How To Optimize Case Hardening For High Carbon Surface Layers

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Case Hardening Technology Background and Objectives

Case hardening, a thermochemical heat treatment process, has evolved significantly since its inception in ancient civilizations. Originally, early blacksmiths discovered that burying iron tools in carbon-rich materials like bone or charcoal during heating could create harder surfaces. This rudimentary understanding has transformed into sophisticated industrial processes that precisely control carbon diffusion into metal surfaces.

The technology has progressed through several distinct phases, from traditional pack carburizing methods to modern gas, vacuum, and plasma carburizing techniques. Each evolutionary step has brought improvements in process control, energy efficiency, and environmental impact. The development of computer-controlled systems in the late 20th century marked a significant advancement, enabling precise manipulation of temperature profiles, atmosphere composition, and treatment duration.

Recent technological trends in case hardening focus on achieving deeper case depths with higher carbon concentrations while maintaining core ductility. The industry has been moving toward more environmentally friendly processes that reduce energy consumption and eliminate hazardous waste. Additionally, there is growing interest in developing hybrid techniques that combine traditional case hardening with other surface modification methods to achieve superior performance characteristics.

The primary technical objective in optimizing case hardening for high carbon surface layers is to achieve a precise balance between surface hardness and core toughness. This involves controlling carbon diffusion to create gradients that transition smoothly from high-carbon surface layers (typically 0.8-1.0% carbon) to the lower-carbon core material. The goal is to produce components with exceptional wear resistance and fatigue strength without compromising impact resistance or introducing excessive brittleness.

Secondary objectives include reducing distortion during the hardening process, minimizing energy consumption, shortening cycle times, and ensuring consistent results across batch processing. There is also significant interest in developing predictive models that can accurately forecast case depth and hardness profiles based on process parameters, reducing the need for extensive trial-and-error testing.

The ultimate aim of current research is to develop case hardening protocols that can be tailored to specific component geometries and service requirements, moving away from one-size-fits-all approaches. This includes optimizing carbon potential in the carburizing atmosphere, controlling diffusion kinetics through precise temperature management, and developing novel quenching techniques that minimize distortion while maximizing hardness.

The technology has progressed through several distinct phases, from traditional pack carburizing methods to modern gas, vacuum, and plasma carburizing techniques. Each evolutionary step has brought improvements in process control, energy efficiency, and environmental impact. The development of computer-controlled systems in the late 20th century marked a significant advancement, enabling precise manipulation of temperature profiles, atmosphere composition, and treatment duration.

Recent technological trends in case hardening focus on achieving deeper case depths with higher carbon concentrations while maintaining core ductility. The industry has been moving toward more environmentally friendly processes that reduce energy consumption and eliminate hazardous waste. Additionally, there is growing interest in developing hybrid techniques that combine traditional case hardening with other surface modification methods to achieve superior performance characteristics.

The primary technical objective in optimizing case hardening for high carbon surface layers is to achieve a precise balance between surface hardness and core toughness. This involves controlling carbon diffusion to create gradients that transition smoothly from high-carbon surface layers (typically 0.8-1.0% carbon) to the lower-carbon core material. The goal is to produce components with exceptional wear resistance and fatigue strength without compromising impact resistance or introducing excessive brittleness.

Secondary objectives include reducing distortion during the hardening process, minimizing energy consumption, shortening cycle times, and ensuring consistent results across batch processing. There is also significant interest in developing predictive models that can accurately forecast case depth and hardness profiles based on process parameters, reducing the need for extensive trial-and-error testing.

The ultimate aim of current research is to develop case hardening protocols that can be tailored to specific component geometries and service requirements, moving away from one-size-fits-all approaches. This includes optimizing carbon potential in the carburizing atmosphere, controlling diffusion kinetics through precise temperature management, and developing novel quenching techniques that minimize distortion while maximizing hardness.

