How To Improve Machinability Of High Carbon Steel Components

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Carbon Steel Machinability Background and Objectives

High carbon steel, containing carbon content typically between 0.60% and 1.00%, has been a cornerstone material in manufacturing industries for decades due to its exceptional hardness, wear resistance, and strength characteristics. The evolution of this material can be traced back to the early 20th century when advancements in metallurgy enabled precise control of carbon content in steel production. Since then, high carbon steel has found extensive applications in cutting tools, dies, springs, and various high-stress components across automotive, aerospace, and industrial machinery sectors.

Despite its superior mechanical properties, the machinability of high carbon steel remains a significant challenge for manufacturers. The very properties that make it valuable—hardness and wear resistance—also make it difficult to machine efficiently. Historical approaches to improving machinability have evolved from basic heat treatment techniques to more sophisticated methods involving microstructure modification and advanced cutting technologies.

Current technological trends in this field are moving toward integrated solutions that combine material science innovations with cutting-edge machining processes. The industry is witnessing a shift from conventional machining methods to more precise, computer-controlled techniques that optimize tool-workpiece interactions. Additionally, there is growing interest in sustainable machining practices that reduce energy consumption and minimize waste while maintaining or improving productivity.

The primary objective of improving high carbon steel machinability is to achieve a balance between maintaining the material's desirable mechanical properties and enhancing its processability. Specific goals include reducing cutting forces, minimizing tool wear, improving surface finish quality, and increasing overall machining efficiency. These improvements would directly translate to cost savings, higher production rates, and extended tool life.

Secondary objectives encompass developing standardized protocols for machining different grades of high carbon steel, establishing predictive models for machining parameters, and creating comprehensive databases of optimal cutting conditions for various applications. The industry also aims to reduce the environmental impact of machining operations through more efficient processes and reduced use of cutting fluids.

Looking forward, the technological roadmap for high carbon steel machinability improvement is likely to incorporate advanced material modifications, innovative tool designs, optimized machining parameters, and intelligent manufacturing systems that can adapt in real-time to changing cutting conditions. The convergence of materials science, mechanical engineering, and digital technologies presents promising avenues for overcoming the longstanding challenges associated with machining high carbon steel components.

Despite its superior mechanical properties, the machinability of high carbon steel remains a significant challenge for manufacturers. The very properties that make it valuable—hardness and wear resistance—also make it difficult to machine efficiently. Historical approaches to improving machinability have evolved from basic heat treatment techniques to more sophisticated methods involving microstructure modification and advanced cutting technologies.

Current technological trends in this field are moving toward integrated solutions that combine material science innovations with cutting-edge machining processes. The industry is witnessing a shift from conventional machining methods to more precise, computer-controlled techniques that optimize tool-workpiece interactions. Additionally, there is growing interest in sustainable machining practices that reduce energy consumption and minimize waste while maintaining or improving productivity.

The primary objective of improving high carbon steel machinability is to achieve a balance between maintaining the material's desirable mechanical properties and enhancing its processability. Specific goals include reducing cutting forces, minimizing tool wear, improving surface finish quality, and increasing overall machining efficiency. These improvements would directly translate to cost savings, higher production rates, and extended tool life.

Secondary objectives encompass developing standardized protocols for machining different grades of high carbon steel, establishing predictive models for machining parameters, and creating comprehensive databases of optimal cutting conditions for various applications. The industry also aims to reduce the environmental impact of machining operations through more efficient processes and reduced use of cutting fluids.

Looking forward, the technological roadmap for high carbon steel machinability improvement is likely to incorporate advanced material modifications, innovative tool designs, optimized machining parameters, and intelligent manufacturing systems that can adapt in real-time to changing cutting conditions. The convergence of materials science, mechanical engineering, and digital technologies presents promising avenues for overcoming the longstanding challenges associated with machining high carbon steel components.

Market Demand Analysis for Improved Steel Machining

The global market for high carbon steel machining solutions has witnessed substantial growth in recent years, driven primarily by expanding applications in automotive, aerospace, defense, and industrial equipment manufacturing sectors. Current market estimates value the high-performance steel machining segment at approximately 12.5 billion USD, with a projected compound annual growth rate of 5.7% through 2028, significantly outpacing general metalworking market growth.

