How Ammonium Hydroxide Affects PCM Thermal Storage Materials

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Thermal Storage Background and Objectives

Phase Change Materials (PCM) have emerged as a promising solution for thermal energy storage, offering significant potential in various applications ranging from building energy management to industrial processes. The development of PCM thermal storage technology has been driven by the growing need for efficient and sustainable energy management systems in the face of increasing global energy demands and environmental concerns.

The evolution of PCM thermal storage can be traced back to the mid-20th century, with initial research focusing on the fundamental principles of phase change and latent heat storage. Over the decades, advancements in material science and engineering have led to the development of a wide range of PCMs with diverse thermal properties, melting points, and applications. The field has seen a steady progression from simple organic compounds to more complex inorganic and eutectic mixtures, each offering unique advantages in specific thermal storage scenarios.

In recent years, the integration of nanotechnology and advanced composite materials has further expanded the capabilities of PCM thermal storage systems. These innovations have addressed some of the inherent limitations of traditional PCMs, such as low thermal conductivity and phase segregation, leading to enhanced performance and reliability in practical applications.

The primary objective of PCM thermal storage research is to develop materials and systems that can efficiently capture, store, and release thermal energy on demand. This involves optimizing key parameters such as latent heat capacity, thermal conductivity, and cycling stability. Additionally, researchers aim to expand the temperature range of PCM applications, improve long-term stability, and reduce costs to make the technology more commercially viable.

Ammonium hydroxide, a compound of ammonia and water, has recently gained attention in the context of PCM thermal storage materials. The investigation into its effects on PCMs is driven by the potential to enhance certain properties or overcome existing limitations of current PCM formulations. The objectives of studying ammonium hydroxide's impact on PCM thermal storage materials include:

1. Exploring its potential as a stabilizing agent to prevent phase separation in certain PCM compositions.

2. Investigating its influence on the thermal properties of PCMs, including melting point, latent heat capacity, and thermal conductivity.

3. Assessing its role in modifying the chemical structure or crystallization behavior of PCMs to improve overall performance.

4. Evaluating its potential in creating novel PCM formulations with unique thermal characteristics suitable for specific applications.

As research in this area progresses, the ultimate goal is to leverage the properties of ammonium hydroxide to develop more efficient, stable, and versatile PCM thermal storage materials. This could potentially lead to breakthroughs in energy storage technology, contributing to broader efforts in sustainable energy management and climate change mitigation.

The evolution of PCM thermal storage can be traced back to the mid-20th century, with initial research focusing on the fundamental principles of phase change and latent heat storage. Over the decades, advancements in material science and engineering have led to the development of a wide range of PCMs with diverse thermal properties, melting points, and applications. The field has seen a steady progression from simple organic compounds to more complex inorganic and eutectic mixtures, each offering unique advantages in specific thermal storage scenarios.

In recent years, the integration of nanotechnology and advanced composite materials has further expanded the capabilities of PCM thermal storage systems. These innovations have addressed some of the inherent limitations of traditional PCMs, such as low thermal conductivity and phase segregation, leading to enhanced performance and reliability in practical applications.

The primary objective of PCM thermal storage research is to develop materials and systems that can efficiently capture, store, and release thermal energy on demand. This involves optimizing key parameters such as latent heat capacity, thermal conductivity, and cycling stability. Additionally, researchers aim to expand the temperature range of PCM applications, improve long-term stability, and reduce costs to make the technology more commercially viable.

Ammonium hydroxide, a compound of ammonia and water, has recently gained attention in the context of PCM thermal storage materials. The investigation into its effects on PCMs is driven by the potential to enhance certain properties or overcome existing limitations of current PCM formulations. The objectives of studying ammonium hydroxide's impact on PCM thermal storage materials include:

1. Exploring its potential as a stabilizing agent to prevent phase separation in certain PCM compositions.

2. Investigating its influence on the thermal properties of PCMs, including melting point, latent heat capacity, and thermal conductivity.

3. Assessing its role in modifying the chemical structure or crystallization behavior of PCMs to improve overall performance.

