses in precision steel manufacturing.

The primary technical objective of this research is to develop comprehensive strategies to prevent quench cracking in high carbon steel components while maintaining optimal mechanical properties. Specifically, we aim to identify critical process parameters that influence crack formation, evaluate alternative quenching media and techniques, and establish predictive models for quench crack susceptibility.

Secondary objectives include quantifying the relationship between steel composition variations and quench crack sensitivity, developing non-destructive testing methodologies for early crack detection, and formulating industry-specific best practices for different high carbon steel applications ranging from automotive components to precision cutting tools.

The long-term technological goal is to establish a unified framework for quench crack prevention that integrates material science principles, process engineering innovations, and computational modeling to achieve zero-defect manufacturing of high carbon steel components across diverse industrial applications.

Market Analysis for Crack-Resistant Steel Components

The global market for crack-resistant high carbon steel components continues to expand, driven primarily by increasing demands in automotive, aerospace, and industrial manufacturing sectors. Current market valuations indicate that the specialized steel components market reached approximately $45 billion in 2022, with crack-resistant variants accounting for nearly 18% of this segment. Industry forecasts project a compound annual growth rate of 6.2% through 2028, significantly outpacing general steel market growth rates.

Automotive manufacturing represents the largest application segment, consuming roughly 38% of all crack-resistant high carbon steel components. This demand stems from stringent safety requirements and the need for durable, high-performance parts in modern vehicle designs. The aerospace sector follows at 22% market share, where component failure can have catastrophic consequences, thus justifying premium pricing for crack-resistant solutions.

Regional analysis reveals that Asia-Pacific dominates production capacity, accounting for 45% of global manufacturing output, with China and Japan leading the region. However, European manufacturers maintain technological leadership in specialized crack-resistant treatments, commanding higher margins despite lower production volumes. North American manufacturers have focused on value-added services and customization, creating defensible market positions in premium segments.

Customer demand patterns show increasing preference for components with documented quality assurance protocols specifically addressing quench crack prevention. This trend has created a price premium of 15-30% for components with certified crack-resistance properties compared to standard alternatives. Furthermore, end-users demonstrate willingness to pay additional premiums for components with extended warranty coverage against stress-related failures.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing, with specialized alloy elements facing periodic supply constraints. These constraints have created price volatility that impacts manufacturer margins, particularly for smaller producers lacking long-term supply agreements. The market has responded with vertical integration strategies among larger players, with five major steel producers acquiring specialized heat treatment facilities between 2020-2023.

Competitive landscape assessment identifies three distinct market tiers: global integrated suppliers offering comprehensive solutions, specialized regional manufacturers with proprietary technologies, and local producers competing primarily on cost and delivery terms. Market concentration remains moderate with the top ten producers accounting for 62% of global revenue, suggesting room for further consolidation as technology barriers increase.

Automotive manufacturing represents the largest application segment, consuming roughly 38% of all crack-resistant high carbon steel components. This demand stems from stringent safety requirements and the need for durable, high-performance parts in modern vehicle designs. The aerospace sector follows at 22% market share, where component failure can have catastrophic consequences, thus justifying premium pricing for crack-resistant solutions.

Regional analysis reveals that Asia-Pacific dominates production capacity, accounting for 45% of global manufacturing output, with China and Japan leading the region. However, European manufacturers maintain technological leadership in specialized crack-resistant treatments, commanding higher margins despite lower production volumes. North American manufacturers have focused on value-added services and customization, creating defensible market positions in premium segments.

Customer demand patterns show increasing preference for components with documented quality assurance protocols specifically addressing quench crack prevention. This trend has created a price premium of 15-30% for components with certified crack-resistance properties compared to standard alternatives. Furthermore, end-users demonstrate willingness to pay additional premiums for components with extended warranty coverage against stress-related failures.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing, with specialized alloy elements facing periodic supply constraints. These constraints have created price volatility that impacts manufacturer margins, particularly for smaller producers lacking long-term supply agreements. The market has responded with vertical integration strategies among larger players, with five major steel producers acquiring specialized heat treatment facilities between 2020-2023.