Automotive industry remains the largest consumer of high carbon steel components, accounting for nearly 38% of the total market share. The increasing demand for lightweight yet durable vehicle parts, particularly in electric vehicle production, has created new requirements for precision machining of high carbon steel. Manufacturers are seeking solutions that can reduce machining time while maintaining tight tolerances and surface finish quality.

The aerospace and defense sectors collectively represent the fastest-growing market segment, with demand increasing at 7.3% annually. These industries require components with exceptional mechanical properties and reliability, driving investment in advanced machining technologies specifically designed for high carbon steel. The need for complex geometries and thin-walled structures in modern aircraft design has further intensified market demand for innovative machining approaches.

Industrial equipment manufacturing constitutes approximately 24% of the market, with particular emphasis on heavy machinery components that require both wear resistance and dimensional stability. This sector shows increasing willingness to invest in premium machining solutions that can demonstrate clear return on investment through reduced tool replacement costs and minimized production downtime.

Regional analysis reveals that Asia-Pacific currently leads the market with 41% share, followed by North America (27%) and Europe (23%). China and India are experiencing the most rapid growth rates due to expanding manufacturing bases and increasing domestic consumption of high-precision components. However, the most sophisticated machining technologies remain concentrated in Germany, Japan, and the United States.

Market research indicates that manufacturers are prioritizing three key performance metrics when selecting machining solutions: tool life extension, reduction in machining cycle time, and improved surface finish quality. Survey data shows that 78% of manufacturing decision-makers would pay premium prices for solutions that can demonstrably improve these metrics when working with high carbon steel.

The market is also witnessing growing demand for environmentally sustainable machining processes, with 63% of large manufacturers now including sustainability criteria in their technology acquisition decisions. This trend is driving interest in dry machining techniques and cutting fluids with reduced environmental impact specifically formulated for high carbon steel applications.

Automotive industry remains the largest consumer of high carbon steel components, accounting for nearly 38% of the total market share. The increasing demand for lightweight yet durable vehicle parts, particularly in electric vehicle production, has created new requirements for precision machining of high carbon steel. Manufacturers are seeking solutions that can reduce machining time while maintaining tight tolerances and surface finish quality.

The aerospace and defense sectors collectively represent the fastest-growing market segment, with demand increasing at 7.3% annually. These industries require components with exceptional mechanical properties and reliability, driving investment in advanced machining technologies specifically designed for high carbon steel. The need for complex geometries and thin-walled structures in modern aircraft design has further intensified market demand for innovative machining approaches.

Industrial equipment manufacturing constitutes approximately 24% of the market, with particular emphasis on heavy machinery components that require both wear resistance and dimensional stability. This sector shows increasing willingness to invest in premium machining solutions that can demonstrate clear return on investment through reduced tool replacement costs and minimized production downtime.

Regional analysis reveals that Asia-Pacific currently leads the market with 41% share, followed by North America (27%) and Europe (23%). China and India are experiencing the most rapid growth rates due to expanding manufacturing bases and increasing domestic consumption of high-precision components. However, the most sophisticated machining technologies remain concentrated in Germany, Japan, and the United States.

Market research indicates that manufacturers are prioritizing three key performance metrics when selecting machining solutions: tool life extension, reduction in machining cycle time, and improved surface finish quality. Survey data shows that 78% of manufacturing decision-makers would pay premium prices for solutions that can demonstrably improve these metrics when working with high carbon steel.

The market is also witnessing growing demand for environmentally sustainable machining processes, with 63% of large manufacturers now including sustainability criteria in their technology acquisition decisions. This trend is driving interest in dry machining techniques and cutting fluids with reduced environmental impact specifically formulated for high carbon steel applications.

Current Challenges in High Carbon Steel Processing

High carbon steel components, containing carbon content typically between 0.60% and 1.00%, present significant machining challenges despite their desirable mechanical properties. The primary obstacle stems from their high hardness and strength, which accelerates tool wear and reduces tool life dramatically. Cutting tools experience severe abrasive wear when machining these materials, often requiring frequent replacement and causing production downtime.

