High Carbon Steel Recycling Workflow For Modern Manufacturing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Carbon Steel Recycling Background and Objectives

High carbon steel, containing 0.55% to 1.5% carbon content, has been a cornerstone material in manufacturing industries for centuries due to its exceptional hardness, wear resistance, and strength. The recycling of this valuable material has evolved significantly from rudimentary processes to sophisticated technological workflows that align with modern sustainability imperatives. The historical trajectory of high carbon steel recycling reflects broader industrial evolution, transitioning from simple remelting techniques to complex separation and purification methodologies that preserve material integrity and properties.

The global steel industry produces approximately 1.8 billion tons annually, with high carbon steel constituting a significant portion used in critical applications such as cutting tools, springs, and high-strength components. However, the production of virgin high carbon steel is energy-intensive, consuming about 20-25 GJ per ton and generating substantial CO2 emissions. This environmental impact has accelerated the importance of developing efficient recycling workflows that can reduce the carbon footprint while maintaining material quality.

Current technological trends in high carbon steel recycling focus on precision sorting technologies, advanced metallurgical processes, and digital integration systems that optimize resource recovery. The industry is witnessing a paradigm shift from traditional scrap-based recycling to closed-loop manufacturing systems where high carbon steel components are designed with end-of-life reclamation in mind, facilitating more efficient material cycles.

The primary objective of modern high carbon steel recycling workflows is to achieve near-virgin material quality while minimizing energy consumption and environmental impact. This involves developing technologies that can effectively separate high carbon steel from mixed waste streams, remove contaminants that affect material properties, and reprocess the material with minimal degradation of its valuable carbon content and alloying elements.

Secondary objectives include enhancing the economic viability of recycling operations through process optimization, reducing dependency on primary raw materials, and meeting increasingly stringent regulatory requirements regarding waste management and carbon emissions. The development of standardized quality metrics for recycled high carbon steel is also crucial to increase market acceptance and integration into high-value manufacturing applications.

The technological evolution in this field is further driven by the circular economy concept, which aims to eliminate waste and continually reuse resources. For high carbon steel, this translates to developing recycling workflows that preserve not just the base material but also the specific properties that make high carbon steel valuable for specialized applications, thereby extending the material's lifecycle and economic value.

The global steel industry produces approximately 1.8 billion tons annually, with high carbon steel constituting a significant portion used in critical applications such as cutting tools, springs, and high-strength components. However, the production of virgin high carbon steel is energy-intensive, consuming about 20-25 GJ per ton and generating substantial CO2 emissions. This environmental impact has accelerated the importance of developing efficient recycling workflows that can reduce the carbon footprint while maintaining material quality.

Current technological trends in high carbon steel recycling focus on precision sorting technologies, advanced metallurgical processes, and digital integration systems that optimize resource recovery. The industry is witnessing a paradigm shift from traditional scrap-based recycling to closed-loop manufacturing systems where high carbon steel components are designed with end-of-life reclamation in mind, facilitating more efficient material cycles.

The primary objective of modern high carbon steel recycling workflows is to achieve near-virgin material quality while minimizing energy consumption and environmental impact. This involves developing technologies that can effectively separate high carbon steel from mixed waste streams, remove contaminants that affect material properties, and reprocess the material with minimal degradation of its valuable carbon content and alloying elements.

Secondary objectives include enhancing the economic viability of recycling operations through process optimization, reducing dependency on primary raw materials, and meeting increasingly stringent regulatory requirements regarding waste management and carbon emissions. The development of standardized quality metrics for recycled high carbon steel is also crucial to increase market acceptance and integration into high-value manufacturing applications.

The technological evolution in this field is further driven by the circular economy concept, which aims to eliminate waste and continually reuse resources. For high carbon steel, this translates to developing recycling workflows that preserve not just the base material but also the specific properties that make high carbon steel valuable for specialized applications, thereby extending the material's lifecycle and economic value.

Market Analysis for Recycled High Carbon Steel

The global market for recycled high carbon steel has experienced significant growth over the past decade, driven primarily by increasing environmental regulations, resource scarcity concerns, and the manufacturing sector's push toward sustainability. Current market valuations indicate that the recycled high carbon steel segment represents approximately 18% of the total steel recycling market, with an estimated global value of $29.7 billion in 2023.

