High Carbon Steel vs Tool Steel: Selection For Cutting Applications

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cutting Steel Evolution and Performance Objectives

The evolution of cutting steel materials has undergone significant transformations over the past century, driven by industrial demands for improved performance, durability, and efficiency. Initially, carbon steel with approximately 0.8-1.2% carbon content served as the primary material for cutting tools in the early 20th century. These high carbon steels offered reasonable hardness and edge retention but suffered from rapid degradation under heat and pressure, limiting their application in high-speed or continuous cutting operations.

The mid-20th century witnessed the emergence of specialized tool steels, specifically engineered for cutting applications. These materials incorporated alloying elements such as tungsten, chromium, vanadium, and molybdenum, which dramatically enhanced their heat resistance, wear characteristics, and overall performance. This technological advancement enabled manufacturing processes to achieve higher cutting speeds and extended tool life, fundamentally transforming production capabilities across industries.

Contemporary cutting applications demand increasingly specialized performance characteristics from steel materials. Modern cutting tools must maintain edge integrity under extreme conditions, including high temperatures, abrasive materials, and variable cutting speeds. The ideal cutting steel must balance several competing objectives: exceptional hardness (typically 60-65 HRC) for edge retention, sufficient toughness to prevent chipping or catastrophic failure, heat resistance to maintain properties at elevated temperatures, and wear resistance against abrasive materials.

Additionally, modern performance objectives extend beyond mere functional requirements to include economic and sustainability considerations. Tool longevity directly impacts production economics through reduced downtime and replacement costs. The ability to maintain dimensional accuracy throughout the tool's service life ensures consistent product quality. Furthermore, the ease of heat treatment and manufacturing processes affects production costs and accessibility.

Recent technological trends have pushed cutting steel development toward nano-structured materials, powder metallurgy processes, and composite solutions that combine the advantages of multiple material types. These innovations aim to overcome the traditional trade-offs between hardness and toughness that have historically limited cutting tool performance.

The evolution trajectory suggests future developments will likely focus on application-specific formulations rather than universal solutions, with materials engineered for particular cutting environments, workpiece materials, and operational parameters. This specialization trend reflects the growing complexity of manufacturing processes and the economic imperative to optimize tool performance for specific applications rather than general-purpose use.

The mid-20th century witnessed the emergence of specialized tool steels, specifically engineered for cutting applications. These materials incorporated alloying elements such as tungsten, chromium, vanadium, and molybdenum, which dramatically enhanced their heat resistance, wear characteristics, and overall performance. This technological advancement enabled manufacturing processes to achieve higher cutting speeds and extended tool life, fundamentally transforming production capabilities across industries.

Contemporary cutting applications demand increasingly specialized performance characteristics from steel materials. Modern cutting tools must maintain edge integrity under extreme conditions, including high temperatures, abrasive materials, and variable cutting speeds. The ideal cutting steel must balance several competing objectives: exceptional hardness (typically 60-65 HRC) for edge retention, sufficient toughness to prevent chipping or catastrophic failure, heat resistance to maintain properties at elevated temperatures, and wear resistance against abrasive materials.

Additionally, modern performance objectives extend beyond mere functional requirements to include economic and sustainability considerations. Tool longevity directly impacts production economics through reduced downtime and replacement costs. The ability to maintain dimensional accuracy throughout the tool's service life ensures consistent product quality. Furthermore, the ease of heat treatment and manufacturing processes affects production costs and accessibility.

Recent technological trends have pushed cutting steel development toward nano-structured materials, powder metallurgy processes, and composite solutions that combine the advantages of multiple material types. These innovations aim to overcome the traditional trade-offs between hardness and toughness that have historically limited cutting tool performance.

The evolution trajectory suggests future developments will likely focus on application-specific formulations rather than universal solutions, with materials engineered for particular cutting environments, workpiece materials, and operational parameters. This specialization trend reflects the growing complexity of manufacturing processes and the economic imperative to optimize tool performance for specific applications rather than general-purpose use.

Market Analysis for Industrial Cutting Applications

The global market for industrial cutting applications continues to expand, driven by manufacturing growth across automotive, aerospace, construction, and general metalworking sectors. Currently valued at approximately 8.7 billion USD, this market is projected to grow at a compound annual growth rate of 5.3% through 2028, with cutting tools representing a significant portion of this value chain.