The formation of hard carbides in high carbon steel microstructure creates additional machining difficulties. These carbide particles act as abrasive elements against cutting tools, causing premature edge deterioration and unpredictable tool failure. This phenomenon is particularly problematic in precision machining operations where dimensional accuracy is critical.

Heat generation during machining represents another major challenge. High carbon steels exhibit poor thermal conductivity, causing heat concentration at the cutting zone. This localized heating can trigger work hardening, where the material becomes progressively harder during the machining process, creating a self-reinforcing cycle of increasing cutting forces and further heat generation. The thermal issues also contribute to built-up edge formation on cutting tools, degrading surface finish quality.

Surface integrity maintenance presents ongoing difficulties in high carbon steel processing. The combination of high cutting forces and thermal effects often results in residual stresses, microstructural alterations, and surface defects that can compromise component performance, particularly in fatigue-critical applications. These surface integrity issues are especially problematic in industries like automotive and aerospace where component reliability is paramount.

Chip control and evacuation pose additional processing challenges. High carbon steels tend to produce continuous, ribbon-like chips that can entangle around the tool and workpiece, interrupting the machining process and potentially damaging both the machine and the component. This chip behavior necessitates frequent operator intervention, reducing productivity and increasing manufacturing costs.

The economic impact of these challenges is substantial. The combination of accelerated tool wear, reduced material removal rates, increased power consumption, and higher quality control requirements significantly elevates the processing costs of high carbon steel components compared to their lower carbon counterparts. These factors collectively constrain the broader industrial application of high carbon steels despite their superior mechanical properties.

Environmental considerations add another dimension to the processing challenges. The higher energy consumption and increased cutting fluid requirements for machining high carbon steels contribute to greater environmental impact, conflicting with growing sustainability imperatives in manufacturing operations.

The formation of hard carbides in high carbon steel microstructure creates additional machining difficulties. These carbide particles act as abrasive elements against cutting tools, causing premature edge deterioration and unpredictable tool failure. This phenomenon is particularly problematic in precision machining operations where dimensional accuracy is critical.

Heat generation during machining represents another major challenge. High carbon steels exhibit poor thermal conductivity, causing heat concentration at the cutting zone. This localized heating can trigger work hardening, where the material becomes progressively harder during the machining process, creating a self-reinforcing cycle of increasing cutting forces and further heat generation. The thermal issues also contribute to built-up edge formation on cutting tools, degrading surface finish quality.

Surface integrity maintenance presents ongoing difficulties in high carbon steel processing. The combination of high cutting forces and thermal effects often results in residual stresses, microstructural alterations, and surface defects that can compromise component performance, particularly in fatigue-critical applications. These surface integrity issues are especially problematic in industries like automotive and aerospace where component reliability is paramount.

Chip control and evacuation pose additional processing challenges. High carbon steels tend to produce continuous, ribbon-like chips that can entangle around the tool and workpiece, interrupting the machining process and potentially damaging both the machine and the component. This chip behavior necessitates frequent operator intervention, reducing productivity and increasing manufacturing costs.

The economic impact of these challenges is substantial. The combination of accelerated tool wear, reduced material removal rates, increased power consumption, and higher quality control requirements significantly elevates the processing costs of high carbon steel components compared to their lower carbon counterparts. These factors collectively constrain the broader industrial application of high carbon steels despite their superior mechanical properties.

Environmental considerations add another dimension to the processing challenges. The higher energy consumption and increased cutting fluid requirements for machining high carbon steels contribute to greater environmental impact, conflicting with growing sustainability imperatives in manufacturing operations.

Current Machinability Enhancement Methods

01 Alloying elements for improved machinability

Specific alloying elements can be added to high carbon steel to improve its machinability. Elements such as sulfur, lead, bismuth, tellurium, and selenium form inclusions that act as chip breakers during machining operations. These elements reduce cutting forces, decrease tool wear, and allow for higher cutting speeds. The controlled addition of these elements results in free-cutting steels that maintain the strength properties of high carbon steel while significantly improving machinability.- Alloying elements for improved machinability: Specific alloying elements can be added to high carbon steel to improve its machinability. Elements such as sulfur, lead, bismuth, tellurium, and selenium form inclusions that act as chip breakers during machining operations. These elements reduce cutting forces, decrease tool wear, and allow for higher cutting speeds. The controlled addition of these elements creates a balance between mechanical properties and machinability.