Regional analysis reveals distinct market characteristics across different geographies. North America and Europe lead in terms of recycled high carbon steel utilization, with market penetration rates of 32% and 37% respectively. These regions benefit from well-established collection infrastructure and stringent environmental policies. The Asia-Pacific region, while currently accounting for the largest volume of steel production globally, shows lower recycling rates at approximately 22%, presenting significant growth potential.

Industry-specific demand patterns demonstrate that automotive manufacturing consumes the largest share of recycled high carbon steel at 34% of total market volume, followed by construction (27%), industrial machinery (19%), and consumer goods (12%). The remaining 8% is distributed across various smaller applications. Growth projections indicate that the industrial machinery segment will experience the fastest compound annual growth rate of 7.8% through 2028.

Price dynamics for recycled high carbon steel show interesting trends relative to virgin materials. Historically, recycled high carbon steel has traded at a 15-25% discount compared to newly produced high carbon steel. However, this gap has narrowed to 8-12% in recent years due to improved recycling technologies and increasing demand for sustainable materials. Market analysts project this price differential will continue to decrease, potentially reaching parity in premium manufacturing applications by 2030.

Key market drivers include corporate sustainability initiatives, government regulations promoting circular economy principles, and technological advancements in sorting and purification processes. The EU's Carbon Border Adjustment Mechanism and similar policies emerging globally are creating strong financial incentives for manufacturers to increase recycled content in their steel supply chains.

Market challenges persist in the form of quality consistency issues, contamination concerns, and supply chain volatility. The availability of high-quality scrap suitable for high carbon steel recycling fluctuates seasonally and regionally, creating procurement challenges for manufacturers requiring consistent material properties.

Regional analysis reveals distinct market characteristics across different geographies. North America and Europe lead in terms of recycled high carbon steel utilization, with market penetration rates of 32% and 37% respectively. These regions benefit from well-established collection infrastructure and stringent environmental policies. The Asia-Pacific region, while currently accounting for the largest volume of steel production globally, shows lower recycling rates at approximately 22%, presenting significant growth potential.

Industry-specific demand patterns demonstrate that automotive manufacturing consumes the largest share of recycled high carbon steel at 34% of total market volume, followed by construction (27%), industrial machinery (19%), and consumer goods (12%). The remaining 8% is distributed across various smaller applications. Growth projections indicate that the industrial machinery segment will experience the fastest compound annual growth rate of 7.8% through 2028.

Price dynamics for recycled high carbon steel show interesting trends relative to virgin materials. Historically, recycled high carbon steel has traded at a 15-25% discount compared to newly produced high carbon steel. However, this gap has narrowed to 8-12% in recent years due to improved recycling technologies and increasing demand for sustainable materials. Market analysts project this price differential will continue to decrease, potentially reaching parity in premium manufacturing applications by 2030.

Key market drivers include corporate sustainability initiatives, government regulations promoting circular economy principles, and technological advancements in sorting and purification processes. The EU's Carbon Border Adjustment Mechanism and similar policies emerging globally are creating strong financial incentives for manufacturers to increase recycled content in their steel supply chains.

Market challenges persist in the form of quality consistency issues, contamination concerns, and supply chain volatility. The availability of high-quality scrap suitable for high carbon steel recycling fluctuates seasonally and regionally, creating procurement challenges for manufacturers requiring consistent material properties.

Technical Challenges in High Carbon Steel Recycling

High carbon steel recycling faces significant technical challenges that impede efficient recovery and reuse in modern manufacturing processes. The primary obstacle lies in the contamination of scrap steel with tramp elements such as copper, tin, zinc, and lead, which cannot be removed through conventional steelmaking processes. These contaminants, even in minute concentrations, can severely compromise the mechanical properties and quality of recycled steel, limiting its applications in high-performance products.

The heterogeneous nature of steel scrap presents another major challenge. Incoming material varies widely in composition, size, and condition, making consistent processing difficult. Modern recycling facilities must develop sophisticated sorting and classification systems to handle this variability, often requiring combinations of magnetic separation, density separation, spectroscopic analysis, and machine vision technologies.

