High Carbon Steel Spring Design: Case Studies And Performance Metrics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Carbon Steel Spring Evolution and Design Objectives

High carbon steel springs have evolved significantly over the past century, transforming from rudimentary mechanical components to precisely engineered elements critical to numerous industrial applications. The journey began in the early 20th century when metallurgical advancements enabled the consistent production of high carbon steel with carbon content typically ranging from 0.60% to 0.95%. This material composition provided the essential combination of strength and elasticity required for effective spring performance.

The 1950s marked a pivotal era with the introduction of controlled heat treatment processes, allowing manufacturers to optimize the microstructure of high carbon steel springs. This period saw the emergence of standardized testing methodologies and the establishment of the first comprehensive performance metrics, laying the groundwork for modern spring design principles.

By the 1980s, computer-aided design revolutionized spring engineering, enabling precise calculations of load-bearing capacities, fatigue resistance, and dimensional stability under varying conditions. This technological leap facilitated the development of application-specific spring designs with predictable performance characteristics across diverse operating environments.

Recent decades have witnessed the integration of advanced surface treatments and coating technologies to enhance corrosion resistance and reduce friction, significantly extending service life in demanding applications. Concurrently, the refinement of steel composition through micro-alloying techniques has yielded springs with superior fatigue resistance and higher operating temperature capabilities.

The current technological trajectory focuses on achieving optimal balance between material efficiency and performance reliability. Design objectives now encompass not only traditional mechanical parameters but also considerations for environmental sustainability, manufacturing efficiency, and total lifecycle costs. Engineers are increasingly employing computational simulation tools to predict spring behavior under complex loading scenarios and environmental conditions.

Contemporary high carbon steel spring design aims to meet several critical objectives: maximizing fatigue life under cyclic loading conditions; ensuring dimensional stability across wide temperature ranges; minimizing material usage while maintaining required performance specifications; and optimizing manufacturability for cost-effective production at scale.

The evolution continues with emerging research into nano-structured high carbon steels and precision-controlled microstructures, promising springs with unprecedented combinations of strength, elasticity, and durability. These advancements are particularly relevant for high-stress applications in automotive, aerospace, and industrial machinery sectors where performance requirements continue to become more demanding.

The 1950s marked a pivotal era with the introduction of controlled heat treatment processes, allowing manufacturers to optimize the microstructure of high carbon steel springs. This period saw the emergence of standardized testing methodologies and the establishment of the first comprehensive performance metrics, laying the groundwork for modern spring design principles.

By the 1980s, computer-aided design revolutionized spring engineering, enabling precise calculations of load-bearing capacities, fatigue resistance, and dimensional stability under varying conditions. This technological leap facilitated the development of application-specific spring designs with predictable performance characteristics across diverse operating environments.

Recent decades have witnessed the integration of advanced surface treatments and coating technologies to enhance corrosion resistance and reduce friction, significantly extending service life in demanding applications. Concurrently, the refinement of steel composition through micro-alloying techniques has yielded springs with superior fatigue resistance and higher operating temperature capabilities.

The current technological trajectory focuses on achieving optimal balance between material efficiency and performance reliability. Design objectives now encompass not only traditional mechanical parameters but also considerations for environmental sustainability, manufacturing efficiency, and total lifecycle costs. Engineers are increasingly employing computational simulation tools to predict spring behavior under complex loading scenarios and environmental conditions.

Contemporary high carbon steel spring design aims to meet several critical objectives: maximizing fatigue life under cyclic loading conditions; ensuring dimensional stability across wide temperature ranges; minimizing material usage while maintaining required performance specifications; and optimizing manufacturability for cost-effective production at scale.

The evolution continues with emerging research into nano-structured high carbon steels and precision-controlled microstructures, promising springs with unprecedented combinations of strength, elasticity, and durability. These advancements are particularly relevant for high-stress applications in automotive, aerospace, and industrial machinery sectors where performance requirements continue to become more demanding.

Market Analysis for High Carbon Steel Springs

The global high carbon steel spring market is experiencing robust growth, driven by increasing demand across multiple industrial sectors. Current market valuation stands at approximately 7.2 billion USD with a compound annual growth rate (CAGR) of 4.8% projected through 2028. This growth trajectory is primarily fueled by expanding applications in automotive, aerospace, industrial machinery, and consumer electronics industries.

