High Carbon Steel Wear Resistance: Coating And Surface Treatments

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Carbon Steel Wear Resistance Background and Objectives

High carbon steel has been a cornerstone material in industrial applications for over a century, valued for its exceptional hardness and strength characteristics. The evolution of high carbon steel wear resistance technologies has progressed significantly from basic heat treatments in the early 20th century to sophisticated surface engineering approaches in the modern era. This technological progression has been driven by increasing demands for extended component lifespans in increasingly harsh operating environments across automotive, aerospace, mining, and manufacturing sectors.

The wear mechanisms affecting high carbon steel components are diverse and complex, including adhesive wear, abrasive wear, erosive wear, and fatigue wear. Each mechanism presents unique challenges that conventional material solutions have struggled to address simultaneously, creating a persistent need for advanced surface treatments and coating technologies.

Recent market analyses indicate that the global wear-resistant coating market is projected to grow at a CAGR of approximately 5.2% through 2028, with high carbon steel applications representing a significant segment of this growth. This expansion is primarily fueled by increasing industrialization in emerging economies and the rising demand for enhanced component durability in established markets.

The primary objective of current research in high carbon steel wear resistance is to develop coating and surface treatment technologies that can simultaneously address multiple wear mechanisms while maintaining or enhancing the base material's beneficial properties. Specifically, researchers aim to create solutions that provide superior hardness, excellent adhesion to the substrate, enhanced corrosion resistance, and reduced friction coefficients—all while remaining economically viable for large-scale industrial implementation.

Secondary objectives include developing environmentally sustainable coating processes that reduce or eliminate hazardous materials commonly used in traditional surface treatments, such as hexavalent chromium and certain cyanide compounds. This environmental imperative is increasingly driven by stringent global regulations and corporate sustainability initiatives.

The technological trajectory suggests a convergence of multiple disciplines, including materials science, nanotechnology, and computational modeling, to create next-generation wear-resistant surfaces for high carbon steel. These interdisciplinary approaches are expected to yield breakthrough innovations in areas such as self-healing coatings, gradient-structured surfaces, and smart materials that can adapt to changing wear conditions in real-time.

The wear mechanisms affecting high carbon steel components are diverse and complex, including adhesive wear, abrasive wear, erosive wear, and fatigue wear. Each mechanism presents unique challenges that conventional material solutions have struggled to address simultaneously, creating a persistent need for advanced surface treatments and coating technologies.

Recent market analyses indicate that the global wear-resistant coating market is projected to grow at a CAGR of approximately 5.2% through 2028, with high carbon steel applications representing a significant segment of this growth. This expansion is primarily fueled by increasing industrialization in emerging economies and the rising demand for enhanced component durability in established markets.

The primary objective of current research in high carbon steel wear resistance is to develop coating and surface treatment technologies that can simultaneously address multiple wear mechanisms while maintaining or enhancing the base material's beneficial properties. Specifically, researchers aim to create solutions that provide superior hardness, excellent adhesion to the substrate, enhanced corrosion resistance, and reduced friction coefficients—all while remaining economically viable for large-scale industrial implementation.

Secondary objectives include developing environmentally sustainable coating processes that reduce or eliminate hazardous materials commonly used in traditional surface treatments, such as hexavalent chromium and certain cyanide compounds. This environmental imperative is increasingly driven by stringent global regulations and corporate sustainability initiatives.

The technological trajectory suggests a convergence of multiple disciplines, including materials science, nanotechnology, and computational modeling, to create next-generation wear-resistant surfaces for high carbon steel. These interdisciplinary approaches are expected to yield breakthrough innovations in areas such as self-healing coatings, gradient-structured surfaces, and smart materials that can adapt to changing wear conditions in real-time.

Market Analysis for Wear-Resistant Steel Applications

The global market for wear-resistant steel applications continues to expand significantly, driven by increasing demands across multiple industrial sectors. The current market size for high carbon steel wear-resistant solutions exceeds $25 billion annually, with projections indicating growth rates between 5-7% through 2030. This growth trajectory is particularly pronounced in mining, construction, and heavy machinery sectors where component longevity directly impacts operational efficiency and maintenance costs.