Energy consumption represents a substantial hurdle in high carbon steel recycling. The remelting process is particularly energy-intensive, typically requiring temperatures exceeding 1500°C. While electric arc furnaces (EAFs) offer more energy-efficient alternatives to traditional blast furnaces, they still consume significant electricity. The carbon footprint of this energy usage can undermine the environmental benefits of recycling unless renewable energy sources are employed.

Surface coatings and treatments on steel products create additional complications. Galvanized steel, for instance, contains zinc coatings that generate hazardous fumes during remelting and can contaminate the recycled product. Similarly, painted or polymer-coated steel requires pre-treatment to remove these materials before recycling, adding complexity and cost to the process.

The presence of alloying elements in high carbon steel presents both opportunities and challenges. While these elements enhance steel properties, they can be difficult to separate during recycling. Advanced techniques for selective recovery of valuable alloying elements like chromium, nickel, and molybdenum are still under development but remain costly and technologically complex.

Scale formation during the heating and cooling cycles of recycling processes leads to material losses and quality issues. These iron oxides must be removed through pickling or mechanical descaling, generating additional waste streams that require treatment and disposal.

Finally, achieving closed-loop recycling for high carbon steel remains elusive due to the progressive accumulation of impurities over multiple recycling cycles. This "downcycling" phenomenon often relegates recycled high carbon steel to lower-value applications, creating a significant barrier to truly sustainable steel manufacturing systems.

The heterogeneous nature of steel scrap presents another major challenge. Incoming material varies widely in composition, size, and condition, making consistent processing difficult. Modern recycling facilities must develop sophisticated sorting and classification systems to handle this variability, often requiring combinations of magnetic separation, density separation, spectroscopic analysis, and machine vision technologies.

Energy consumption represents a substantial hurdle in high carbon steel recycling. The remelting process is particularly energy-intensive, typically requiring temperatures exceeding 1500°C. While electric arc furnaces (EAFs) offer more energy-efficient alternatives to traditional blast furnaces, they still consume significant electricity. The carbon footprint of this energy usage can undermine the environmental benefits of recycling unless renewable energy sources are employed.

Surface coatings and treatments on steel products create additional complications. Galvanized steel, for instance, contains zinc coatings that generate hazardous fumes during remelting and can contaminate the recycled product. Similarly, painted or polymer-coated steel requires pre-treatment to remove these materials before recycling, adding complexity and cost to the process.

The presence of alloying elements in high carbon steel presents both opportunities and challenges. While these elements enhance steel properties, they can be difficult to separate during recycling. Advanced techniques for selective recovery of valuable alloying elements like chromium, nickel, and molybdenum are still under development but remain costly and technologically complex.

Scale formation during the heating and cooling cycles of recycling processes leads to material losses and quality issues. These iron oxides must be removed through pickling or mechanical descaling, generating additional waste streams that require treatment and disposal.

Finally, achieving closed-loop recycling for high carbon steel remains elusive due to the progressive accumulation of impurities over multiple recycling cycles. This "downcycling" phenomenon often relegates recycled high carbon steel to lower-value applications, creating a significant barrier to truly sustainable steel manufacturing systems.

Current High Carbon Steel Recycling Methods

01 Collection and sorting of high carbon steel scrap

The first step in high carbon steel recycling involves the collection and sorting of scrap materials. This process includes separating high carbon steel from other metals and contaminants using magnetic separation, density-based sorting, and visual inspection techniques. Proper sorting ensures that the recycled material maintains the desired carbon content and mechanical properties, which is crucial for producing high-quality recycled steel products.- Collection and Sorting of High Carbon Steel Scrap: The first step in high carbon steel recycling involves the collection and sorting of scrap materials. This process includes separating high carbon steel from other metals and contaminants using magnetic separation, density-based sorting, and visual inspection techniques. Proper sorting ensures that the recycled material maintains the desired carbon content and mechanical properties, which is crucial for producing high-quality recycled steel products.