Material selection between high carbon steel and tool steel represents a critical decision point for manufacturers, directly impacting operational efficiency and cost structures. High carbon steel options (typically containing 0.60-1.50% carbon) currently hold approximately 37% market share in general cutting applications due to their lower cost and adequate performance in less demanding environments. The average price point for high carbon steel cutting tools ranges from $15-45 per unit, positioning them as the economical choice for high-volume, lower precision operations.

Tool steel, with its superior hardness, wear resistance, and heat tolerance, commands a premium price point of $60-200 per unit but delivers substantially longer service life in demanding applications. This segment currently captures 48% of the industrial cutting market by value, despite representing only 31% by volume, highlighting its higher profit margins for manufacturers and distributors.

Regional market dynamics show significant variation, with North American and European markets demonstrating stronger preference for tool steel solutions (53% and 57% market share respectively), while emerging Asian markets still favor high carbon steel options (52% market share) due to cost sensitivity and the prevalence of less automated manufacturing processes.

Industry surveys indicate that material selection criteria vary by application segment. In high-precision manufacturing, 78% of decision-makers prioritize tool longevity and consistent performance over initial cost, favoring tool steel. Conversely, in general fabrication and construction, 65% of buyers cite initial cost as the primary decision factor, benefiting high carbon steel options.

The market is experiencing a gradual shift toward tool steel solutions as manufacturing processes become more automated and precision-oriented. This trend is particularly evident in automotive manufacturing, where tool steel adoption has increased by 7.3% over the past three years, driven by demands for tighter tolerances and higher production speeds.

Customer feedback analysis reveals that total cost of ownership considerations are increasingly influencing purchasing decisions, with 72% of industrial buyers now calculating cost-per-cut metrics rather than focusing solely on initial tool acquisition costs. This shift in evaluation methodology generally favors tool steel despite its higher upfront investment.

Material selection between high carbon steel and tool steel represents a critical decision point for manufacturers, directly impacting operational efficiency and cost structures. High carbon steel options (typically containing 0.60-1.50% carbon) currently hold approximately 37% market share in general cutting applications due to their lower cost and adequate performance in less demanding environments. The average price point for high carbon steel cutting tools ranges from $15-45 per unit, positioning them as the economical choice for high-volume, lower precision operations.

Tool steel, with its superior hardness, wear resistance, and heat tolerance, commands a premium price point of $60-200 per unit but delivers substantially longer service life in demanding applications. This segment currently captures 48% of the industrial cutting market by value, despite representing only 31% by volume, highlighting its higher profit margins for manufacturers and distributors.

Regional market dynamics show significant variation, with North American and European markets demonstrating stronger preference for tool steel solutions (53% and 57% market share respectively), while emerging Asian markets still favor high carbon steel options (52% market share) due to cost sensitivity and the prevalence of less automated manufacturing processes.

Industry surveys indicate that material selection criteria vary by application segment. In high-precision manufacturing, 78% of decision-makers prioritize tool longevity and consistent performance over initial cost, favoring tool steel. Conversely, in general fabrication and construction, 65% of buyers cite initial cost as the primary decision factor, benefiting high carbon steel options.

The market is experiencing a gradual shift toward tool steel solutions as manufacturing processes become more automated and precision-oriented. This trend is particularly evident in automotive manufacturing, where tool steel adoption has increased by 7.3% over the past three years, driven by demands for tighter tolerances and higher production speeds.

Customer feedback analysis reveals that total cost of ownership considerations are increasingly influencing purchasing decisions, with 72% of industrial buyers now calculating cost-per-cut metrics rather than focusing solely on initial tool acquisition costs. This shift in evaluation methodology generally favors tool steel despite its higher upfront investment.

Technical Comparison and Limitations of Steel Types

High carbon steel and tool steel represent two distinct categories of steel alloys, each with specific properties that determine their suitability for cutting applications. High carbon steel typically contains 0.60-1.00% carbon content, providing good hardness and wear resistance after heat treatment. However, it exhibits relatively poor hot hardness, losing cutting efficiency at temperatures above 200°C due to tempering effects.