Regional analysis reveals that Asia-Pacific dominates the market share at approximately 40%, led by China's massive infrastructure development and manufacturing base. North America and Europe follow with 25% and 22% respectively, while emerging markets in Latin America and Africa show the highest growth rates, albeit from smaller bases.

Mining operations represent the largest end-user segment, accounting for 32% of market demand. These applications require exceptional abrasion resistance under extreme conditions, where high carbon steel with specialized coatings and surface treatments delivers superior performance compared to alternative materials. Construction equipment follows at 28%, with agricultural machinery and automotive components comprising 15% and 12% respectively.

Customer demand patterns indicate a clear shift toward total cost of ownership considerations rather than initial acquisition costs. End-users increasingly recognize that premium wear-resistant solutions, though commanding higher upfront investments, deliver substantial long-term value through extended service life, reduced downtime, and lower maintenance requirements. Market research indicates that properly treated high carbon steel components can extend service life by 200-300% compared to untreated alternatives in severe abrasion environments.

Price sensitivity varies significantly by application segment. Critical components in high-value equipment demonstrate low price elasticity, with customers willing to pay premium prices for guaranteed performance. Conversely, mass-market applications remain highly price-sensitive, creating distinct market tiers that manufacturers must address with differentiated product offerings.

Emerging market trends include growing demand for customized wear solutions tailored to specific operational environments, increased interest in environmentally sustainable treatment processes, and rising adoption of advanced surface engineering techniques that combine multiple treatment methods. Additionally, digital monitoring capabilities that predict component wear rates are gaining traction, particularly in premium market segments where predictive maintenance delivers substantial operational benefits.

The competitive landscape features both specialized coating service providers and integrated steel manufacturers expanding their value-added service offerings. This market structure is driving innovation while simultaneously putting pressure on margins for standardized treatments.

Regional analysis reveals that Asia-Pacific dominates the market share at approximately 40%, led by China's massive infrastructure development and manufacturing base. North America and Europe follow with 25% and 22% respectively, while emerging markets in Latin America and Africa show the highest growth rates, albeit from smaller bases.

Mining operations represent the largest end-user segment, accounting for 32% of market demand. These applications require exceptional abrasion resistance under extreme conditions, where high carbon steel with specialized coatings and surface treatments delivers superior performance compared to alternative materials. Construction equipment follows at 28%, with agricultural machinery and automotive components comprising 15% and 12% respectively.

Customer demand patterns indicate a clear shift toward total cost of ownership considerations rather than initial acquisition costs. End-users increasingly recognize that premium wear-resistant solutions, though commanding higher upfront investments, deliver substantial long-term value through extended service life, reduced downtime, and lower maintenance requirements. Market research indicates that properly treated high carbon steel components can extend service life by 200-300% compared to untreated alternatives in severe abrasion environments.

Price sensitivity varies significantly by application segment. Critical components in high-value equipment demonstrate low price elasticity, with customers willing to pay premium prices for guaranteed performance. Conversely, mass-market applications remain highly price-sensitive, creating distinct market tiers that manufacturers must address with differentiated product offerings.

Emerging market trends include growing demand for customized wear solutions tailored to specific operational environments, increased interest in environmentally sustainable treatment processes, and rising adoption of advanced surface engineering techniques that combine multiple treatment methods. Additionally, digital monitoring capabilities that predict component wear rates are gaining traction, particularly in premium market segments where predictive maintenance delivers substantial operational benefits.

The competitive landscape features both specialized coating service providers and integrated steel manufacturers expanding their value-added service offerings. This market structure is driving innovation while simultaneously putting pressure on margins for standardized treatments.

Current Challenges in Surface Treatment Technologies

Despite significant advancements in surface treatment technologies for high carbon steel, several critical challenges persist that limit optimal wear resistance performance. The primary challenge remains the trade-off between hardness and toughness in treated surfaces. When extreme hardness is achieved through certain coating methods, the treated layer often becomes brittle and susceptible to cracking under impact loads, negating the wear resistance benefits in dynamic applications.