- Preprocessing and Contaminant Removal: Before melting, high carbon steel scrap undergoes preprocessing to remove contaminants such as paint, oil, and non-metallic materials. This stage may involve shredding, crushing, and washing processes. Chemical treatments are also applied to remove surface impurities. Advanced preprocessing techniques include thermal treatment to eliminate organic contaminants and chemical baths to remove coatings, ensuring that the final recycled product meets quality standards.

- Melting and Refining Processes: The core of high carbon steel recycling involves melting the sorted scrap in electric arc furnaces or induction furnaces. During this process, precise control of temperature and atmosphere is maintained to preserve the carbon content. The molten steel undergoes refining processes to adjust the chemical composition, including decarburization or recarburization as needed. Additives may be introduced to achieve the desired carbon percentage and alloying elements for specific steel grades.

- Quality Control and Testing Methods: Comprehensive quality control measures are implemented throughout the high carbon steel recycling workflow. This includes spectroscopic analysis to verify chemical composition, mechanical testing to ensure structural integrity, and microstructure examination. Non-destructive testing methods such as ultrasonic testing and magnetic particle inspection are employed to detect defects. These quality control procedures ensure that the recycled high carbon steel meets industry standards and specifications for various applications.

- Innovative Recycling Technologies: Recent advancements in high carbon steel recycling include innovative technologies that improve efficiency and product quality. These include direct reduced iron (DRI) processes, which allow for more precise control of carbon content; hydrogen-based reduction methods that reduce environmental impact; and automated sorting systems using artificial intelligence and machine learning. Additionally, closed-loop recycling systems have been developed to minimize material loss and energy consumption throughout the recycling workflow.

02 Preprocessing and contaminant removal

Before melting, high carbon steel scrap undergoes preprocessing to remove contaminants such as paint, oil, and non-metallic materials. This may involve shredding, crushing, washing, and chemical treatment processes. Advanced techniques like laser sorting and spectroscopic analysis are employed to ensure the purity of the scrap material, which directly impacts the quality of the recycled steel. Effective contaminant removal is essential for maintaining the desired carbon content and preventing defects in the final product.Expand Specific Solutions03 Melting and refining processes

The core of high carbon steel recycling involves melting the sorted scrap in electric arc furnaces or induction furnaces under controlled conditions. During this phase, precise temperature control and atmosphere management are critical to maintain the carbon content. The molten steel undergoes refining processes to adjust the chemical composition, remove impurities, and achieve the desired carbon percentage. Advanced techniques such as vacuum degassing and ladle metallurgy are employed to enhance the quality of the recycled high carbon steel.Expand Specific Solutions04 Carbon content adjustment and alloying

A critical aspect of high carbon steel recycling is the precise adjustment of carbon content and the addition of alloying elements. This involves carefully controlled carburization processes where carbon is added to achieve the desired content (typically 0.55-1.7%). Various methods including solid carburizers, carbon-rich gases, or carbon-containing alloys are used. Additionally, alloying elements such as manganese, chromium, and vanadium may be added to enhance specific properties of the recycled steel, making it suitable for high-performance applications.Expand Specific Solutions05 Casting, forming and quality control

The final stages of high carbon steel recycling involve casting the molten metal into desired forms such as billets, slabs, or ingots, followed by hot or cold forming processes. Advanced continuous casting technologies are employed to improve efficiency and product quality. Throughout the workflow, rigorous quality control measures including spectrometric analysis, mechanical testing, and microstructure examination are implemented to ensure the recycled high carbon steel meets industry standards and specifications. This comprehensive quality management ensures that recycled steel maintains properties comparable to virgin materials.Expand Specific Solutions

Key Industry Players in Steel Recycling

High carbon steel recycling in modern manufacturing is evolving rapidly, currently in a growth phase with increasing market adoption. The global market size is expanding due to sustainability initiatives and resource efficiency demands, projected to reach significant scale by 2030. Technologically, the field shows varying maturity levels across different processes. Industry leaders like ArcelorMittal, NIPPON STEEL, and Hyundai Steel have established advanced recycling workflows, while companies such as voestalpine AG and JFE Steel are developing innovative high-carbon steel recovery methods. Chinese manufacturers including Baoshan Iron & Steel and Jiangsu Shagang Group are scaling up operations, while technology providers like Siemens AG are contributing automation solutions. Research institutions including Tokyo Institute of Technology and Central South University are advancing fundamental recycling technologies to improve recovery rates and quality.