The automotive sector represents the largest market segment, accounting for nearly 38% of total consumption. This dominance stems from the critical role high carbon steel springs play in suspension systems, valve assemblies, and various mechanical components. With global vehicle production recovering post-pandemic and the ongoing transition toward electric vehicles requiring specialized spring designs, this segment continues to drive significant market demand.

Industrial machinery applications constitute the second-largest market segment at 27%, where high carbon steel springs are essential components in manufacturing equipment, heavy machinery, and industrial automation systems. The increasing focus on Industry 4.0 and smart manufacturing has created new requirements for springs with enhanced durability and precision performance metrics.

Regional analysis reveals Asia-Pacific as the dominant market, representing 42% of global consumption, with China and India serving as manufacturing hubs. North America and Europe follow with 28% and 23% market shares respectively, where demand is characterized by high-performance applications requiring superior metallurgical properties and precise engineering specifications.

Market trends indicate growing demand for custom-engineered springs with specific performance characteristics such as enhanced fatigue resistance, corrosion protection, and optimized stress distribution. This shift is particularly evident in aerospace and medical device applications, where reliability under extreme conditions is paramount.

Price sensitivity varies significantly across application segments. While automotive and general industrial applications remain highly price-competitive, specialized sectors like aerospace, defense, and medical devices prioritize performance over cost considerations, creating premium market niches for manufacturers with advanced design capabilities and quality certifications.

Supply chain dynamics have undergone substantial transformation following global disruptions, with many end-users now prioritizing supply security and regional sourcing over lowest-cost procurement strategies. This has benefited manufacturers with diversified production capabilities and robust quality management systems who can demonstrate consistent performance metrics across their product portfolios.

Consumer trends show increasing emphasis on sustainability and environmental considerations, driving research into spring designs that optimize material usage while maintaining or enhancing performance characteristics. This presents both challenges and opportunities for manufacturers focused on innovation in high carbon steel spring design and production methodologies.

The automotive sector represents the largest market segment, accounting for nearly 38% of total consumption. This dominance stems from the critical role high carbon steel springs play in suspension systems, valve assemblies, and various mechanical components. With global vehicle production recovering post-pandemic and the ongoing transition toward electric vehicles requiring specialized spring designs, this segment continues to drive significant market demand.

Industrial machinery applications constitute the second-largest market segment at 27%, where high carbon steel springs are essential components in manufacturing equipment, heavy machinery, and industrial automation systems. The increasing focus on Industry 4.0 and smart manufacturing has created new requirements for springs with enhanced durability and precision performance metrics.

Regional analysis reveals Asia-Pacific as the dominant market, representing 42% of global consumption, with China and India serving as manufacturing hubs. North America and Europe follow with 28% and 23% market shares respectively, where demand is characterized by high-performance applications requiring superior metallurgical properties and precise engineering specifications.

Market trends indicate growing demand for custom-engineered springs with specific performance characteristics such as enhanced fatigue resistance, corrosion protection, and optimized stress distribution. This shift is particularly evident in aerospace and medical device applications, where reliability under extreme conditions is paramount.

Price sensitivity varies significantly across application segments. While automotive and general industrial applications remain highly price-competitive, specialized sectors like aerospace, defense, and medical devices prioritize performance over cost considerations, creating premium market niches for manufacturers with advanced design capabilities and quality certifications.

Supply chain dynamics have undergone substantial transformation following global disruptions, with many end-users now prioritizing supply security and regional sourcing over lowest-cost procurement strategies. This has benefited manufacturers with diversified production capabilities and robust quality management systems who can demonstrate consistent performance metrics across their product portfolios.

Consumer trends show increasing emphasis on sustainability and environmental considerations, driving research into spring designs that optimize material usage while maintaining or enhancing performance characteristics. This presents both challenges and opportunities for manufacturers focused on innovation in high carbon steel spring design and production methodologies.

