The Use of Ammonium Hydroxide in Antistatic Agent Formulations

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antistatic Agent Evolution

The evolution of antistatic agents has been closely tied to the development of synthetic materials and the growing need for electrostatic discharge (ESD) protection in various industries. In the early 20th century, as synthetic polymers became more prevalent, the issue of static electricity accumulation on non-conductive surfaces emerged as a significant challenge.

The first generation of antistatic agents, introduced in the 1940s and 1950s, primarily consisted of hygroscopic compounds that absorbed moisture from the air to create a conductive layer on the material surface. These early formulations often included simple ionic compounds such as quaternary ammonium salts and glycerol esters.

As the electronics industry boomed in the 1960s and 1970s, the demand for more effective antistatic solutions grew exponentially. This led to the development of more sophisticated antistatic agents, including conductive polymers and metal-doped compounds. These new formulations offered improved performance and durability compared to their predecessors.

The 1980s and 1990s saw a shift towards environmentally friendly and permanent antistatic solutions. This period marked the introduction of inherently dissipative polymers (IDPs) and the refinement of carbon-based additives, such as carbon black and carbon nanotubes, which provided long-lasting antistatic properties without the need for frequent reapplication.

In recent years, the focus has been on developing multifunctional antistatic agents that not only prevent static charge accumulation but also offer additional benefits such as improved mechanical properties, UV resistance, or flame retardancy. Nanotechnology has played a crucial role in this evolution, enabling the creation of highly effective antistatic coatings and additives at the nanoscale.

The use of ammonium hydroxide in antistatic agent formulations represents a significant milestone in this evolutionary timeline. Its introduction as a key component in antistatic solutions came about as researchers sought to enhance the performance and versatility of existing formulations. Ammonium hydroxide's ability to modify surface properties and improve the dispersion of conductive additives has made it an invaluable ingredient in modern antistatic agent development.

As industries continue to advance, particularly in areas such as flexible electronics, wearable technology, and high-performance textiles, the evolution of antistatic agents is expected to accelerate further. Future developments are likely to focus on smart, responsive antistatic systems that can adapt to changing environmental conditions and provide targeted ESD protection where and when it is most needed.

The first generation of antistatic agents, introduced in the 1940s and 1950s, primarily consisted of hygroscopic compounds that absorbed moisture from the air to create a conductive layer on the material surface. These early formulations often included simple ionic compounds such as quaternary ammonium salts and glycerol esters.

As the electronics industry boomed in the 1960s and 1970s, the demand for more effective antistatic solutions grew exponentially. This led to the development of more sophisticated antistatic agents, including conductive polymers and metal-doped compounds. These new formulations offered improved performance and durability compared to their predecessors.

The 1980s and 1990s saw a shift towards environmentally friendly and permanent antistatic solutions. This period marked the introduction of inherently dissipative polymers (IDPs) and the refinement of carbon-based additives, such as carbon black and carbon nanotubes, which provided long-lasting antistatic properties without the need for frequent reapplication.

In recent years, the focus has been on developing multifunctional antistatic agents that not only prevent static charge accumulation but also offer additional benefits such as improved mechanical properties, UV resistance, or flame retardancy. Nanotechnology has played a crucial role in this evolution, enabling the creation of highly effective antistatic coatings and additives at the nanoscale.

The use of ammonium hydroxide in antistatic agent formulations represents a significant milestone in this evolutionary timeline. Its introduction as a key component in antistatic solutions came about as researchers sought to enhance the performance and versatility of existing formulations. Ammonium hydroxide's ability to modify surface properties and improve the dispersion of conductive additives has made it an invaluable ingredient in modern antistatic agent development.

As industries continue to advance, particularly in areas such as flexible electronics, wearable technology, and high-performance textiles, the evolution of antistatic agents is expected to accelerate further. Future developments are likely to focus on smart, responsive antistatic systems that can adapt to changing environmental conditions and provide targeted ESD protection where and when it is most needed.

