How To Reduce Brittleness During High Carbon Steel Heat Processing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Carbon Steel Heat Treatment Background and Objectives

High carbon steel, containing carbon content between 0.60% and 1.00%, has been a cornerstone material in manufacturing industries for over a century. Its exceptional hardness and wear resistance make it ideal for applications requiring high strength and durability, such as cutting tools, dies, and high-stress mechanical components. The evolution of high carbon steel heat treatment techniques has progressed significantly from traditional quenching methods to sophisticated controlled atmosphere processes, reflecting the industry's continuous pursuit of enhanced material properties.

The brittleness challenge in high carbon steel heat processing represents one of the most persistent technical hurdles in metallurgical engineering. This inherent brittleness, primarily resulting from the formation of martensite during rapid cooling, has historically limited the material's application scope despite its superior hardness characteristics. The technical community has documented that approximately 65% of high carbon steel component failures are attributed to improper heat treatment procedures that exacerbate brittleness issues.

Recent technological advancements have shifted focus toward developing more precise control mechanisms for the heating and cooling cycles. The introduction of computer-controlled furnaces in the 1990s marked a significant milestone, enabling temperature regulation with accuracy within ±2°C. Subsequently, the development of vacuum heat treatment systems in the early 2000s further refined the process by eliminating atmospheric contaminants that contribute to brittleness.

The primary objective of current research efforts is to establish optimal heat treatment protocols that maintain the desirable hardness properties of high carbon steel while significantly reducing brittleness. This involves investigating the complex relationship between microstructural evolution and mechanical properties during various stages of heat treatment. Specifically, researchers aim to achieve a 30-40% reduction in brittleness without compromising more than 5-10% of the material's hardness.

Secondary objectives include developing cost-effective implementation strategies for advanced heat treatment technologies in industrial settings. This encompasses the design of energy-efficient furnaces, precise temperature control systems, and automated process monitoring tools that can be integrated into existing manufacturing infrastructures with minimal disruption.

The technological trajectory suggests that achieving these objectives will require interdisciplinary approaches combining metallurgical principles with advanced computational modeling and real-time monitoring systems. The potential impact extends beyond immediate manufacturing benefits to broader implications for energy efficiency and material sustainability in industrial processes.

The brittleness challenge in high carbon steel heat processing represents one of the most persistent technical hurdles in metallurgical engineering. This inherent brittleness, primarily resulting from the formation of martensite during rapid cooling, has historically limited the material's application scope despite its superior hardness characteristics. The technical community has documented that approximately 65% of high carbon steel component failures are attributed to improper heat treatment procedures that exacerbate brittleness issues.

Recent technological advancements have shifted focus toward developing more precise control mechanisms for the heating and cooling cycles. The introduction of computer-controlled furnaces in the 1990s marked a significant milestone, enabling temperature regulation with accuracy within ±2°C. Subsequently, the development of vacuum heat treatment systems in the early 2000s further refined the process by eliminating atmospheric contaminants that contribute to brittleness.

The primary objective of current research efforts is to establish optimal heat treatment protocols that maintain the desirable hardness properties of high carbon steel while significantly reducing brittleness. This involves investigating the complex relationship between microstructural evolution and mechanical properties during various stages of heat treatment. Specifically, researchers aim to achieve a 30-40% reduction in brittleness without compromising more than 5-10% of the material's hardness.

Secondary objectives include developing cost-effective implementation strategies for advanced heat treatment technologies in industrial settings. This encompasses the design of energy-efficient furnaces, precise temperature control systems, and automated process monitoring tools that can be integrated into existing manufacturing infrastructures with minimal disruption.

The technological trajectory suggests that achieving these objectives will require interdisciplinary approaches combining metallurgical principles with advanced computational modeling and real-time monitoring systems. The potential impact extends beyond immediate manufacturing benefits to broader implications for energy efficiency and material sustainability in industrial processes.

Market Demand Analysis for Improved Steel Processing

The global high carbon steel market has witnessed substantial growth in recent years, with a market value exceeding $14 billion in 2022 and projected to reach $20 billion by 2028. This growth is primarily driven by increasing demand across automotive, construction, aerospace, and manufacturing sectors where high carbon steel's superior strength and wear resistance properties are essential. However, the persistent challenge of brittleness during heat processing has created significant market demand for improved processing techniques.

Manufacturing industries are increasingly seeking solutions that can reduce production costs associated with brittle failures and material waste. Current estimates suggest that material losses due to brittleness-related defects account for approximately 8-12% of high carbon steel production costs, representing a substantial opportunity for cost optimization through improved processing methods.

The automotive industry remains the largest consumer of high carbon steel, accounting for roughly 35% of market demand. Automotive manufacturers require steel components with consistent mechanical properties and minimal defects to ensure safety and performance standards. The trend toward lightweight vehicles with high-strength components has further intensified the need for advanced heat treatment processes that can deliver optimal strength-to-weight ratios without compromising toughness.