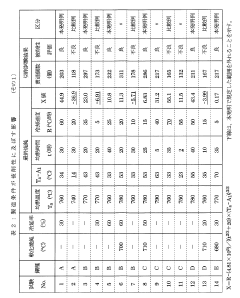

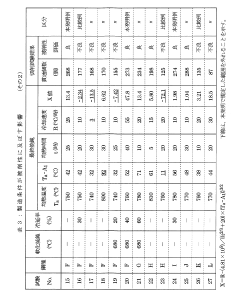

- Heat treatment processes for optimized machinability: Various heat treatment processes can be applied to high carbon steel to optimize its machinability. Processes such as annealing, normalizing, and spheroidizing can modify the microstructure to reduce hardness while maintaining strength. Spheroidized microstructures, where carbides form spherical particles instead of networks, are particularly beneficial for machining operations as they reduce tool wear and improve surface finish quality.

- Microstructure control for enhanced machinability: Controlling the microstructure of high carbon steel components significantly impacts their machinability. Fine-grained structures with evenly distributed carbides provide better machining characteristics than coarse structures with carbide networks. Techniques to achieve optimal microstructures include controlled cooling rates, deoxidation practices, and specific rolling parameters. The size, shape, and distribution of carbides within the steel matrix directly influence chip formation and tool life during machining operations.

- Surface treatments to improve machinability: Surface treatments can be applied to high carbon steel components to improve their machinability. These treatments include coatings, chemical treatments, and mechanical surface modifications that reduce friction between the tool and workpiece. By modifying the surface properties, these treatments can reduce cutting forces, minimize built-up edge formation, and extend tool life. Some treatments also provide lubrication effects that facilitate chip evacuation during machining operations.

- Machining parameter optimization for high carbon steel: Optimizing machining parameters is crucial for efficiently processing high carbon steel components. Parameters such as cutting speed, feed rate, depth of cut, tool geometry, and cooling strategies must be carefully selected based on the specific grade and condition of the high carbon steel. Advanced machining strategies like high-speed machining, cryogenic cooling, and specialized tool paths can significantly improve productivity while maintaining component quality and dimensional accuracy.

02 Heat treatment processes for optimized machinability

Various heat treatment processes can be applied to high carbon steel components to optimize their machinability. Processes such as spheroidizing annealing, normalizing, and controlled cooling after hot working can modify the microstructure to improve machinability. These treatments help to soften the material, reduce hardness variations, and create a more uniform microstructure that is easier to machine while maintaining the required mechanical properties for the final application.Expand Specific Solutions03 Microstructure control for enhanced machinability

Controlling the microstructure of high carbon steel is crucial for enhancing its machinability. Techniques to achieve favorable microstructures include controlling grain size, promoting spheroidized carbide formation, and ensuring uniform carbide distribution. A fine, uniform microstructure with well-distributed carbides reduces tool wear and improves surface finish during machining operations. Advanced processing methods can be employed to achieve the desired microstructure that balances machinability with the mechanical properties required for high carbon steel components.Expand Specific Solutions04 Surface treatments to facilitate machining

Various surface treatments can be applied to high carbon steel components to facilitate machining operations. These treatments include controlled decarburization, surface softening, and application of specialized coatings. By modifying the surface properties while maintaining the core characteristics of the high carbon steel, these treatments can significantly improve machinability, reduce tool wear, and enhance surface finish quality. Surface treatments can be particularly effective for components with complex geometries or tight tolerances.Expand Specific Solutions05 Machining parameter optimization