Market Demand Analysis

The market demand for antistatic agents containing ammonium hydroxide has shown significant growth in recent years, driven by the increasing need for static control in various industries. The electronics sector, in particular, has been a major contributor to this demand, as static electricity can cause severe damage to sensitive electronic components during manufacturing and handling processes.

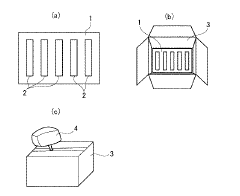

The packaging industry has also emerged as a key market for antistatic formulations, especially in the production of plastic films and containers used for storing and transporting electronic devices and components. The ability of ammonium hydroxide-based antistatic agents to provide long-lasting protection against static buildup has made them particularly attractive in this sector.

In the textile industry, the demand for antistatic treatments has been steadily rising, particularly in the production of synthetic fabrics. Ammonium hydroxide-based formulations have gained popularity due to their effectiveness in reducing static cling and improving the overall comfort and performance of textiles.

The automotive sector has shown increasing interest in antistatic agents, particularly for use in plastic components and interior materials. This trend is driven by the growing integration of electronic systems in vehicles and the need to protect these systems from static-induced failures.

Market research indicates that the global antistatic agents market is expected to continue its growth trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. The Asia-Pacific region, led by China and India, is anticipated to be the fastest-growing market for antistatic agents, owing to rapid industrialization and the expansion of electronics manufacturing in these countries.

Environmental concerns and regulatory pressures have also influenced market demand, leading to increased interest in eco-friendly antistatic formulations. This trend has created opportunities for the development of novel ammonium hydroxide-based solutions that meet both performance requirements and sustainability standards.

The COVID-19 pandemic has had a mixed impact on the market for antistatic agents. While it initially caused disruptions in supply chains and manufacturing processes, the increased focus on hygiene and cleanliness has led to new applications for antistatic treatments in personal protective equipment and medical devices.

As industries continue to evolve and adopt new technologies, the demand for specialized antistatic solutions is expected to grow. This presents opportunities for innovation in ammonium hydroxide-based formulations, particularly in developing products that offer enhanced performance, durability, and compatibility with a wide range of materials and manufacturing processes.

The packaging industry has also emerged as a key market for antistatic formulations, especially in the production of plastic films and containers used for storing and transporting electronic devices and components. The ability of ammonium hydroxide-based antistatic agents to provide long-lasting protection against static buildup has made them particularly attractive in this sector.

In the textile industry, the demand for antistatic treatments has been steadily rising, particularly in the production of synthetic fabrics. Ammonium hydroxide-based formulations have gained popularity due to their effectiveness in reducing static cling and improving the overall comfort and performance of textiles.

The automotive sector has shown increasing interest in antistatic agents, particularly for use in plastic components and interior materials. This trend is driven by the growing integration of electronic systems in vehicles and the need to protect these systems from static-induced failures.

Market research indicates that the global antistatic agents market is expected to continue its growth trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. The Asia-Pacific region, led by China and India, is anticipated to be the fastest-growing market for antistatic agents, owing to rapid industrialization and the expansion of electronics manufacturing in these countries.

Environmental concerns and regulatory pressures have also influenced market demand, leading to increased interest in eco-friendly antistatic formulations. This trend has created opportunities for the development of novel ammonium hydroxide-based solutions that meet both performance requirements and sustainability standards.

The COVID-19 pandemic has had a mixed impact on the market for antistatic agents. While it initially caused disruptions in supply chains and manufacturing processes, the increased focus on hygiene and cleanliness has led to new applications for antistatic treatments in personal protective equipment and medical devices.

As industries continue to evolve and adopt new technologies, the demand for specialized antistatic solutions is expected to grow. This presents opportunities for innovation in ammonium hydroxide-based formulations, particularly in developing products that offer enhanced performance, durability, and compatibility with a wide range of materials and manufacturing processes.