Market Demand Analysis for High Carbon Surface Treatments

The global market for high carbon surface treatments, particularly case hardening processes, has been experiencing steady growth driven by increasing demands across multiple industrial sectors. The automotive industry remains the largest consumer of case hardened components, accounting for approximately 40% of the total market share. This demand is primarily fueled by the need for durable transmission components, gears, and engine parts that can withstand high stress and fatigue conditions while maintaining dimensional stability.

Aerospace and defense sectors represent the second largest market segment, with particular emphasis on landing gear components, turbine parts, and critical fasteners. These applications require exceptional surface hardness combined with core toughness to ensure safety and reliability under extreme operating conditions. Market analysis indicates this sector is growing at a compound annual rate of 5.7%, outpacing the overall market average.

Heavy machinery and industrial equipment manufacturers constitute another significant market segment, particularly in mining, construction, and agricultural equipment where components are subjected to severe abrasive wear and impact loading. The demand for optimized case hardening solutions in this sector has increased by 6.3% over the past three years, reflecting the industry's focus on extending component service life and reducing maintenance costs.

Regional market distribution shows North America and Europe as traditional strongholds for advanced case hardening technologies, collectively accounting for 58% of global market value. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 8.2% annually, driven by rapid industrialization and expanding manufacturing capabilities in automotive and machinery sectors.

Economic factors influencing market demand include increasing pressure for cost reduction in manufacturing processes, with customers seeking case hardening solutions that minimize energy consumption and processing time while maintaining or improving quality standards. This has accelerated interest in optimized case hardening processes that can achieve deeper carbon penetration in shorter cycle times.

Environmental regulations are also reshaping market demands, with stricter controls on quenching oils, salt bath compositions, and emissions from heat treatment facilities. This regulatory landscape has created growing interest in environmentally friendly alternatives such as vacuum carburizing and plasma-assisted processes, which are projected to gain 12% market share over the next five years.

Customer requirements are increasingly focused on precision and consistency, with specifications for case depth tolerance becoming more stringent. Industries are demanding surface carbon concentrations that can be controlled within ±0.05% and case depths within ±0.1mm, particularly for high-precision components in automotive transmissions and aerospace applications.

Aerospace and defense sectors represent the second largest market segment, with particular emphasis on landing gear components, turbine parts, and critical fasteners. These applications require exceptional surface hardness combined with core toughness to ensure safety and reliability under extreme operating conditions. Market analysis indicates this sector is growing at a compound annual rate of 5.7%, outpacing the overall market average.

Heavy machinery and industrial equipment manufacturers constitute another significant market segment, particularly in mining, construction, and agricultural equipment where components are subjected to severe abrasive wear and impact loading. The demand for optimized case hardening solutions in this sector has increased by 6.3% over the past three years, reflecting the industry's focus on extending component service life and reducing maintenance costs.

Regional market distribution shows North America and Europe as traditional strongholds for advanced case hardening technologies, collectively accounting for 58% of global market value. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 8.2% annually, driven by rapid industrialization and expanding manufacturing capabilities in automotive and machinery sectors.

Economic factors influencing market demand include increasing pressure for cost reduction in manufacturing processes, with customers seeking case hardening solutions that minimize energy consumption and processing time while maintaining or improving quality standards. This has accelerated interest in optimized case hardening processes that can achieve deeper carbon penetration in shorter cycle times.

Environmental regulations are also reshaping market demands, with stricter controls on quenching oils, salt bath compositions, and emissions from heat treatment facilities. This regulatory landscape has created growing interest in environmentally friendly alternatives such as vacuum carburizing and plasma-assisted processes, which are projected to gain 12% market share over the next five years.

Customer requirements are increasingly focused on precision and consistency, with specifications for case depth tolerance becoming more stringent. Industries are demanding surface carbon concentrations that can be controlled within ±0.05% and case depths within ±0.1mm, particularly for high-precision components in automotive transmissions and aerospace applications.