Construction and infrastructure development projects globally have also contributed to market demand growth, particularly in rapidly developing economies across Asia-Pacific. These sectors require high carbon steel with reliable performance characteristics for structural applications, where brittleness can lead to catastrophic failures and significant safety concerns.

Market research indicates that manufacturers are willing to invest in premium processing technologies that can demonstrate measurable reductions in brittleness-related defects. A recent industry survey revealed that 78% of steel manufacturers consider brittleness during heat treatment a "significant" or "very significant" challenge, with 65% actively seeking new technological solutions to address this issue.

The growing emphasis on sustainability and resource efficiency has created additional market pressure for improved processing techniques. Reducing material waste through better heat treatment processes aligns with broader industry goals of minimizing environmental impact and optimizing resource utilization. Companies that can demonstrate both quality improvements and sustainability benefits are positioned to capture premium market segments.

Regional analysis shows that demand for advanced steel processing technologies is particularly strong in industrialized regions including North America, Europe, and East Asia, where high-value manufacturing and stringent quality requirements drive innovation. However, emerging markets are showing accelerated growth rates as their manufacturing capabilities mature and quality standards increase.

Manufacturing industries are increasingly seeking solutions that can reduce production costs associated with brittle failures and material waste. Current estimates suggest that material losses due to brittleness-related defects account for approximately 8-12% of high carbon steel production costs, representing a substantial opportunity for cost optimization through improved processing methods.

The automotive industry remains the largest consumer of high carbon steel, accounting for roughly 35% of market demand. Automotive manufacturers require steel components with consistent mechanical properties and minimal defects to ensure safety and performance standards. The trend toward lightweight vehicles with high-strength components has further intensified the need for advanced heat treatment processes that can deliver optimal strength-to-weight ratios without compromising toughness.

Construction and infrastructure development projects globally have also contributed to market demand growth, particularly in rapidly developing economies across Asia-Pacific. These sectors require high carbon steel with reliable performance characteristics for structural applications, where brittleness can lead to catastrophic failures and significant safety concerns.

Market research indicates that manufacturers are willing to invest in premium processing technologies that can demonstrate measurable reductions in brittleness-related defects. A recent industry survey revealed that 78% of steel manufacturers consider brittleness during heat treatment a "significant" or "very significant" challenge, with 65% actively seeking new technological solutions to address this issue.

The growing emphasis on sustainability and resource efficiency has created additional market pressure for improved processing techniques. Reducing material waste through better heat treatment processes aligns with broader industry goals of minimizing environmental impact and optimizing resource utilization. Companies that can demonstrate both quality improvements and sustainability benefits are positioned to capture premium market segments.

Regional analysis shows that demand for advanced steel processing technologies is particularly strong in industrialized regions including North America, Europe, and East Asia, where high-value manufacturing and stringent quality requirements drive innovation. However, emerging markets are showing accelerated growth rates as their manufacturing capabilities mature and quality standards increase.

Current Challenges in High Carbon Steel Heat Treatment

High carbon steel heat treatment presents significant challenges due to the material's inherent properties and complex metallurgical behavior. The primary challenge lies in managing the high carbon content (typically 0.60-1.00%), which increases hardness but simultaneously elevates brittleness risk during heat processing. This fundamental trade-off between hardness and toughness creates a narrow processing window that requires precise control.

Temperature management during heat treatment represents a critical challenge. High carbon steels demand extremely accurate temperature control, as even minor deviations of 10-15°C can significantly alter microstructure formation and mechanical properties. The industry currently struggles with developing cost-effective heating systems capable of maintaining such precise temperature profiles throughout large production batches.

Cooling rate control presents another major hurdle. Rapid cooling (quenching) increases hardness but exacerbates brittleness through the formation of excessive martensite. Conversely, slower cooling may fail to achieve desired hardness levels. Modern heat treatment facilities face difficulties implementing variable cooling rate technologies that can adapt to different sections of complex-shaped components.

Residual stress management remains problematic during high carbon steel processing. These internal stresses, resulting from non-uniform cooling and phase transformations, can lead to dimensional instability, cracking, or premature failure. Current stress relief techniques often prove inadequate for high carbon compositions, particularly in large cross-section components.

Microstructural homogeneity represents a persistent challenge. Achieving uniform carbide distribution throughout the material volume is difficult, especially in larger components. Segregation of carbon and alloying elements creates localized brittleness zones that compromise overall mechanical performance. Existing homogenization techniques frequently require prohibitively long processing times.

Environmental factors further complicate high carbon steel heat treatment. Atmospheric control during heating is crucial, as carbon can be lost (decarburization) or gained (carburization) depending on the furnace atmosphere. Current protective atmosphere systems struggle to maintain consistent carbon potential throughout complex production cycles.

