High Carbon Steel Heat Treatment Windows For Target Hardness

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Carbon Steel Heat Treatment Background and Objectives

Heat treatment of high carbon steel has been a cornerstone of metallurgical engineering since the early industrial revolution. With carbon content typically ranging from 0.60% to 1.50%, high carbon steels offer exceptional hardness and wear resistance when properly heat treated. The evolution of heat treatment techniques has progressed from primitive forge hardening to precisely controlled industrial processes utilizing advanced furnace technologies and computational modeling.

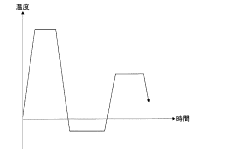

The technological trajectory has moved from empirical trial-and-error approaches toward scientifically informed methodologies based on time-temperature-transformation (TTT) and continuous cooling transformation (CCT) diagrams. These advancements have enabled manufacturers to achieve increasingly precise control over microstructural development and resultant mechanical properties, particularly hardness.

Current industry demands require tight tolerances for hardness specifications across various applications including cutting tools, dies, bearings, and high-performance mechanical components. The ability to consistently achieve target hardness values within narrow windows (often ±1-2 HRC) represents a significant competitive advantage in high-precision manufacturing sectors.

The primary objective of this technical research is to establish optimal heat treatment parameters that reliably produce specified target hardness values in high carbon steels. This involves identifying precise processing windows for austenitizing temperatures, soaking times, quenching media selection, and tempering protocols that consistently yield the desired hardness while minimizing distortion and residual stress.

Secondary objectives include developing predictive models that can accurately forecast hardness outcomes based on steel composition, section thickness, and heat treatment variables. These models would significantly reduce development time and material waste during process optimization for new components or alloy variants.

Additionally, this research aims to explore the relationship between microstructural features (carbide size, distribution, and morphology) and macroscopic hardness properties. Understanding these correlations will enable more sophisticated control strategies that consider not only hardness but also toughness, wear resistance, and fatigue performance.

The technological significance extends beyond immediate manufacturing benefits to include energy efficiency improvements through optimized heating cycles, reduced scrap rates through more consistent outcomes, and enhanced product performance through tailored microstructural control. As advanced materials continue to drive innovation across industries, mastering the precise control of high carbon steel heat treatment windows represents a fundamental capability with far-reaching implications.

The technological trajectory has moved from empirical trial-and-error approaches toward scientifically informed methodologies based on time-temperature-transformation (TTT) and continuous cooling transformation (CCT) diagrams. These advancements have enabled manufacturers to achieve increasingly precise control over microstructural development and resultant mechanical properties, particularly hardness.

Current industry demands require tight tolerances for hardness specifications across various applications including cutting tools, dies, bearings, and high-performance mechanical components. The ability to consistently achieve target hardness values within narrow windows (often ±1-2 HRC) represents a significant competitive advantage in high-precision manufacturing sectors.

The primary objective of this technical research is to establish optimal heat treatment parameters that reliably produce specified target hardness values in high carbon steels. This involves identifying precise processing windows for austenitizing temperatures, soaking times, quenching media selection, and tempering protocols that consistently yield the desired hardness while minimizing distortion and residual stress.

Secondary objectives include developing predictive models that can accurately forecast hardness outcomes based on steel composition, section thickness, and heat treatment variables. These models would significantly reduce development time and material waste during process optimization for new components or alloy variants.

Additionally, this research aims to explore the relationship between microstructural features (carbide size, distribution, and morphology) and macroscopic hardness properties. Understanding these correlations will enable more sophisticated control strategies that consider not only hardness but also toughness, wear resistance, and fatigue performance.

The technological significance extends beyond immediate manufacturing benefits to include energy efficiency improvements through optimized heating cycles, reduced scrap rates through more consistent outcomes, and enhanced product performance through tailored microstructural control. As advanced materials continue to drive innovation across industries, mastering the precise control of high carbon steel heat treatment windows represents a fundamental capability with far-reaching implications.