Adhesion issues between coatings and high carbon steel substrates continue to be problematic, particularly with thicker coatings that provide superior wear protection. The coefficient of thermal expansion mismatch between coating materials and the steel substrate creates internal stresses during thermal cycling, leading to delamination and premature coating failure. This is especially evident in applications experiencing wide temperature fluctuations.

Uniformity in coating thickness and properties presents another significant challenge. Complex geometries and internal surfaces often receive inconsistent treatment, creating weak points in the overall wear protection system. Current technologies struggle to deliver homogeneous coverage on intricate component designs, resulting in localized wear and eventual system failure.

Environmental considerations have introduced additional constraints on surface treatment processes. Traditional methods like hard chrome plating face increasing regulatory restrictions due to hexavalent chromium toxicity. Alternative environmentally friendly processes often cannot match the performance characteristics of conventional treatments, creating a technology gap in sustainable wear-resistant solutions.

Cost-effectiveness remains a substantial barrier, particularly for advanced coating technologies like PVD and CVD. The high capital investment and operational costs limit widespread industrial adoption, especially for large components or high-volume production scenarios. This economic constraint forces many manufacturers to compromise on wear performance to maintain competitive pricing.

Process control and quality assurance present ongoing challenges, as slight variations in treatment parameters can significantly impact wear resistance properties. The industry lacks standardized, non-destructive testing methods to verify coating quality and predict service life accurately, making quality control difficult to maintain across production batches.

Integration of multiple surface properties beyond wear resistance—such as corrosion protection, thermal barrier capabilities, and reduced friction—remains technically challenging. Creating multifunctional surfaces that simultaneously address several performance requirements without compromising wear resistance continues to be an elusive goal for current treatment technologies.

Adhesion issues between coatings and high carbon steel substrates continue to be problematic, particularly with thicker coatings that provide superior wear protection. The coefficient of thermal expansion mismatch between coating materials and the steel substrate creates internal stresses during thermal cycling, leading to delamination and premature coating failure. This is especially evident in applications experiencing wide temperature fluctuations.

Uniformity in coating thickness and properties presents another significant challenge. Complex geometries and internal surfaces often receive inconsistent treatment, creating weak points in the overall wear protection system. Current technologies struggle to deliver homogeneous coverage on intricate component designs, resulting in localized wear and eventual system failure.

Environmental considerations have introduced additional constraints on surface treatment processes. Traditional methods like hard chrome plating face increasing regulatory restrictions due to hexavalent chromium toxicity. Alternative environmentally friendly processes often cannot match the performance characteristics of conventional treatments, creating a technology gap in sustainable wear-resistant solutions.

Cost-effectiveness remains a substantial barrier, particularly for advanced coating technologies like PVD and CVD. The high capital investment and operational costs limit widespread industrial adoption, especially for large components or high-volume production scenarios. This economic constraint forces many manufacturers to compromise on wear performance to maintain competitive pricing.

Process control and quality assurance present ongoing challenges, as slight variations in treatment parameters can significantly impact wear resistance properties. The industry lacks standardized, non-destructive testing methods to verify coating quality and predict service life accurately, making quality control difficult to maintain across production batches.

Integration of multiple surface properties beyond wear resistance—such as corrosion protection, thermal barrier capabilities, and reduced friction—remains technically challenging. Creating multifunctional surfaces that simultaneously address several performance requirements without compromising wear resistance continues to be an elusive goal for current treatment technologies.

Current Coating and Surface Treatment Solutions

01 Alloying elements for improved wear resistance

High carbon steel wear resistance can be significantly enhanced through the addition of specific alloying elements. Elements such as chromium, manganese, molybdenum, and vanadium form hard carbides within the steel matrix, increasing hardness and wear resistance. These alloying elements also improve the hardenability of the steel, allowing for more effective heat treatment processes that further enhance wear resistance properties. The distribution and morphology of these carbides play a crucial role in determining the overall wear performance of high carbon steels.- Carbon content and alloying elements for wear resistance: High carbon steel's wear resistance can be significantly enhanced by optimizing carbon content and adding specific alloying elements. The carbon content typically ranges from 0.6% to 1.2%, which promotes the formation of hard carbides that resist abrasion. Alloying elements such as chromium, manganese, and vanadium form complex carbides that further improve wear resistance. These elements contribute to increased hardness while maintaining adequate toughness for industrial applications.