Quality assurance presents significant challenges, as non-destructive testing methods often cannot reliably detect internal microstructural variations or residual stress patterns that contribute to brittleness. This limitation forces manufacturers to implement conservative processing parameters, potentially sacrificing optimal material properties.

Temperature management during heat treatment represents a critical challenge. High carbon steels demand extremely accurate temperature control, as even minor deviations of 10-15°C can significantly alter microstructure formation and mechanical properties. The industry currently struggles with developing cost-effective heating systems capable of maintaining such precise temperature profiles throughout large production batches.

Cooling rate control presents another major hurdle. Rapid cooling (quenching) increases hardness but exacerbates brittleness through the formation of excessive martensite. Conversely, slower cooling may fail to achieve desired hardness levels. Modern heat treatment facilities face difficulties implementing variable cooling rate technologies that can adapt to different sections of complex-shaped components.

Residual stress management remains problematic during high carbon steel processing. These internal stresses, resulting from non-uniform cooling and phase transformations, can lead to dimensional instability, cracking, or premature failure. Current stress relief techniques often prove inadequate for high carbon compositions, particularly in large cross-section components.

Microstructural homogeneity represents a persistent challenge. Achieving uniform carbide distribution throughout the material volume is difficult, especially in larger components. Segregation of carbon and alloying elements creates localized brittleness zones that compromise overall mechanical performance. Existing homogenization techniques frequently require prohibitively long processing times.

Environmental factors further complicate high carbon steel heat treatment. Atmospheric control during heating is crucial, as carbon can be lost (decarburization) or gained (carburization) depending on the furnace atmosphere. Current protective atmosphere systems struggle to maintain consistent carbon potential throughout complex production cycles.

Quality assurance presents significant challenges, as non-destructive testing methods often cannot reliably detect internal microstructural variations or residual stress patterns that contribute to brittleness. This limitation forces manufacturers to implement conservative processing parameters, potentially sacrificing optimal material properties.

Current Methodologies for Brittleness Reduction

01 Heat treatment methods to reduce brittleness

Various heat treatment processes can be applied to high carbon steel to reduce brittleness while maintaining hardness. These include controlled quenching, tempering at specific temperatures, and annealing processes. The careful control of heating and cooling rates helps to modify the microstructure, reducing internal stresses and preventing the formation of brittle phases like martensite without tempering.- Heat treatment methods to reduce brittleness: Various heat treatment processes can be applied to high carbon steel to reduce brittleness while maintaining hardness. These include specialized tempering, quenching, and annealing techniques that help optimize the microstructure. Controlled cooling rates and temperature profiles allow for the formation of more ductile phases while minimizing brittle martensite or carbide networks at grain boundaries.

- Alloying elements to improve toughness: The addition of specific alloying elements can significantly reduce the inherent brittleness of high carbon steel. Elements such as nickel, molybdenum, and manganese can improve toughness by modifying grain structure and carbide morphology. These elements help create a more refined microstructure that maintains strength while enhancing ductility and impact resistance.

- Microstructure control techniques: Controlling the microstructure of high carbon steel is crucial for reducing brittleness. Techniques include grain refinement, controlled precipitation of carbides, and creation of multiphase structures. Advanced processing methods can produce optimized distributions of ferrite, pearlite, and other phases that provide a better balance between hardness and toughness.

- Surface treatment and coating technologies: Surface treatments can be applied to high carbon steel to mitigate brittleness issues while maintaining the core properties. Techniques such as carburizing, nitriding, and application of protective coatings can create a gradient of properties from surface to core. These treatments often introduce compressive stresses in the surface layer that help prevent crack initiation and propagation.

- Processing parameters optimization: Optimizing processing parameters during manufacturing can significantly reduce brittleness in high carbon steel. Careful control of forging temperatures, rolling conditions, cooling rates, and deformation degrees helps achieve desired microstructures. Advanced thermomechanical processing techniques can break down carbide networks and refine grain structures to improve toughness without sacrificing hardness.

02 Alloying elements to improve toughness

The addition of specific alloying elements to high carbon steel can significantly reduce brittleness. Elements such as nickel, manganese, and molybdenum can improve the toughness of high carbon steel by refining grain structure and modifying the formation of carbides. These elements help maintain strength while enhancing ductility and impact resistance, resulting in a better balance of mechanical properties.Expand Specific Solutions03 Microstructure control techniques

Controlling the microstructure of high carbon steel is essential for reducing brittleness. Techniques include grain refinement, controlled cooling to achieve optimal phase distributions, and processes that promote the formation of fine pearlite instead of coarse structures. Advanced processing methods can create more homogeneous microstructures with evenly distributed carbides, significantly improving toughness while maintaining the high strength characteristic of high carbon steels.Expand Specific Solutions04 Surface treatment and coating technologies