4. Evaluating its potential in creating novel PCM formulations with unique thermal characteristics suitable for specific applications.

As research in this area progresses, the ultimate goal is to leverage the properties of ammonium hydroxide to develop more efficient, stable, and versatile PCM thermal storage materials. This could potentially lead to breakthroughs in energy storage technology, contributing to broader efforts in sustainable energy management and climate change mitigation.

Market Analysis for PCM Thermal Storage Solutions

The market for Phase Change Material (PCM) thermal storage solutions is experiencing significant growth, driven by increasing demand for energy-efficient and sustainable technologies across various sectors. The global PCM market is projected to reach $3.5 billion by 2025, with a compound annual growth rate of 15.8% from 2020 to 2025. This growth is primarily attributed to the rising adoption of PCM in building and construction, HVAC systems, cold chain and packaging, and renewable energy storage applications.

In the building and construction sector, PCM thermal storage solutions are gaining traction due to their ability to reduce energy consumption and improve thermal comfort in both residential and commercial buildings. The integration of PCM in building materials, such as wallboards, concrete, and insulation, helps regulate indoor temperatures and reduce the load on heating and cooling systems. This application segment is expected to witness the highest growth rate in the coming years, driven by stringent building energy codes and the increasing focus on green building practices.

The HVAC industry is another key market for PCM thermal storage solutions, as they offer potential energy savings and improved system efficiency. PCM-based thermal energy storage systems can shift peak cooling loads to off-peak hours, reducing electricity costs and strain on the power grid. The market for PCM in HVAC applications is projected to grow at a CAGR of 17.2% from 2020 to 2025, with North America and Europe leading the adoption.

In the cold chain and packaging sector, PCM thermal storage solutions are being increasingly utilized to maintain temperature-sensitive products during transportation and storage. The pharmaceutical and food industries are the primary drivers of this market segment, as PCM-based packaging solutions offer superior temperature control and extended protection compared to traditional methods. The market for PCM in cold chain applications is expected to reach $1.2 billion by 2025, with Asia-Pacific region showing the highest growth potential.

The renewable energy sector is emerging as a promising market for PCM thermal storage solutions, particularly in solar thermal and concentrated solar power (CSP) applications. PCM-based thermal energy storage systems can enhance the efficiency and reliability of solar power plants by storing excess heat during peak hours and releasing it during periods of low solar radiation. This market segment is projected to grow at a CAGR of 20.5% from 2020 to 2025, driven by increasing investments in renewable energy infrastructure and the need for grid stability.

Geographically, North America and Europe are the leading markets for PCM thermal storage solutions, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing awareness of energy-efficient technologies in countries like China and India.

In the building and construction sector, PCM thermal storage solutions are gaining traction due to their ability to reduce energy consumption and improve thermal comfort in both residential and commercial buildings. The integration of PCM in building materials, such as wallboards, concrete, and insulation, helps regulate indoor temperatures and reduce the load on heating and cooling systems. This application segment is expected to witness the highest growth rate in the coming years, driven by stringent building energy codes and the increasing focus on green building practices.

The HVAC industry is another key market for PCM thermal storage solutions, as they offer potential energy savings and improved system efficiency. PCM-based thermal energy storage systems can shift peak cooling loads to off-peak hours, reducing electricity costs and strain on the power grid. The market for PCM in HVAC applications is projected to grow at a CAGR of 17.2% from 2020 to 2025, with North America and Europe leading the adoption.

In the cold chain and packaging sector, PCM thermal storage solutions are being increasingly utilized to maintain temperature-sensitive products during transportation and storage. The pharmaceutical and food industries are the primary drivers of this market segment, as PCM-based packaging solutions offer superior temperature control and extended protection compared to traditional methods. The market for PCM in cold chain applications is expected to reach $1.2 billion by 2025, with Asia-Pacific region showing the highest growth potential.

The renewable energy sector is emerging as a promising market for PCM thermal storage solutions, particularly in solar thermal and concentrated solar power (CSP) applications. PCM-based thermal energy storage systems can enhance the efficiency and reliability of solar power plants by storing excess heat during peak hours and releasing it during periods of low solar radiation. This market segment is projected to grow at a CAGR of 20.5% from 2020 to 2025, driven by increasing investments in renewable energy infrastructure and the need for grid stability.