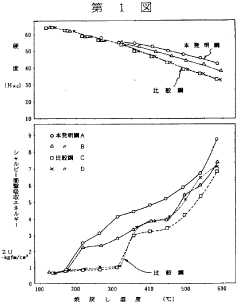

- Heat treatment processes for improved wear resistance: Various heat treatment processes can be applied to high carbon steel to enhance its wear resistance properties. These include quenching and tempering, austempering, and specialized surface hardening techniques. The controlled heating and cooling cycles create optimal microstructures with martensite and retained austenite phases that provide superior hardness and wear resistance. The tempering temperature and duration are critical factors that balance hardness with toughness to prevent brittle failure during service.

- Surface modification techniques for enhanced wear resistance: Surface modification techniques can significantly improve the wear resistance of high carbon steel components. These include carburizing, nitriding, carbonitriding, and various coating methods. These processes create a hardened surface layer while maintaining a relatively tough core. Advanced techniques like laser surface hardening and plasma nitriding provide precise control over the case depth and hardness profile, resulting in components with superior wear resistance for demanding applications.

- Microstructural control for optimized wear resistance: Controlling the microstructure of high carbon steel is essential for achieving optimal wear resistance. Fine-grained structures with uniformly distributed carbides provide superior wear resistance compared to coarse structures. The size, shape, distribution, and type of carbides significantly influence wear behavior. Advanced processing techniques can create nanostructured high carbon steels with exceptional wear resistance due to their refined microstructure and increased number of grain boundaries that impede crack propagation and material removal during wear.

- Composite and multi-layer high carbon steel systems: Composite and multi-layer systems incorporating high carbon steel offer enhanced wear resistance for specialized applications. These include bimetallic structures with a high carbon steel wear layer bonded to a tougher substrate, gradient materials with varying carbon content, and reinforced high carbon steel composites. These systems combine the excellent wear resistance of high carbon steel with the toughness or other beneficial properties of complementary materials, resulting in components that can withstand severe wear conditions while maintaining structural integrity.

02 Heat treatment processes for enhanced wear resistance

Various heat treatment processes can be applied to high carbon steels to optimize their wear resistance properties. These include quenching and tempering, austempering, and surface hardening techniques such as induction hardening or flame hardening. These processes alter the microstructure of the steel, promoting the formation of martensite or bainite phases that exhibit superior hardness and wear resistance. Controlled cooling rates and precise temperature management during heat treatment are essential for achieving the desired microstructure and mechanical properties in high carbon steels.Expand Specific Solutions03 Surface modification techniques

Surface modification techniques can significantly improve the wear resistance of high carbon steels without altering their bulk properties. These techniques include carburizing, nitriding, carbonitriding, and various coating methods such as physical vapor deposition (PVD) and chemical vapor deposition (CVD). These processes create a hard, wear-resistant layer on the steel surface while maintaining the toughness of the core material. The thickness, hardness, and adhesion of these modified surface layers are critical factors that determine their effectiveness in enhancing wear resistance.Expand Specific Solutions04 Microstructural control for optimized wear resistance

Controlling the microstructure of high carbon steels is essential for optimizing their wear resistance. This involves managing grain size, phase distribution, and carbide morphology through precise processing parameters. Fine-grained structures generally exhibit better wear resistance than coarse-grained ones. The distribution, size, and type of carbides present in the microstructure significantly influence wear behavior. Advanced processing techniques such as controlled rolling, rapid solidification, and thermomechanical treatments can be employed to achieve the desired microstructural features that enhance wear resistance.Expand Specific Solutions05 Composite and reinforced high carbon steel systems

Composite and reinforced high carbon steel systems offer enhanced wear resistance through the strategic combination of high carbon steel with other wear-resistant materials. These systems include high carbon steel matrices reinforced with ceramic particles, hard metal carbides, or other high-hardness phases. Cladding, hardfacing, and powder metallurgy techniques can be used to create these composite structures. The interface between the steel matrix and reinforcement phases is critical for the overall performance of these systems. These composite approaches allow for tailored wear resistance in specific applications while maintaining other desirable properties of high carbon steels.Expand Specific Solutions