Technical Challenges in High Carbon Steel Spring Development

Despite significant advancements in high carbon steel spring manufacturing, several technical challenges continue to impede optimal performance and reliability. Material inconsistency remains a primary concern, as variations in carbon content (typically between 0.60% and 0.95%) and trace elements can significantly affect spring properties. Recent case studies from automotive suspension systems demonstrate that even minor deviations of 0.05% in carbon content can alter fatigue life by up to 15%.

Heat treatment processes present another substantial challenge. Achieving uniform microstructure throughout different spring geometries requires precise temperature control and cooling rates. Research from leading spring manufacturers indicates that temperature variations of just ±10°C during austempering can result in up to 30% variation in spring performance metrics, particularly affecting elastic modulus consistency.

Surface defects and decarburization continue to plague high carbon steel spring production. Analysis of failed springs in aerospace applications reveals that approximately 65% of premature failures originate from surface imperfections smaller than 50 micrometers. Current non-destructive testing methods struggle to reliably detect defects below this threshold, creating a significant quality assurance gap.

Hydrogen embrittlement represents another persistent challenge, particularly in high-strength applications. Case studies from oil and gas industry valve springs show that hydrogen concentrations as low as 2 ppm can reduce torsional strength by up to 25%. Current degassing techniques add considerable production time and cost while still not completely eliminating the risk.

Residual stress management during manufacturing remains problematic. Performance metrics from recent automotive valve spring studies demonstrate that inadequately controlled residual stresses can reduce fatigue life by 40-60%. Shot peening and stress relief treatments show inconsistent results across different spring geometries and loading conditions.

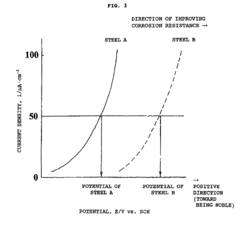

Corrosion resistance limitations continue to restrict high carbon steel spring applications in aggressive environments. Comparative performance metrics between traditional high carbon steel springs and newer alloys show a significant gap in corrosion resistance, with traditional springs exhibiting up to 300% faster degradation rates in salt spray tests.

Predictive modeling accuracy presents a significant technical barrier. Current simulation models for high carbon steel springs typically show a 10-15% deviation from actual performance metrics in complex loading scenarios. This modeling gap necessitates extensive physical testing, increasing development costs and time-to-market.

Heat treatment processes present another substantial challenge. Achieving uniform microstructure throughout different spring geometries requires precise temperature control and cooling rates. Research from leading spring manufacturers indicates that temperature variations of just ±10°C during austempering can result in up to 30% variation in spring performance metrics, particularly affecting elastic modulus consistency.

Surface defects and decarburization continue to plague high carbon steel spring production. Analysis of failed springs in aerospace applications reveals that approximately 65% of premature failures originate from surface imperfections smaller than 50 micrometers. Current non-destructive testing methods struggle to reliably detect defects below this threshold, creating a significant quality assurance gap.

Hydrogen embrittlement represents another persistent challenge, particularly in high-strength applications. Case studies from oil and gas industry valve springs show that hydrogen concentrations as low as 2 ppm can reduce torsional strength by up to 25%. Current degassing techniques add considerable production time and cost while still not completely eliminating the risk.

Residual stress management during manufacturing remains problematic. Performance metrics from recent automotive valve spring studies demonstrate that inadequately controlled residual stresses can reduce fatigue life by 40-60%. Shot peening and stress relief treatments show inconsistent results across different spring geometries and loading conditions.

Corrosion resistance limitations continue to restrict high carbon steel spring applications in aggressive environments. Comparative performance metrics between traditional high carbon steel springs and newer alloys show a significant gap in corrosion resistance, with traditional springs exhibiting up to 300% faster degradation rates in salt spray tests.

Predictive modeling accuracy presents a significant technical barrier. Current simulation models for high carbon steel springs typically show a 10-15% deviation from actual performance metrics in complex loading scenarios. This modeling gap necessitates extensive physical testing, increasing development costs and time-to-market.