Optimizing machining parameters is essential for efficiently processing high carbon steel components. This includes selecting appropriate cutting speeds, feed rates, depth of cut, and tool geometries specifically designed for high carbon steels. Proper cooling and lubrication strategies, such as high-pressure coolant application or minimum quantity lubrication, can significantly improve machinability by reducing cutting temperatures and friction. Advanced machining strategies, such as high-speed machining with optimized tool paths, can also enhance productivity while maintaining component quality.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The high carbon steel machinability improvement market is in a growth phase, with increasing demand driven by automotive, aerospace, and industrial applications. Major players like NIPPON STEEL, Daido Steel, JFE Steel, and ArcelorMittal are leading technological advancements in this field. The market is characterized by varying levels of technical maturity, with established companies like Kobe Steel and POSCO Holdings offering conventional solutions while newer innovations emerge from research collaborations between industry and academic institutions such as Yanshan University and University of Science & Technology Beijing. Companies like Schaeffler Technologies and Hitachi are developing specialized machining techniques and tool coatings, while automotive manufacturers including Honda, Mazda, and Hyundai are driving demand for improved machinability solutions to enhance manufacturing efficiency and component performance.

NIPPON STEEL CORP.

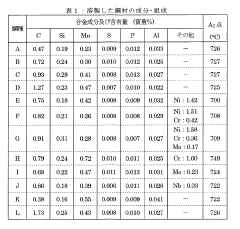

Technical Solution: Nippon Steel has developed advanced machinability-enhanced high carbon steel through microstructure control techniques. Their approach involves precise control of non-metallic inclusions, particularly sulfides and oxides, which act as stress concentration points during machining. By optimizing the size, distribution, and morphology of these inclusions, they create controlled fracture points that reduce cutting forces and tool wear. Additionally, Nippon Steel employs specialized heat treatment processes to achieve optimal carbide distribution and size, preventing the formation of large, abrasive carbide networks that typically impair machinability. Their proprietary "Free-Cutting Steel" technology incorporates controlled amounts of elements like sulfur, lead (in non-environmentally sensitive applications), calcium, and tellurium to form soft phases that act as solid lubricants during machining operations[1][3]. Recent developments include lead-free alternatives that maintain excellent machinability while meeting environmental regulations.

Strengths: Superior balance between high strength and machinability; environmentally compliant formulations; consistent quality across large production volumes; reduced tool wear leading to longer tool life. Weaknesses: Higher production costs compared to standard grades; requires precise process control; some specialty grades have limited availability; potential for batch-to-batch variation in machinability performance.

Daido Steel Co., Ltd.

Technical Solution: Daido Steel has pioneered the development of DEX series high carbon steels with enhanced machinability specifically designed for bearing and automotive applications. Their technology focuses on controlled spheroidization of carbides through precise thermal cycling processes, resulting in uniformly distributed spherical carbides rather than the typical network structures found in conventional high carbon steels. This microstructural engineering significantly reduces tool-workpiece friction and cutting forces. Daido's proprietary "Clean Steel" technology minimizes harmful inclusions while strategically introducing beneficial ones that promote chip breaking. Their advanced vacuum degassing processes reduce oxygen content to below 10ppm, preventing the formation of hard, abrasive oxides that accelerate tool wear[2]. Additionally, Daido employs controlled cooling techniques after hot rolling to achieve optimal pearlite spacing and cementite morphology, factors critical to improving machinability while maintaining the mechanical properties required for high-stress applications.

Strengths: Exceptional dimensional stability during machining; superior surface finish quality; consistent machinability across different production batches; excellent balance of hardness and machinability. Weaknesses: Higher initial material cost compared to standard grades; requires specialized heat treatment facilities; limited availability for small-volume orders; some grades require specific cutting parameters to achieve optimal results.

Key Technological Innovations in Tool Materials

High carbon high manganese steel with high machinability

PatentInactiveJP1980076042A

Innovation

- Controlling the composition of nonmetallic inclusions (oxides) to be in the anorthite region of the CaO-Al2O3-SiO2 ternary phase diagram to enhance machinability of high carbon high manganese steel.

- Setting the ternary oxide amount to 80% of the total oxide amount to achieve improved machinability in high strength nonmagnetic or wear and impact resistant materials.

- Optional addition of 0.0005-0.02% Ca along with Pb, S, and Se to further enhance the machinability of high carbon high manganese steel.