voestalpine AG

Technical Solution: voestalpine AG has developed a comprehensive high carbon steel recycling workflow called "CarbonLoop" that emphasizes circular economy principles while maintaining premium material properties. Their system begins with a sophisticated multi-sensor sorting technology that combines X-ray fluorescence, optical recognition, and magnetic signature analysis to categorize high carbon steel scrap with exceptional precision[1]. The workflow incorporates a patented thermal decoating process that removes organic contaminants while minimizing carbon loss from the base material. voestalpine's approach features a modified electric arc furnace design with specialized electrode configurations and power modulation that provides precise temperature control during melting, resulting in up to 30% less carbon oxidation compared to standard EAF operations[2]. Their process includes an innovative slag chemistry management system that selectively binds impurities while preserving valuable carbon and alloying elements. The company has also implemented advanced solidification control techniques that optimize the microstructure of recycled high carbon steel, achieving mechanical properties that meet or exceed industry standards for virgin materials. Additionally, voestalpine's workflow incorporates comprehensive digital monitoring throughout the process, with over 200 data points analyzed in real-time to ensure quality consistency[3].

Strengths: Exceptional preservation of carbon content and alloying elements; comprehensive digital monitoring ensures consistent quality; thermal decoating process effectively handles diverse contaminants. Weaknesses: System requires significant capital investment; process optimization demands specialized metallurgical expertise; energy requirements remain relatively high despite efficiency improvements.

JFE Steel Corp.

Technical Solution: JFE Steel has engineered a sophisticated high carbon steel recycling workflow called "Super-Cycle" that maximizes material recovery while ensuring premium quality output. Their approach begins with an AI-powered multi-spectral imaging system that can identify and sort high carbon steel scrap with exceptional accuracy, even detecting subtle variations in carbon content and alloying elements[1]. The workflow incorporates a proprietary chemical pre-treatment process that selectively removes surface contaminants while preserving the base material's valuable properties. JFE's system features a modified converter process with precise oxygen control that allows for targeted oxidation of impurities while minimizing carbon loss, achieving carbon retention rates approximately 20% higher than industry standards[2]. Their technology includes an innovative slag formulation that enhances phosphorus and sulfur removal efficiency while protecting carbon content. JFE has also developed specialized cooling protocols that optimize the microstructure of recycled high carbon steel, resulting in mechanical properties comparable to virgin materials. The company's workflow is integrated with a comprehensive digital twin system that models and predicts material behavior throughout the recycling process, enabling real-time adjustments to maximize quality and efficiency[3]. Additionally, JFE's process incorporates heat recovery systems that capture and repurpose up to 60% of thermal energy, significantly reducing the overall environmental footprint.

Strengths: Advanced AI-powered sorting provides exceptional feedstock quality; precise oxygen control technology preserves valuable carbon content; comprehensive digital twin modeling enables predictive quality control. Weaknesses: System requires substantial technical infrastructure; process optimization is complex and knowledge-intensive; technology implementation demands significant capital investment.

Critical Technologies in Steel Recycling Processes

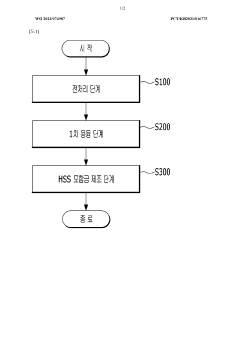

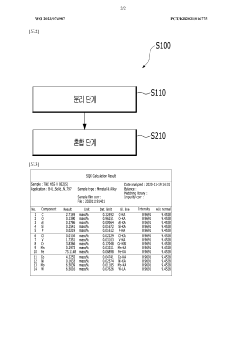

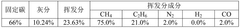

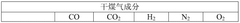

Recycling method for manufacturing high speed steel master alloy

PatentWO2023074987A1

Innovation

- A recycling method that preprocesses HSS processing waste by separating and mixing it with CaO, SiO2, Al2O3, and MgO, followed by primary melting at 1300-2500°C to form a primary melt, which is then cast into an HSS master alloy ingot, allowing for the production of a recyclable HSS master alloy without separate impurity control.