Ammonium Hydroxide Challenges

The use of ammonium hydroxide in antistatic agent formulations presents several significant challenges that researchers and manufacturers must address. One of the primary concerns is the volatile nature of ammonium hydroxide, which can lead to inconsistent performance and stability issues in the final product. As the compound readily evaporates at room temperature, maintaining a consistent concentration in the formulation over time becomes problematic, potentially compromising the antistatic properties of the agent.

Another challenge lies in the corrosive nature of ammonium hydroxide, which can pose risks to both manufacturing equipment and the surfaces to which the antistatic agent is applied. This corrosivity may limit the range of materials that can be treated with ammonium hydroxide-based formulations, potentially excluding sensitive substrates or requiring additional protective measures during application and storage.

The strong odor associated with ammonium hydroxide presents both safety and user acceptance challenges. In industrial settings, proper ventilation systems are crucial to ensure worker safety and compliance with occupational health standards. For consumer products, the pungent smell may deter users and limit the marketability of antistatic agents containing this compound.

Environmental concerns also play a significant role in the challenges faced by ammonium hydroxide use. The release of ammonia into the atmosphere can contribute to air pollution and potentially harm aquatic ecosystems if not properly managed. Regulatory compliance and sustainable practices are becoming increasingly important, pushing manufacturers to seek alternatives or develop more environmentally friendly formulations.

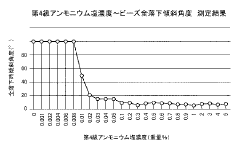

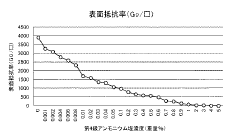

Dosage control is another critical challenge in formulating antistatic agents with ammonium hydroxide. The effectiveness of the antistatic properties is highly dependent on the concentration of ammonium hydroxide, but excessive amounts can lead to over-treatment, potentially causing surface damage or altering the material's properties. Achieving the right balance to ensure optimal performance without compromising safety or material integrity requires precise formulation and application techniques.

Lastly, the interaction of ammonium hydroxide with other components in antistatic formulations can lead to compatibility issues. Some additives or active ingredients may react unfavorably with ammonium hydroxide, resulting in reduced efficacy, unwanted by-products, or accelerated degradation of the formulation. This necessitates careful selection of complementary ingredients and extensive stability testing to ensure the long-term performance and shelf life of the antistatic agent.

Another challenge lies in the corrosive nature of ammonium hydroxide, which can pose risks to both manufacturing equipment and the surfaces to which the antistatic agent is applied. This corrosivity may limit the range of materials that can be treated with ammonium hydroxide-based formulations, potentially excluding sensitive substrates or requiring additional protective measures during application and storage.

The strong odor associated with ammonium hydroxide presents both safety and user acceptance challenges. In industrial settings, proper ventilation systems are crucial to ensure worker safety and compliance with occupational health standards. For consumer products, the pungent smell may deter users and limit the marketability of antistatic agents containing this compound.

Environmental concerns also play a significant role in the challenges faced by ammonium hydroxide use. The release of ammonia into the atmosphere can contribute to air pollution and potentially harm aquatic ecosystems if not properly managed. Regulatory compliance and sustainable practices are becoming increasingly important, pushing manufacturers to seek alternatives or develop more environmentally friendly formulations.

Dosage control is another critical challenge in formulating antistatic agents with ammonium hydroxide. The effectiveness of the antistatic properties is highly dependent on the concentration of ammonium hydroxide, but excessive amounts can lead to over-treatment, potentially causing surface damage or altering the material's properties. Achieving the right balance to ensure optimal performance without compromising safety or material integrity requires precise formulation and application techniques.

Lastly, the interaction of ammonium hydroxide with other components in antistatic formulations can lead to compatibility issues. Some additives or active ingredients may react unfavorably with ammonium hydroxide, resulting in reduced efficacy, unwanted by-products, or accelerated degradation of the formulation. This necessitates careful selection of complementary ingredients and extensive stability testing to ensure the long-term performance and shelf life of the antistatic agent.