Current State and Challenges in Case Hardening Processes

Case hardening technology has evolved significantly over the past decades, with current industrial practices primarily centered around three main processes: carburizing, carbonitriding, and nitrocarburizing. These processes have been refined to achieve high carbon surface layers with improved wear resistance, fatigue strength, and overall component durability. However, despite technological advancements, several challenges persist in optimizing these processes for consistent and predictable results.

The global case hardening market is dominated by gas carburizing, which accounts for approximately 60% of all industrial case hardening applications. This process typically achieves carbon concentrations of 0.8-1.0% in the surface layer, with case depths ranging from 0.5 to 2.0 mm. Vacuum carburizing has gained significant traction in the past decade, growing at a CAGR of 7.2%, particularly in aerospace and high-precision automotive applications.

A major technical challenge in current case hardening processes is the precise control of carbon potential during the diffusion phase. Fluctuations in carbon potential can lead to inconsistent case depths and carbon gradients, affecting the mechanical properties of the treated components. Studies indicate that even a 0.05% variation in carbon concentration can result in hardness deviations of up to 2-3 HRC points, which is unacceptable for high-precision applications.

Another significant challenge is the formation of carbide networks at grain boundaries when processing high-carbon steels. These networks can lead to brittleness and reduced impact resistance. Current mitigation strategies include carefully controlled cooling rates and post-carburizing heat treatments, but these add complexity and cost to the overall process.

Distortion control remains one of the most persistent challenges in case hardening processes. Recent industry data suggests that distortion-related rework and scrap accounts for 4-8% of production costs in precision component manufacturing. The multifactorial nature of distortion—influenced by material composition, component geometry, fixture design, and quenching parameters—makes it particularly difficult to predict and control.

Energy efficiency and environmental impact present additional challenges. Traditional gas carburizing processes operate at temperatures between 900-950°C for extended periods, resulting in significant energy consumption. Modern vacuum carburizing systems have improved efficiency by 15-20%, but further optimization is needed to meet increasingly stringent sustainability requirements and carbon footprint reduction targets.

The integration of digital technologies for process monitoring and control represents both an opportunity and a challenge. While Industry 4.0 concepts offer potential for real-time process optimization, the implementation of comprehensive sensor networks capable of withstanding harsh furnace environments remains technically challenging. Current sensor technologies often suffer from drift and limited lifespan in high-temperature, carbon-rich atmospheres.

The global case hardening market is dominated by gas carburizing, which accounts for approximately 60% of all industrial case hardening applications. This process typically achieves carbon concentrations of 0.8-1.0% in the surface layer, with case depths ranging from 0.5 to 2.0 mm. Vacuum carburizing has gained significant traction in the past decade, growing at a CAGR of 7.2%, particularly in aerospace and high-precision automotive applications.

A major technical challenge in current case hardening processes is the precise control of carbon potential during the diffusion phase. Fluctuations in carbon potential can lead to inconsistent case depths and carbon gradients, affecting the mechanical properties of the treated components. Studies indicate that even a 0.05% variation in carbon concentration can result in hardness deviations of up to 2-3 HRC points, which is unacceptable for high-precision applications.

Another significant challenge is the formation of carbide networks at grain boundaries when processing high-carbon steels. These networks can lead to brittleness and reduced impact resistance. Current mitigation strategies include carefully controlled cooling rates and post-carburizing heat treatments, but these add complexity and cost to the overall process.

Distortion control remains one of the most persistent challenges in case hardening processes. Recent industry data suggests that distortion-related rework and scrap accounts for 4-8% of production costs in precision component manufacturing. The multifactorial nature of distortion—influenced by material composition, component geometry, fixture design, and quenching parameters—makes it particularly difficult to predict and control.

Energy efficiency and environmental impact present additional challenges. Traditional gas carburizing processes operate at temperatures between 900-950°C for extended periods, resulting in significant energy consumption. Modern vacuum carburizing systems have improved efficiency by 15-20%, but further optimization is needed to meet increasingly stringent sustainability requirements and carbon footprint reduction targets.