Tool steel, by contrast, is specifically engineered for cutting, forming, and shaping other materials. It contains higher amounts of alloying elements such as tungsten, molybdenum, vanadium, and chromium, which contribute to superior edge retention, wear resistance, and red hardness (ability to maintain hardness at elevated temperatures). Tool steels can maintain their cutting properties at temperatures up to 500-600°C, making them significantly more suitable for high-speed cutting operations.

The microstructural differences between these steel types are substantial. High carbon steel primarily relies on iron carbides for hardness, while tool steels feature complex carbide structures formed by the interaction of carbon with various alloying elements. These complex carbides provide tool steel with superior abrasion resistance and edge retention characteristics critical for cutting applications.

Toughness characteristics also differ markedly. High carbon steel tends to be more brittle, especially after hardening, making it susceptible to chipping or fracturing under impact loads. Tool steels, particularly shock-resistant grades like S7, offer better impact resistance while maintaining necessary hardness for cutting operations.

Regarding heat treatment response, high carbon steel requires relatively simple heat treatment processes but offers limited hardness potential (typically 58-62 HRC). Tool steels demand more complex and precisely controlled heat treatment protocols but can achieve higher hardness levels (60-68 HRC) with better dimensional stability.

Cost considerations represent a significant limitation for tool steel implementation. High carbon steel is considerably less expensive, making it economically viable for applications where frequent replacement is acceptable. Tool steels can cost 3-10 times more depending on the specific grade and alloying elements, requiring justification through extended tool life or improved performance.

Machinability presents another limitation, as tool steels are generally more difficult to machine in their annealed state compared to high carbon steel, requiring more specialized equipment and expertise for fabrication. This increases both production time and manufacturing costs for cutting tools made from tool steel.

Tool steel, by contrast, is specifically engineered for cutting, forming, and shaping other materials. It contains higher amounts of alloying elements such as tungsten, molybdenum, vanadium, and chromium, which contribute to superior edge retention, wear resistance, and red hardness (ability to maintain hardness at elevated temperatures). Tool steels can maintain their cutting properties at temperatures up to 500-600°C, making them significantly more suitable for high-speed cutting operations.

The microstructural differences between these steel types are substantial. High carbon steel primarily relies on iron carbides for hardness, while tool steels feature complex carbide structures formed by the interaction of carbon with various alloying elements. These complex carbides provide tool steel with superior abrasion resistance and edge retention characteristics critical for cutting applications.

Toughness characteristics also differ markedly. High carbon steel tends to be more brittle, especially after hardening, making it susceptible to chipping or fracturing under impact loads. Tool steels, particularly shock-resistant grades like S7, offer better impact resistance while maintaining necessary hardness for cutting operations.

Regarding heat treatment response, high carbon steel requires relatively simple heat treatment processes but offers limited hardness potential (typically 58-62 HRC). Tool steels demand more complex and precisely controlled heat treatment protocols but can achieve higher hardness levels (60-68 HRC) with better dimensional stability.

Cost considerations represent a significant limitation for tool steel implementation. High carbon steel is considerably less expensive, making it economically viable for applications where frequent replacement is acceptable. Tool steels can cost 3-10 times more depending on the specific grade and alloying elements, requiring justification through extended tool life or improved performance.

Machinability presents another limitation, as tool steels are generally more difficult to machine in their annealed state compared to high carbon steel, requiring more specialized equipment and expertise for fabrication. This increases both production time and manufacturing costs for cutting tools made from tool steel.

Current Steel Selection Methodologies for Cutting Tools

01 Composition and heat treatment of high carbon steel for improved cutting performance

High carbon steel's cutting performance can be significantly enhanced through specific composition adjustments and heat treatment processes. These steels typically contain carbon content above 0.6% along with alloying elements such as chromium, vanadium, and tungsten that contribute to hardness and wear resistance. Proper heat treatment processes including quenching and tempering help achieve optimal hardness and toughness balance, resulting in superior cutting edge retention and durability during machining operations.- Cutting tool material composition for high carbon steel: Specific material compositions for cutting tools designed to process high carbon steel. These compositions typically include carbide-based materials, ceramic composites, or specialized steel alloys with optimized hardness and wear resistance properties. The materials are engineered to withstand the high cutting forces and temperatures encountered when machining high carbon steel, resulting in improved tool life and cutting performance.