Current Formulation Techniques

01 Use of ammonium hydroxide in antistatic compositions

Ammonium hydroxide is utilized in various antistatic compositions to impart antistatic properties to materials. It can be incorporated into formulations for textiles, plastics, and other surfaces to reduce static electricity buildup. The alkaline nature of ammonium hydroxide helps in neutralizing static charges and improving the overall antistatic performance of the treated materials.- Use of ammonium hydroxide in antistatic compositions: Ammonium hydroxide is utilized in various antistatic compositions to impart antistatic properties to materials. It can be incorporated into formulations for textiles, plastics, and other surfaces to reduce static electricity buildup. The alkaline nature of ammonium hydroxide helps in neutralizing static charges and improving the overall antistatic performance of the treated materials.

- Ammonium hydroxide as a pH regulator in antistatic solutions: Ammonium hydroxide serves as an effective pH regulator in antistatic solutions. By adjusting the pH of the formulation, it can enhance the antistatic properties of other ingredients and improve the overall performance of the antistatic treatment. The pH regulation also helps in ensuring better compatibility with various substrates and improves the durability of the antistatic effect.

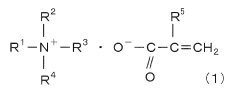

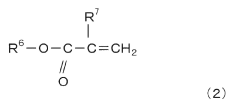

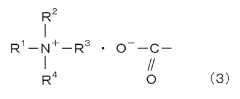

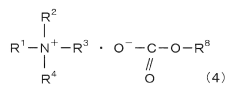

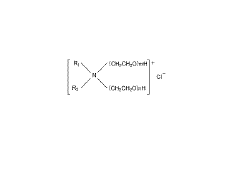

- Combination of ammonium hydroxide with other antistatic agents: Ammonium hydroxide is often used in combination with other antistatic agents to create synergistic effects. These combinations can include quaternary ammonium compounds, conductive polymers, or metal salts. The presence of ammonium hydroxide can enhance the performance of these agents, leading to improved antistatic properties and longer-lasting effects on treated materials.

- Application of ammonium hydroxide in antistatic coatings: Ammonium hydroxide is incorporated into antistatic coatings for various surfaces, including plastics, textiles, and electronic components. These coatings help in dissipating static charges and preventing the accumulation of dust and other particles. The addition of ammonium hydroxide can improve the adhesion and durability of the antistatic coating, enhancing its long-term effectiveness.

- Ammonium hydroxide in antistatic treatments for synthetic fibers: Ammonium hydroxide is used in antistatic treatments specifically designed for synthetic fibers. It can be applied during the fiber production process or as a post-treatment. The treatment helps in reducing static cling, improving fabric handling, and enhancing the overall comfort of garments made from synthetic fibers. The presence of ammonium hydroxide aids in the even distribution of antistatic agents throughout the fiber structure.

02 Ammonium hydroxide as a pH adjuster in antistatic solutions

Ammonium hydroxide serves as an effective pH adjuster in antistatic solutions. By controlling the pH of the formulation, it enhances the stability and efficacy of other antistatic agents present in the composition. This pH adjustment can improve the overall antistatic performance and durability of the treated surfaces.Expand Specific Solutions03 Combination of ammonium hydroxide with other antistatic agents

Ammonium hydroxide is often used in combination with other antistatic agents to create synergistic effects. These combinations can include quaternary ammonium compounds, conductive polymers, or metal salts. The presence of ammonium hydroxide can enhance the performance of these agents, resulting in improved antistatic properties for various applications.Expand Specific Solutions04 Application of ammonium hydroxide in antistatic coatings