The integration of digital technologies for process monitoring and control represents both an opportunity and a challenge. While Industry 4.0 concepts offer potential for real-time process optimization, the implementation of comprehensive sensor networks capable of withstanding harsh furnace environments remains technically challenging. Current sensor technologies often suffer from drift and limited lifespan in high-temperature, carbon-rich atmospheres.

Current Technical Solutions for Carbon Surface Layer Optimization

01 Carburizing processes for case hardening

Various carburizing processes can be used to create hardened carbon surface layers on metal components. These processes involve introducing carbon into the surface of the metal at high temperatures, followed by quenching to achieve the desired hardness. Methods include gas carburizing, pack carburizing, and vacuum carburizing, each offering different advantages in terms of control, depth of case hardening, and environmental impact.- Carburizing processes for case hardening: Various carburizing processes can be used to create hardened carbon surface layers on metal components. These processes involve introducing carbon into the surface of the metal at elevated temperatures, followed by quenching to achieve the desired hardness. Methods include gas carburizing, pack carburizing, and vacuum carburizing, each offering different advantages in terms of control, depth of case hardening, and environmental impact.

- Plasma and ion-based surface hardening techniques: Advanced techniques using plasma or ion implantation can be employed to create hardened carbon surface layers. These methods offer precise control over the case depth and composition, allowing for tailored surface properties. Plasma-assisted processes can operate at lower temperatures than traditional carburizing, reducing distortion in treated components while achieving high surface hardness and wear resistance.

- Heat treatment parameters for optimal case hardening: Specific heat treatment parameters significantly influence the quality and characteristics of carbon-hardened surface layers. These parameters include temperature profiles, holding times, cooling rates, and post-treatment tempering processes. Optimizing these variables allows for control over case depth, hardness distribution, and microstructural development, resulting in improved wear resistance and fatigue strength of the treated components.

- Specialized carbon-based coatings and surface treatments: Various specialized carbon-based coatings and surface treatments can be applied to enhance surface hardness. These include diamond-like carbon (DLC) coatings, carbon-rich composite layers, and hybrid treatment processes combining different hardening mechanisms. Such treatments can provide exceptional wear resistance, low friction coefficients, and corrosion protection while maintaining the toughness of the base material.

- Component-specific case hardening applications: Case hardening processes can be tailored for specific components and applications, such as gears, bearings, shafts, and tools. The geometry, base material, and intended service conditions influence the selection of appropriate case hardening methods. Localized hardening techniques may be employed to treat only critical areas of components, optimizing performance while minimizing processing costs and potential distortion issues.

02 Plasma and ion-based surface hardening techniques

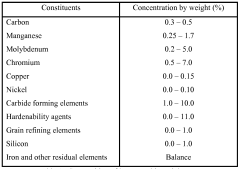

Advanced plasma and ion-based techniques offer precise control over the case hardening process. These methods use plasma or ion bombardment to introduce carbon into the metal surface, creating hardened layers with specific characteristics. These techniques typically operate at lower temperatures than traditional carburizing methods and can produce more uniform case depths with reduced distortion of the treated components.Expand Specific Solutions03 Specialized alloys and compositions for enhanced case hardening

The development of specialized alloys and material compositions can significantly improve the case hardening process and results. These materials are designed to respond optimally to carbon diffusion, creating superior hardened surface layers. The compositions may include specific elements that promote carbon absorption or enhance the microstructural properties of the hardened layer, resulting in improved wear resistance and fatigue strength.Expand Specific Solutions04 Heat treatment protocols for optimized case hardening

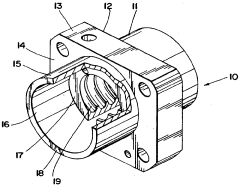

Specific heat treatment protocols are crucial for achieving optimal case hardening results. These protocols involve precise control of temperature, time, and cooling rates during the carburizing and subsequent hardening processes. Advanced heat treatment methods may include multi-stage heating cycles, controlled atmosphere environments, and specialized quenching techniques to minimize distortion while maximizing surface hardness and case depth.Expand Specific Solutions05 Equipment and tooling for case hardening applications