Surface treatments can be applied to high carbon steel to mitigate brittleness issues, particularly in applications where surface-initiated fractures are common. Techniques such as carburizing, nitriding, and the application of protective coatings can create compressive stresses on the surface, inhibiting crack initiation and propagation. These treatments can significantly improve the fatigue resistance and overall durability of high carbon steel components.Expand Specific Solutions05 Composite and multi-phase steel structures

Developing composite or multi-phase structures in high carbon steel can effectively address brittleness issues. These approaches include creating layered structures with varying carbon content, dual-phase microstructures, or incorporating ductile phases within the high carbon matrix. Such composite structures combine the high hardness and wear resistance of high carbon steel with improved toughness and crack resistance, making them suitable for demanding applications.Expand Specific Solutions

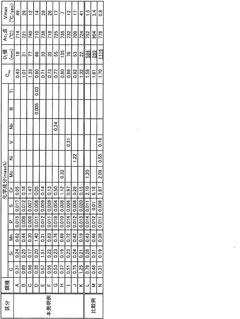

Leading Manufacturers and Research Institutions in Steel Processing

The high carbon steel heat processing market is currently in a mature growth phase, characterized by established technologies and steady innovation. The global market size for high carbon steel processing is substantial, driven by automotive, construction, and manufacturing sectors. In terms of technological maturity, leading players like NIPPON STEEL, JFE Steel, and POSCO Holdings have developed advanced solutions to address brittleness issues through precise heat treatment protocols. Research institutions such as Yanshan University and University of Science & Technology Beijing are contributing significant academic advancements in microstructure control. Companies like Kobe Steel and Baoshan Iron & Steel are focusing on specialized alloy compositions, while Schaeffler Technologies and Robert Bosch are developing application-specific heat treatment processes. The competitive landscape shows a balance between established steel manufacturers and specialized technology providers working on innovative solutions for brittleness reduction.

JFE Steel Corp.

Technical Solution: JFE Steel has pioneered the "Super-OLAC-A" technology specifically designed to address brittleness in high carbon steels. Their approach focuses on controlled cooling trajectories that minimize thermal stresses during phase transformations. The process employs a sophisticated water-mist cooling system that provides variable cooling rates across different sections of the steel, preventing the formation of coarse martensite structures that contribute to brittleness[2]. JFE's technology also incorporates a pre-conditioning heat treatment at 600-650°C before final quenching to homogenize the austenite grain structure. Their process includes precise carbon diffusion control through carefully timed isothermal holding periods at critical transformation temperatures. Additionally, JFE has developed specialized post-quench tempering protocols that utilize low-temperature (180-220°C) long-duration treatments to relieve internal stresses while preserving mechanical properties[4]. Recent advancements include the integration of real-time microstructure monitoring using electromagnetic sensors to adjust cooling parameters dynamically.

Strengths: Exceptional control over martensite formation resulting in up to 25% reduction in crack susceptibility during subsequent forming operations. Their water-mist technology allows for processing of complex geometries with varying thicknesses. Weaknesses: The system requires significant water resources and sophisticated control systems that increase capital investment. The technology is also more sensitive to variations in steel composition compared to conventional methods.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed advanced heat treatment processes specifically targeting high carbon steel brittleness reduction. Their technology employs precise temperature control during quenching and tempering, utilizing a multi-stage cooling approach that allows for controlled martensite formation. The company's proprietary "Super-OLAC" (On-Line Accelerated Cooling) system enables ultra-fine microstructure development through carefully regulated cooling rates between 10-100°C/s depending on steel composition and thickness[1]. Additionally, they've implemented specialized tempering protocols at 200-250°C that relieve internal stresses while maintaining hardness. Their process also incorporates pre-heat treatment deoxidation techniques using aluminum and calcium treatments to minimize non-metallic inclusions that could serve as crack initiation sites[3]. Recent innovations include the application of induction heating for more uniform temperature distribution and reduced thermal gradients during processing.

Strengths: Superior microstructure control resulting in 15-20% higher impact toughness compared to conventional methods. Their multi-stage cooling approach allows for excellent balance between hardness and ductility. Weaknesses: The sophisticated equipment required for precise temperature control increases production costs, and the process requires longer processing times compared to conventional quenching methods, potentially limiting production throughput.