Market Demand Analysis for Precision Heat-Treated Steel

The global market for precision heat-treated high carbon steel continues to expand significantly, driven by increasing demand across multiple industrial sectors. Automotive manufacturing represents the largest market segment, accounting for approximately 35% of total consumption, with requirements for critical components such as gears, shafts, and bearings that demand precise hardness specifications. The aerospace industry follows closely, where high-performance steel components with tightly controlled hardness properties are essential for safety-critical applications.

Recent market research indicates that the precision heat treatment services market is growing at a compound annual rate of 5.7%, expected to reach $29.4 billion by 2027. This growth is particularly pronounced in regions with strong manufacturing bases, including East Asia, North America, and Western Europe. China has emerged as both the largest producer and consumer of heat-treated high carbon steel, followed by the United States and Germany.

The market is increasingly segmented by application-specific requirements, with premium pricing for heat treatment processes that can consistently achieve narrow hardness windows. Industries are willing to pay 15-20% more for heat treatment services that can guarantee hardness variations of less than ±1 HRC (Rockwell C scale) across components, reflecting the critical nature of these specifications in high-value applications.

Customer demand patterns show a clear shift toward more stringent quality requirements. Five years ago, typical hardness tolerance specifications were ±3 HRC; today's standard specifications often require ±2 HRC, with premium applications demanding ±1 HRC or better. This trend is driving significant investment in advanced heat treatment technologies and process control systems.

The market also shows increasing demand for environmentally sustainable heat treatment processes. Customers are seeking solutions that reduce energy consumption and carbon emissions while maintaining precise hardness control. This has led to the development of more efficient furnace technologies and alternative heating methods, creating a new competitive dimension in the market.

Supply chain considerations are becoming more prominent, with manufacturers increasingly preferring local heat treatment providers to reduce logistics costs and lead times. This trend has accelerated following global supply chain disruptions, creating opportunities for regional heat treatment specialists who can offer precision services with quick turnaround times.

Recent market research indicates that the precision heat treatment services market is growing at a compound annual rate of 5.7%, expected to reach $29.4 billion by 2027. This growth is particularly pronounced in regions with strong manufacturing bases, including East Asia, North America, and Western Europe. China has emerged as both the largest producer and consumer of heat-treated high carbon steel, followed by the United States and Germany.

The market is increasingly segmented by application-specific requirements, with premium pricing for heat treatment processes that can consistently achieve narrow hardness windows. Industries are willing to pay 15-20% more for heat treatment services that can guarantee hardness variations of less than ±1 HRC (Rockwell C scale) across components, reflecting the critical nature of these specifications in high-value applications.

Customer demand patterns show a clear shift toward more stringent quality requirements. Five years ago, typical hardness tolerance specifications were ±3 HRC; today's standard specifications often require ±2 HRC, with premium applications demanding ±1 HRC or better. This trend is driving significant investment in advanced heat treatment technologies and process control systems.

The market also shows increasing demand for environmentally sustainable heat treatment processes. Customers are seeking solutions that reduce energy consumption and carbon emissions while maintaining precise hardness control. This has led to the development of more efficient furnace technologies and alternative heating methods, creating a new competitive dimension in the market.

Supply chain considerations are becoming more prominent, with manufacturers increasingly preferring local heat treatment providers to reduce logistics costs and lead times. This trend has accelerated following global supply chain disruptions, creating opportunities for regional heat treatment specialists who can offer precision services with quick turnaround times.

Current Challenges in High Carbon Steel Heat Treatment

Despite significant advancements in heat treatment technologies, high carbon steel heat treatment processes continue to face several critical challenges that impact manufacturing efficiency, product quality, and cost-effectiveness. The primary challenge remains the narrow processing window for achieving target hardness values, which requires precise control of multiple parameters simultaneously.