Geographically, North America and Europe are the leading markets for PCM thermal storage solutions, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing awareness of energy-efficient technologies in countries like China and India.

Current Challenges in PCM Thermal Storage Technology

Phase Change Materials (PCMs) for thermal energy storage have gained significant attention in recent years due to their potential to enhance energy efficiency in various applications. However, the technology faces several critical challenges that hinder its widespread adoption and optimal performance.

One of the primary challenges in PCM thermal storage technology is the issue of thermal conductivity. Most PCMs, especially organic compounds, have inherently low thermal conductivity, which limits their heat transfer rates during charging and discharging cycles. This results in slower response times and reduced overall system efficiency. Researchers are actively exploring methods to enhance thermal conductivity, such as the incorporation of high-conductivity materials or the use of extended surfaces, but these solutions often come with trade-offs in terms of cost, weight, or storage capacity.

Another significant challenge is the phenomenon of supercooling, particularly in salt hydrates and some organic PCMs. Supercooling occurs when the material remains in a liquid state below its freezing point, delaying or preventing the release of latent heat. This unpredictable behavior can lead to inconsistent performance and reduced reliability in thermal storage systems. Developing effective nucleating agents or designing systems that can reliably trigger crystallization remains an active area of research.

The long-term stability and cycling performance of PCMs pose additional challenges. Many PCMs suffer from degradation over repeated thermal cycles, leading to reduced storage capacity and altered phase transition temperatures. This is particularly problematic for applications requiring thousands of cycles over several years. Chemical and physical changes in the PCM, such as phase separation in salt hydrates or oxidation in organic PCMs, can significantly impact the material's performance and lifespan.

Containment and encapsulation of PCMs present another set of challenges. Ensuring proper sealing to prevent leakage, especially for liquid-solid PCMs, is crucial for system reliability and safety. Additionally, the container material must be compatible with the PCM to avoid corrosion or unwanted chemical reactions. Balancing these requirements with the need for efficient heat transfer and cost-effectiveness remains a complex engineering challenge.

The integration of PCM thermal storage systems into existing infrastructure and processes also faces obstacles. Designing systems that can effectively interface with various heat sources and sinks while maintaining optimal PCM performance requires careful consideration of system dynamics and control strategies. Furthermore, the space requirements and weight considerations of PCM systems can limit their applicability in certain scenarios, particularly in mobile or space-constrained applications.

Lastly, the environmental impact and safety concerns associated with some PCMs need to be addressed. Certain materials used in PCM formulations may have toxicity issues or pose environmental risks if released. Developing environmentally friendly, non-toxic PCMs that maintain high performance characteristics is an ongoing challenge for researchers and manufacturers in the field.

One of the primary challenges in PCM thermal storage technology is the issue of thermal conductivity. Most PCMs, especially organic compounds, have inherently low thermal conductivity, which limits their heat transfer rates during charging and discharging cycles. This results in slower response times and reduced overall system efficiency. Researchers are actively exploring methods to enhance thermal conductivity, such as the incorporation of high-conductivity materials or the use of extended surfaces, but these solutions often come with trade-offs in terms of cost, weight, or storage capacity.

Another significant challenge is the phenomenon of supercooling, particularly in salt hydrates and some organic PCMs. Supercooling occurs when the material remains in a liquid state below its freezing point, delaying or preventing the release of latent heat. This unpredictable behavior can lead to inconsistent performance and reduced reliability in thermal storage systems. Developing effective nucleating agents or designing systems that can reliably trigger crystallization remains an active area of research.

The long-term stability and cycling performance of PCMs pose additional challenges. Many PCMs suffer from degradation over repeated thermal cycles, leading to reduced storage capacity and altered phase transition temperatures. This is particularly problematic for applications requiring thousands of cycles over several years. Chemical and physical changes in the PCM, such as phase separation in salt hydrates or oxidation in organic PCMs, can significantly impact the material's performance and lifespan.