Specialized equipment and tooling have been developed for various case hardening applications. These include furnaces with precise atmosphere control, fixtures for holding components during treatment, and monitoring systems to ensure process consistency. Innovations in equipment design focus on energy efficiency, process automation, and the ability to handle components of various sizes and geometries while maintaining uniform case hardening results.Expand Specific Solutions

Key Industry Players in Surface Hardening Technologies

The case hardening optimization market for high carbon surface layers is currently in a growth phase, with increasing demand across automotive, aerospace, and industrial sectors. The competitive landscape is characterized by a mix of established players and specialized technology providers. Companies like Timken, SKF, and Komatsu lead with mature case hardening technologies, while Oerlikon Surface Solutions and Applied Materials are advancing innovative surface treatment methods. The market is witnessing technological evolution from traditional processes toward precision-controlled, environmentally-friendly solutions. Research institutions like Fraunhofer-Gesellschaft and University of Sheffield are collaborating with industry leaders such as POSCO, Nippon Steel, and Kobe Steel to develop next-generation case hardening techniques that optimize carbon diffusion while minimizing distortion and energy consumption.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed advanced case hardening technologies focusing on precise carbon control in surface layers. Their proprietary Super Case Hardening (SCH) process utilizes controlled atmosphere carburizing with precise carbon potential management to achieve optimal carbon gradients. The company employs computer-controlled gas carburizing systems that dynamically adjust carbon potential throughout the process cycle, resulting in more uniform case depths and improved surface hardness profiles. Their technology incorporates post-carburizing heat treatments including specialized quenching protocols that minimize distortion while maximizing hardness. NIPPON STEEL has also pioneered vacuum carburizing techniques that allow for higher temperature processing (950-1050°C) which accelerates carbon diffusion while preventing oxidation, resulting in cleaner surfaces and more consistent case depths across complex geometries.

Strengths: Superior carbon gradient control resulting in optimized mechanical properties; reduced distortion through advanced quenching techniques; excellent process repeatability through computerized control systems. Weaknesses: Higher implementation costs compared to conventional methods; requires specialized equipment and technical expertise; process parameters need careful optimization for each specific application.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon Surface Solutions has developed BALITHERM® IONIT OX, an advanced plasma-assisted case hardening technology specifically designed for high carbon surface layers. This process combines plasma nitriding with post-oxidation treatment to create exceptionally hard surfaces (>1000 HV) with excellent wear and corrosion resistance. Their technology utilizes precisely controlled low-pressure plasma environments to diffuse carbon and nitrogen simultaneously into the material surface at temperatures between 350-580°C, significantly lower than traditional case hardening methods. The process employs sophisticated pulse technology that allows for precise control of the plasma intensity and ion bombardment energy, enabling tailored case depth profiles ranging from 0.1 to 0.7 mm. The subsequent oxidation phase creates a magnetite (Fe3O4) layer that enhances corrosion protection while maintaining the hardened case properties.

Strengths: Lower processing temperatures reduce part distortion; excellent dimensional stability; environmentally friendly process with no toxic waste; superior corrosion resistance compared to conventional case hardening. Weaknesses: Limited case depth compared to traditional carburizing; higher initial equipment investment; process requires highly specialized technical expertise; not suitable for all base materials.

Critical Patents and Research in High Carbon Case Hardening

Method of case hardening ferrometallic parts

PatentInactiveUS5100483A

Innovation

- A method that involves heating the ferrometallic part at a carburizing temperature in contact with a carbon source, machining to create high and low carbon content regions, and then heating in a gaseous atmosphere with a carbon content ranging from 85% to 115% of the low carbon content region's carbon content during the hardening step, eliminating the need for protective coatings and reducing process steps.