Temperature control precision presents a significant hurdle, as high carbon steels demand heating accuracy within ±5°C to achieve consistent microstructural development. Even minor temperature fluctuations can lead to incomplete austenization or excessive grain growth, both detrimental to final hardness properties. This challenge is particularly pronounced in large-scale industrial operations where maintaining uniform temperature distribution throughout bulky components proves difficult.

Time-dependent transformation kinetics further complicates the process. The relationship between holding time, cooling rate, and resultant microstructure is highly non-linear in high carbon steels, creating a complex processing matrix that varies significantly with minor compositional differences. Manufacturers struggle to develop robust time-temperature profiles that accommodate these sensitivities while maintaining production efficiency.

Distortion and cracking during quenching represent another major challenge. The high carbon content that enables superior hardness also increases susceptibility to thermal shock during rapid cooling. This creates a technical paradox where the cooling rates necessary for optimal hardness often induce unacceptable levels of internal stress, leading to dimensional instability or catastrophic failure.

Retained austenite management remains problematic, particularly when targeting specific hardness ranges. The incomplete transformation of austenite during quenching creates microstructural instability that can lead to dimensional changes and hardness variations during service. Current processes struggle to consistently minimize retained austenite without compromising other mechanical properties.

Batch-to-batch variability in raw material composition, particularly regarding trace elements and inclusions, significantly impacts heat treatment response. Even within specification limits, minor variations in manganese, chromium, or silicon content can shift hardening behavior unpredictably, requiring constant process adjustments that reduce manufacturing efficiency.

Energy consumption and environmental considerations pose additional challenges as regulatory pressures increase. Traditional heat treatment methods for high carbon steels are energy-intensive, and developing more sustainable approaches without compromising hardness targets remains difficult. This challenge is compounded by the industry's conservative approach to adopting new technologies without extensive validation.

Temperature control precision presents a significant hurdle, as high carbon steels demand heating accuracy within ±5°C to achieve consistent microstructural development. Even minor temperature fluctuations can lead to incomplete austenization or excessive grain growth, both detrimental to final hardness properties. This challenge is particularly pronounced in large-scale industrial operations where maintaining uniform temperature distribution throughout bulky components proves difficult.

Time-dependent transformation kinetics further complicates the process. The relationship between holding time, cooling rate, and resultant microstructure is highly non-linear in high carbon steels, creating a complex processing matrix that varies significantly with minor compositional differences. Manufacturers struggle to develop robust time-temperature profiles that accommodate these sensitivities while maintaining production efficiency.

Distortion and cracking during quenching represent another major challenge. The high carbon content that enables superior hardness also increases susceptibility to thermal shock during rapid cooling. This creates a technical paradox where the cooling rates necessary for optimal hardness often induce unacceptable levels of internal stress, leading to dimensional instability or catastrophic failure.

Retained austenite management remains problematic, particularly when targeting specific hardness ranges. The incomplete transformation of austenite during quenching creates microstructural instability that can lead to dimensional changes and hardness variations during service. Current processes struggle to consistently minimize retained austenite without compromising other mechanical properties.

Batch-to-batch variability in raw material composition, particularly regarding trace elements and inclusions, significantly impacts heat treatment response. Even within specification limits, minor variations in manganese, chromium, or silicon content can shift hardening behavior unpredictably, requiring constant process adjustments that reduce manufacturing efficiency.

Energy consumption and environmental considerations pose additional challenges as regulatory pressures increase. Traditional heat treatment methods for high carbon steels are energy-intensive, and developing more sustainable approaches without compromising hardness targets remains difficult. This challenge is compounded by the industry's conservative approach to adopting new technologies without extensive validation.