Key Innovations in Microstructure Control Technologies

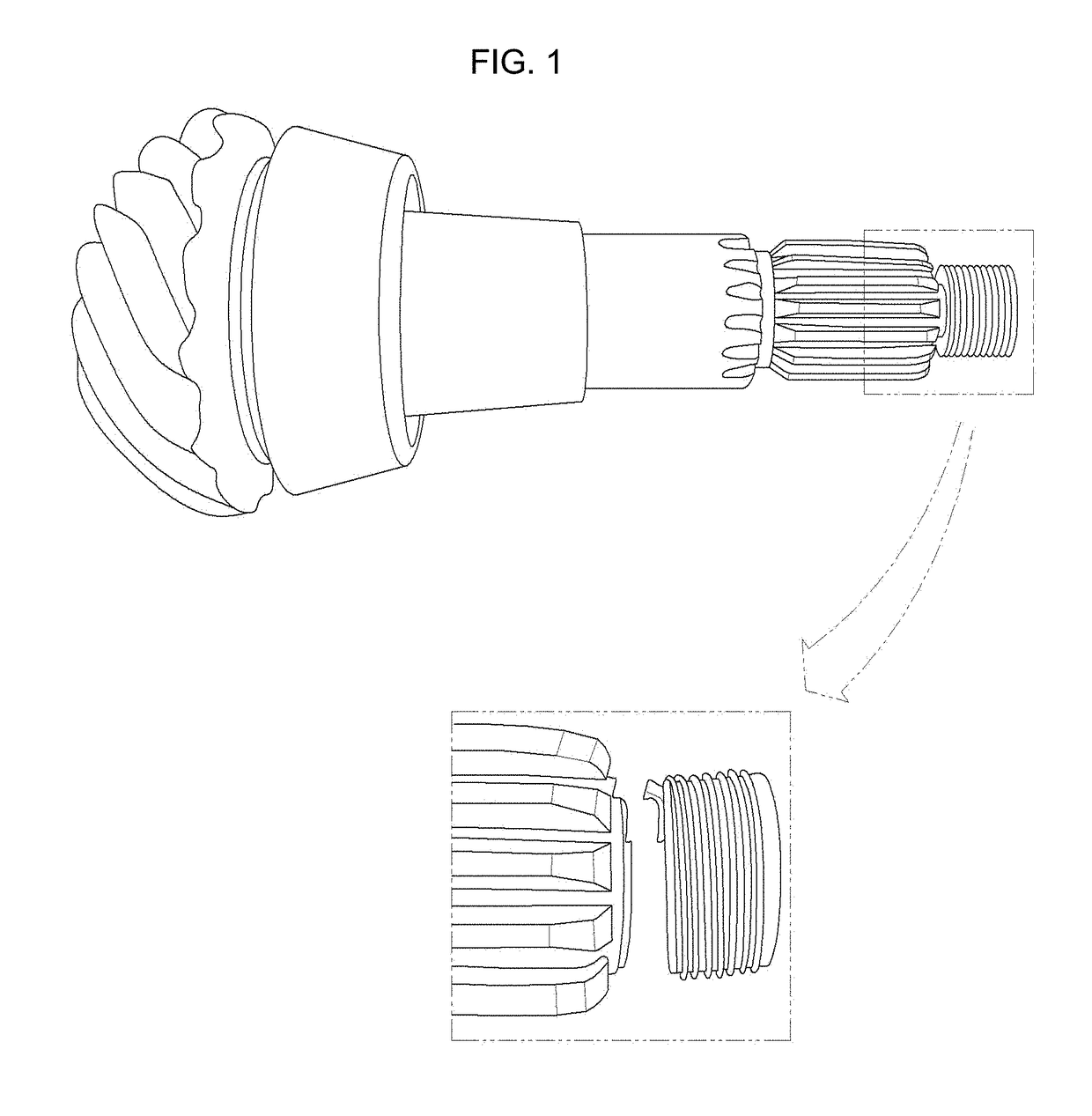

Alloy steel in which carburization is prevented by processing load and method of manufacturing the same

PatentActiveUS20180187295A1

Innovation

- An alloy steel composition with specific ranges of carbon, silicon, manganese, chromium, niobium, aluminum, and vanadium, processed under a high load to form an oxide film, which suppresses carburization without the need for anti-carburizing liquids, and a manufacturing method involving forging, heat treatment, working under a processing load, carburizing heat treatment, and polishing.