Wear component with a carburized case

PatentWO2010080369A2

Innovation

- A wear component with a carburized case featuring a high volume fraction of carbides, particularly non-spheroidal carbides, extending to a depth of at least 5 microns from the surface and a thickness of over 100 microns, formed using alloy steel with a carbon content between 0.36% to 0.5% by weight, to enhance wear resistance and durability.

Environmental Impact and Sustainability Considerations

Case hardening processes, while effective for enhancing surface properties of steel components, carry significant environmental implications that demand careful consideration. Traditional case hardening methods often involve energy-intensive heating cycles that consume substantial amounts of fossil fuels, contributing to greenhouse gas emissions. The quenching media used in these processes, particularly oil-based quenchants, pose environmental hazards through potential soil contamination and water pollution when improperly disposed. Additionally, many conventional carburizing compounds contain toxic chemicals such as cyanide-based compounds, which present serious environmental and health risks.

Recent sustainability initiatives in the heat treatment industry have focused on developing cleaner alternatives. Low-pressure vacuum carburizing represents a significant advancement, reducing energy consumption by up to 30% compared to conventional gas carburizing while eliminating the need for environmentally harmful quenchants. This technology also minimizes distortion, reducing material waste and the need for post-treatment machining operations.

The implementation of closed-loop systems for quenchant recycling has emerged as another important sustainability measure. These systems can recover and reuse up to 95% of quenching media, substantially reducing waste generation and resource consumption. Furthermore, the transition to water-based or biodegradable quenchants offers promising environmental benefits, though challenges remain in achieving comparable hardening performance to traditional oil-based alternatives.

Carbon footprint assessment has become increasingly important in evaluating case hardening processes. Life cycle analysis studies indicate that optimized case hardening can reduce overall carbon emissions by 15-25% compared to traditional methods when considering the entire production chain. This includes not only direct process emissions but also embedded carbon in materials and energy sources.

Regulatory frameworks worldwide are evolving to address environmental concerns in industrial heat treatment. The EU's REACH regulations and similar initiatives in North America and Asia have established stricter controls on hazardous substances used in case hardening. Companies implementing sustainable case hardening technologies often benefit from regulatory compliance advantages and potential carbon tax savings.

Looking forward, emerging technologies such as plasma-assisted carburizing and induction hardening offer promising pathways to further reduce environmental impact while maintaining or improving surface layer quality. These technologies can reduce process times by up to 50% and energy consumption by 40% compared to conventional methods, representing the next frontier in sustainable case hardening for high carbon surface layers.

Recent sustainability initiatives in the heat treatment industry have focused on developing cleaner alternatives. Low-pressure vacuum carburizing represents a significant advancement, reducing energy consumption by up to 30% compared to conventional gas carburizing while eliminating the need for environmentally harmful quenchants. This technology also minimizes distortion, reducing material waste and the need for post-treatment machining operations.

The implementation of closed-loop systems for quenchant recycling has emerged as another important sustainability measure. These systems can recover and reuse up to 95% of quenching media, substantially reducing waste generation and resource consumption. Furthermore, the transition to water-based or biodegradable quenchants offers promising environmental benefits, though challenges remain in achieving comparable hardening performance to traditional oil-based alternatives.

Carbon footprint assessment has become increasingly important in evaluating case hardening processes. Life cycle analysis studies indicate that optimized case hardening can reduce overall carbon emissions by 15-25% compared to traditional methods when considering the entire production chain. This includes not only direct process emissions but also embedded carbon in materials and energy sources.

Regulatory frameworks worldwide are evolving to address environmental concerns in industrial heat treatment. The EU's REACH regulations and similar initiatives in North America and Asia have established stricter controls on hazardous substances used in case hardening. Companies implementing sustainable case hardening technologies often benefit from regulatory compliance advantages and potential carbon tax savings.

Looking forward, emerging technologies such as plasma-assisted carburizing and induction hardening offer promising pathways to further reduce environmental impact while maintaining or improving surface layer quality. These technologies can reduce process times by up to 50% and energy consumption by 40% compared to conventional methods, representing the next frontier in sustainable case hardening for high carbon surface layers.