Competitive landscape assessment identifies three distinct market tiers: global integrated suppliers offering comprehensive solutions, specialized regional manufacturers with proprietary technologies, and local producers competing primarily on cost and delivery terms. Market concentration remains moderate with the top ten producers accounting for 62% of global revenue, suggesting room for further consolidation as technology barriers increase.

Current Challenges in Quench Crack Prevention

Despite significant advancements in heat treatment technologies, quench cracking remains one of the most persistent and costly challenges in the processing of high carbon steel parts. The fundamental issue stems from the inherent metallurgical behavior of high carbon steels during rapid cooling, where thermal gradients and phase transformations create internal stresses that exceed the material's fracture strength. These cracks often manifest without warning and may not be detected until final inspection, resulting in substantial material waste and production delays.

Current detection methods for quench cracks suffer from significant limitations. Non-destructive testing techniques such as magnetic particle inspection and ultrasonic testing can identify surface and some subsurface cracks, but they struggle with detecting micro-cracks that may propagate during subsequent processing or service. This detection gap represents a major quality assurance challenge for manufacturers of critical components like automotive transmission gears, tool steels, and high-performance bearings.

The industry also faces challenges related to process parameter optimization. The relationship between cooling rate, part geometry, carbon content, and alloying elements creates a complex multivariable problem that resists standardization. Many manufacturers still rely heavily on empirical approaches and historical data rather than predictive models, leading to inconsistent results when processing new part designs or material compositions.

Environmental considerations have introduced additional complications to quench crack prevention. Traditional quenchants like oil-based media are facing increasing regulatory scrutiny due to their environmental impact. Water-polymer quenchants offer more environmentally friendly alternatives but introduce new variables that affect cooling uniformity and crack susceptibility, requiring extensive reformulation of established processes.

Digital simulation tools for predicting quench behavior have advanced significantly but still struggle with accurately modeling the complex phase transformations and resulting stress distributions in high carbon steels. The computational requirements for high-fidelity simulations remain prohibitive for many manufacturers, limiting widespread adoption of these potentially valuable predictive tools.

Economic pressures continue to drive manufacturers toward faster processing times and higher throughput, often at the expense of optimal quench parameters. This production-focused approach frequently results in higher rejection rates due to quench cracking, creating a counterproductive cycle that ultimately increases costs and reduces efficiency.

The knowledge gap between academic research and industrial practice presents another significant challenge. While research institutions continue to develop sophisticated models of phase transformation kinetics and residual stress formation, translating these insights into practical shop-floor procedures remains difficult, particularly for smaller manufacturers with limited metallurgical expertise.

Current detection methods for quench cracks suffer from significant limitations. Non-destructive testing techniques such as magnetic particle inspection and ultrasonic testing can identify surface and some subsurface cracks, but they struggle with detecting micro-cracks that may propagate during subsequent processing or service. This detection gap represents a major quality assurance challenge for manufacturers of critical components like automotive transmission gears, tool steels, and high-performance bearings.

The industry also faces challenges related to process parameter optimization. The relationship between cooling rate, part geometry, carbon content, and alloying elements creates a complex multivariable problem that resists standardization. Many manufacturers still rely heavily on empirical approaches and historical data rather than predictive models, leading to inconsistent results when processing new part designs or material compositions.

Environmental considerations have introduced additional complications to quench crack prevention. Traditional quenchants like oil-based media are facing increasing regulatory scrutiny due to their environmental impact. Water-polymer quenchants offer more environmentally friendly alternatives but introduce new variables that affect cooling uniformity and crack susceptibility, requiring extensive reformulation of established processes.

Digital simulation tools for predicting quench behavior have advanced significantly but still struggle with accurately modeling the complex phase transformations and resulting stress distributions in high carbon steels. The computational requirements for high-fidelity simulations remain prohibitive for many manufacturers, limiting widespread adoption of these potentially valuable predictive tools.

Economic pressures continue to drive manufacturers toward faster processing times and higher throughput, often at the expense of optimal quench parameters. This production-focused approach frequently results in higher rejection rates due to quench cracking, creating a counterproductive cycle that ultimately increases costs and reduces efficiency.