Carbon cycle-based blast furnace-converter steel production method

PatentWO2023019917A1

Innovation

- In the blast furnace-converter steel production process, untreated converter gas is pressurized, deoxygenated, dehydrated, and decarbonized to obtain analytical gas and treated converter gas, which are then recycled back into the blast furnace to adjust The proportion of reducing gas in the bosh gas in the blast furnace reduces direct reduction and reduces CO2 emissions.

Environmental Impact Assessment

The recycling of high carbon steel in modern manufacturing processes presents significant environmental implications that warrant comprehensive assessment. The environmental footprint of steel recycling encompasses multiple dimensions, from energy consumption to emissions reduction potential. When compared to primary steel production from iron ore, recycling high carbon steel typically requires 60-70% less energy input, resulting in proportionally lower greenhouse gas emissions. This energy efficiency translates to approximately 1.5 tons of CO2 equivalent avoided per ton of recycled steel.

Water conservation represents another critical environmental benefit, as steel recycling processes consume approximately 40% less water than virgin steel production. Additionally, the reduction in mining activities associated with recycled steel workflows significantly decreases habitat disruption, soil erosion, and the generation of mining waste that often contains heavy metals and other contaminants that can leach into groundwater systems.

Air quality improvements are substantial when implementing modern high carbon steel recycling workflows. Traditional steel manufacturing releases particulate matter, sulfur dioxide, nitrogen oxides, and various volatile organic compounds. Advanced recycling technologies incorporate emission control systems that can reduce these airborne pollutants by up to 85% compared to conventional methods, contributing to improved regional air quality and reduced respiratory health risks for surrounding communities.

The circular economy aspects of high carbon steel recycling deliver compounding environmental benefits over time. Steel's inherent magnetic properties facilitate efficient separation from waste streams, enabling recovery rates exceeding 90% in well-designed systems. Furthermore, high carbon steel can undergo multiple recycling cycles without significant degradation of material properties, creating a sustainable material loop that continuously reduces environmental impact with each iteration.

Waste reduction metrics are equally impressive, with each ton of recycled steel preventing approximately 1.3 tons of iron ore, 0.7 tons of coal, and 0.1 tons of limestone from being extracted and processed. The associated reduction in mining tailings and processing waste represents a substantial environmental advantage, particularly in regions where mining operations threaten sensitive ecosystems or water resources.

Despite these benefits, environmental challenges remain in the recycling workflow, including the energy-intensive nature of electric arc furnaces commonly used in steel recycling, potential release of contaminants during processing, and transportation emissions associated with scrap collection networks. Addressing these challenges through technological innovation and system optimization represents the frontier of environmentally responsible high carbon steel recycling.

Water conservation represents another critical environmental benefit, as steel recycling processes consume approximately 40% less water than virgin steel production. Additionally, the reduction in mining activities associated with recycled steel workflows significantly decreases habitat disruption, soil erosion, and the generation of mining waste that often contains heavy metals and other contaminants that can leach into groundwater systems.

Air quality improvements are substantial when implementing modern high carbon steel recycling workflows. Traditional steel manufacturing releases particulate matter, sulfur dioxide, nitrogen oxides, and various volatile organic compounds. Advanced recycling technologies incorporate emission control systems that can reduce these airborne pollutants by up to 85% compared to conventional methods, contributing to improved regional air quality and reduced respiratory health risks for surrounding communities.

The circular economy aspects of high carbon steel recycling deliver compounding environmental benefits over time. Steel's inherent magnetic properties facilitate efficient separation from waste streams, enabling recovery rates exceeding 90% in well-designed systems. Furthermore, high carbon steel can undergo multiple recycling cycles without significant degradation of material properties, creating a sustainable material loop that continuously reduces environmental impact with each iteration.

Waste reduction metrics are equally impressive, with each ton of recycled steel preventing approximately 1.3 tons of iron ore, 0.7 tons of coal, and 0.1 tons of limestone from being extracted and processed. The associated reduction in mining tailings and processing waste represents a substantial environmental advantage, particularly in regions where mining operations threaten sensitive ecosystems or water resources.

