The Utilization of Ammonium Hydroxide in Textile Pre-Treatment Processes

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Textiles: Background and Objectives

Ammonium hydroxide has been a significant component in textile pre-treatment processes for decades. Its use in the textile industry can be traced back to the early 20th century when manufacturers began seeking more efficient methods to prepare fabrics for dyeing and finishing. The evolution of ammonium hydroxide's application in textiles has been driven by the industry's constant pursuit of improved fabric quality, reduced environmental impact, and enhanced production efficiency.

The primary objective of utilizing ammonium hydroxide in textile pre-treatment is to effectively remove impurities, natural waxes, and oils from fabric fibers. This process, known as scouring, is crucial for ensuring optimal dye uptake and uniform coloration in subsequent stages. Ammonium hydroxide's alkaline properties make it particularly effective in breaking down and emulsifying these unwanted substances, allowing for their easy removal from the fabric surface.

Another key goal in employing ammonium hydroxide is to improve the overall sustainability of textile processing. As environmental concerns have grown more prominent in recent years, the industry has been compelled to seek alternatives to traditional, more harmful chemicals. Ammonium hydroxide, when used correctly, offers a relatively eco-friendly option compared to some conventional scouring agents, aligning with the increasing demand for greener textile production methods.

The technical objectives of ammonium hydroxide usage extend beyond mere cleaning. It also plays a role in modifying the fiber structure, enhancing the fabric's receptivity to dyes and finishes. This dual functionality makes it a valuable tool in streamlining pre-treatment processes, potentially reducing water and energy consumption in textile manufacturing.

As the textile industry continues to evolve, the use of ammonium hydroxide faces both opportunities and challenges. Ongoing research aims to optimize its application, exploring new formulations and methodologies to maximize its effectiveness while minimizing any potential negative impacts. The industry is also investigating synergistic effects when combining ammonium hydroxide with other pre-treatment agents, seeking to develop more comprehensive and efficient processing solutions.

Looking ahead, the objectives for ammonium hydroxide in textile pre-treatment are likely to focus on further enhancing its eco-friendly profile, improving its efficiency at lower concentrations, and expanding its compatibility with a wider range of fabric types and subsequent treatment processes. These goals align with the broader industry trends towards sustainability, cost-effectiveness, and versatility in textile production.

The primary objective of utilizing ammonium hydroxide in textile pre-treatment is to effectively remove impurities, natural waxes, and oils from fabric fibers. This process, known as scouring, is crucial for ensuring optimal dye uptake and uniform coloration in subsequent stages. Ammonium hydroxide's alkaline properties make it particularly effective in breaking down and emulsifying these unwanted substances, allowing for their easy removal from the fabric surface.

Another key goal in employing ammonium hydroxide is to improve the overall sustainability of textile processing. As environmental concerns have grown more prominent in recent years, the industry has been compelled to seek alternatives to traditional, more harmful chemicals. Ammonium hydroxide, when used correctly, offers a relatively eco-friendly option compared to some conventional scouring agents, aligning with the increasing demand for greener textile production methods.

The technical objectives of ammonium hydroxide usage extend beyond mere cleaning. It also plays a role in modifying the fiber structure, enhancing the fabric's receptivity to dyes and finishes. This dual functionality makes it a valuable tool in streamlining pre-treatment processes, potentially reducing water and energy consumption in textile manufacturing.

As the textile industry continues to evolve, the use of ammonium hydroxide faces both opportunities and challenges. Ongoing research aims to optimize its application, exploring new formulations and methodologies to maximize its effectiveness while minimizing any potential negative impacts. The industry is also investigating synergistic effects when combining ammonium hydroxide with other pre-treatment agents, seeking to develop more comprehensive and efficient processing solutions.

Looking ahead, the objectives for ammonium hydroxide in textile pre-treatment are likely to focus on further enhancing its eco-friendly profile, improving its efficiency at lower concentrations, and expanding its compatibility with a wider range of fabric types and subsequent treatment processes. These goals align with the broader industry trends towards sustainability, cost-effectiveness, and versatility in textile production.

Market Demand Analysis for Eco-Friendly Textile Pre-Treatment

The textile industry is experiencing a significant shift towards eco-friendly pre-treatment processes, driven by increasing environmental concerns and stringent regulations. This trend has created a growing market demand for sustainable alternatives to traditional chemical treatments, with ammonium hydroxide emerging as a promising option.