The knowledge gap between academic research and industrial practice presents another significant challenge. While research institutions continue to develop sophisticated models of phase transformation kinetics and residual stress formation, translating these insights into practical shop-floor procedures remains difficult, particularly for smaller manufacturers with limited metallurgical expertise.

Established Quench Cracking Prevention Methods

01 Controlled cooling processes to prevent quench cracking

Implementing controlled cooling processes during quenching can significantly reduce the risk of cracking in high carbon steel parts. These methods include step quenching, interrupted quenching, and graduated cooling rates that allow for more uniform temperature distribution throughout the part. By controlling the cooling rate, especially during the critical temperature ranges where martensite formation occurs, internal stresses can be minimized, thereby reducing the likelihood of crack formation.- Controlled cooling processes to prevent quench cracking: Implementing controlled cooling processes during quenching can significantly reduce the risk of cracking in high carbon steel parts. This involves carefully managing cooling rates, using step quenching techniques, or interrupted quenching methods that allow for more uniform temperature distribution throughout the part. These processes help minimize thermal gradients and associated stresses that lead to cracking, while still achieving desired hardness and microstructural properties.

- Quenchant composition and additives: The composition of quenching media plays a crucial role in preventing quench cracking. Specialized quenchants containing polymers, oils with specific additives, or water-based solutions with surfactants can modify the cooling characteristics to reduce cracking risk. These additives control the vapor blanket stage of quenching and promote more uniform cooling across complex geometries, thereby minimizing internal stresses that lead to cracking in high carbon steel parts.

- Pre-treatment and part design considerations: Pre-treatment processes and part design modifications can help prevent quench cracking in high carbon steel components. Techniques such as proper homogenization, controlled pre-heating, stress relief before quenching, and designing parts with uniform cross-sections or gradual transitions between thick and thin sections can significantly reduce cracking tendency. Avoiding sharp corners and ensuring proper fillet radii also helps distribute stresses more evenly during the quenching process.

- Alternative hardening methods: Alternative hardening methods can be employed to reduce quench cracking in high carbon steel parts. These include induction hardening, laser hardening, austempering, and selective hardening techniques that limit the thermal shock experienced by the entire component. These methods provide more localized or controlled heat treatment, reducing the overall stress in the part and minimizing the risk of cracking while still achieving the required hardness in critical areas.

- Post-quench treatments and stress management: Post-quench treatments can effectively manage residual stresses and prevent delayed cracking in high carbon steel parts. Techniques such as immediate tempering after quenching, cryogenic treatment, stress relief processes, and controlled martempering can significantly reduce the risk of cracking. These treatments help redistribute internal stresses, stabilize the microstructure, and improve the overall toughness of the quenched components without sacrificing hardness.