Leading Companies in High Carbon Steel Treatment Industry

The high carbon steel wear resistance market is currently in a growth phase, with increasing demand across automotive, industrial machinery, and aerospace sectors. The global market size for surface treatments and coatings is estimated to exceed $12 billion, driven by the need for extended component lifespans and reduced maintenance costs. Technologically, the field shows moderate maturity with established processes like PVD, CVD, and nitriding, but continues to evolve with innovative approaches. Leading players include Sumitomo Electric Industries and Mitsubishi Materials with advanced coating technologies, Oerlikon Surface Solutions specializing in PVD/CVD solutions, Sandvik and SKF focusing on industrial applications, while academic institutions like Kyushu University and University of Science & Technology Beijing contribute significant research advancements in novel coating formulations and surface modification techniques.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric Industries has developed a comprehensive suite of surface treatment technologies specifically optimized for high carbon steel components. Their flagship technology is a multi-stage process combining plasma nitriding with specialized PVD coating layers. The process begins with a proprietary low-temperature plasma nitriding treatment that creates a diffusion zone extending 50-200μm into the steel substrate without compromising the core mechanical properties. This is followed by the application of their Super ZX coating system, which incorporates alternating layers of chromium nitride and titanium aluminum nitride with precisely controlled stoichiometry. The resulting surface exhibits exceptional hardness (>3000 HV) while maintaining excellent adhesion due to the graded interface between the diffusion zone and coating layers. For applications requiring extreme wear resistance, Sumitomo has developed a specialized diamond-like carbon (DLC) top layer with hydrogen content below 5%, resulting in friction coefficients as low as 0.05 against steel counterparts while maintaining wear rates below 10^-16 m³/Nm in standardized testing conditions.

Strengths: Exceptional combination of surface hardness and core toughness; superior adhesion due to graded interface design; excellent performance in both dry and lubricated conditions; proven longevity in high-stress industrial applications. Weaknesses: Complex multi-stage process increases production time and cost; requires specialized equipment and expertise; some limitations in treating complex geometries uniformly.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon Surface Solutions has developed advanced PVD (Physical Vapor Deposition) coating technologies specifically designed for high carbon steel applications. Their BALINIT® coating portfolio includes specialized solutions like BALINIT ALCRONA PRO and BALINIT ALNOVA that provide exceptional wear protection for high carbon steel components. These coatings utilize a proprietary multi-layer architecture with alternating nano-layers of metal nitrides and carbides, creating a surface hardness exceeding 3,500 HV while maintaining excellent adhesion to the steel substrate. The company's S3p® (Scalable Pulsed Power Plasma) technology enables precise control of coating microstructure, resulting in ultra-smooth surfaces with friction coefficients as low as 0.1 against steel counterparts. For extreme wear applications, they offer specialized BALIQ® coatings incorporating hydrogen-free carbon (a-C) that can withstand contact pressures exceeding 3 GPa while maintaining structural integrity.

Strengths: Superior hardness-to-toughness ratio compared to conventional coatings; excellent adhesion to high carbon steel substrates; ability to maintain performance under extreme temperatures (up to 1100°C); environmentally friendly processes with minimal waste. Weaknesses: Higher initial cost compared to traditional treatments; requires specialized equipment for application; some coatings may have thickness limitations for precision components.

Key Innovations in Wear Resistance Technologies

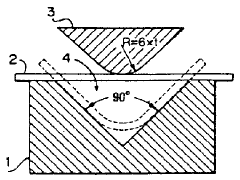

Method of treating the surfaces of high carbon steel bodies and bodies of high carbon steel

PatentInactiveEP0033403A1

Innovation

- A method involving heating high carbon steel in a carburizing atmosphere to generate a differential in retained austenite and primary carbides between the surface and core, followed by quenching to establish a compressive residual stress gradient, using a gas blend of endothermic gas and methane, and controlling chromium content to increase surface hardness and carbon gradient.