- Cutting edge geometry optimization: Specialized cutting edge geometries designed specifically for high carbon and tool steel machining. These geometries include optimized rake angles, relief angles, and edge preparations that reduce cutting forces and heat generation. The proper edge geometry helps manage chip formation and evacuation while minimizing tool wear when cutting hard materials, resulting in improved surface finish and dimensional accuracy.

- Coating technologies for cutting tools: Advanced coating technologies applied to cutting tools for high carbon and tool steel machining. These coatings include PVD, CVD, and multi-layer systems that provide enhanced hardness, thermal resistance, and reduced friction. The coatings act as thermal barriers and reduce chemical interactions between the tool and workpiece material, significantly extending tool life and enabling higher cutting speeds.

- Cutting parameters optimization: Optimization of cutting parameters such as speed, feed rate, and depth of cut specifically for high carbon and tool steel machining. These parameters are carefully selected to balance productivity with tool life and surface quality. Advanced algorithms and modeling techniques help determine the optimal cutting conditions based on material properties, tool geometry, and machine capabilities, resulting in more efficient machining processes.

- Cooling and lubrication strategies: Specialized cooling and lubrication strategies for high carbon and tool steel cutting operations. These include high-pressure coolant delivery, minimum quantity lubrication (MQL), cryogenic cooling, and dry machining techniques. Effective cooling and lubrication management reduces thermal damage to both the tool and workpiece, controls chip formation, and extends tool life while maintaining dimensional accuracy and surface quality.

02 Tool steel coating technologies for enhanced cutting performance

Advanced coating technologies applied to tool steels can dramatically improve cutting performance. These coatings include physical vapor deposition (PVD), chemical vapor deposition (CVD), and various nitride-based surface treatments that create wear-resistant layers on cutting tools. Such coatings reduce friction, heat generation, and tool wear while increasing hardness at the cutting edge. This results in extended tool life, higher cutting speeds, and improved surface finish of machined parts, particularly when cutting hardened materials.Expand Specific Solutions03 Microstructure optimization for cutting tool performance

The microstructure of high carbon and tool steels plays a crucial role in determining cutting performance. Controlled cooling rates and specialized heat treatments can produce optimal carbide distribution, grain refinement, and phase transformations. Fine, evenly distributed carbides enhance wear resistance while maintaining adequate toughness. Techniques such as cryogenic treatment and multiple tempering cycles can further refine the microstructure, resulting in tools with superior hardness, wear resistance, and edge retention during cutting operations.Expand Specific Solutions04 Cutting tool geometry and edge preparation techniques

The geometry and edge preparation of high carbon and tool steel cutting implements significantly impact performance. Optimized rake angles, clearance angles, and cutting edge radii can reduce cutting forces and heat generation. Advanced edge preparation techniques such as micro-blasting, honing, and laser treatment can strengthen the cutting edge, preventing premature chipping and failure. These geometric optimizations enable higher cutting speeds, improved chip evacuation, and extended tool life when machining various materials.Expand Specific Solutions05 Novel alloying elements and manufacturing processes for specialized cutting applications

Innovative alloying elements and manufacturing processes are being developed to create high carbon and tool steels for specialized cutting applications. These include powder metallurgy techniques, additive manufacturing, and the incorporation of rare earth elements or nano-additives. Such approaches allow for more precise control of material properties, enabling the creation of cutting tools with exceptional hardness-to-toughness ratios, thermal stability, and wear resistance. These advanced materials excel in challenging applications such as high-speed machining, dry cutting, and processing of difficult-to-machine materials.Expand Specific Solutions

Leading Manufacturers and Market Competition

The high carbon steel vs tool steel cutting application market is in a mature growth phase, with an estimated global market size of $3-4 billion annually. The competitive landscape features established players with varying technological capabilities. Leading companies like Kennametal, Mitsubishi Materials, and Sumitomo Electric Hardmetal have achieved high technical maturity through extensive R&D investments, offering advanced cutting solutions with specialized coatings and geometries. Mid-tier competitors including Seco Tools, Wilson Tool, and Uddeholms AB demonstrate strong technical competence in specific application niches. Emerging players from Asia, particularly Zhuzhou Cemented Carbide and companies from Japan's steel sector (Daido Steel, Kobe Steel), are rapidly advancing their technical capabilities through strategic partnerships and increased R&D spending, challenging traditional market leaders.