02 Quenching media selection and optimization

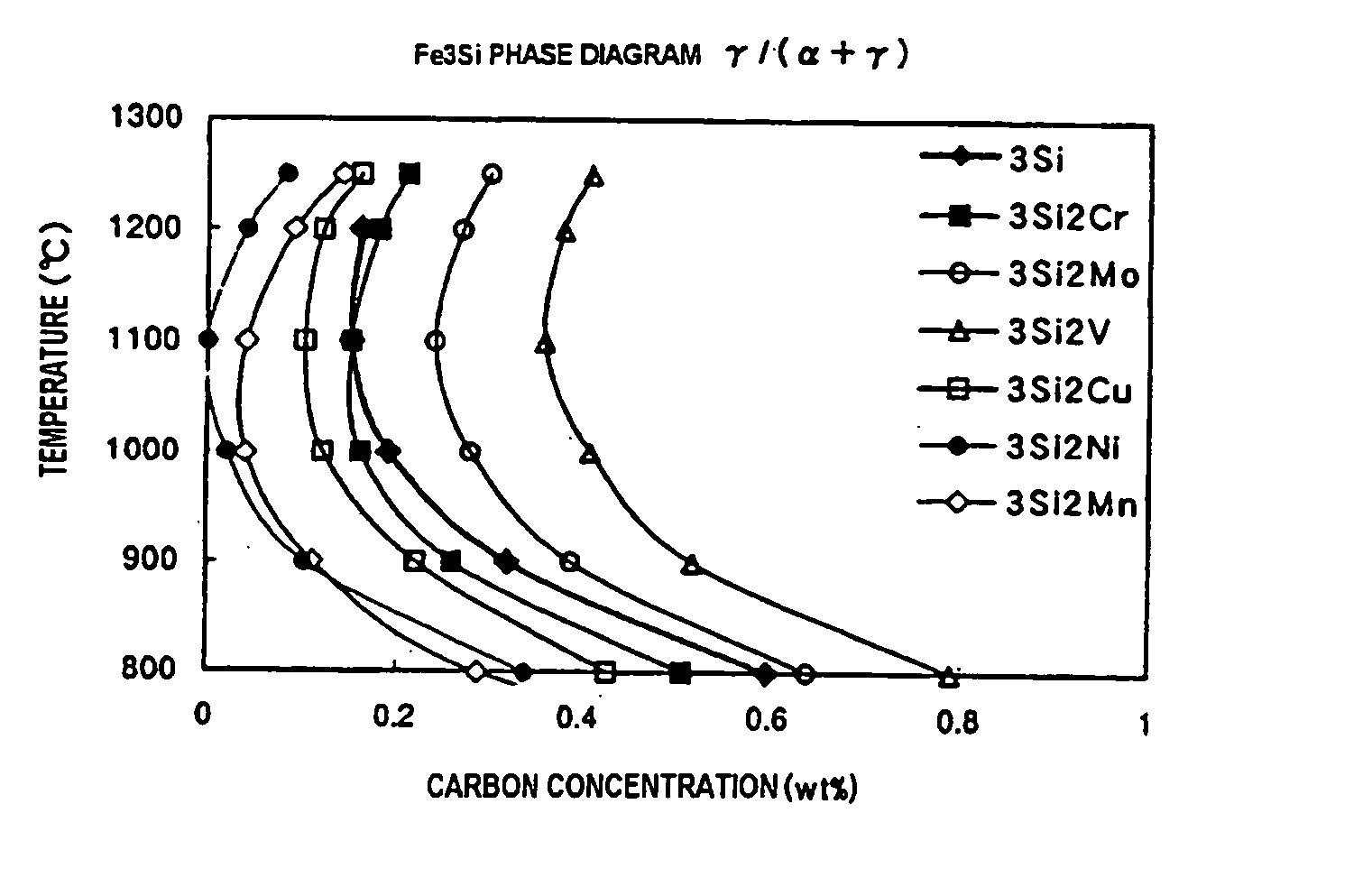

The selection of appropriate quenching media plays a crucial role in preventing quench cracking of high carbon steel parts. Various quenching media such as polymer solutions, oil, water, and salt baths offer different cooling rates and characteristics. Polymer-based quenchants provide more uniform cooling and reduced distortion compared to water. Oil quenchants, while slower than water, provide more consistent cooling and less thermal shock. Optimizing the composition, temperature, and agitation of the quenching media can significantly reduce the risk of cracking.Expand Specific Solutions03 Pre-treatment and alloying modifications