Consumer awareness of environmental issues has led to a surge in demand for sustainably produced textiles. Major fashion brands and retailers are responding to this consumer pressure by setting ambitious sustainability targets, which include reducing the environmental impact of their supply chains. This has cascaded down to textile manufacturers, who are now actively seeking greener pre-treatment solutions.

The global market for eco-friendly textile chemicals is projected to grow substantially in the coming years. This growth is fueled by the increasing adoption of sustainable practices across the textile value chain, from fiber production to garment manufacturing. Ammonium hydroxide, as a less harmful alternative to conventional alkaline agents, is well-positioned to capture a significant share of this expanding market.

Regulatory pressures are also driving the demand for eco-friendly pre-treatment processes. Governments worldwide are implementing stricter environmental regulations, particularly concerning water pollution and chemical usage in industrial processes. The textile industry, known for its high water consumption and chemical intensity, is under scrutiny to reduce its environmental footprint. This regulatory landscape is creating a strong incentive for manufacturers to adopt more sustainable pre-treatment methods, such as those utilizing ammonium hydroxide.

The market for ammonium hydroxide in textile pre-treatment is further bolstered by its potential to improve process efficiency and reduce costs. As manufacturers seek to optimize their operations, solutions that offer both environmental benefits and economic advantages are highly sought after. Ammonium hydroxide's ability to effectively remove impurities at lower temperatures and with reduced water consumption aligns well with these industry goals.

Geographically, the demand for eco-friendly textile pre-treatment solutions is particularly strong in regions with developed textile industries and stringent environmental regulations. Europe and North America are leading the adoption of sustainable practices, while rapidly growing textile markets in Asia are also showing increased interest in green technologies to meet export requirements and address local environmental challenges.

The market demand analysis indicates a clear trend towards more sustainable textile production methods, with ammonium hydroxide positioned as a key enabler of this transition. As the industry continues to evolve, the demand for eco-friendly pre-treatment processes is expected to grow, presenting significant opportunities for innovation and market expansion in the coming years.

Consumer awareness of environmental issues has led to a surge in demand for sustainably produced textiles. Major fashion brands and retailers are responding to this consumer pressure by setting ambitious sustainability targets, which include reducing the environmental impact of their supply chains. This has cascaded down to textile manufacturers, who are now actively seeking greener pre-treatment solutions.

The global market for eco-friendly textile chemicals is projected to grow substantially in the coming years. This growth is fueled by the increasing adoption of sustainable practices across the textile value chain, from fiber production to garment manufacturing. Ammonium hydroxide, as a less harmful alternative to conventional alkaline agents, is well-positioned to capture a significant share of this expanding market.

Regulatory pressures are also driving the demand for eco-friendly pre-treatment processes. Governments worldwide are implementing stricter environmental regulations, particularly concerning water pollution and chemical usage in industrial processes. The textile industry, known for its high water consumption and chemical intensity, is under scrutiny to reduce its environmental footprint. This regulatory landscape is creating a strong incentive for manufacturers to adopt more sustainable pre-treatment methods, such as those utilizing ammonium hydroxide.

The market for ammonium hydroxide in textile pre-treatment is further bolstered by its potential to improve process efficiency and reduce costs. As manufacturers seek to optimize their operations, solutions that offer both environmental benefits and economic advantages are highly sought after. Ammonium hydroxide's ability to effectively remove impurities at lower temperatures and with reduced water consumption aligns well with these industry goals.

Geographically, the demand for eco-friendly textile pre-treatment solutions is particularly strong in regions with developed textile industries and stringent environmental regulations. Europe and North America are leading the adoption of sustainable practices, while rapidly growing textile markets in Asia are also showing increased interest in green technologies to meet export requirements and address local environmental challenges.

The market demand analysis indicates a clear trend towards more sustainable textile production methods, with ammonium hydroxide positioned as a key enabler of this transition. As the industry continues to evolve, the demand for eco-friendly pre-treatment processes is expected to grow, presenting significant opportunities for innovation and market expansion in the coming years.

Current Challenges in Ammonium Hydroxide Application

The application of ammonium hydroxide in textile pre-treatment processes faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary concerns is the environmental impact associated with its use. Ammonium hydroxide, when released into water systems, can contribute to eutrophication and pose risks to aquatic ecosystems. This has led to increased scrutiny from environmental regulatory bodies and a push for more sustainable alternatives.

Another challenge lies in the health and safety aspects of handling ammonium hydroxide. Its corrosive nature and potential to release ammonia gas pose risks to workers in textile processing facilities. Ensuring proper ventilation, personal protective equipment, and stringent safety protocols adds complexity and cost to its implementation.