Quality Control and Testing Methodologies

Quality control and testing methodologies are critical components in optimizing case hardening processes for high carbon surface layers. Effective quality assurance begins with pre-process material verification, ensuring that the base material meets compositional and structural requirements before undergoing case hardening. This includes spectrographic analysis to confirm chemical composition and preliminary hardness testing to establish baseline properties.

During the case hardening process, real-time monitoring systems have become increasingly sophisticated, employing sensors that track temperature profiles, carbon potential, and atmosphere composition within the furnace environment. Advanced systems utilize infrared thermography and gas chromatography to maintain precise control over the carburizing atmosphere, ensuring consistent carbon diffusion into the workpiece surface.

Post-process testing represents the most comprehensive quality control phase, incorporating multiple methodologies to verify the success of the case hardening operation. Microhardness testing using Vickers or Knoop indenters allows for precise hardness profiling across the case depth, typically measured at intervals of 0.05-0.1mm from the surface inward. This creates a hardness traverse that visualizes the transition from the hardened case to the core material.

Metallographic examination serves as another crucial testing methodology, involving sample sectioning, mounting, polishing, and etching to reveal the microstructure. When examined under optical or electron microscopes, these samples reveal critical information about case depth, grain structure, and the presence of carbides or other microstructural features that influence performance.

Non-destructive testing methods have gained prominence in production environments where preserving all components is necessary. Eddy current testing can rapidly assess case depth variations across large production batches, while ultrasonic techniques evaluate subsurface integrity without damaging the component. X-ray diffraction provides insights into residual stress patterns, which significantly impact fatigue resistance and service life.

Mechanical property verification extends beyond hardness testing to include specialized fatigue testing, wear resistance evaluation, and impact testing. These assessments more directly correlate with in-service performance than simple hardness measurements. Modern facilities often employ automated testing systems that can rapidly process multiple samples while maintaining statistical process control.

Digital image analysis has revolutionized quality control by enabling quantitative assessment of microstructural features. Software algorithms can now automatically measure case depth, quantify carbide distribution, and evaluate grain size with greater consistency than manual methods, reducing operator-dependent variations in quality assessment.

During the case hardening process, real-time monitoring systems have become increasingly sophisticated, employing sensors that track temperature profiles, carbon potential, and atmosphere composition within the furnace environment. Advanced systems utilize infrared thermography and gas chromatography to maintain precise control over the carburizing atmosphere, ensuring consistent carbon diffusion into the workpiece surface.

Post-process testing represents the most comprehensive quality control phase, incorporating multiple methodologies to verify the success of the case hardening operation. Microhardness testing using Vickers or Knoop indenters allows for precise hardness profiling across the case depth, typically measured at intervals of 0.05-0.1mm from the surface inward. This creates a hardness traverse that visualizes the transition from the hardened case to the core material.

Metallographic examination serves as another crucial testing methodology, involving sample sectioning, mounting, polishing, and etching to reveal the microstructure. When examined under optical or electron microscopes, these samples reveal critical information about case depth, grain structure, and the presence of carbides or other microstructural features that influence performance.

Non-destructive testing methods have gained prominence in production environments where preserving all components is necessary. Eddy current testing can rapidly assess case depth variations across large production batches, while ultrasonic techniques evaluate subsurface integrity without damaging the component. X-ray diffraction provides insights into residual stress patterns, which significantly impact fatigue resistance and service life.

Mechanical property verification extends beyond hardness testing to include specialized fatigue testing, wear resistance evaluation, and impact testing. These assessments more directly correlate with in-service performance than simple hardness measurements. Modern facilities often employ automated testing systems that can rapidly process multiple samples while maintaining statistical process control.

Digital image analysis has revolutionized quality control by enabling quantitative assessment of microstructural features. Software algorithms can now automatically measure case depth, quantify carbide distribution, and evaluate grain size with greater consistency than manual methods, reducing operator-dependent variations in quality assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!