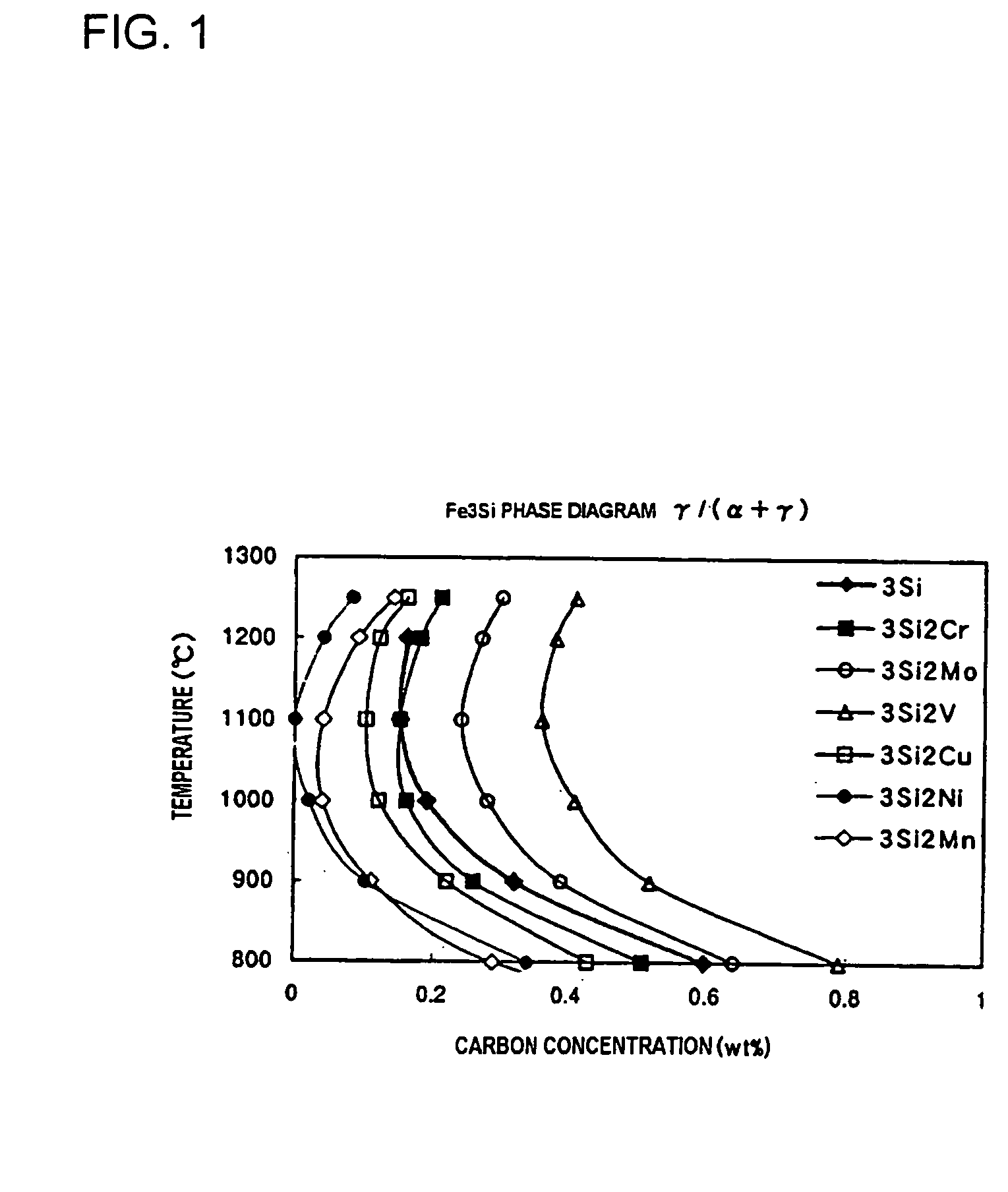

Pre-treatment processes and alloying modifications can enhance the quench hardenability of high carbon steel while reducing susceptibility to cracking. Techniques such as normalizing before quenching, controlled pre-heating, and the addition of alloying elements like chromium, nickel, and molybdenum can improve hardenability and reduce distortion during quenching. These modifications help in achieving a more uniform microstructure and reducing the thermal gradients that lead to cracking.Expand Specific Solutions04 Part design and geometry considerations

The design and geometry of high carbon steel parts significantly influence their susceptibility to quench cracking. Sharp corners, abrupt section changes, and non-uniform wall thicknesses create stress concentrations during quenching. Implementing design modifications such as rounded corners, gradual section transitions, and uniform wall thicknesses can distribute thermal stresses more evenly. Additionally, proper fixturing during heat treatment can prevent distortion and reduce the risk of cracking.Expand Specific Solutions05 Post-quench treatments to relieve stress