The volatility of ammonium hydroxide presents technical difficulties in maintaining consistent concentration levels during the pre-treatment process. This can lead to variations in treatment effectiveness and fabric quality, necessitating precise control systems and frequent monitoring, which increases operational complexity and costs.

Furthermore, the alkaline nature of ammonium hydroxide can potentially damage certain types of fibers, particularly natural fibers like wool and silk. This limitation restricts its applicability across different textile materials and requires careful consideration of fabric composition in process design.

The rising cost of ammonia production, driven by increasing energy prices and environmental regulations, is also impacting the economic viability of ammonium hydroxide in textile pre-treatment. This economic pressure is compelling manufacturers to seek more cost-effective alternatives or to optimize their processes for reduced chemical consumption.

There are also challenges related to the integration of ammonium hydroxide-based processes with existing textile manufacturing systems. Retrofitting older facilities or adapting current production lines to accommodate the specific requirements of ammonium hydroxide treatment can be both technically challenging and financially burdensome.

Lastly, the textile industry faces growing consumer demand for eco-friendly and sustainable production methods. The use of ammonium hydroxide, despite its effectiveness, may not align with these market trends, potentially affecting brand image and market competitiveness for manufacturers employing this chemical in their pre-treatment processes.

Another challenge lies in the health and safety aspects of handling ammonium hydroxide. Its corrosive nature and potential to release ammonia gas pose risks to workers in textile processing facilities. Ensuring proper ventilation, personal protective equipment, and stringent safety protocols adds complexity and cost to its implementation.

The volatility of ammonium hydroxide presents technical difficulties in maintaining consistent concentration levels during the pre-treatment process. This can lead to variations in treatment effectiveness and fabric quality, necessitating precise control systems and frequent monitoring, which increases operational complexity and costs.

Furthermore, the alkaline nature of ammonium hydroxide can potentially damage certain types of fibers, particularly natural fibers like wool and silk. This limitation restricts its applicability across different textile materials and requires careful consideration of fabric composition in process design.

The rising cost of ammonia production, driven by increasing energy prices and environmental regulations, is also impacting the economic viability of ammonium hydroxide in textile pre-treatment. This economic pressure is compelling manufacturers to seek more cost-effective alternatives or to optimize their processes for reduced chemical consumption.

There are also challenges related to the integration of ammonium hydroxide-based processes with existing textile manufacturing systems. Retrofitting older facilities or adapting current production lines to accommodate the specific requirements of ammonium hydroxide treatment can be both technically challenging and financially burdensome.

Lastly, the textile industry faces growing consumer demand for eco-friendly and sustainable production methods. The use of ammonium hydroxide, despite its effectiveness, may not align with these market trends, potentially affecting brand image and market competitiveness for manufacturers employing this chemical in their pre-treatment processes.

Existing Ammonium Hydroxide Pre-Treatment Solutions

01 Use in chemical processes

Ammonium hydroxide is widely used in various chemical processes, including as a reactant, pH adjuster, and neutralizing agent. It plays a crucial role in the production of certain chemicals and materials, and can be used to control the acidity or alkalinity of solutions in industrial applications.- Use in chemical processes: Ammonium hydroxide is widely used in various chemical processes, including as a reactant, catalyst, or pH adjuster. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste streams. Its alkaline properties make it useful for neutralizing acidic solutions and controlling pH in manufacturing processes.

- Application in cleaning and surface treatment: Ammonium hydroxide is utilized in cleaning formulations and surface treatment applications. It is effective in removing grease, oils, and other contaminants from surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Additionally, it finds use in leather tanning, textile processing, and as a component in household cleaning products.

- Role in environmental applications: Ammonium hydroxide plays a significant role in environmental applications, particularly in air pollution control and wastewater treatment. It is used to neutralize acidic gases in flue gas desulfurization systems and to remove nitrogen oxides from industrial emissions. In wastewater treatment, it helps in pH adjustment and nitrogen removal processes.

- Use in agricultural and horticultural products: Ammonium hydroxide is an important component in agricultural and horticultural products. It serves as a source of nitrogen in fertilizers, promoting plant growth and improving crop yields. In horticulture, it is used in nutrient solutions for hydroponic systems and as a foliar spray to correct nitrogen deficiencies in plants.

