The Role of Ammonium Hydroxide in Synthesizing Biodegradable Adhesives

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Biodegradable Adhesives: Background and Objectives

Biodegradable adhesives have gained significant attention in recent years due to growing environmental concerns and the need for sustainable materials. Ammonium hydroxide, a common industrial chemical, has emerged as a key component in the synthesis of these eco-friendly adhesives. The development of biodegradable adhesives using ammonium hydroxide represents a convergence of green chemistry principles and practical industrial applications.

The evolution of adhesive technology has been driven by the demand for stronger, more versatile, and environmentally friendly bonding agents. Traditional adhesives, often derived from petroleum-based sources, have long dominated the market. However, their non-biodegradable nature and potential toxicity have spurred research into alternative solutions. This shift in focus has led to the exploration of bio-based materials and green synthesis methods, with ammonium hydroxide playing a crucial role in this transition.

Ammonium hydroxide, also known as aqueous ammonia, has been utilized in various industrial processes for decades. Its application in biodegradable adhesive synthesis represents a novel approach to addressing environmental challenges. The compound's ability to modify the properties of natural polymers and facilitate cross-linking reactions has made it an attractive option for researchers and manufacturers alike.

The primary objective of incorporating ammonium hydroxide in biodegradable adhesive synthesis is to develop adhesives that maintain high performance while minimizing environmental impact. Researchers aim to create products that offer strong bonding capabilities, durability, and versatility comparable to conventional adhesives, but with the added benefit of biodegradability. This goal aligns with broader sustainability initiatives and circular economy principles.

Another key objective is to optimize the synthesis process to ensure scalability and cost-effectiveness. As the demand for eco-friendly alternatives grows, it is crucial to develop manufacturing methods that can be implemented on an industrial scale without compromising economic viability. Ammonium hydroxide's role in this context extends beyond its chemical properties to its potential for streamlining production processes.

The development of biodegradable adhesives using ammonium hydroxide also aims to expand the range of applications for these materials. From packaging and construction to medical and consumer goods, the potential uses for environmentally friendly adhesives are vast. Researchers are exploring ways to tailor the properties of these adhesives to meet the specific requirements of different industries, further driving innovation in this field.

As the technology continues to evolve, there is a growing focus on understanding the long-term environmental impact of ammonium hydroxide-based biodegradable adhesives. This includes studying their degradation mechanisms, assessing potential byproducts, and ensuring that these materials truly offer a sustainable alternative to conventional adhesives throughout their lifecycle.

The evolution of adhesive technology has been driven by the demand for stronger, more versatile, and environmentally friendly bonding agents. Traditional adhesives, often derived from petroleum-based sources, have long dominated the market. However, their non-biodegradable nature and potential toxicity have spurred research into alternative solutions. This shift in focus has led to the exploration of bio-based materials and green synthesis methods, with ammonium hydroxide playing a crucial role in this transition.

Ammonium hydroxide, also known as aqueous ammonia, has been utilized in various industrial processes for decades. Its application in biodegradable adhesive synthesis represents a novel approach to addressing environmental challenges. The compound's ability to modify the properties of natural polymers and facilitate cross-linking reactions has made it an attractive option for researchers and manufacturers alike.

The primary objective of incorporating ammonium hydroxide in biodegradable adhesive synthesis is to develop adhesives that maintain high performance while minimizing environmental impact. Researchers aim to create products that offer strong bonding capabilities, durability, and versatility comparable to conventional adhesives, but with the added benefit of biodegradability. This goal aligns with broader sustainability initiatives and circular economy principles.

Another key objective is to optimize the synthesis process to ensure scalability and cost-effectiveness. As the demand for eco-friendly alternatives grows, it is crucial to develop manufacturing methods that can be implemented on an industrial scale without compromising economic viability. Ammonium hydroxide's role in this context extends beyond its chemical properties to its potential for streamlining production processes.

The development of biodegradable adhesives using ammonium hydroxide also aims to expand the range of applications for these materials. From packaging and construction to medical and consumer goods, the potential uses for environmentally friendly adhesives are vast. Researchers are exploring ways to tailor the properties of these adhesives to meet the specific requirements of different industries, further driving innovation in this field.

As the technology continues to evolve, there is a growing focus on understanding the long-term environmental impact of ammonium hydroxide-based biodegradable adhesives. This includes studying their degradation mechanisms, assessing potential byproducts, and ensuring that these materials truly offer a sustainable alternative to conventional adhesives throughout their lifecycle.

Market Analysis for Eco-friendly Adhesive Solutions

The market for eco-friendly adhesive solutions has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on conventional adhesives. The global biodegradable adhesives market is expected to reach a substantial value by 2027, with a compound annual growth rate surpassing that of traditional adhesives. This growth is primarily fueled by the rising demand for sustainable packaging solutions across various industries, including food and beverage, cosmetics, and pharmaceuticals.

The use of ammonium hydroxide in synthesizing biodegradable adhesives has garnered attention due to its potential to enhance the performance and environmental profile of these products. Ammonium hydroxide acts as a catalyst and pH regulator in the synthesis process, enabling the creation of adhesives with improved bonding strength and durability while maintaining their biodegradable properties. This innovation addresses a key challenge in the eco-friendly adhesives market: balancing performance with sustainability.

Consumer preferences are shifting towards products with minimal environmental impact, driving manufacturers to adopt green technologies and sustainable raw materials. The food packaging industry, in particular, has shown a strong inclination towards biodegradable adhesives, as they align with the broader trend of eco-friendly packaging solutions. Additionally, the construction and woodworking sectors are exploring biodegradable adhesives as alternatives to formaldehyde-based products, further expanding the market potential.