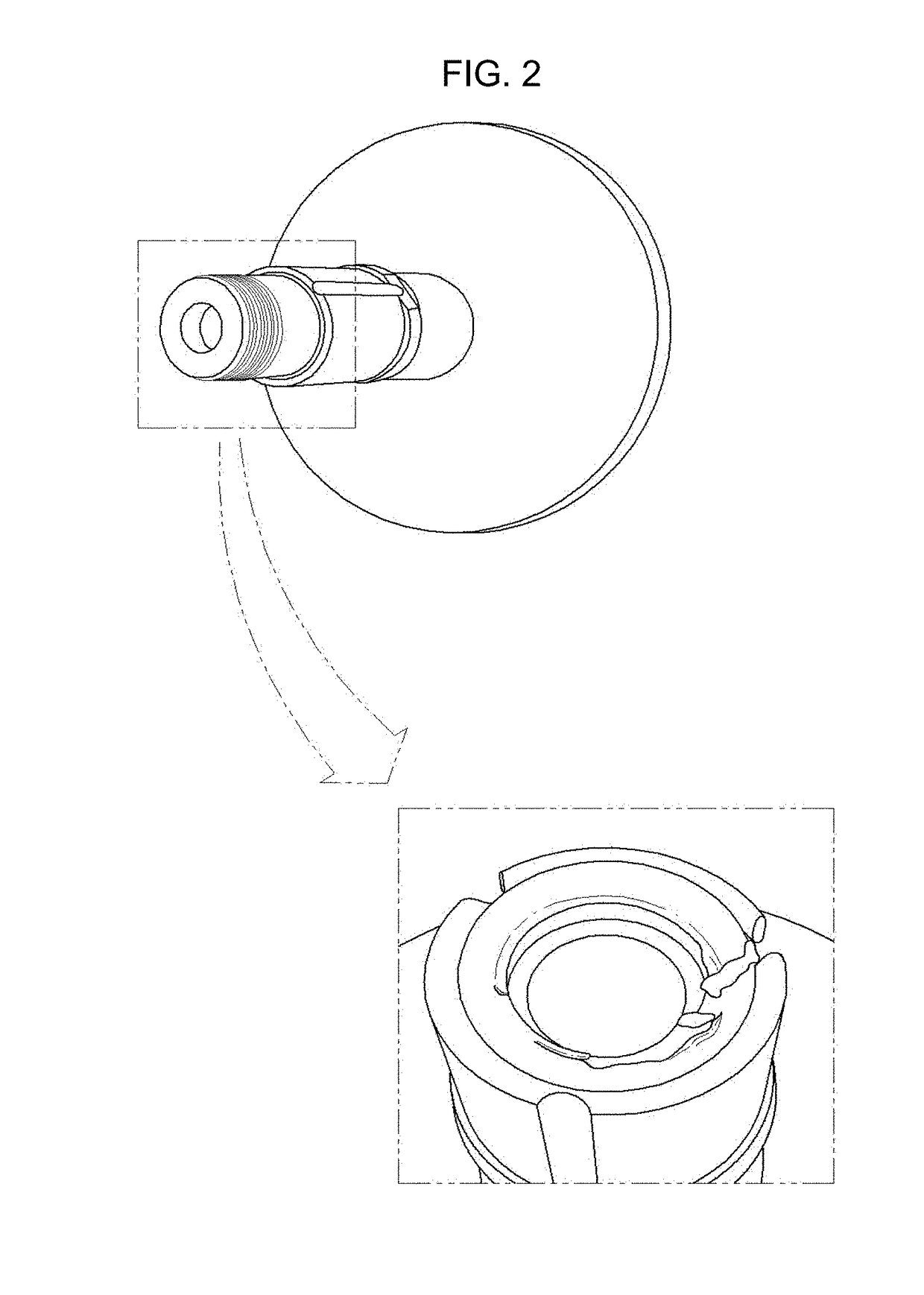

Carbon steel material welding method

PatentWO2021100218A1

Innovation

- A welding method that involves preheating the carbon steel materials to a temperature above the Ac1 transformation point before cooling, followed by slow cooling to 500°C at a rate not exceeding the maximum allowable cooling rate, to prevent martensite formation and reduce the carbon equivalent, thereby softening the weld and reducing the risk of brittle fracture.

Material Science Advancements for Enhanced Steel Properties

Recent advancements in materials science have significantly contributed to enhancing steel properties, particularly in addressing the challenge of brittleness during high carbon steel heat processing. These developments encompass innovative approaches in microstructure control, alloying element optimization, and novel heat treatment methodologies that collectively improve mechanical properties while reducing brittleness.