Current Heat Treatment Methods for Target Hardness Achievement

01 Heat treatment processes for high carbon steel hardness

Various heat treatment processes can be applied to high carbon steel to enhance its hardness properties. These processes include quenching, tempering, and annealing, which alter the microstructure of the steel to achieve desired hardness levels. The specific temperature, duration, and cooling rate of these treatments significantly impact the final hardness properties, allowing for customization based on application requirements.- Heat treatment methods for high carbon steel hardness: Various heat treatment processes can be applied to high carbon steel to enhance its hardness properties. These methods include quenching, tempering, annealing, and normalizing. The specific temperature, duration, and cooling rate during these processes significantly influence the final hardness achieved. Proper heat treatment can optimize the microstructure of high carbon steel, resulting in improved hardness while maintaining other mechanical properties.

- Carbon content influence on steel hardness: The carbon content in steel directly affects its hardness characteristics. High carbon steel, typically containing 0.55% to 1.5% carbon, can achieve significantly higher hardness levels compared to medium or low carbon steels. The increased carbon content enables the formation of carbides and martensite structures during heat treatment, which are primarily responsible for the enhanced hardness properties. The relationship between carbon percentage and achievable hardness follows a generally proportional trend up to the eutectoid composition.

- Alloying elements effect on high carbon steel hardness: Various alloying elements can be added to high carbon steel to further enhance its hardness properties. Elements such as chromium, manganese, molybdenum, and vanadium form complex carbides that contribute to increased hardness. These alloying elements can also improve hardenability, allowing the steel to achieve higher hardness even with slower cooling rates or in larger cross-sections. The specific combination and proportion of alloying elements can be tailored to achieve desired hardness levels for particular applications.

- Surface hardening techniques for high carbon steel: Surface hardening techniques can be applied to high carbon steel to create components with hard, wear-resistant surfaces while maintaining tougher, more ductile cores. Methods include carburizing, nitriding, carbonitriding, induction hardening, and flame hardening. These processes modify the surface composition or structure of the steel, resulting in localized hardness enhancement. Surface hardening is particularly valuable for components that require wear resistance at the surface while maintaining impact resistance in the core.

- Hardness testing and measurement methods for high carbon steel: Various testing methods are employed to accurately measure and characterize the hardness of high carbon steel. Common techniques include Rockwell, Brinell, Vickers, and microhardness testing. Each method has specific applications depending on the material thickness, expected hardness range, and required precision. Advanced techniques may include mapping hardness distribution across heat-treated components or measuring hardness at different depths to evaluate the effectiveness of surface hardening treatments. Proper hardness testing is essential for quality control and ensuring that high carbon steel components meet design specifications.

02 Carbon content influence on steel hardness

The carbon content in steel directly affects its hardness properties. High carbon steel, typically containing 0.55% to 1.5% carbon, exhibits significantly higher hardness potential than medium or low carbon variants. The increased carbon content enables the formation of more carbides and martensite structures during heat treatment, resulting in superior hardness and wear resistance, though often at the expense of ductility and toughness.Expand Specific Solutions03 Alloying elements for enhanced hardness

The addition of specific alloying elements to high carbon steel can significantly enhance its hardness properties. Elements such as chromium, manganese, molybdenum, and vanadium form complex carbides that contribute to increased hardness and wear resistance. These alloying elements also affect hardenability, allowing for deeper hardening and more uniform hardness throughout the steel component.Expand Specific Solutions04 Surface hardening techniques for high carbon steel

Various surface hardening techniques can be applied to high carbon steel to achieve enhanced hardness in specific areas while maintaining core properties. These techniques include induction hardening, flame hardening, carburizing, and nitriding. Surface hardening creates a wear-resistant outer layer with high hardness while preserving the toughness of the inner core, making it ideal for components subjected to high wear and impact loads.Expand Specific Solutions05 Microstructure control for optimized hardness

Controlling the microstructure of high carbon steel is crucial for achieving optimal hardness properties. Techniques such as grain refinement, controlled cooling, and specific phase transformations can be employed to develop desired microstructures like fine pearlite, bainite, or tempered martensite. The resulting microstructure significantly influences not only hardness but also other mechanical properties such as strength, toughness, and wear resistance.Expand Specific Solutions