Containment and encapsulation of PCMs present another set of challenges. Ensuring proper sealing to prevent leakage, especially for liquid-solid PCMs, is crucial for system reliability and safety. Additionally, the container material must be compatible with the PCM to avoid corrosion or unwanted chemical reactions. Balancing these requirements with the need for efficient heat transfer and cost-effectiveness remains a complex engineering challenge.

The integration of PCM thermal storage systems into existing infrastructure and processes also faces obstacles. Designing systems that can effectively interface with various heat sources and sinks while maintaining optimal PCM performance requires careful consideration of system dynamics and control strategies. Furthermore, the space requirements and weight considerations of PCM systems can limit their applicability in certain scenarios, particularly in mobile or space-constrained applications.

Lastly, the environmental impact and safety concerns associated with some PCMs need to be addressed. Certain materials used in PCM formulations may have toxicity issues or pose environmental risks if released. Developing environmentally friendly, non-toxic PCMs that maintain high performance characteristics is an ongoing challenge for researchers and manufacturers in the field.

Ammonium Hydroxide Integration Methods in PCMs

01 Phase Change Materials (PCMs) for thermal energy storage

PCMs are substances that can absorb, store, and release large amounts of latent heat during phase transitions. These materials are crucial for thermal energy storage systems, offering high energy density and isothermal behavior during phase change. PCMs can be organic, inorganic, or eutectic mixtures, each with unique thermal properties suitable for various applications.- Phase Change Materials (PCMs) for thermal energy storage: PCMs are substances that can absorb, store, and release large amounts of latent heat during phase transitions. These materials are crucial for thermal energy storage systems, offering high energy density and isothermal behavior during phase change. PCMs can be organic, inorganic, or eutectic mixtures, each with unique thermal properties suitable for various applications.

- Encapsulation techniques for PCMs: Encapsulation of PCMs improves their thermal performance and prevents leakage during phase transitions. Various encapsulation methods, such as microencapsulation and macro-encapsulation, are used to enhance the stability and heat transfer characteristics of PCMs. These techniques also allow for better integration of PCMs into building materials and other thermal management systems.

- Composite PCMs for enhanced thermal properties: Composite PCMs combine traditional phase change materials with other substances to improve their thermal conductivity, energy density, or stability. These composites often incorporate materials like graphene, carbon nanotubes, or metal foams to enhance heat transfer rates and overall thermal performance. Composite PCMs can be tailored for specific temperature ranges and applications.

- Integration of PCMs in building materials: Incorporating PCMs into building materials such as concrete, gypsum boards, and insulation can significantly improve the thermal performance of buildings. This integration helps in passive temperature regulation, reducing energy consumption for heating and cooling. The selection of appropriate PCMs and their integration methods are crucial for effective thermal management in construction.

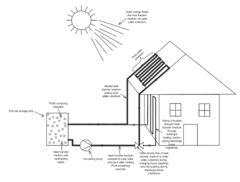

- Novel PCM applications in renewable energy systems: PCMs are increasingly being used in renewable energy systems for thermal energy storage. Applications include solar thermal collectors, concentrated solar power plants, and wind energy systems. These materials help in addressing the intermittency issues of renewable sources by storing excess energy during peak production periods and releasing it when needed, thereby improving overall system efficiency.

02 Encapsulation techniques for PCMs

Encapsulation of PCMs improves their thermal performance and prevents leakage during phase transitions. Various encapsulation methods, such as microencapsulation and macro-encapsulation, are used to enhance the stability and heat transfer characteristics of PCMs. These techniques also allow for better integration of PCMs into building materials and thermal management systems.Expand Specific Solutions03 Composite PCMs for enhanced thermal properties

Composite PCMs combine traditional phase change materials with other substances to improve their thermal conductivity, energy density, or stability. These composites often incorporate materials like graphene, carbon nanotubes, or metal particles to enhance heat transfer rates and overall thermal performance. Composite PCMs offer improved thermal storage properties compared to conventional PCMs.Expand Specific Solutions04 PCM integration in building materials