- Application in personal care and cosmetic products: Ammonium hydroxide finds applications in personal care and cosmetic products. It is used as a pH adjuster in hair dyes, helping to open the hair cuticle for better color penetration. In some cosmetic formulations, it acts as a buffering agent to maintain product stability. It may also be used in small amounts in certain skin care products for its alkaline properties.

02 Application in cleaning and surface treatment

Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It can effectively remove grease, oils, and other contaminants from surfaces. Additionally, it is used in etching and polishing processes for metals and semiconductors, as well as in the treatment of textiles and leather.Expand Specific Solutions03 Role in agricultural and fertilizer applications

Ammonium hydroxide serves as a source of nitrogen in fertilizers and is used in various agricultural applications. It can be directly applied to soil or incorporated into fertilizer formulations to provide essential nutrients for plant growth. Its use helps improve crop yields and soil fertility.Expand Specific Solutions04 Use in wastewater treatment

Ammonium hydroxide is employed in wastewater treatment processes for pH adjustment, ammonia removal, and nitrogen management. It can help neutralize acidic effluents and assist in the precipitation of certain contaminants. Its application contributes to improving water quality and meeting environmental regulations.Expand Specific Solutions05 Application in personal care and cosmetic products

Ammonium hydroxide finds use in personal care and cosmetic formulations. It can act as a pH adjuster, buffering agent, or neutralizer in various products such as hair dyes, skin care items, and nail treatments. Its properties help stabilize formulations and enhance product performance.Expand Specific Solutions

Key Players in Textile Chemical Industry

The utilization of ammonium hydroxide in textile pre-treatment processes is in a mature stage of development, with a well-established market and proven technologies. The global market for textile chemicals, including pre-treatment agents, is substantial and growing, driven by increasing demand for textiles across various industries. Key players in this field include BASF Corp., Henkel AG & Co. KGaA, and Dow Global Technologies LLC, who have developed advanced formulations and processes for efficient textile pre-treatment. Universities such as Donghua University and Jiangnan University contribute to ongoing research and innovation in this area, focusing on improving efficiency, sustainability, and environmental impact of pre-treatment processes.

BASF Corp.

Technical Solution: BASF has developed an innovative pre-treatment process utilizing ammonium hydroxide for textile applications. Their method involves a low-temperature treatment (30-50°C) with a dilute ammonium hydroxide solution (1-5% concentration) [1]. This process effectively removes natural impurities and improves fabric wettability without compromising fiber strength. BASF's approach also incorporates a closed-loop system for ammonia recovery, reducing environmental impact and operational costs [3]. The company has further enhanced this technology by combining it with enzymes for synergistic effects, resulting in up to 30% reduction in energy consumption compared to conventional alkaline scouring [5].

Strengths: Eco-friendly, energy-efficient, and cost-effective. Preserves fiber integrity. Weaknesses: May require specialized equipment for ammonia handling and recovery.

Henkel AG & Co. KGaA

Technical Solution: Henkel has pioneered a novel ammonium hydroxide-based pre-treatment system for textiles, focusing on sustainable and efficient processing. Their approach utilizes a proprietary blend of ammonium hydroxide (3-7% concentration) with surfactants and chelating agents [2]. This formulation allows for simultaneous scouring and bleaching at moderate temperatures (40-60°C), reducing processing time by up to 40% compared to traditional methods. Henkel's system also incorporates an innovative spray application technique, ensuring uniform treatment and minimizing chemical usage [4]. Additionally, they have developed a smart process control system that optimizes ammonium hydroxide concentration in real-time, based on fabric type and soiling level, leading to a 25% reduction in chemical consumption [6].

Strengths: Combines multiple pre-treatment steps, reducing time and resource use. Advanced process control for optimization. Weaknesses: May require initial investment in specialized application equipment.

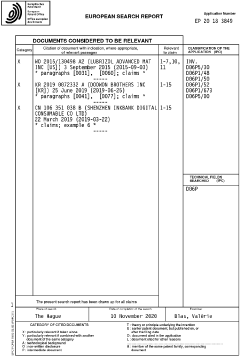

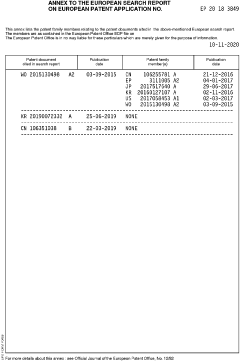

Innovations in Ammonium Hydroxide Formulations

Method of treatment of knitted textiles using liquid ammonia

PatentPendingTH163935A

Innovation

- Use of liquid ammonia for treating knitted textiles, which can potentially improve fabric properties and processing efficiency.