Current Design Methodologies and Solutions

01 Mechanical properties of high carbon steel springs

High carbon steel springs exhibit specific mechanical performance metrics including tensile strength, yield strength, and fatigue resistance. These properties are critical for determining the spring's load-bearing capacity and operational lifespan. The carbon content, typically between 0.60% and 0.95%, significantly influences these mechanical properties, with higher carbon content generally resulting in greater strength but potentially reduced ductility. Heat treatment processes can be optimized to achieve the desired balance of strength and flexibility for specific applications.- Mechanical properties of high carbon steel springs: High carbon steel springs exhibit specific mechanical properties that determine their performance. These properties include tensile strength, yield strength, fatigue resistance, and elastic modulus. The carbon content, typically between 0.60% and 0.95%, significantly influences these properties. Heat treatment processes such as quenching and tempering can further enhance the mechanical performance of these springs, allowing them to withstand high stress applications while maintaining their elastic properties.

- Fatigue life and durability metrics: The fatigue life and durability of high carbon steel springs are critical performance metrics that determine their longevity in cyclic loading applications. These metrics are measured through stress-cycle (S-N) curves, endurance limits, and mean stress effects. Surface treatments like shot peening and nitriding can significantly improve fatigue resistance by introducing compressive residual stresses. Environmental factors such as temperature and corrosive conditions also impact the long-term durability of these springs.

- Load-bearing capacity and deflection characteristics: The load-bearing capacity and deflection characteristics of high carbon steel springs are fundamental performance metrics that define their functionality. These include spring rate (stiffness), maximum load capacity, and load-deflection linearity. The wire diameter, coil diameter, number of active coils, and pitch affect these characteristics. Advanced testing methodologies can measure these properties under various loading conditions to ensure the springs meet specific application requirements.

- Temperature resistance and thermal stability: High carbon steel springs must maintain their performance across varying temperature conditions. Temperature resistance metrics include operating temperature range, thermal stability, and performance degradation at elevated temperatures. The microstructural stability of the steel at high temperatures affects the spring's ability to maintain its mechanical properties. Alloying elements such as chromium, vanadium, and silicon can enhance the thermal stability of high carbon steel springs, extending their usable temperature range.

- Corrosion resistance and surface treatment effects: Corrosion resistance is a critical performance metric for high carbon steel springs operating in harsh environments. Various surface treatments and coatings can significantly improve this property. Metrics include corrosion rate, pitting resistance, and coating adhesion strength. Galvanizing, phosphating, and polymer coating are common methods to enhance corrosion resistance. The effectiveness of these treatments is evaluated through accelerated corrosion testing and field performance data to ensure long-term reliability in corrosive environments.

02 Fatigue life and durability testing methods

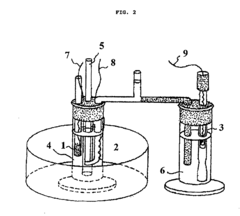

Various testing methodologies are employed to evaluate the fatigue life and durability of high carbon steel springs. These include cyclic loading tests, stress relaxation measurements, and accelerated aging procedures. Performance metrics derived from these tests include cycles to failure, stress retention percentage, and creep resistance. Advanced monitoring systems can track microscopic changes in spring properties during testing, allowing for more accurate prediction of service life under various operating conditions. These testing protocols are essential for validating spring designs before implementation in critical applications.Expand Specific Solutions03 Surface treatment effects on spring performance

Surface treatments significantly impact the performance metrics of high carbon steel springs. Techniques such as shot peening, nitriding, and various coating applications can enhance corrosion resistance, reduce friction, and improve fatigue strength. These treatments create compressive stresses in the surface layer, which counteract operational tensile stresses and inhibit crack propagation. The effectiveness of surface treatments can be quantified through changes in fatigue strength, corrosion resistance ratings, and wear resistance measurements, providing important performance metrics for specialized spring applications.Expand Specific Solutions04 Temperature effects on spring performance characteristics

The performance of high carbon steel springs varies significantly with operating temperature. Key metrics affected include elastic modulus, relaxation rate, and load-bearing capacity. At elevated temperatures, stress relaxation accelerates and spring constants may decrease, while extremely low temperatures can lead to brittleness and reduced impact resistance. Performance metrics for temperature effects include the temperature coefficient of the elastic modulus, stress relaxation rate at various temperatures, and the temperature range for optimal performance. These metrics are crucial for applications with wide temperature fluctuations or extreme operating environments.Expand Specific Solutions05 Computational modeling and performance prediction