Daido Steel Co., Ltd.

Technical Solution: Daido Steel has developed a comprehensive matrix for selecting between high carbon and tool steel for cutting applications based on workpiece hardness, cutting speed, and environmental conditions. Their SKH series high-speed tool steels incorporate precise amounts of tungsten, molybdenum, vanadium, and cobalt to optimize performance in high-temperature cutting operations. For applications requiring extreme wear resistance, their SKD series cold work tool steels feature carefully controlled carbon content (typically 0.85-1.55%) and chromium (5-12%) to balance hardness and toughness. Daido's research has demonstrated that their specially formulated tool steels can maintain hardness at temperatures up to 600°C, significantly outperforming high carbon steels which typically begin to lose hardness above 200°C[3]. Their technical approach includes specialized heat treatment protocols that optimize the microstructure for specific cutting applications, with particular attention to carbide size and distribution.

Strengths: Exceptional high-temperature performance, comprehensive material selection methodology based on application requirements, and consistent quality control. Weaknesses: Higher cost compared to standard high carbon steels, and some grades require specialized heat treatment facilities that may not be widely available.

Kennametal, Inc.

Technical Solution: Kennametal has pioneered innovative coating technologies for both high carbon and tool steel cutting applications. Their Beyond™ platform utilizes PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coating technologies to enhance the performance of cutting tools. For high carbon steel applications, they've developed specialized cobalt-enriched substrates that provide improved thermal stability and wear resistance. Their research indicates that properly coated high carbon steel tools can achieve up to 30% longer tool life in certain applications compared to uncoated versions[2]. For more demanding applications, Kennametal's KCU25™ grade tool steel incorporates proprietary nano-scale multilayer coatings that significantly enhance edge strength and heat resistance. Their technical approach emphasizes application-specific solutions, recognizing that the optimal choice between high carbon and tool steel depends on workpiece material, cutting parameters, and economic considerations.

Strengths: Extensive coating expertise that can enhance the performance of both steel types, comprehensive application engineering support, and broad product range covering various cutting applications. Weaknesses: Higher initial investment required for coated tools, and some of their advanced coatings require specific handling and maintenance protocols.

Key Metallurgical Innovations in Cutting Steels

Tool steel having strength and high impact toughness

PatentActiveUS11008634B2

Innovation

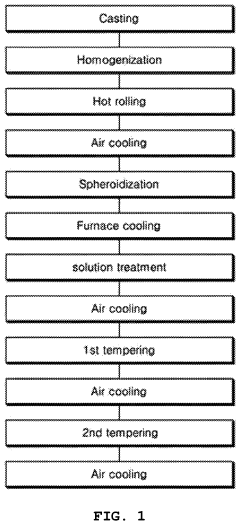

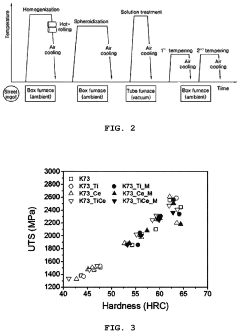

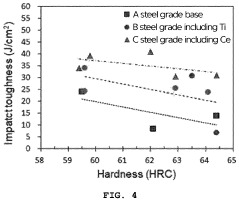

- The development of super-high-strength tool steel containing 0.7 to 0.9 wt% C, 0.4 to 0.6 wt% Si, 0.4 to 0.6 wt% Mn, 7.0 to 9.0 wt% Cr, 1.5 to 2.5 wt% Mo, and at least one of 0.1 wt% Ti and 0.1 wt% Ce, with a specific heat treatment process involving homogenization, hot rolling, spheroidization, solution treatment, and tempering to reduce primary carbide content and enhance impact toughness at high hardness levels.