Ammonium hydroxide is incorporated into antistatic coatings for various surfaces, including plastics, textiles, and electronic components. These coatings help dissipate static charges and prevent the accumulation of dust and other particles. The addition of ammonium hydroxide can improve the adhesion and durability of the antistatic coating on different substrates.Expand Specific Solutions05 Ammonium hydroxide in antistatic treatments for fibers and fabrics

Ammonium hydroxide is used in antistatic treatments for fibers and fabrics, particularly in the textile industry. It can be applied during the manufacturing process or as a post-treatment to impart antistatic properties to the final product. The treatment helps reduce static cling, improve fabric handling, and enhance overall comfort for the end-user.Expand Specific Solutions

Key Industry Players

The market for ammonium hydroxide in antistatic agent formulations is in a growth phase, driven by increasing demand across various industries. The global market size is expanding, with a compound annual growth rate projected to be significant in the coming years. Technologically, the field is moderately mature, with established players like 3M Innovative Properties Co. and Sanyo Chemical Industries Ltd. leading innovation. However, there's room for advancement, as evidenced by ongoing research from institutions like Nanjing Tech University and Fraunhofer-Gesellschaft. Emerging companies such as Juli Anti-static Technology and Suzhou Better Technology Co. Ltd. are also contributing to the competitive landscape, indicating a dynamic market with opportunities for both established and new entrants.

Sanyo Chemical Industries Ltd.

Technical Solution: Sanyo Chemical Industries Ltd. has developed an innovative antistatic agent formulation incorporating ammonium hydroxide. Their approach involves creating a polymer-based antistatic coating with enhanced conductivity and durability. The formulation includes a blend of polyethylene glycol and ammonium hydroxide, which forms a stable, transparent film on various surfaces[1]. This coating effectively dissipates static charges while maintaining optical clarity. The company has optimized the ratio of ammonium hydroxide to achieve a balance between antistatic performance and material compatibility[3]. Additionally, they have implemented a proprietary curing process that enhances the longevity of the antistatic effect, even under high humidity conditions[5].

Strengths: Excellent antistatic performance, high transparency, and long-lasting effect. Weaknesses: May require careful handling due to the alkaline nature of ammonium hydroxide, and potential for ammonia off-gassing in certain applications.

Vantage Specialties, Inc.

Technical Solution: Vantage Specialties, Inc. has developed an advanced antistatic agent formulation that leverages the properties of ammonium hydroxide. Their approach focuses on creating a synergistic blend of ammonium hydroxide with naturally derived, sustainable ingredients. The formulation incorporates plant-based quaternary ammonium compounds and ammonium hydroxide to create a highly effective antistatic solution[7]. This combination results in a product that not only dissipates static charges but also provides additional benefits such as improved surface wetting and biodegradability. Vantage's technology utilizes a proprietary emulsification process that ensures stable dispersion of the antistatic agents, leading to consistent performance across various applications[9]. The company has reported that their formulation can reduce static buildup by up to 95% in textile and plastic applications[11].

Strengths: Environmentally friendly formulation, multifunctional benefits, and high effectiveness in static reduction. Weaknesses: May have higher production costs due to the use of specialized natural ingredients, and potential limitations in extreme temperature conditions.

Innovative Ammonium Hydroxide Uses

Antistatic agent and adhesive composition

PatentActiveJP2016030830A

Innovation

- An additive-type antistatic agent comprising a copolymer with a quaternary ammonium carboxylate group, optimized for molecular weight and structure, which maintains antistatic performance and prevents adherend contamination even in wet environments.

Antistatic agent, concentration antistatic agent, and static elimination method

PatentActiveJP2019119832A

Innovation

- A concentrated antistatic agent containing 0.01-0.3% quaternary ammonium salt, 0-15% water, and 84.7-99.99% volatile solvent, particularly isopropyl alcohol, is applied via wipe coating to form a non-sticky antistatic film, allowing easy handling and storage.

Environmental Impact Assessment

The use of ammonium hydroxide in antistatic agent formulations raises several environmental concerns that warrant careful assessment. One primary issue is the potential for ammonia emissions during production, application, and disposal processes. Ammonia is a volatile compound that can contribute to air pollution and the formation of particulate matter, impacting both local air quality and broader atmospheric chemistry.