Implementing appropriate post-quench treatments is essential for relieving residual stresses that could lead to delayed cracking in high carbon steel parts. Tempering immediately after quenching helps to reduce internal stresses while maintaining desired hardness levels. Other stress relief methods include sub-zero treatments, controlled reheating, and mechanical stress relief techniques. These post-quench processes help to stabilize the microstructure and minimize the risk of both immediate and delayed cracking.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The high carbon steel quench cracking prevention market is currently in a growth phase, with increasing demand driven by automotive, industrial machinery, and construction sectors. The global market size is estimated at $3-4 billion annually, expanding at 5-7% CAGR. Leading steel manufacturers like NIPPON STEEL, JFE Steel, and Kobe Steel have developed advanced quenching technologies with controlled cooling rates and specialized quenchants. Research institutions including Shanghai Jiao Tong University and Central South University collaborate with industry leaders on innovative solutions. Automotive companies (BMW, Nissan) and machinery manufacturers (Komatsu, Kawasaki) are implementing these technologies to enhance component durability. The technology maturity varies, with established methods coexisting alongside emerging techniques like computer-simulated quenching processes and specialized alloy formulations.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed a comprehensive approach to prevent quench cracking in high carbon steel parts through their NSafe-HCWR (High Carbon Wear Resistant) technology. Their solution involves precise control of steel chemistry with optimized carbon content (typically 0.70-0.85%) and careful management of alloying elements like manganese, chromium, and silicon to improve hardenability while minimizing distortion[1]. The company employs controlled heating rates during austenitization (typically 850-870°C) followed by stepped quenching processes where parts are initially quenched to an intermediate temperature (around 200-250°C) before complete cooling[3]. This reduces thermal gradients and associated stresses. Additionally, Nippon Steel utilizes pre-quench microstructure refinement through thermomechanical processing and has implemented advanced computer simulation models that predict residual stress distribution during quenching, allowing for process optimization before actual production[5].

Strengths: Superior control of microstructure through advanced metallurgical expertise; proprietary stepped quenching technology minimizes thermal gradients; comprehensive simulation capabilities for process optimization. Weaknesses: Their solutions may require specialized equipment not available to all manufacturers; higher implementation costs compared to conventional methods; process parameters often need customization for specific part geometries.

JFE Steel Corp.

Technical Solution: JFE Steel has pioneered an innovative approach to quench crack prevention in high carbon steels through their JFE-HCQT (High Carbon Quench Technology) system. Their method incorporates precise control of pre-quench microstructure through carefully regulated hot working parameters and controlled cooling before heat treatment[2]. The company has developed specialized quenching media with modified polymer concentrations that create a more uniform cooling rate across complex part geometries. Their process includes a proprietary two-stage quenching protocol where parts are initially quenched to approximately 230-280°C, held for a calculated duration based on section thickness, then cooled to ambient temperature[4]. This significantly reduces thermal gradients between surface and core. JFE also employs advanced carbon distribution control during steelmaking, creating a slightly lower carbon content at the surface compared to the core (typically 0.05-0.10% difference), which helps minimize surface tensile stresses during quenching[7]. Their technology is particularly effective for automotive drivetrain components and heavy machinery parts.

Strengths: Two-stage quenching protocol significantly reduces thermal stress; specialized quenching media provides more uniform cooling across complex geometries; carbon distribution control creates beneficial stress patterns. Weaknesses: Process requires precise temperature control equipment; longer processing times compared to direct quenching; higher operational costs due to specialized quenching media requirements.

Critical Patents and Research on Quench Control

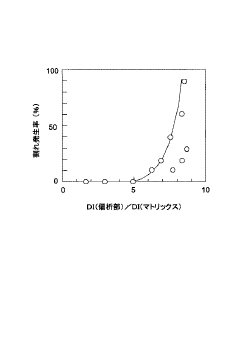

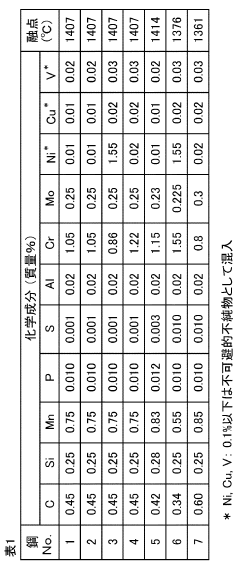

Steel material for high frequency quenching and method for manufacturing the same

PatentActiveJP2013122087A

Innovation

- A steel material for induction hardening is produced through ingot casting followed by soaking diffusion annealing, controlling microsegregation by limiting the DI (segregation part) to DI (matrix) ratio to less than 5.00, with specific elemental compositions and annealing temperatures to prevent quench cracks.