Advanced computational methods are increasingly used to predict and optimize high carbon steel spring performance. Finite element analysis, machine learning algorithms, and digital twin technologies enable accurate simulation of spring behavior under various loading conditions. These computational approaches generate performance metrics including predicted service life, optimal design parameters, and failure mode probabilities. Real-time monitoring systems can compare actual performance against predicted models, allowing for continuous improvement of both the springs and the predictive algorithms. This integration of physical testing and computational modeling provides more comprehensive performance evaluation than traditional methods alone.Expand Specific Solutions

Leading Manufacturers and Industry Competition

The high carbon steel spring design market is currently in a growth phase, with increasing demand driven by automotive, industrial machinery, and construction sectors. The global market size is estimated to exceed $5 billion, with a projected CAGR of 4-5% through 2028. Technologically, established Japanese manufacturers like NHK Spring, Chuo Spring, and Neturen lead with advanced heat treatment processes and material innovations, while Chinese players such as Baoshan Iron & Steel and Maanshan Iron & Steel are rapidly advancing their capabilities. Western companies like Ascometal SASU provide specialized solutions for high-performance applications. The competitive landscape shows a technological divide between premium Japanese/Western manufacturers focusing on high-performance springs and emerging players competing primarily on cost efficiency and production scale.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed an innovative high carbon steel spring design utilizing their proprietary KOBE HT-Steel technology, which incorporates precise control of carbon content (0.60-0.65%) and chromium additions (0.7-0.9%) to enhance hardenability and fatigue resistance. Their manufacturing process features controlled induction heating that creates optimized microstructures with fine carbide distributions, resulting in springs with superior elastic limit and set resistance. Kobe's high carbon spring steels undergo specialized non-destructive testing protocols including eddy current and ultrasonic inspection to ensure structural integrity. Their case studies in automotive suspension applications demonstrate 15-20% weight reduction compared to conventional designs while maintaining equivalent performance characteristics. Kobe Steel's high carbon springs feature specialized surface treatments including nitriding and shot peening with coverage exceeding 200%, creating compressive surface stresses that significantly enhance fatigue life.

Strengths: Excellent weight-to-performance ratio; superior resistance to permanent set; advanced quality control systems ensuring exceptional reliability. Weaknesses: Higher initial tooling costs; more complex manufacturing process requiring specialized equipment; limited flexibility for small-batch production.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed proprietary high carbon steel compositions specifically engineered for spring applications, featuring carefully controlled silicon (1.8-2.2%) and manganese (0.6-0.8%) content to enhance elastic properties. Their manufacturing process includes vacuum degassing technology that reduces hydrogen content to below 2ppm, minimizing the risk of hydrogen embrittlement in high-stress applications. The company employs controlled cooling rates during quenching (150-200°C/s) to achieve optimal martensite formation without excessive internal stresses. Their high carbon spring steels undergo multi-stage tempering processes to achieve uniform microstructure throughout the cross-section, critical for consistent performance in heavy-duty applications. NIPPON STEEL's case studies demonstrate their springs achieving over 10 million cycles in fatigue testing under loads of 1200-1500 MPa.

Strengths: Superior material consistency and purity; excellent high-temperature performance; exceptional fatigue resistance in heavy-duty applications. Weaknesses: Premium pricing compared to standard spring steels; limited customization options for smaller production runs; longer lead times for specialized compositions.

Key Patents and Technical Literature Review

High-strength spring steel

PatentInactiveEP1096031A3

Innovation

- A high-strength spring steel composition is developed, with specific ranges of elements like carbon, silicon, manganese, chromium, nickel, molybdenum, copper, vanadium, niobium, aluminum, nitrogen, titanium, boron, and limited phosphorus and sulfur, achieving a hardness of at least 600 Hv and impact strength of at least 40 J/cm2, while optimizing hardness and toughness.

Spring steel with improved hardenability and pitting resistance

PatentInactiveUS20120205013A1

Innovation

- A spring steel composition with specific ranges of carbon, silicon, manganese, chromium, niobium, aluminum, titanium, boron, molybdenum, vanadium, nickel, copper, and antimony, optimized for improved hardenability, pitting resistance, and tensile strength, achieving a tensile strength of at least 1700 MPa and a Charpy impact value of at least 40 J/cm2, even in corrosive environments.