High carbon steel excellent in wear resistance and toughness

PatentInactiveJP1992045243A

Innovation

- A high carbon steel composition with controlled levels of C, Si, Mn, P, Ni, Mo, V, and Cr, optimized for quenching and tempering treatments to enhance toughness and wear resistance, including a reduced Mo content to prevent tempering embrittlement and promote finer austenite crystal grains, while maintaining workability.

Environmental Impact of Surface Treatment Processes

Surface treatment processes for high carbon steel, while enhancing wear resistance, carry significant environmental implications that must be carefully considered. Traditional coating and surface treatment methods often involve hazardous chemicals, heavy metals, and energy-intensive processes that generate substantial waste streams. Electroplating processes, commonly used for chromium and nickel coatings, release hexavalent chromium compounds and other toxic heavy metals that pose serious threats to aquatic ecosystems and human health when improperly managed.

Thermal spray coating techniques, while effective for wear resistance, typically consume considerable energy and produce particulate emissions that can contribute to air pollution. The high-temperature processes involved in plasma spraying and HVOF (High-Velocity Oxygen Fuel) coating generate greenhouse gases and nitrogen oxides, contributing to climate change and atmospheric degradation when not properly controlled.

Chemical vapor deposition (CVD) and physical vapor deposition (PVD) processes, though more environmentally friendly than wet chemical methods, still utilize precursor gases that may include greenhouse gases or ozone-depleting substances. The vacuum systems and high-energy requirements of these processes also contribute to their environmental footprint, though advancements in technology have improved efficiency in recent years.

Waste management presents another critical environmental challenge. Surface preparation steps, including degreasing, pickling, and etching, generate acidic and alkaline waste streams containing dissolved metals and organic contaminants. These require specialized treatment before discharge to prevent water pollution and comply with increasingly stringent environmental regulations worldwide.

Recent regulatory frameworks, such as REACH in Europe and similar initiatives globally, have driven significant changes in surface treatment technologies. The industry has responded with more sustainable alternatives, including water-based coating systems, powder coating technologies, and trivalent chromium processes that reduce environmental impact while maintaining performance characteristics.

Life cycle assessment studies indicate that despite initial environmental costs, durable surface treatments can provide net environmental benefits by extending component lifespans and reducing the need for replacement parts. This perspective highlights the importance of considering environmental impacts across the entire product lifecycle rather than focusing solely on the treatment process.

Emerging technologies show promise for further reducing environmental impacts. These include dry ice blasting for surface preparation, supercritical CO2 as a replacement for organic solvents, and cold spray technologies that eliminate the need for high-temperature processing while achieving excellent wear resistance properties for high carbon steel applications.

Thermal spray coating techniques, while effective for wear resistance, typically consume considerable energy and produce particulate emissions that can contribute to air pollution. The high-temperature processes involved in plasma spraying and HVOF (High-Velocity Oxygen Fuel) coating generate greenhouse gases and nitrogen oxides, contributing to climate change and atmospheric degradation when not properly controlled.

Chemical vapor deposition (CVD) and physical vapor deposition (PVD) processes, though more environmentally friendly than wet chemical methods, still utilize precursor gases that may include greenhouse gases or ozone-depleting substances. The vacuum systems and high-energy requirements of these processes also contribute to their environmental footprint, though advancements in technology have improved efficiency in recent years.

Waste management presents another critical environmental challenge. Surface preparation steps, including degreasing, pickling, and etching, generate acidic and alkaline waste streams containing dissolved metals and organic contaminants. These require specialized treatment before discharge to prevent water pollution and comply with increasingly stringent environmental regulations worldwide.

Recent regulatory frameworks, such as REACH in Europe and similar initiatives globally, have driven significant changes in surface treatment technologies. The industry has responded with more sustainable alternatives, including water-based coating systems, powder coating technologies, and trivalent chromium processes that reduce environmental impact while maintaining performance characteristics.

Life cycle assessment studies indicate that despite initial environmental costs, durable surface treatments can provide net environmental benefits by extending component lifespans and reducing the need for replacement parts. This perspective highlights the importance of considering environmental impacts across the entire product lifecycle rather than focusing solely on the treatment process.