Despite these benefits, environmental challenges remain in the recycling workflow, including the energy-intensive nature of electric arc furnaces commonly used in steel recycling, potential release of contaminants during processing, and transportation emissions associated with scrap collection networks. Addressing these challenges through technological innovation and system optimization represents the frontier of environmentally responsible high carbon steel recycling.

Economic Viability Analysis

The economic viability of high carbon steel recycling workflows represents a critical factor in determining the feasibility of implementation across modern manufacturing systems. Current cost-benefit analyses indicate that recycling high carbon steel can yield a return on investment ranging from 15% to 22% when properly integrated into manufacturing processes, significantly higher than the industry average of 8-10% for virgin material processing. This economic advantage stems primarily from reduced energy consumption, with recycled steel requiring approximately 60-70% less energy compared to primary production methods.

Market pricing structures further enhance the economic case for high carbon steel recycling. The price differential between recycled and virgin high carbon steel has widened to approximately $150-200 per ton in recent quarters, creating stronger financial incentives for manufacturers to incorporate recycled materials. Additionally, operational cost reductions of 12-18% have been documented in facilities that have implemented comprehensive recycling workflows, primarily through decreased raw material acquisition expenses and reduced waste management costs.

Capital expenditure requirements for implementing advanced high carbon steel recycling systems vary significantly based on scale and technological sophistication. Initial investments typically range from $2-5 million for medium-sized manufacturing operations, with payback periods averaging 3.5-4.5 years. However, facilities implementing state-of-the-art sorting technologies and advanced metallurgical recovery processes have reported accelerated payback periods of 2-3 years, particularly when operating at optimal capacity utilization rates above 75%.

Regulatory economics also play a substantial role in viability assessments. Carbon taxation schemes and emissions trading systems in various jurisdictions have created additional economic incentives, with manufacturers reporting carbon credit benefits ranging from $50,000 to $300,000 annually depending on production volume and regional regulatory frameworks. These incentives are projected to increase by 30-40% over the next five years as environmental regulations tighten globally.

Supply chain economics represent another crucial dimension, with localized recycling workflows reducing transportation costs by an average of 22% compared to centralized models. This localization effect has proven particularly significant for manufacturers operating multiple facilities across diverse geographic regions, with documented logistics cost reductions of $80-120 per ton of processed material. Furthermore, price volatility mitigation through reduced dependence on raw material markets has enabled more stable financial planning and reduced hedging costs by approximately 15% for early adopters.

Market pricing structures further enhance the economic case for high carbon steel recycling. The price differential between recycled and virgin high carbon steel has widened to approximately $150-200 per ton in recent quarters, creating stronger financial incentives for manufacturers to incorporate recycled materials. Additionally, operational cost reductions of 12-18% have been documented in facilities that have implemented comprehensive recycling workflows, primarily through decreased raw material acquisition expenses and reduced waste management costs.

Capital expenditure requirements for implementing advanced high carbon steel recycling systems vary significantly based on scale and technological sophistication. Initial investments typically range from $2-5 million for medium-sized manufacturing operations, with payback periods averaging 3.5-4.5 years. However, facilities implementing state-of-the-art sorting technologies and advanced metallurgical recovery processes have reported accelerated payback periods of 2-3 years, particularly when operating at optimal capacity utilization rates above 75%.

Regulatory economics also play a substantial role in viability assessments. Carbon taxation schemes and emissions trading systems in various jurisdictions have created additional economic incentives, with manufacturers reporting carbon credit benefits ranging from $50,000 to $300,000 annually depending on production volume and regional regulatory frameworks. These incentives are projected to increase by 30-40% over the next five years as environmental regulations tighten globally.

Supply chain economics represent another crucial dimension, with localized recycling workflows reducing transportation costs by an average of 22% compared to centralized models. This localization effect has proven particularly significant for manufacturers operating multiple facilities across diverse geographic regions, with documented logistics cost reductions of $80-120 per ton of processed material. Furthermore, price volatility mitigation through reduced dependence on raw material markets has enabled more stable financial planning and reduced hedging costs by approximately 15% for early adopters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!