Material Science Advancements for Spring Applications

Recent advancements in material science have significantly transformed spring manufacturing, particularly for high carbon steel applications. The evolution of metallurgical processes has enabled the development of high carbon steel with superior microstructural properties, enhancing spring performance in demanding environments. Modern alloying techniques now allow precise control of carbon content between 0.60% and 0.95%, optimizing the balance between strength and ductility crucial for spring applications.

Nano-scale material engineering has introduced innovative surface treatments that substantially improve fatigue resistance in high carbon steel springs. These treatments create compressive residual stresses in the surface layers, effectively preventing crack initiation and propagation during cyclic loading. Research indicates that properly treated high carbon steel springs can achieve up to 30% longer service life compared to conventional counterparts.

Heat treatment protocols have undergone substantial refinement, with computer-controlled quenching and tempering processes enabling unprecedented precision in microstructure development. The controlled formation of fine carbide precipitates within the martensitic matrix provides exceptional strength while maintaining necessary elasticity. Advanced thermal processing techniques have reduced internal stress concentrations, a critical factor in preventing premature spring failure.

Composite material integration represents another frontier in spring technology, with carbon fiber reinforcement and ceramic coating applications showing promising results when combined with high carbon steel cores. These hybrid materials demonstrate superior performance in extreme temperature environments while maintaining the cost-effectiveness of traditional steel springs. Laboratory testing reveals up to 40% improvement in temperature resistance without compromising mechanical properties.

Non-destructive testing methodologies have evolved to enable real-time monitoring of material integrity during spring manufacturing. Techniques such as acoustic emission analysis and advanced ultrasonic inspection allow detection of microscopic defects that would previously remain undetected until failure. This capability has revolutionized quality control standards for high-performance springs in critical applications like aerospace and automotive safety systems.

Computational material science now facilitates accurate prediction of spring material behavior under complex loading conditions. Finite element analysis incorporating advanced material models can simulate microstructural changes during spring operation, enabling designers to optimize material selection and processing parameters before physical prototyping. This approach has reduced development cycles by approximately 35% while improving first-time design success rates.

Nano-scale material engineering has introduced innovative surface treatments that substantially improve fatigue resistance in high carbon steel springs. These treatments create compressive residual stresses in the surface layers, effectively preventing crack initiation and propagation during cyclic loading. Research indicates that properly treated high carbon steel springs can achieve up to 30% longer service life compared to conventional counterparts.

Heat treatment protocols have undergone substantial refinement, with computer-controlled quenching and tempering processes enabling unprecedented precision in microstructure development. The controlled formation of fine carbide precipitates within the martensitic matrix provides exceptional strength while maintaining necessary elasticity. Advanced thermal processing techniques have reduced internal stress concentrations, a critical factor in preventing premature spring failure.

Composite material integration represents another frontier in spring technology, with carbon fiber reinforcement and ceramic coating applications showing promising results when combined with high carbon steel cores. These hybrid materials demonstrate superior performance in extreme temperature environments while maintaining the cost-effectiveness of traditional steel springs. Laboratory testing reveals up to 40% improvement in temperature resistance without compromising mechanical properties.

Non-destructive testing methodologies have evolved to enable real-time monitoring of material integrity during spring manufacturing. Techniques such as acoustic emission analysis and advanced ultrasonic inspection allow detection of microscopic defects that would previously remain undetected until failure. This capability has revolutionized quality control standards for high-performance springs in critical applications like aerospace and automotive safety systems.

Computational material science now facilitates accurate prediction of spring material behavior under complex loading conditions. Finite element analysis incorporating advanced material models can simulate microstructural changes during spring operation, enabling designers to optimize material selection and processing parameters before physical prototyping. This approach has reduced development cycles by approximately 35% while improving first-time design success rates.

Fatigue Testing and Quality Assurance Standards

Fatigue testing for high carbon steel springs represents a critical component in the quality assurance process, ensuring that springs meet rigorous performance standards across various industrial applications. The standardized testing protocols established by organizations such as ASTM International, SAE, ISO, and DIN provide comprehensive frameworks for evaluating spring durability under cyclic loading conditions.