Major Industry Players in Heat Treatment Technology

The high carbon steel heat treatment market is in a mature growth phase, characterized by established technologies and steady demand across automotive, industrial, and construction sectors. The global market size is estimated at $15-20 billion with projected 4-5% annual growth through 2030. Leading players include integrated steel manufacturers like NIPPON STEEL, JFE Steel, POSCO Holdings, and thyssenkrupp Steel Europe, who have developed proprietary heat treatment technologies for achieving precise hardness specifications. Technical maturity varies, with Japanese and European companies (Kobe Steel, Sumitomo Metal Industries) demonstrating advanced capabilities in controlled cooling processes and microstructure optimization. Research institutions like University of Science & Technology Beijing and Centre de Recherches Métallurgiques provide innovation support, while specialized equipment manufacturers such as Hitachi and Komatsu offer complementary technologies for industrial implementation.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed advanced heat treatment protocols for high carbon steel that precisely control the time-temperature relationship during austenitizing, quenching, and tempering processes. Their technology utilizes computer-controlled continuous annealing lines with precise temperature control within ±3°C across the entire steel sheet. For high carbon steels (0.60-1.0% C), they've established specific heat treatment windows that achieve target hardness values between 58-65 HRC while maintaining optimal microstructural balance. Their process involves austenitization at 820-860°C followed by controlled quenching rates (20-80°C/s) and tempering at 150-300°C depending on the desired hardness-toughness balance. This approach minimizes distortion and residual stress while maximizing hardness uniformity throughout the component.

Strengths: Superior microstructural control resulting in consistent hardness distribution; excellent balance between hardness and toughness; minimized distortion during heat treatment. Weaknesses: Requires sophisticated equipment with precise temperature control capabilities; process parameters must be carefully calibrated for each specific steel composition.

JFE Steel Corp.

Technical Solution: JFE Steel has developed a sophisticated approach to high carbon steel heat treatment that focuses on optimizing the austenitizing temperature and time to control dissolved carbon content prior to quenching. Their research has established specific heat treatment windows for different carbon contents (0.55-1.0%) that correlate austenitizing parameters with achievable hardness ranges. For steels containing 0.8-0.9% carbon, they've determined that austenitizing at 800-830°C for 15-30 minutes followed by oil quenching can reliably achieve hardness values of 62-65 HRC. Their process incorporates a proprietary "differential quenching" technique where cooling rates are varied during the quenching process—initially rapid (>100°C/s) to avoid the pearlite nose of the TTT curve, then moderated (30-50°C/s) through the martensite transformation range to minimize distortion and cracking risks. This approach has been particularly successful for large cross-section components where hardness uniformity is challenging to achieve.

Strengths: Excellent hardness uniformity throughout varying section thicknesses; reduced cracking tendency in complex geometries; consistent mechanical properties. Weaknesses: Requires precise temperature control and timing; process parameters must be carefully calibrated for each specific component geometry.

Key Technical Innovations in Hardness Control

Heat treatment hardening type high carbon steel sheet and manufacturing method thereof

PatentActiveJP2021505772A

Innovation

- A heat-hardening high-carbon steel sheet with optimized alloy composition (C: 0.65-1.0%, Si: 0.5% or less, Mn: 0.1-2.0%, P: 0.05% or less, S: 0.03% or less) and controlled heat treatment, including heating above Ae3°C, cryogenic cooling, and subsequent heat treatment, to achieve a microstructure with 85% martensite, 5% retained austenite or less, and 10% or less carbide and ferrite phases.

Heat treatment method for ultra-high-carbon bearing steel

PatentWO2018107316A1

Innovation

- A heat treatment method for ultra-high carbon bearing steel is adopted, including annealing, normalizing, primary quenching, secondary quenching and tempering, and through solid carburizing treatment, the temperature and time are strictly controlled to ensure the comprehensive performance of the bearing steel. .