High carbon steel and production method thereof

PatentInactiveUS7147730B2

Innovation

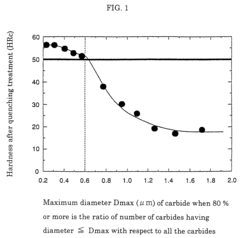

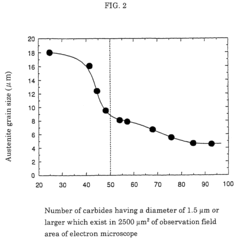

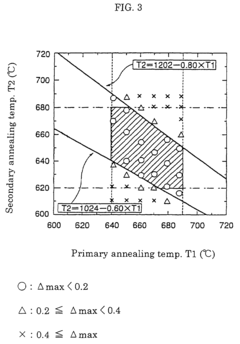

- A high carbon steel sheet with a chemical composition where 80% of carbides have diameters of 0.6 μm or less and more than 50 carbides have diameters of 1.5 μm or larger in a 2500 μm² area, produced through hot rolling, coiling, primary annealing, cold rolling, and secondary annealing processes that optimize carbide distribution and reduce planar anisotropy.

Cost-Benefit Analysis of Steel Types

When evaluating high carbon steel versus tool steel for cutting applications, cost considerations must be analyzed comprehensively against performance benefits. Initial acquisition costs show significant differences, with high carbon steel typically priced at $2-5 per pound, while tool steels range from $8-25 per pound depending on specific grades and alloying elements. This price differential of 300-500% represents a substantial upfront investment consideration for manufacturers.

Tool steels demonstrate superior longevity in cutting applications, with service life often 3-5 times longer than high carbon steel counterparts when used in similar conditions. This extended lifespan significantly impacts the total cost of ownership calculation, as replacement frequency decreases proportionally with durability improvements.

Maintenance requirements further differentiate these materials economically. High carbon steel cutting tools typically require more frequent resharpening and reconditioning, with maintenance intervals averaging 30-50% shorter than tool steel equivalents. This translates to increased downtime and labor costs, estimated at $75-150 per maintenance cycle depending on application complexity and production environment.

Production efficiency metrics reveal that tool steel cutting implements maintain optimal performance characteristics for longer periods, reducing quality variations in manufactured products. This consistency minimizes scrap rates by approximately 2-4% compared to high carbon steel tools, representing substantial material savings in high-volume production environments.

Energy consumption during heat treatment processes differs significantly between these steel types. Tool steel typically requires more precise and energy-intensive heat treatment protocols, increasing processing costs by 25-40% compared to high carbon steel. However, these additional processing expenses are generally offset by the extended service life and improved performance.

For small-batch or limited production runs, high carbon steel often presents the more economical choice despite its performance limitations. Conversely, in high-volume industrial applications where tool longevity and consistent performance directly impact productivity, tool steel's higher initial investment typically yields superior return on investment, with break-even points occurring after 2-3 replacement cycles of equivalent high carbon steel tools.

Environmental cost factors should also be considered, as the reduced replacement frequency of tool steel implements results in lower material consumption and waste generation over the operational lifetime. This sustainability advantage increasingly translates to tangible economic benefits as environmental compliance costs continue to rise across manufacturing sectors.

Tool steels demonstrate superior longevity in cutting applications, with service life often 3-5 times longer than high carbon steel counterparts when used in similar conditions. This extended lifespan significantly impacts the total cost of ownership calculation, as replacement frequency decreases proportionally with durability improvements.

Maintenance requirements further differentiate these materials economically. High carbon steel cutting tools typically require more frequent resharpening and reconditioning, with maintenance intervals averaging 30-50% shorter than tool steel equivalents. This translates to increased downtime and labor costs, estimated at $75-150 per maintenance cycle depending on application complexity and production environment.

Production efficiency metrics reveal that tool steel cutting implements maintain optimal performance characteristics for longer periods, reducing quality variations in manufactured products. This consistency minimizes scrap rates by approximately 2-4% compared to high carbon steel tools, representing substantial material savings in high-volume production environments.

Energy consumption during heat treatment processes differs significantly between these steel types. Tool steel typically requires more precise and energy-intensive heat treatment protocols, increasing processing costs by 25-40% compared to high carbon steel. However, these additional processing expenses are generally offset by the extended service life and improved performance.

For small-batch or limited production runs, high carbon steel often presents the more economical choice despite its performance limitations. Conversely, in high-volume industrial applications where tool longevity and consistent performance directly impact productivity, tool steel's higher initial investment typically yields superior return on investment, with break-even points occurring after 2-3 replacement cycles of equivalent high carbon steel tools.