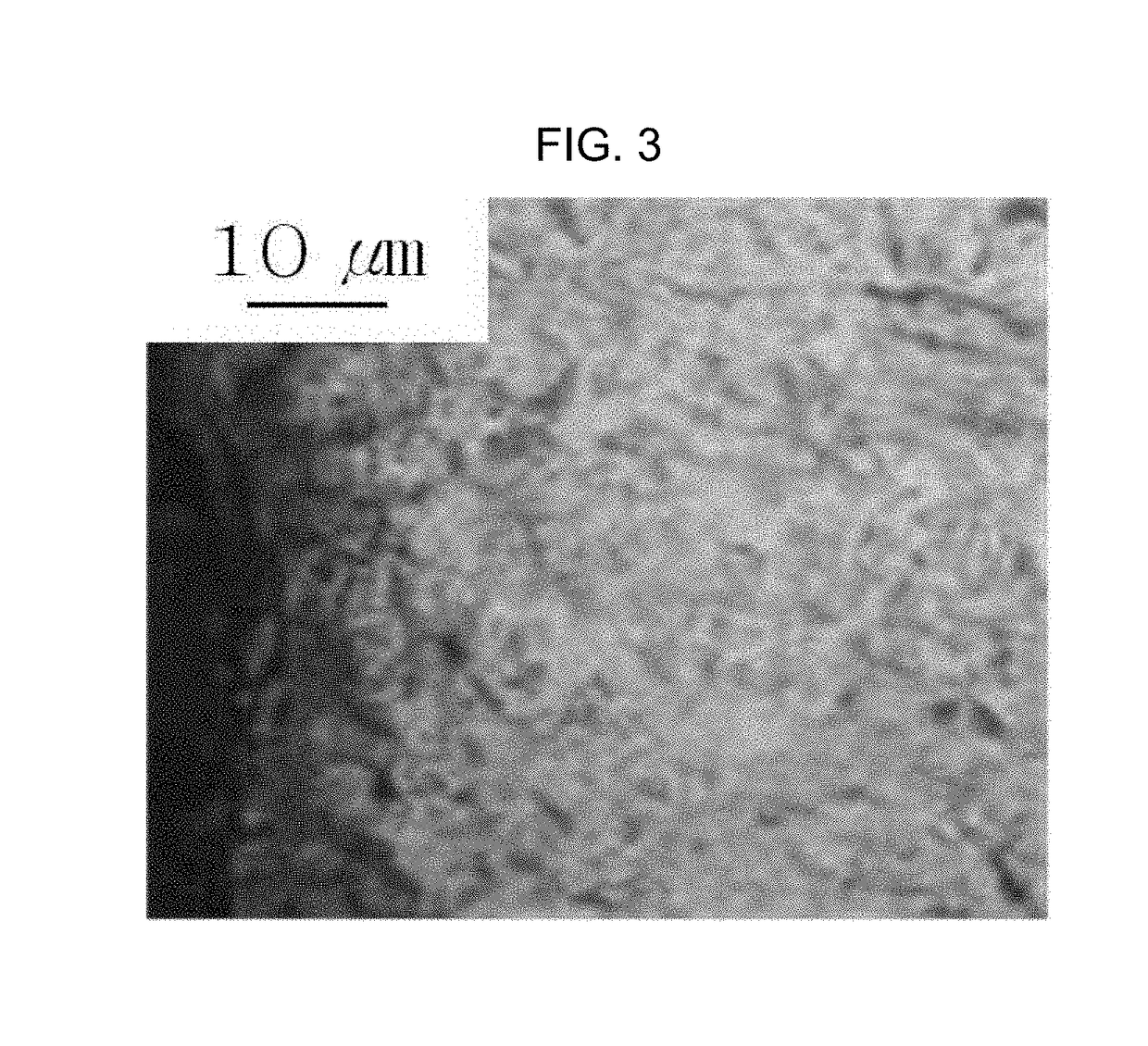

Nanomaterial integration represents one of the most promising frontiers in steel enhancement. The incorporation of nanoparticles, such as titanium nitride and vanadium carbide, into high carbon steel matrices has demonstrated remarkable effectiveness in grain refinement and dislocation pinning. These nanoscale additions create barriers to crack propagation, thereby increasing toughness without compromising hardness or wear resistance.

Advanced computational modeling has revolutionized the understanding of phase transformations during heat treatment. Machine learning algorithms now enable precise prediction of microstructural evolution under various thermal conditions, allowing metallurgists to design optimized heat treatment protocols that minimize brittleness. These models account for complex interactions between carbon content, alloying elements, and cooling rates to achieve ideal microstructures.

Controlled atmosphere processing represents another significant advancement. The development of specialized furnace environments with precisely regulated oxygen, nitrogen, and hydrogen levels has minimized detrimental reactions during heat treatment. Vacuum carburizing and low-pressure carburizing technologies have emerged as superior alternatives to conventional methods, producing more uniform carbon distribution and reducing internal stresses that contribute to brittleness.

Surface engineering techniques have evolved to create gradient structures in high carbon steels. Processes such as laser surface modification, plasma nitriding, and selective heat treatment generate engineered surfaces with varying mechanical properties across the depth profile. These gradient structures effectively combine surface hardness with core toughness, addressing the traditional brittleness-hardness trade-off.

Rapid solidification and quenching technologies have been refined through the development of specialized quenchants and controlled cooling systems. Polymer quenchants with programmable cooling characteristics allow for precise control over martensite formation, minimizing thermal gradients and associated internal stresses that contribute to brittleness. Similarly, advanced austempering processes produce bainitic structures with exceptional combinations of strength and toughness.

Nanomaterial integration represents one of the most promising frontiers in steel enhancement. The incorporation of nanoparticles, such as titanium nitride and vanadium carbide, into high carbon steel matrices has demonstrated remarkable effectiveness in grain refinement and dislocation pinning. These nanoscale additions create barriers to crack propagation, thereby increasing toughness without compromising hardness or wear resistance.

Advanced computational modeling has revolutionized the understanding of phase transformations during heat treatment. Machine learning algorithms now enable precise prediction of microstructural evolution under various thermal conditions, allowing metallurgists to design optimized heat treatment protocols that minimize brittleness. These models account for complex interactions between carbon content, alloying elements, and cooling rates to achieve ideal microstructures.