Method for manufacturing middle or high carbon steel sheet excellent in machinability

PatentInactiveJP2011117084A

Innovation

- Controlled composition of steel components and heat treatment conditions, including specific soaking temperatures, times, and cooling rates, to stabilize machinability by forming a mixed structure of spheroidal cementite and pearlite, without relying on additional elements or precipitation dispersion.

Economic Impact Assessment of Improved Machining

Improving the machinability of high carbon steel components yields significant economic benefits across multiple industrial sectors. Manufacturing companies can achieve cost reductions of 15-30% through decreased tool wear and extended tool life, which directly impacts production expenses. Tool replacement frequency decreases substantially, with documented cases showing up to 40% longer tool life when optimized machining parameters and appropriate cooling techniques are implemented.

Production efficiency gains translate to measurable economic advantages, with manufacturing cycle times potentially decreasing by 10-25%. This improvement allows for higher throughput without additional capital investment in machinery or floor space. Energy consumption during machining operations can be reduced by 8-20%, contributing to both cost savings and environmental sustainability goals that increasingly factor into economic calculations.

Quality improvements resulting from enhanced machinability deliver downstream economic benefits through reduced scrap rates and rework requirements. Studies across automotive and aerospace sectors indicate scrap reduction of 5-15% when implementing advanced machining techniques for high carbon steel components. The associated warranty and liability cost reductions, though difficult to quantify precisely, represent significant long-term economic value.

Supply chain economics also benefit from improved machinability. Just-in-time manufacturing becomes more reliable with consistent machining outcomes, reducing inventory carrying costs by 7-12% in documented implementation cases. The ability to machine components closer to final dimensions reduces secondary processing requirements, creating additional cost efficiencies throughout the manufacturing value chain.

From a market competitiveness perspective, manufacturers who master high carbon steel machinability gain pricing advantages or margin improvements of 3-8% compared to competitors struggling with traditional approaches. This competitive edge enables strategic pricing flexibility or improved profitability, depending on market conditions and corporate objectives.

Labor cost implications are equally significant, with skilled machinist time being utilized more efficiently when dealing with materials that machine predictably. Reduced setup times, fewer adjustments during production runs, and decreased supervision requirements contribute to labor productivity improvements of 10-18% in optimized operations.

When quantified across the entire product lifecycle, the economic impact of improved high carbon steel machinability represents a compelling return on investment, with typical payback periods for technology implementation ranging from 8-24 months depending on production volumes and component complexity.

Production efficiency gains translate to measurable economic advantages, with manufacturing cycle times potentially decreasing by 10-25%. This improvement allows for higher throughput without additional capital investment in machinery or floor space. Energy consumption during machining operations can be reduced by 8-20%, contributing to both cost savings and environmental sustainability goals that increasingly factor into economic calculations.

Quality improvements resulting from enhanced machinability deliver downstream economic benefits through reduced scrap rates and rework requirements. Studies across automotive and aerospace sectors indicate scrap reduction of 5-15% when implementing advanced machining techniques for high carbon steel components. The associated warranty and liability cost reductions, though difficult to quantify precisely, represent significant long-term economic value.

Supply chain economics also benefit from improved machinability. Just-in-time manufacturing becomes more reliable with consistent machining outcomes, reducing inventory carrying costs by 7-12% in documented implementation cases. The ability to machine components closer to final dimensions reduces secondary processing requirements, creating additional cost efficiencies throughout the manufacturing value chain.

From a market competitiveness perspective, manufacturers who master high carbon steel machinability gain pricing advantages or margin improvements of 3-8% compared to competitors struggling with traditional approaches. This competitive edge enables strategic pricing flexibility or improved profitability, depending on market conditions and corporate objectives.

Labor cost implications are equally significant, with skilled machinist time being utilized more efficiently when dealing with materials that machine predictably. Reduced setup times, fewer adjustments during production runs, and decreased supervision requirements contribute to labor productivity improvements of 10-18% in optimized operations.

When quantified across the entire product lifecycle, the economic impact of improved high carbon steel machinability represents a compelling return on investment, with typical payback periods for technology implementation ranging from 8-24 months depending on production volumes and component complexity.