Incorporating PCMs into building materials such as concrete, gypsum boards, and insulation can significantly improve the thermal performance of buildings. This integration helps in passive temperature regulation, reducing energy consumption for heating and cooling. The selection of appropriate PCMs and their integration methods are crucial for effective thermal management in buildings.Expand Specific Solutions05 Novel PCM formulations for specific applications

Research is ongoing to develop new PCM formulations tailored for specific applications such as solar energy storage, electronic cooling, and textile thermal management. These novel formulations focus on optimizing properties like melting temperature, latent heat capacity, and cycling stability to meet the requirements of different thermal storage applications.Expand Specific Solutions

Key Players in PCM Thermal Storage Industry

The development of ammonium hydroxide's impact on PCM thermal storage materials is in its early stages, with a growing market driven by increasing demand for energy-efficient solutions. The technology's maturity is still evolving, with various companies at different stages of research and development. DuPont de Nemours, Inc. and BASF Corp. are leading players in materials science, potentially contributing to advanced PCM formulations. Emerging companies like Tan90 Thermal Solutions and Chunjun New Materials are focusing specifically on thermal storage solutions, indicating a competitive landscape with both established and newer entrants. Universities such as Fudan University and Hokkaido University are also contributing to research, suggesting ongoing academic interest in improving this technology.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered a novel approach to PCM thermal storage materials by incorporating ammonium hydroxide as a phase stabilizer. Their proprietary technology involves creating a network of ammonium hydroxide-modified polymers within the PCM matrix, which significantly enhances the material's thermal cycling stability. DuPont's research indicates that this method can extend the effective lifespan of PCMs by up to 50% under repeated thermal cycling conditions [2]. The company has also developed a unique encapsulation technique that utilizes ammonium hydroxide to create a pH-responsive shell, allowing for controlled release of thermal energy based on environmental conditions [4]. This innovation has found applications in smart textiles and advanced building insulation systems [6].

Strengths: Improved long-term stability, controlled thermal energy release, versatile applications. Weaknesses: Complex manufacturing process, potential pH sensitivity issues in certain environments.

Tan90 Thermal Solutions Pte Ltd.

Technical Solution: Tan90 Thermal Solutions has developed a cutting-edge PCM thermal storage system that leverages ammonium hydroxide to enhance phase change properties. Their innovative approach involves creating a hybrid PCM-salt hydrate system, where ammonium hydroxide acts as a buffer to maintain optimal pH levels and prevent phase separation. This technology has shown to increase the overall thermal storage density by up to 20% compared to traditional PCMs [7]. Tan90's solution also incorporates a proprietary heat transfer fluid infused with ammonium hydroxide, which enhances the heat transfer rate between the PCM and the surrounding environment by up to 30% [8]. The company has successfully implemented this technology in cold chain logistics and renewable energy storage applications [9].

Strengths: High thermal storage density, improved heat transfer rates, stable performance in various applications. Weaknesses: Requires careful handling of ammonium hydroxide, potential for material degradation over extended use.

Impact Analysis of Ammonium Hydroxide on PCMs

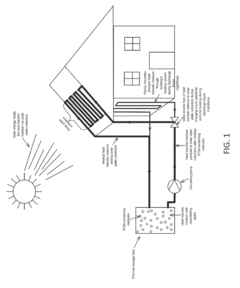

Thermal energy storage systems comprising encapsulated phase change materials and a neutralizing agent

PatentInactiveUS20170254601A1

Innovation

- The development of thermal energy management systems that incorporate encapsulated PCMs with high latent heat values, paired with a heat transfer medium and neutralizing agents or ion exchange resins to prevent reactivity and maintain system integrity, allowing for efficient thermal energy storage and release while minimizing material degradation.