Rolling elements

PatentInactiveUS20050247377A1

Innovation

- Development of rolling elements made from steel alloys with specific compositions, including Al, Si, Ni, and other elements, which are carburized, quenched, and tempered to achieve a hardness of HRC 58 or more at 300°C, enhancing both temper softening resistance and pitting resistance.

Material Science Advancements for Crack Resistance

Recent advancements in materials science have significantly contributed to improving crack resistance in high carbon steel parts during quenching processes. The development of novel alloy compositions represents one of the most promising approaches. By incorporating specific microalloying elements such as vanadium, niobium, and titanium in precise quantities, researchers have created steel variants with enhanced grain refinement capabilities that maintain structural integrity during rapid cooling.

Nanotechnology applications have revolutionized the field by enabling the creation of nanostructured steels with superior crack resistance properties. These materials feature engineered grain boundaries and dispersed nanoparticles that effectively impede crack propagation pathways. Studies have demonstrated that nanostructured high carbon steels can withstand thermal shock up to 40% better than their conventional counterparts while maintaining comparable mechanical properties.

Surface engineering technologies have evolved to create protective layers that mitigate quench cracking. Advanced coating systems, including ceramic-metallic composites and specialized polymer films, provide thermal buffering during the quenching process. These coatings regulate heat transfer rates and minimize the formation of steep thermal gradients that typically lead to crack initiation.

Computational materials science has enabled precise prediction of microstructural evolution during quenching. Machine learning algorithms now accurately model phase transformations and residual stress development, allowing for optimization of steel compositions specifically designed to resist cracking under various quenching conditions. These digital tools have reduced experimental iterations by approximately 60%, accelerating the development of crack-resistant alloys.

Controlled transformation hardening represents another significant advancement, where the martensitic transformation is managed through stepped cooling protocols. This approach allows internal stresses to partially relieve during the quenching process rather than accumulating to critical levels. Research indicates that properly implemented transformation control can reduce crack incidence by up to 75% in high carbon tool steels.

Microstructural engineering through grain boundary design has emerged as a promising technique. By controlling the distribution and character of grain boundaries, materials scientists have created high carbon steels with enhanced crack deflection capabilities. These engineered microstructures effectively dissipate strain energy along predetermined paths, preventing catastrophic crack propagation during thermal shock.

Nanotechnology applications have revolutionized the field by enabling the creation of nanostructured steels with superior crack resistance properties. These materials feature engineered grain boundaries and dispersed nanoparticles that effectively impede crack propagation pathways. Studies have demonstrated that nanostructured high carbon steels can withstand thermal shock up to 40% better than their conventional counterparts while maintaining comparable mechanical properties.

Surface engineering technologies have evolved to create protective layers that mitigate quench cracking. Advanced coating systems, including ceramic-metallic composites and specialized polymer films, provide thermal buffering during the quenching process. These coatings regulate heat transfer rates and minimize the formation of steep thermal gradients that typically lead to crack initiation.

Computational materials science has enabled precise prediction of microstructural evolution during quenching. Machine learning algorithms now accurately model phase transformations and residual stress development, allowing for optimization of steel compositions specifically designed to resist cracking under various quenching conditions. These digital tools have reduced experimental iterations by approximately 60%, accelerating the development of crack-resistant alloys.

Controlled transformation hardening represents another significant advancement, where the martensitic transformation is managed through stepped cooling protocols. This approach allows internal stresses to partially relieve during the quenching process rather than accumulating to critical levels. Research indicates that properly implemented transformation control can reduce crack incidence by up to 75% in high carbon tool steels.

Microstructural engineering through grain boundary design has emerged as a promising technique. By controlling the distribution and character of grain boundaries, materials scientists have created high carbon steels with enhanced crack deflection capabilities. These engineered microstructures effectively dissipate strain energy along predetermined paths, preventing catastrophic crack propagation during thermal shock.