- Implementation of multiple heating rollers to vaporize ammonia, allowing for efficient removal of the chemical from the fabric.

- Incorporation of a scrubbing unit to remove ammonia residue, ensuring a cleaner final product.

Method and formulation for pre-treatment of printed textile

PatentPendingEP3760787A1

Innovation

- A pre-treatment liquid is developed by mixing synthetic and natural thickeners with water and adjusting the pH to a range of 2.5 to 7, optionally adding ammonium sulphate, to create a stable solution that allows for efficient ink fixation and reduced ink usage.

Environmental Impact Assessment

The utilization of ammonium hydroxide in textile pre-treatment processes has significant environmental implications that warrant careful consideration. This chemical compound, while effective in certain textile applications, poses potential risks to ecosystems and human health if not properly managed.

Ammonium hydroxide, when released into aquatic environments, can lead to eutrophication, a process that causes excessive algae growth and subsequent oxygen depletion in water bodies. This can have devastating effects on aquatic life, disrupting entire ecosystems. Furthermore, the compound's high pH levels can directly harm fish and other aquatic organisms, altering their habitats and reproductive cycles.

Air pollution is another concern associated with ammonium hydroxide use. Volatilization of ammonia from textile processing facilities can contribute to the formation of particulate matter and smog, impacting local air quality and potentially causing respiratory issues in nearby populations. The compound's strong odor can also be a nuisance to communities surrounding textile manufacturing plants.

Soil contamination is a potential risk when ammonium hydroxide-containing wastewater is improperly disposed of or when spills occur. This can lead to changes in soil pH, affecting plant growth and soil microbial communities. Long-term accumulation of ammonia in soil can result in decreased soil fertility and altered nutrient cycles.

From a broader environmental perspective, the production of ammonium hydroxide itself has a carbon footprint. The Haber-Bosch process, commonly used to synthesize ammonia, is energy-intensive and typically relies on fossil fuels, contributing to greenhouse gas emissions and climate change.

However, it's important to note that the environmental impact of ammonium hydroxide in textile pre-treatment can be mitigated through proper management and technological innovations. Closed-loop systems, which recycle and reuse chemicals, can significantly reduce emissions and wastewater discharge. Advanced wastewater treatment technologies, such as biological nitrification-denitrification processes, can effectively remove ammonia from effluents before release into the environment.

Moreover, the textile industry is increasingly exploring alternatives to traditional chemical pre-treatments. Enzyme-based processes and plasma treatments are emerging as more environmentally friendly options that could potentially replace or reduce the use of ammonium hydroxide in certain applications.

In conclusion, while ammonium hydroxide offers benefits in textile pre-treatment, its environmental impact necessitates careful management and ongoing research into sustainable alternatives. Balancing the compound's efficacy with environmental protection remains a key challenge for the textile industry moving forward.

Ammonium hydroxide, when released into aquatic environments, can lead to eutrophication, a process that causes excessive algae growth and subsequent oxygen depletion in water bodies. This can have devastating effects on aquatic life, disrupting entire ecosystems. Furthermore, the compound's high pH levels can directly harm fish and other aquatic organisms, altering their habitats and reproductive cycles.

Air pollution is another concern associated with ammonium hydroxide use. Volatilization of ammonia from textile processing facilities can contribute to the formation of particulate matter and smog, impacting local air quality and potentially causing respiratory issues in nearby populations. The compound's strong odor can also be a nuisance to communities surrounding textile manufacturing plants.

Soil contamination is a potential risk when ammonium hydroxide-containing wastewater is improperly disposed of or when spills occur. This can lead to changes in soil pH, affecting plant growth and soil microbial communities. Long-term accumulation of ammonia in soil can result in decreased soil fertility and altered nutrient cycles.

From a broader environmental perspective, the production of ammonium hydroxide itself has a carbon footprint. The Haber-Bosch process, commonly used to synthesize ammonia, is energy-intensive and typically relies on fossil fuels, contributing to greenhouse gas emissions and climate change.

However, it's important to note that the environmental impact of ammonium hydroxide in textile pre-treatment can be mitigated through proper management and technological innovations. Closed-loop systems, which recycle and reuse chemicals, can significantly reduce emissions and wastewater discharge. Advanced wastewater treatment technologies, such as biological nitrification-denitrification processes, can effectively remove ammonia from effluents before release into the environment.