Controlled atmosphere processing represents another significant advancement. The development of specialized furnace environments with precisely regulated oxygen, nitrogen, and hydrogen levels has minimized detrimental reactions during heat treatment. Vacuum carburizing and low-pressure carburizing technologies have emerged as superior alternatives to conventional methods, producing more uniform carbon distribution and reducing internal stresses that contribute to brittleness.

Surface engineering techniques have evolved to create gradient structures in high carbon steels. Processes such as laser surface modification, plasma nitriding, and selective heat treatment generate engineered surfaces with varying mechanical properties across the depth profile. These gradient structures effectively combine surface hardness with core toughness, addressing the traditional brittleness-hardness trade-off.

Rapid solidification and quenching technologies have been refined through the development of specialized quenchants and controlled cooling systems. Polymer quenchants with programmable cooling characteristics allow for precise control over martensite formation, minimizing thermal gradients and associated internal stresses that contribute to brittleness. Similarly, advanced austempering processes produce bainitic structures with exceptional combinations of strength and toughness.

Environmental Impact of Heat Treatment Processes

Heat treatment processes in high carbon steel manufacturing contribute significantly to environmental concerns across multiple dimensions. The energy-intensive nature of these processes, particularly during austenitizing which requires temperatures between 800-950°C, results in substantial carbon emissions. Traditional heat treatment facilities typically consume between 3,000-5,000 kWh per ton of processed steel, with approximately 70% of this energy derived from fossil fuel sources, directly contributing to greenhouse gas emissions.

Water usage presents another critical environmental challenge. Quenching operations consume approximately 2-5 cubic meters of water per ton of steel processed. This water becomes contaminated with oils, dissolved metals, and treatment chemicals, requiring extensive treatment before discharge. Many facilities still operate with outdated water management systems that fail to meet contemporary environmental standards.

Atmospheric emissions from heat treatment processes extend beyond carbon dioxide to include nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter. Particularly concerning are volatile organic compounds (VOCs) released during oil quenching, which contribute to ground-level ozone formation and respiratory health issues in surrounding communities. Modern facilities have reduced these emissions by 40-60% through advanced filtration systems, but older operations continue to pose significant environmental hazards.

Waste generation includes spent quenchants, scale, and sludge containing heavy metals and other contaminants. Approximately 15-20 kg of hazardous waste is generated per ton of heat-treated high carbon steel. The disposal of these materials presents long-term environmental liabilities and increasing regulatory compliance costs for manufacturers.

Recent technological innovations offer promising pathways to reduce these environmental impacts. Induction heating systems can reduce energy consumption by 30-50% compared to conventional furnaces. Vacuum heat treatment eliminates the need for protective atmospheres and reduces emissions. Dry quenching technologies can decrease water usage by up to 80% while simultaneously capturing waste heat for reuse.

Regulatory frameworks worldwide are increasingly stringent regarding environmental compliance in industrial processes. The European Union's Industrial Emissions Directive and similar regulations in North America and Asia are driving manufacturers to adopt cleaner technologies. Companies implementing environmentally responsible heat treatment processes not only reduce compliance costs but often realize operational savings through improved energy efficiency and reduced waste management expenses.

Water usage presents another critical environmental challenge. Quenching operations consume approximately 2-5 cubic meters of water per ton of steel processed. This water becomes contaminated with oils, dissolved metals, and treatment chemicals, requiring extensive treatment before discharge. Many facilities still operate with outdated water management systems that fail to meet contemporary environmental standards.

Atmospheric emissions from heat treatment processes extend beyond carbon dioxide to include nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter. Particularly concerning are volatile organic compounds (VOCs) released during oil quenching, which contribute to ground-level ozone formation and respiratory health issues in surrounding communities. Modern facilities have reduced these emissions by 40-60% through advanced filtration systems, but older operations continue to pose significant environmental hazards.

Waste generation includes spent quenchants, scale, and sludge containing heavy metals and other contaminants. Approximately 15-20 kg of hazardous waste is generated per ton of heat-treated high carbon steel. The disposal of these materials presents long-term environmental liabilities and increasing regulatory compliance costs for manufacturers.

Recent technological innovations offer promising pathways to reduce these environmental impacts. Induction heating systems can reduce energy consumption by 30-50% compared to conventional furnaces. Vacuum heat treatment eliminates the need for protective atmospheres and reduces emissions. Dry quenching technologies can decrease water usage by up to 80% while simultaneously capturing waste heat for reuse.

Regulatory frameworks worldwide are increasingly stringent regarding environmental compliance in industrial processes. The European Union's Industrial Emissions Directive and similar regulations in North America and Asia are driving manufacturers to adopt cleaner technologies. Companies implementing environmentally responsible heat treatment processes not only reduce compliance costs but often realize operational savings through improved energy efficiency and reduced waste management expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!