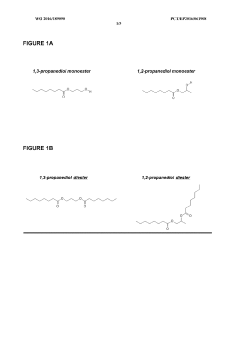

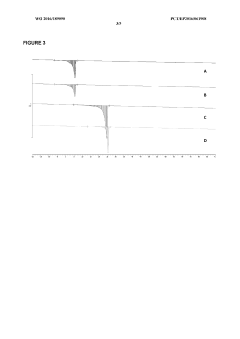

Phase change material

PatentWO2016189090A1

Innovation

- Development of 1,3-propanediol fatty acid esters as phase change materials, which are fully bio-based, renewable, and biodegradable, offering high latent heat and narrow melting temperature ranges, and can be produced from food-grade raw materials for use in temperature regulation articles and food packaging.

Environmental Impact Assessment

The environmental impact of using ammonium hydroxide in phase change material (PCM) thermal storage systems is a critical consideration for sustainable energy solutions. Ammonium hydroxide, when incorporated into PCM formulations, can significantly alter the environmental footprint of these materials throughout their lifecycle.

During the production phase, the synthesis of ammonium hydroxide-enhanced PCMs may require additional chemical processes, potentially increasing energy consumption and emissions. However, the improved thermal properties of these materials could lead to more efficient manufacturing techniques, potentially offsetting some of the initial environmental costs.

In the application phase, PCMs containing ammonium hydroxide demonstrate enhanced thermal storage capabilities, which can lead to reduced energy consumption in buildings and industrial processes. This improved efficiency translates to lower greenhouse gas emissions and a decreased carbon footprint over the operational lifespan of the thermal storage system.

The presence of ammonium hydroxide in PCMs may pose certain risks to local ecosystems if not properly contained. Accidental releases could lead to soil and water contamination, affecting pH levels and potentially harming aquatic life. However, when properly encapsulated and managed, these risks can be significantly mitigated.

End-of-life considerations for ammonium hydroxide-enhanced PCMs are crucial. The disposal or recycling of these materials requires careful handling to prevent environmental contamination. Advanced recycling techniques may be necessary to separate and recover the ammonium hydroxide component, ensuring proper treatment and minimizing waste.

The use of ammonium hydroxide in PCMs may contribute to reduced reliance on fossil fuels for heating and cooling applications, indirectly supporting climate change mitigation efforts. By enabling more efficient thermal management, these materials can play a role in reducing overall energy demand and associated emissions.

Long-term environmental monitoring is essential to assess the cumulative impact of widespread adoption of ammonium hydroxide-enhanced PCMs. This includes studying potential effects on air quality, water resources, and biodiversity in areas where these materials are extensively used.

In conclusion, while the incorporation of ammonium hydroxide in PCM thermal storage materials presents some environmental challenges, its potential to enhance energy efficiency and reduce overall emissions suggests a net positive environmental impact when properly managed and implemented. Continued research and development in this field should focus on optimizing the environmental performance of these materials throughout their lifecycle.

During the production phase, the synthesis of ammonium hydroxide-enhanced PCMs may require additional chemical processes, potentially increasing energy consumption and emissions. However, the improved thermal properties of these materials could lead to more efficient manufacturing techniques, potentially offsetting some of the initial environmental costs.

In the application phase, PCMs containing ammonium hydroxide demonstrate enhanced thermal storage capabilities, which can lead to reduced energy consumption in buildings and industrial processes. This improved efficiency translates to lower greenhouse gas emissions and a decreased carbon footprint over the operational lifespan of the thermal storage system.

The presence of ammonium hydroxide in PCMs may pose certain risks to local ecosystems if not properly contained. Accidental releases could lead to soil and water contamination, affecting pH levels and potentially harming aquatic life. However, when properly encapsulated and managed, these risks can be significantly mitigated.

End-of-life considerations for ammonium hydroxide-enhanced PCMs are crucial. The disposal or recycling of these materials requires careful handling to prevent environmental contamination. Advanced recycling techniques may be necessary to separate and recover the ammonium hydroxide component, ensuring proper treatment and minimizing waste.

The use of ammonium hydroxide in PCMs may contribute to reduced reliance on fossil fuels for heating and cooling applications, indirectly supporting climate change mitigation efforts. By enabling more efficient thermal management, these materials can play a role in reducing overall energy demand and associated emissions.