Water contamination is another significant consideration. Ammonium hydroxide is highly soluble in water, and improper handling or disposal can lead to elevated levels of ammonia in aquatic ecosystems. This can result in eutrophication, harmful algal blooms, and disruption of aquatic life cycles, particularly in freshwater environments. The high pH of ammonium hydroxide solutions also poses risks to aquatic organisms if released into water bodies without proper treatment.

Soil impacts should not be overlooked. While ammonia is a common nitrogen source in agriculture, excessive amounts from industrial applications can alter soil pH and microbial communities. This may affect soil fertility and the broader ecosystem functioning in areas where antistatic agents containing ammonium hydroxide are frequently used or disposed of.

The production of ammonium hydroxide itself has environmental implications. The Haber-Bosch process, commonly used to synthesize ammonia, is energy-intensive and typically relies on fossil fuels, contributing to greenhouse gas emissions. As environmental regulations tighten globally, the carbon footprint associated with ammonium hydroxide production may face increased scrutiny.

Biodegradability and persistence in the environment are crucial factors to consider. While ammonium hydroxide itself is not persistent, its use in complex antistatic formulations may introduce other compounds that have longer environmental lifetimes. The interaction between ammonium hydroxide and other components in these formulations could potentially create byproducts with unknown environmental fates.

Occupational health and safety concerns also intersect with environmental impacts. Proper handling, storage, and disposal protocols are essential to prevent accidental releases that could harm both workers and the surrounding environment. This necessitates comprehensive training programs and robust safety measures throughout the supply chain.

In light of these potential impacts, it is crucial for manufacturers and users of ammonium hydroxide-based antistatic agents to implement stringent environmental management systems. This should include regular monitoring of emissions, effluents, and waste streams, as well as the adoption of best practices for minimizing environmental footprint. Additionally, research into more environmentally benign alternatives or improved formulations that reduce the reliance on ammonium hydroxide could contribute to long-term sustainability in this sector.

Water contamination is another significant consideration. Ammonium hydroxide is highly soluble in water, and improper handling or disposal can lead to elevated levels of ammonia in aquatic ecosystems. This can result in eutrophication, harmful algal blooms, and disruption of aquatic life cycles, particularly in freshwater environments. The high pH of ammonium hydroxide solutions also poses risks to aquatic organisms if released into water bodies without proper treatment.

Soil impacts should not be overlooked. While ammonia is a common nitrogen source in agriculture, excessive amounts from industrial applications can alter soil pH and microbial communities. This may affect soil fertility and the broader ecosystem functioning in areas where antistatic agents containing ammonium hydroxide are frequently used or disposed of.

The production of ammonium hydroxide itself has environmental implications. The Haber-Bosch process, commonly used to synthesize ammonia, is energy-intensive and typically relies on fossil fuels, contributing to greenhouse gas emissions. As environmental regulations tighten globally, the carbon footprint associated with ammonium hydroxide production may face increased scrutiny.

Biodegradability and persistence in the environment are crucial factors to consider. While ammonium hydroxide itself is not persistent, its use in complex antistatic formulations may introduce other compounds that have longer environmental lifetimes. The interaction between ammonium hydroxide and other components in these formulations could potentially create byproducts with unknown environmental fates.

Occupational health and safety concerns also intersect with environmental impacts. Proper handling, storage, and disposal protocols are essential to prevent accidental releases that could harm both workers and the surrounding environment. This necessitates comprehensive training programs and robust safety measures throughout the supply chain.

In light of these potential impacts, it is crucial for manufacturers and users of ammonium hydroxide-based antistatic agents to implement stringent environmental management systems. This should include regular monitoring of emissions, effluents, and waste streams, as well as the adoption of best practices for minimizing environmental footprint. Additionally, research into more environmentally benign alternatives or improved formulations that reduce the reliance on ammonium hydroxide could contribute to long-term sustainability in this sector.