Material Science Considerations for Optimal Heat Treatment

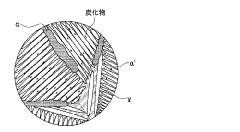

The fundamental properties of high carbon steel significantly influence the heat treatment process and achievable hardness levels. High carbon steels, typically containing 0.60-1.00% carbon, possess excellent hardenability due to carbon's ability to form hard martensite structures during quenching. The microstructural composition before heat treatment—including ferrite, pearlite, and carbide distributions—establishes the baseline for transformation during the heating cycle.

Alloying elements present in high carbon steels play crucial roles in determining heat treatment parameters. Elements such as chromium, molybdenum, and vanadium form stable carbides that resist dissolution during austenitizing, requiring higher temperatures or longer soaking times. Manganese and nickel, conversely, enhance hardenability by slowing critical cooling rates, effectively widening the processing window for achieving target hardness values.

Grain size considerations represent another critical material science factor. Finer initial grain structures generally yield superior mechanical properties after heat treatment, including improved toughness without sacrificing hardness. The austenitizing temperature must be carefully controlled to prevent excessive grain growth while ensuring complete dissolution of carbon into the austenite matrix—a delicate balance that directly impacts final hardness uniformity.

Prior processing history introduces significant variables affecting heat treatment response. Cold-worked materials contain stored energy in the form of dislocations, which can accelerate phase transformations during heating. This necessitates adjustments to standard heat treatment protocols, particularly in tempering cycles, to achieve consistent hardness results across different production batches.

Carbide morphology and distribution represent perhaps the most critical microstructural features influencing hardness development. Primary carbides that remain undissolved during austenitizing serve as both hardness contributors and potential fracture initiation sites. The size, shape, and distribution of these carbides must be carefully managed through proper austenitizing temperatures and times to optimize the hardness-toughness balance.

Homogeneity across the material cross-section presents challenges, particularly in larger sections where thermal gradients during heating and cooling create variable microstructures. Advanced material science approaches, including controlled heating rates and stepped austenitizing cycles, can minimize these variations to achieve more uniform hardness profiles throughout the component volume.

Alloying elements present in high carbon steels play crucial roles in determining heat treatment parameters. Elements such as chromium, molybdenum, and vanadium form stable carbides that resist dissolution during austenitizing, requiring higher temperatures or longer soaking times. Manganese and nickel, conversely, enhance hardenability by slowing critical cooling rates, effectively widening the processing window for achieving target hardness values.

Grain size considerations represent another critical material science factor. Finer initial grain structures generally yield superior mechanical properties after heat treatment, including improved toughness without sacrificing hardness. The austenitizing temperature must be carefully controlled to prevent excessive grain growth while ensuring complete dissolution of carbon into the austenite matrix—a delicate balance that directly impacts final hardness uniformity.

Prior processing history introduces significant variables affecting heat treatment response. Cold-worked materials contain stored energy in the form of dislocations, which can accelerate phase transformations during heating. This necessitates adjustments to standard heat treatment protocols, particularly in tempering cycles, to achieve consistent hardness results across different production batches.

Carbide morphology and distribution represent perhaps the most critical microstructural features influencing hardness development. Primary carbides that remain undissolved during austenitizing serve as both hardness contributors and potential fracture initiation sites. The size, shape, and distribution of these carbides must be carefully managed through proper austenitizing temperatures and times to optimize the hardness-toughness balance.

Homogeneity across the material cross-section presents challenges, particularly in larger sections where thermal gradients during heating and cooling create variable microstructures. Advanced material science approaches, including controlled heating rates and stepped austenitizing cycles, can minimize these variations to achieve more uniform hardness profiles throughout the component volume.

Quality Control Standards for Heat-Treated High Carbon Steel

Quality control standards for heat-treated high carbon steel must be rigorously established and maintained to ensure consistent mechanical properties and performance characteristics. These standards typically encompass multiple testing methodologies that verify the achievement of target hardness values within specified tolerance ranges. The primary quality control measures include hardness testing (Rockwell, Brinell, or Vickers), microstructural examination, and non-destructive testing protocols.