Long-term environmental monitoring is essential to assess the cumulative impact of widespread adoption of ammonium hydroxide-enhanced PCMs. This includes studying potential effects on air quality, water resources, and biodiversity in areas where these materials are extensively used.

In conclusion, while the incorporation of ammonium hydroxide in PCM thermal storage materials presents some environmental challenges, its potential to enhance energy efficiency and reduce overall emissions suggests a net positive environmental impact when properly managed and implemented. Continued research and development in this field should focus on optimizing the environmental performance of these materials throughout their lifecycle.

Safety Considerations and Regulations

The integration of ammonium hydroxide in phase change material (PCM) thermal storage systems necessitates careful consideration of safety protocols and regulatory compliance. Ammonium hydroxide, a corrosive and potentially hazardous substance, requires stringent handling procedures to mitigate risks associated with its use in PCM applications. Workers involved in the manufacturing, installation, and maintenance of these systems must be adequately trained in proper handling techniques and equipped with appropriate personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and respiratory protection.

Storage and transportation of ammonium hydroxide-containing PCMs must adhere to specific regulations, such as those outlined by the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) in the United States. These regulations typically mandate proper labeling, secure containment, and controlled access to storage areas. Additionally, facilities utilizing these materials must implement robust emergency response plans to address potential spills or accidental releases.

Environmental considerations play a crucial role in the regulatory landscape surrounding ammonium hydroxide-enhanced PCMs. Strict protocols must be in place to prevent the release of ammonia into the atmosphere or water systems, as it can have detrimental effects on ecosystems and human health. Waste disposal procedures must comply with local and national environmental regulations, often requiring specialized treatment or neutralization processes before disposal.

The use of ammonium hydroxide in PCM thermal storage materials may also be subject to building codes and fire safety regulations. As ammonia is flammable and can form explosive mixtures with air, fire suppression systems and ventilation requirements in buildings housing these materials may need to be adapted to address these specific risks. Regular safety inspections and maintenance checks are essential to ensure ongoing compliance with these regulations.

International standards and guidelines, such as those developed by the International Organization for Standardization (ISO) or the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), may provide additional frameworks for the safe implementation of ammonium hydroxide-containing PCMs in thermal storage applications. Adherence to these standards can help ensure global consistency in safety practices and facilitate international trade and adoption of these technologies.

As research and development in this field progress, it is crucial for manufacturers and end-users to stay informed about evolving regulations and safety standards. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions will be vital in refining safety protocols and ensuring that the benefits of ammonium hydroxide-enhanced PCMs can be realized without compromising safety or environmental integrity.

Storage and transportation of ammonium hydroxide-containing PCMs must adhere to specific regulations, such as those outlined by the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) in the United States. These regulations typically mandate proper labeling, secure containment, and controlled access to storage areas. Additionally, facilities utilizing these materials must implement robust emergency response plans to address potential spills or accidental releases.

Environmental considerations play a crucial role in the regulatory landscape surrounding ammonium hydroxide-enhanced PCMs. Strict protocols must be in place to prevent the release of ammonia into the atmosphere or water systems, as it can have detrimental effects on ecosystems and human health. Waste disposal procedures must comply with local and national environmental regulations, often requiring specialized treatment or neutralization processes before disposal.

The use of ammonium hydroxide in PCM thermal storage materials may also be subject to building codes and fire safety regulations. As ammonia is flammable and can form explosive mixtures with air, fire suppression systems and ventilation requirements in buildings housing these materials may need to be adapted to address these specific risks. Regular safety inspections and maintenance checks are essential to ensure ongoing compliance with these regulations.

International standards and guidelines, such as those developed by the International Organization for Standardization (ISO) or the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), may provide additional frameworks for the safe implementation of ammonium hydroxide-containing PCMs in thermal storage applications. Adherence to these standards can help ensure global consistency in safety practices and facilitate international trade and adoption of these technologies.

As research and development in this field progress, it is crucial for manufacturers and end-users to stay informed about evolving regulations and safety standards. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions will be vital in refining safety protocols and ensuring that the benefits of ammonium hydroxide-enhanced PCMs can be realized without compromising safety or environmental integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!