Environmental Impact of Quenching Technologies

The environmental impact of quenching technologies in high carbon steel manufacturing represents a critical consideration for modern industrial practices. Traditional quenching methods, particularly those utilizing oil-based quenchants, contribute significantly to environmental pollution through volatile organic compound (VOC) emissions, waste disposal challenges, and potential soil and water contamination from spills. These environmental concerns have prompted regulatory bodies worldwide to implement increasingly stringent standards governing industrial processes involving quenchants.

Water-based quenching alternatives offer reduced environmental impact compared to oil quenchants but present their own challenges. While water quenching produces fewer direct emissions, it often requires additives that may contain environmentally harmful compounds. Additionally, the wastewater generated requires treatment before discharge, adding complexity and cost to the manufacturing process.

Polymer quenchants have emerged as environmentally superior options, offering biodegradability and reduced toxicity compared to traditional oil-based solutions. These advanced formulations minimize environmental footprint while maintaining effective heat transfer properties necessary for preventing quench cracking in high carbon steel parts. However, their production processes may still involve environmental considerations that manufacturers must address.

Gas quenching technologies represent the most environmentally friendly approach, utilizing inert gases like nitrogen or helium that produce virtually no harmful emissions or waste. These systems operate in closed-loop configurations that minimize resource consumption and environmental impact. The primary environmental consideration with gas quenching relates to the energy requirements, which can be substantial but are increasingly being addressed through renewable energy integration and efficiency improvements.

The carbon footprint of quenching operations extends beyond the quenchants themselves to include energy consumption during the heating and cooling processes. Modern facilities are implementing heat recovery systems that capture and repurpose thermal energy from quenching operations, significantly reducing overall environmental impact while improving operational efficiency.

Regulatory compliance represents an increasingly important factor in quenching technology selection. Companies must navigate complex environmental regulations that vary by region but generally trend toward stricter emissions controls and waste management requirements. Forward-thinking manufacturers are adopting life cycle assessment approaches to evaluate the comprehensive environmental impact of their quenching processes, from raw material extraction through disposal or recycling of spent quenchants.

The industry continues to invest in research and development of more sustainable quenching technologies that balance technical performance requirements with environmental responsibility. These innovations include bio-based quenchants derived from renewable resources and advanced process controls that optimize quenching parameters to minimize both cracking risks and environmental impact.

Water-based quenching alternatives offer reduced environmental impact compared to oil quenchants but present their own challenges. While water quenching produces fewer direct emissions, it often requires additives that may contain environmentally harmful compounds. Additionally, the wastewater generated requires treatment before discharge, adding complexity and cost to the manufacturing process.

Polymer quenchants have emerged as environmentally superior options, offering biodegradability and reduced toxicity compared to traditional oil-based solutions. These advanced formulations minimize environmental footprint while maintaining effective heat transfer properties necessary for preventing quench cracking in high carbon steel parts. However, their production processes may still involve environmental considerations that manufacturers must address.

Gas quenching technologies represent the most environmentally friendly approach, utilizing inert gases like nitrogen or helium that produce virtually no harmful emissions or waste. These systems operate in closed-loop configurations that minimize resource consumption and environmental impact. The primary environmental consideration with gas quenching relates to the energy requirements, which can be substantial but are increasingly being addressed through renewable energy integration and efficiency improvements.

The carbon footprint of quenching operations extends beyond the quenchants themselves to include energy consumption during the heating and cooling processes. Modern facilities are implementing heat recovery systems that capture and repurpose thermal energy from quenching operations, significantly reducing overall environmental impact while improving operational efficiency.

Regulatory compliance represents an increasingly important factor in quenching technology selection. Companies must navigate complex environmental regulations that vary by region but generally trend toward stricter emissions controls and waste management requirements. Forward-thinking manufacturers are adopting life cycle assessment approaches to evaluate the comprehensive environmental impact of their quenching processes, from raw material extraction through disposal or recycling of spent quenchants.

The industry continues to invest in research and development of more sustainable quenching technologies that balance technical performance requirements with environmental responsibility. These innovations include bio-based quenchants derived from renewable resources and advanced process controls that optimize quenching parameters to minimize both cracking risks and environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!