Sustainability Considerations in Steel Processing

The environmental impact of steel processing has become a critical consideration in modern manufacturing, particularly when improving the machinability of high carbon steel components. Sustainable practices in this domain must address the entire lifecycle of steel processing, from raw material extraction to end-of-life recycling. The energy-intensive nature of machining high carbon steel presents significant environmental challenges that require innovative solutions.

Traditional machining methods for high carbon steel typically consume substantial energy and often utilize environmentally harmful cutting fluids. Recent advancements have focused on developing biodegradable cutting fluids derived from vegetable oils and other renewable sources, which significantly reduce environmental toxicity while maintaining or even enhancing machinability performance. These bio-based alternatives have demonstrated promising results in reducing tool wear and improving surface finish quality.

Waste reduction strategies have emerged as another crucial aspect of sustainable steel processing. Precision machining techniques, such as near-net-shape manufacturing and optimized tool path planning, minimize material waste by reducing the amount of metal removed during machining operations. Additionally, the implementation of closed-loop recycling systems for metal chips and cutting fluids has shown considerable potential for reducing the environmental footprint of high carbon steel component production.

Energy efficiency improvements represent a significant opportunity for enhancing sustainability in steel processing. Advanced machine tools with regenerative drives can recover energy during deceleration phases, while intelligent process monitoring systems optimize cutting parameters in real-time to minimize energy consumption. Studies indicate that such technologies can reduce energy usage by 15-30% compared to conventional machining systems.

Carbon footprint reduction has become increasingly important in steel processing sustainability. Heat treatment modifications that lower processing temperatures while maintaining desired material properties can substantially reduce greenhouse gas emissions. Furthermore, the integration of renewable energy sources into manufacturing facilities offers a pathway to carbon-neutral steel processing operations, with several leading manufacturers already implementing solar and wind power systems to offset their carbon emissions.

Lifecycle assessment (LCA) methodologies are now being applied to evaluate the environmental impact of different machinability enhancement techniques for high carbon steel. These assessments consider factors such as resource depletion, global warming potential, and human toxicity across the entire product lifecycle. Recent LCA studies have revealed that certain machinability improvements, such as microstructural modifications through controlled heat treatment, can deliver significant environmental benefits compared to traditional approaches that rely heavily on aggressive cutting fluids and high-energy machining processes.

Traditional machining methods for high carbon steel typically consume substantial energy and often utilize environmentally harmful cutting fluids. Recent advancements have focused on developing biodegradable cutting fluids derived from vegetable oils and other renewable sources, which significantly reduce environmental toxicity while maintaining or even enhancing machinability performance. These bio-based alternatives have demonstrated promising results in reducing tool wear and improving surface finish quality.

Waste reduction strategies have emerged as another crucial aspect of sustainable steel processing. Precision machining techniques, such as near-net-shape manufacturing and optimized tool path planning, minimize material waste by reducing the amount of metal removed during machining operations. Additionally, the implementation of closed-loop recycling systems for metal chips and cutting fluids has shown considerable potential for reducing the environmental footprint of high carbon steel component production.

Energy efficiency improvements represent a significant opportunity for enhancing sustainability in steel processing. Advanced machine tools with regenerative drives can recover energy during deceleration phases, while intelligent process monitoring systems optimize cutting parameters in real-time to minimize energy consumption. Studies indicate that such technologies can reduce energy usage by 15-30% compared to conventional machining systems.

Carbon footprint reduction has become increasingly important in steel processing sustainability. Heat treatment modifications that lower processing temperatures while maintaining desired material properties can substantially reduce greenhouse gas emissions. Furthermore, the integration of renewable energy sources into manufacturing facilities offers a pathway to carbon-neutral steel processing operations, with several leading manufacturers already implementing solar and wind power systems to offset their carbon emissions.

Lifecycle assessment (LCA) methodologies are now being applied to evaluate the environmental impact of different machinability enhancement techniques for high carbon steel. These assessments consider factors such as resource depletion, global warming potential, and human toxicity across the entire product lifecycle. Recent LCA studies have revealed that certain machinability improvements, such as microstructural modifications through controlled heat treatment, can deliver significant environmental benefits compared to traditional approaches that rely heavily on aggressive cutting fluids and high-energy machining processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!