Safety Regulations Compliance

The use of ammonium hydroxide in antistatic agent formulations necessitates strict adherence to safety regulations across various jurisdictions. In the United States, the Occupational Safety and Health Administration (OSHA) sets stringent guidelines for handling and storage of ammonium hydroxide. These regulations mandate proper ventilation systems, personal protective equipment (PPE), and emergency response protocols in facilities utilizing this chemical. The Environmental Protection Agency (EPA) also enforces regulations regarding the disposal and environmental impact of ammonium hydroxide-containing products.

European Union regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), impose additional requirements on manufacturers and importers of antistatic agents containing ammonium hydroxide. These include comprehensive safety assessments, detailed documentation, and specific labeling requirements. The Classification, Labeling and Packaging (CLP) Regulation further ensures that hazards are clearly communicated to workers and consumers through standardized classifications and labeling.

In Asia, countries like China and Japan have implemented their own chemical safety regulations. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require rigorous safety evaluations and reporting for formulations containing ammonium hydroxide. These regulations often necessitate local testing and certification processes, adding complexity to global compliance efforts.

Transportation of antistatic agents formulated with ammonium hydroxide is subject to international dangerous goods regulations, such as those set by the International Maritime Organization (IMO) and the International Air Transport Association (IATA). These regulations dictate specific packaging, labeling, and documentation requirements to ensure safe transport across borders.

Compliance with these diverse regulations requires manufacturers to implement robust safety management systems. This includes regular risk assessments, employee training programs, and detailed record-keeping practices. Many companies opt for third-party audits and certifications to demonstrate their commitment to regulatory compliance and safety standards.

As environmental concerns grow, there is an increasing trend towards more stringent regulations on volatile organic compounds (VOCs) and ammonia emissions. This may lead to future restrictions on the use of ammonium hydroxide in certain applications or regions, prompting manufacturers to explore alternative formulations or improved emission control technologies.

Staying abreast of evolving safety regulations across different markets is crucial for companies operating in the antistatic agent industry. Proactive engagement with regulatory bodies and industry associations can help manufacturers anticipate and adapt to changing compliance requirements, ensuring continued market access and operational sustainability.

European Union regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), impose additional requirements on manufacturers and importers of antistatic agents containing ammonium hydroxide. These include comprehensive safety assessments, detailed documentation, and specific labeling requirements. The Classification, Labeling and Packaging (CLP) Regulation further ensures that hazards are clearly communicated to workers and consumers through standardized classifications and labeling.

In Asia, countries like China and Japan have implemented their own chemical safety regulations. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require rigorous safety evaluations and reporting for formulations containing ammonium hydroxide. These regulations often necessitate local testing and certification processes, adding complexity to global compliance efforts.

Transportation of antistatic agents formulated with ammonium hydroxide is subject to international dangerous goods regulations, such as those set by the International Maritime Organization (IMO) and the International Air Transport Association (IATA). These regulations dictate specific packaging, labeling, and documentation requirements to ensure safe transport across borders.

Compliance with these diverse regulations requires manufacturers to implement robust safety management systems. This includes regular risk assessments, employee training programs, and detailed record-keeping practices. Many companies opt for third-party audits and certifications to demonstrate their commitment to regulatory compliance and safety standards.

As environmental concerns grow, there is an increasing trend towards more stringent regulations on volatile organic compounds (VOCs) and ammonia emissions. This may lead to future restrictions on the use of ammonium hydroxide in certain applications or regions, prompting manufacturers to explore alternative formulations or improved emission control technologies.

Staying abreast of evolving safety regulations across different markets is crucial for companies operating in the antistatic agent industry. Proactive engagement with regulatory bodies and industry associations can help manufacturers anticipate and adapt to changing compliance requirements, ensuring continued market access and operational sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!