Moreover, the textile industry is increasingly exploring alternatives to traditional chemical pre-treatments. Enzyme-based processes and plasma treatments are emerging as more environmentally friendly options that could potentially replace or reduce the use of ammonium hydroxide in certain applications.

In conclusion, while ammonium hydroxide offers benefits in textile pre-treatment, its environmental impact necessitates careful management and ongoing research into sustainable alternatives. Balancing the compound's efficacy with environmental protection remains a key challenge for the textile industry moving forward.

Occupational Safety and Health Considerations

The utilization of ammonium hydroxide in textile pre-treatment processes necessitates careful consideration of occupational safety and health factors. Workers in textile facilities are potentially exposed to various hazards associated with this chemical compound, primarily through inhalation and skin contact. Ammonium hydroxide, being a corrosive substance, can cause severe irritation and burns to the skin, eyes, and respiratory system if not handled properly.

To mitigate these risks, comprehensive safety protocols must be implemented. Personal protective equipment (PPE) is crucial, including chemical-resistant gloves, safety goggles, and appropriate respiratory protection. The selection of PPE should be based on the specific concentration and application method of ammonium hydroxide used in the pre-treatment process.

Proper ventilation systems are essential to maintain safe air quality in the workplace. Local exhaust ventilation should be installed at points of potential ammonia release to minimize worker exposure. Regular air monitoring is necessary to ensure that ammonia levels remain below permissible exposure limits set by regulatory agencies such as OSHA.

Emergency response procedures must be established and regularly practiced. This includes the installation of eyewash stations and safety showers in easily accessible locations, as well as training workers on proper use of these facilities. A spill response plan should be in place, with designated personnel trained in containment and cleanup procedures.

Worker education is a critical component of occupational safety. Employees should receive comprehensive training on the hazards of ammonium hydroxide, proper handling techniques, and emergency procedures. This training should be ongoing and updated as processes or regulations change.

Storage and handling of ammonium hydroxide require special attention. The chemical should be stored in a cool, well-ventilated area, away from incompatible materials. Proper labeling and secondary containment systems are necessary to prevent accidental releases and ensure quick identification in case of emergencies.

Regular health monitoring of workers exposed to ammonium hydroxide is advisable. This may include periodic medical examinations and lung function tests to detect any early signs of respiratory issues. Maintaining detailed exposure records for each worker is also important for long-term health surveillance.

Compliance with regulatory standards is paramount. Employers must ensure that their facilities meet or exceed the requirements set forth by relevant occupational safety and health authorities. This includes adhering to permissible exposure limits, implementing proper hazard communication systems, and maintaining up-to-date safety data sheets for ammonium hydroxide and other chemicals used in the textile pre-treatment process.

To mitigate these risks, comprehensive safety protocols must be implemented. Personal protective equipment (PPE) is crucial, including chemical-resistant gloves, safety goggles, and appropriate respiratory protection. The selection of PPE should be based on the specific concentration and application method of ammonium hydroxide used in the pre-treatment process.

Proper ventilation systems are essential to maintain safe air quality in the workplace. Local exhaust ventilation should be installed at points of potential ammonia release to minimize worker exposure. Regular air monitoring is necessary to ensure that ammonia levels remain below permissible exposure limits set by regulatory agencies such as OSHA.

Emergency response procedures must be established and regularly practiced. This includes the installation of eyewash stations and safety showers in easily accessible locations, as well as training workers on proper use of these facilities. A spill response plan should be in place, with designated personnel trained in containment and cleanup procedures.

Worker education is a critical component of occupational safety. Employees should receive comprehensive training on the hazards of ammonium hydroxide, proper handling techniques, and emergency procedures. This training should be ongoing and updated as processes or regulations change.

Storage and handling of ammonium hydroxide require special attention. The chemical should be stored in a cool, well-ventilated area, away from incompatible materials. Proper labeling and secondary containment systems are necessary to prevent accidental releases and ensure quick identification in case of emergencies.

Regular health monitoring of workers exposed to ammonium hydroxide is advisable. This may include periodic medical examinations and lung function tests to detect any early signs of respiratory issues. Maintaining detailed exposure records for each worker is also important for long-term health surveillance.

Compliance with regulatory standards is paramount. Employers must ensure that their facilities meet or exceed the requirements set forth by relevant occupational safety and health authorities. This includes adhering to permissible exposure limits, implementing proper hazard communication systems, and maintaining up-to-date safety data sheets for ammonium hydroxide and other chemicals used in the textile pre-treatment process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!