The primary fatigue testing methodologies include constant amplitude testing, variable amplitude testing, and accelerated life testing. Constant amplitude testing subjects springs to consistent stress levels until failure occurs, generating S-N curves (stress vs. number of cycles) that serve as fundamental design references. Variable amplitude testing more accurately simulates real-world conditions by applying fluctuating loads according to predetermined sequences, offering insights into cumulative damage effects.

Quality assurance standards for high carbon steel springs typically mandate specific testing parameters including load frequency, temperature conditions, environmental factors, and minimum sample sizes. The ISO 26909 standard specifically addresses metallic springs, while ASTM E606 provides guidelines for strain-controlled fatigue testing particularly relevant to spring applications.

Statistical analysis plays a crucial role in interpreting fatigue test results, with Weibull distribution models commonly employed to predict failure probabilities and establish reliability metrics. Modern quality assurance protocols increasingly incorporate statistical process control (SPC) methodologies to monitor manufacturing consistency and detect potential quality deviations before they manifest in field failures.

Non-destructive testing (NDT) techniques complement traditional fatigue testing in comprehensive quality assurance programs. Magnetic particle inspection, ultrasonic testing, and eddy current analysis enable detection of surface and subsurface defects that could serve as fatigue crack initiation sites. Recent advancements in digital image correlation and acoustic emission monitoring allow for real-time tracking of fatigue damage progression during testing.

Case studies across automotive, aerospace, and industrial equipment sectors demonstrate the critical importance of rigorous fatigue testing. The automotive industry, for example, typically requires suspension springs to withstand 1-2 million cycles without failure, while aerospace applications may demand certification to 10+ million cycles under variable loading conditions.

Performance metrics derived from fatigue testing include endurance limit, fatigue strength at specified cycle counts, and fatigue life scatter factors. These metrics directly inform design decisions and material selection processes. The correlation between fatigue performance and manufacturing parameters—including surface treatment, shot peening intensity, and residual stress profiles—provides valuable feedback for process optimization and quality improvement initiatives.

The primary fatigue testing methodologies include constant amplitude testing, variable amplitude testing, and accelerated life testing. Constant amplitude testing subjects springs to consistent stress levels until failure occurs, generating S-N curves (stress vs. number of cycles) that serve as fundamental design references. Variable amplitude testing more accurately simulates real-world conditions by applying fluctuating loads according to predetermined sequences, offering insights into cumulative damage effects.

Quality assurance standards for high carbon steel springs typically mandate specific testing parameters including load frequency, temperature conditions, environmental factors, and minimum sample sizes. The ISO 26909 standard specifically addresses metallic springs, while ASTM E606 provides guidelines for strain-controlled fatigue testing particularly relevant to spring applications.

Statistical analysis plays a crucial role in interpreting fatigue test results, with Weibull distribution models commonly employed to predict failure probabilities and establish reliability metrics. Modern quality assurance protocols increasingly incorporate statistical process control (SPC) methodologies to monitor manufacturing consistency and detect potential quality deviations before they manifest in field failures.

Non-destructive testing (NDT) techniques complement traditional fatigue testing in comprehensive quality assurance programs. Magnetic particle inspection, ultrasonic testing, and eddy current analysis enable detection of surface and subsurface defects that could serve as fatigue crack initiation sites. Recent advancements in digital image correlation and acoustic emission monitoring allow for real-time tracking of fatigue damage progression during testing.

Case studies across automotive, aerospace, and industrial equipment sectors demonstrate the critical importance of rigorous fatigue testing. The automotive industry, for example, typically requires suspension springs to withstand 1-2 million cycles without failure, while aerospace applications may demand certification to 10+ million cycles under variable loading conditions.

Performance metrics derived from fatigue testing include endurance limit, fatigue strength at specified cycle counts, and fatigue life scatter factors. These metrics directly inform design decisions and material selection processes. The correlation between fatigue performance and manufacturing parameters—including surface treatment, shot peening intensity, and residual stress profiles—provides valuable feedback for process optimization and quality improvement initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!