Environmental cost factors should also be considered, as the reduced replacement frequency of tool steel implements results in lower material consumption and waste generation over the operational lifetime. This sustainability advantage increasingly translates to tangible economic benefits as environmental compliance costs continue to rise across manufacturing sectors.

Sustainability Considerations in Steel Production

The steel industry faces increasing pressure to reduce its environmental footprint, particularly in the production of specialized steels for cutting applications. Both high carbon steel and tool steel manufacturing processes are energy-intensive and generate significant carbon emissions, with tool steel typically requiring more complex processing and alloying elements, resulting in a larger environmental impact per unit produced.

Life cycle assessment studies indicate that tool steel production generates approximately 30-40% higher CO2 emissions compared to high carbon steel due to additional heat treatments and the inclusion of rare alloying elements such as tungsten, molybdenum, and vanadium. These elements not only increase production costs but also raise sustainability concerns related to mining practices and resource scarcity.

Recent innovations in electric arc furnace technology have enabled manufacturers to reduce energy consumption by up to 25% when producing both steel types. Additionally, the implementation of hydrogen-based reduction processes instead of traditional coal-based methods shows promise in decreasing carbon emissions by 30-50%, though these technologies remain in early adoption phases for specialized steel production.

Material efficiency represents another critical sustainability factor. Tool steels typically offer 3-5 times longer service life in cutting applications compared to high carbon steels, potentially offsetting their higher initial environmental impact through reduced replacement frequency and associated manufacturing emissions. This extended lifespan must be factored into comprehensive sustainability assessments.

Recycling capabilities differ between these steel types as well. High carbon steel, with its simpler composition, achieves recycling rates of approximately 85-90%, while tool steel recycling presents greater challenges due to complex alloying elements, resulting in lower effective recycling rates of 70-75%. Improved sorting technologies and dedicated recycling streams for specialized steels are being developed to address this gap.

Water usage and pollution also vary significantly, with tool steel production typically requiring 1.5-2 times more water than high carbon steel manufacturing. Advanced water treatment and closed-loop systems are increasingly being implemented to mitigate these impacts, with leading manufacturers achieving water reuse rates exceeding 90%.

For manufacturers selecting between these materials for cutting applications, a comprehensive sustainability assessment should consider not only production impacts but also performance efficiency, service life, and end-of-life recyclability to determine the truly more sustainable option for specific cutting requirements.

Life cycle assessment studies indicate that tool steel production generates approximately 30-40% higher CO2 emissions compared to high carbon steel due to additional heat treatments and the inclusion of rare alloying elements such as tungsten, molybdenum, and vanadium. These elements not only increase production costs but also raise sustainability concerns related to mining practices and resource scarcity.

Recent innovations in electric arc furnace technology have enabled manufacturers to reduce energy consumption by up to 25% when producing both steel types. Additionally, the implementation of hydrogen-based reduction processes instead of traditional coal-based methods shows promise in decreasing carbon emissions by 30-50%, though these technologies remain in early adoption phases for specialized steel production.

Material efficiency represents another critical sustainability factor. Tool steels typically offer 3-5 times longer service life in cutting applications compared to high carbon steels, potentially offsetting their higher initial environmental impact through reduced replacement frequency and associated manufacturing emissions. This extended lifespan must be factored into comprehensive sustainability assessments.

Recycling capabilities differ between these steel types as well. High carbon steel, with its simpler composition, achieves recycling rates of approximately 85-90%, while tool steel recycling presents greater challenges due to complex alloying elements, resulting in lower effective recycling rates of 70-75%. Improved sorting technologies and dedicated recycling streams for specialized steels are being developed to address this gap.

Water usage and pollution also vary significantly, with tool steel production typically requiring 1.5-2 times more water than high carbon steel manufacturing. Advanced water treatment and closed-loop systems are increasingly being implemented to mitigate these impacts, with leading manufacturers achieving water reuse rates exceeding 90%.

For manufacturers selecting between these materials for cutting applications, a comprehensive sustainability assessment should consider not only production impacts but also performance efficiency, service life, and end-of-life recyclability to determine the truly more sustainable option for specific cutting requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!