Hardness testing represents the cornerstone of quality verification, with most industrial applications requiring measurements at multiple points across the component to ensure uniform heat treatment penetration. For high carbon steels (0.60-1.00% carbon content), acceptable hardness variations typically should not exceed ±2 HRC (Rockwell C) for critical applications. More stringent aerospace or automotive safety components may require even tighter tolerances of ±1 HRC.

Microstructural examination through metallographic analysis provides crucial verification of proper phase transformation. Quality standards typically specify the expected microstructure (e.g., tempered martensite, bainite, or specific carbide distributions) and acceptable grain size ranges. ASTM E112 often serves as the reference standard for grain size determination, with most high-performance applications requiring fine grain structures between 7-10 on the ASTM scale.

Statistical process control (SPC) methodologies have become increasingly important in modern heat treatment operations. Continuous monitoring through control charts helps identify process drift before parts fall outside specification limits. Industry standards typically require Cpk values (process capability index) of at least 1.33 for general applications, while safety-critical components may demand Cpk values of 1.67 or higher.

Documentation requirements constitute another critical aspect of quality control standards. Complete heat treatment records must include furnace temperature profiles, soak times, cooling rates, and all test results. Traceability to specific heat treatment batches must be maintained throughout the product lifecycle, particularly for aerospace, medical, and automotive safety applications.

Calibration standards for testing equipment represent a frequently overlooked but essential component of quality control. ASTM E18 governs hardness tester calibration, requiring verification at defined intervals using certified test blocks. Similarly, temperature measurement devices must be calibrated according to standards like AMS2750 with specific requirements for thermocouple placement, system accuracy tests, and temperature uniformity surveys.

Non-conformance procedures must be clearly defined within the quality control framework. These procedures should specify containment actions, root cause analysis methodologies, and disposition options for heat-treated components that fall outside target hardness windows. Statistical evaluation of non-conforming parts often provides valuable insights for process improvement initiatives.

Hardness testing represents the cornerstone of quality verification, with most industrial applications requiring measurements at multiple points across the component to ensure uniform heat treatment penetration. For high carbon steels (0.60-1.00% carbon content), acceptable hardness variations typically should not exceed ±2 HRC (Rockwell C) for critical applications. More stringent aerospace or automotive safety components may require even tighter tolerances of ±1 HRC.

Microstructural examination through metallographic analysis provides crucial verification of proper phase transformation. Quality standards typically specify the expected microstructure (e.g., tempered martensite, bainite, or specific carbide distributions) and acceptable grain size ranges. ASTM E112 often serves as the reference standard for grain size determination, with most high-performance applications requiring fine grain structures between 7-10 on the ASTM scale.

Statistical process control (SPC) methodologies have become increasingly important in modern heat treatment operations. Continuous monitoring through control charts helps identify process drift before parts fall outside specification limits. Industry standards typically require Cpk values (process capability index) of at least 1.33 for general applications, while safety-critical components may demand Cpk values of 1.67 or higher.

Documentation requirements constitute another critical aspect of quality control standards. Complete heat treatment records must include furnace temperature profiles, soak times, cooling rates, and all test results. Traceability to specific heat treatment batches must be maintained throughout the product lifecycle, particularly for aerospace, medical, and automotive safety applications.

Calibration standards for testing equipment represent a frequently overlooked but essential component of quality control. ASTM E18 governs hardness tester calibration, requiring verification at defined intervals using certified test blocks. Similarly, temperature measurement devices must be calibrated according to standards like AMS2750 with specific requirements for thermocouple placement, system accuracy tests, and temperature uniformity surveys.

Non-conformance procedures must be clearly defined within the quality control framework. These procedures should specify containment actions, root cause analysis methodologies, and disposition options for heat-treated components that fall outside target hardness windows. Statistical evaluation of non-conforming parts often provides valuable insights for process improvement initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!