Emerging technologies show promise for further reducing environmental impacts. These include dry ice blasting for surface preparation, supercritical CO2 as a replacement for organic solvents, and cold spray technologies that eliminate the need for high-temperature processing while achieving excellent wear resistance properties for high carbon steel applications.

Cost-Benefit Analysis of Treatment Technologies

When evaluating surface treatment technologies for high carbon steel, cost-benefit analysis provides critical insights for industrial decision-making. Initial investment costs vary significantly across treatment options, with thermal spray coatings typically requiring substantial capital expenditure for equipment and facilities, ranging from $100,000 to $500,000. PVD and CVD systems demand even higher initial investments, often exceeding $1 million for industrial-scale operations. Conversely, traditional heat treatments and carburizing processes generally require lower upfront costs but may incur higher operational expenses over time.

Operational costs must be assessed through comprehensive lifecycle analysis. Energy consumption represents a significant factor, with vacuum-based processes like PVD consuming 30-50% more electricity than atmospheric treatments. Material costs also vary considerably—specialized coating materials for thermal spray applications can cost $200-600 per kilogram, while nitriding processes utilize relatively inexpensive nitrogen sources. Labor requirements differ substantially, with advanced coating technologies demanding highly skilled operators commanding premium wages.

Treatment durability directly impacts long-term economic value. Field studies indicate that properly applied PVD coatings can extend component lifespan by 300-500% compared to untreated high carbon steel in severe abrasive environments. This translates to significant maintenance cost reductions and decreased production downtime. For instance, coated industrial cutting tools demonstrate 2-4 times longer service intervals than uncoated counterparts, generating substantial operational savings.

Environmental compliance costs increasingly influence treatment selection. Traditional chrome plating faces mounting regulatory pressure due to hexavalent chromium concerns, potentially adding 15-25% in compliance costs. Newer technologies like HVOF thermal spray and PVD offer environmentally superior alternatives but at premium prices. The regulatory landscape continues to evolve, potentially altering the cost-benefit equation for certain treatments in coming years.

Industry-specific return on investment varies markedly. In automotive manufacturing, nitrided components typically achieve ROI within 8-14 months through reduced warranty claims and maintenance. Aerospace applications of specialized PVD coatings may require 18-24 months to reach breakeven but subsequently deliver superior long-term value. Mining equipment treated with thermal spray carbide coatings demonstrates particularly compelling economics, with documented ROI periods of 3-6 months in high-wear applications despite higher initial treatment costs.

Operational costs must be assessed through comprehensive lifecycle analysis. Energy consumption represents a significant factor, with vacuum-based processes like PVD consuming 30-50% more electricity than atmospheric treatments. Material costs also vary considerably—specialized coating materials for thermal spray applications can cost $200-600 per kilogram, while nitriding processes utilize relatively inexpensive nitrogen sources. Labor requirements differ substantially, with advanced coating technologies demanding highly skilled operators commanding premium wages.

Treatment durability directly impacts long-term economic value. Field studies indicate that properly applied PVD coatings can extend component lifespan by 300-500% compared to untreated high carbon steel in severe abrasive environments. This translates to significant maintenance cost reductions and decreased production downtime. For instance, coated industrial cutting tools demonstrate 2-4 times longer service intervals than uncoated counterparts, generating substantial operational savings.

Environmental compliance costs increasingly influence treatment selection. Traditional chrome plating faces mounting regulatory pressure due to hexavalent chromium concerns, potentially adding 15-25% in compliance costs. Newer technologies like HVOF thermal spray and PVD offer environmentally superior alternatives but at premium prices. The regulatory landscape continues to evolve, potentially altering the cost-benefit equation for certain treatments in coming years.

Industry-specific return on investment varies markedly. In automotive manufacturing, nitrided components typically achieve ROI within 8-14 months through reduced warranty claims and maintenance. Aerospace applications of specialized PVD coatings may require 18-24 months to reach breakeven but subsequently deliver superior long-term value. Mining equipment treated with thermal spray carbide coatings demonstrates particularly compelling economics, with documented ROI periods of 3-6 months in high-wear applications despite higher initial treatment costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!