Regulatory bodies worldwide are implementing stricter guidelines on volatile organic compound (VOC) emissions and hazardous substances in adhesives. This regulatory landscape favors the adoption of biodegradable adhesives, including those synthesized using ammonium hydroxide, as they typically have lower VOC emissions and reduced environmental toxicity compared to conventional alternatives.

The Asia-Pacific region is emerging as a key growth market for eco-friendly adhesive solutions, driven by rapid industrialization, increasing environmental concerns, and supportive government policies promoting sustainable technologies. North America and Europe continue to be significant markets, with a strong focus on research and development in advanced biodegradable adhesive formulations.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs to compete with traditional adhesives. Ongoing research and development efforts, including those focused on optimizing the use of ammonium hydroxide in synthesis processes, aim to address these challenges and further improve the performance of biodegradable adhesives.

The use of ammonium hydroxide in synthesizing biodegradable adhesives has garnered attention due to its potential to enhance the performance and environmental profile of these products. Ammonium hydroxide acts as a catalyst and pH regulator in the synthesis process, enabling the creation of adhesives with improved bonding strength and durability while maintaining their biodegradable properties. This innovation addresses a key challenge in the eco-friendly adhesives market: balancing performance with sustainability.

Consumer preferences are shifting towards products with minimal environmental impact, driving manufacturers to adopt green technologies and sustainable raw materials. The food packaging industry, in particular, has shown a strong inclination towards biodegradable adhesives, as they align with the broader trend of eco-friendly packaging solutions. Additionally, the construction and woodworking sectors are exploring biodegradable adhesives as alternatives to formaldehyde-based products, further expanding the market potential.

Regulatory bodies worldwide are implementing stricter guidelines on volatile organic compound (VOC) emissions and hazardous substances in adhesives. This regulatory landscape favors the adoption of biodegradable adhesives, including those synthesized using ammonium hydroxide, as they typically have lower VOC emissions and reduced environmental toxicity compared to conventional alternatives.

The Asia-Pacific region is emerging as a key growth market for eco-friendly adhesive solutions, driven by rapid industrialization, increasing environmental concerns, and supportive government policies promoting sustainable technologies. North America and Europe continue to be significant markets, with a strong focus on research and development in advanced biodegradable adhesive formulations.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs to compete with traditional adhesives. Ongoing research and development efforts, including those focused on optimizing the use of ammonium hydroxide in synthesis processes, aim to address these challenges and further improve the performance of biodegradable adhesives.

Current Challenges in Biodegradable Adhesive Synthesis

The synthesis of biodegradable adhesives faces several significant challenges that hinder widespread adoption and commercial viability. One of the primary obstacles is achieving a balance between biodegradability and adhesive performance. Many biodegradable materials lack the strength and durability required for effective adhesion, especially in demanding applications or harsh environments.

Another major challenge lies in the cost-effectiveness of production processes. Traditional petroleum-based adhesives benefit from well-established, efficient manufacturing methods, while biodegradable alternatives often require more complex and expensive production techniques. This cost disparity makes it difficult for biodegradable adhesives to compete in the market, particularly in price-sensitive industries.

The variability in raw material quality and availability presents another hurdle. Biodegradable adhesives often rely on natural or bio-based ingredients, which can be subject to seasonal fluctuations, regional availability, and quality inconsistencies. This variability can lead to inconsistent product performance and complicate large-scale production efforts.

Stability and shelf life pose additional challenges. Many biodegradable adhesives are more susceptible to degradation during storage, potentially leading to reduced effectiveness or premature breakdown. This issue necessitates careful formulation and packaging considerations to ensure product longevity and reliability.

Environmental conditions during application and curing can significantly impact the performance of biodegradable adhesives. Factors such as humidity, temperature, and substrate characteristics may affect bonding strength and durability more prominently than with conventional adhesives. This sensitivity requires more precise application protocols and potentially limits the range of suitable use cases.

Regulatory compliance and standardization represent another set of challenges. The lack of universally accepted standards for biodegradability and eco-friendliness in adhesives creates uncertainty for manufacturers and consumers alike. Navigating diverse regulatory landscapes across different regions adds complexity to product development and marketing efforts.

Lastly, the integration of ammonium hydroxide in biodegradable adhesive synthesis introduces specific challenges. While ammonium hydroxide can enhance certain properties, such as pH control and crosslinking, its volatile nature and potential environmental impact require careful consideration. Balancing the benefits of ammonium hydroxide with its drawbacks in terms of safety, odor, and long-term stability remains a significant challenge for researchers and manufacturers in this field.

Another major challenge lies in the cost-effectiveness of production processes. Traditional petroleum-based adhesives benefit from well-established, efficient manufacturing methods, while biodegradable alternatives often require more complex and expensive production techniques. This cost disparity makes it difficult for biodegradable adhesives to compete in the market, particularly in price-sensitive industries.

The variability in raw material quality and availability presents another hurdle. Biodegradable adhesives often rely on natural or bio-based ingredients, which can be subject to seasonal fluctuations, regional availability, and quality inconsistencies. This variability can lead to inconsistent product performance and complicate large-scale production efforts.

Stability and shelf life pose additional challenges. Many biodegradable adhesives are more susceptible to degradation during storage, potentially leading to reduced effectiveness or premature breakdown. This issue necessitates careful formulation and packaging considerations to ensure product longevity and reliability.

Environmental conditions during application and curing can significantly impact the performance of biodegradable adhesives. Factors such as humidity, temperature, and substrate characteristics may affect bonding strength and durability more prominently than with conventional adhesives. This sensitivity requires more precise application protocols and potentially limits the range of suitable use cases.

Regulatory compliance and standardization represent another set of challenges. The lack of universally accepted standards for biodegradability and eco-friendliness in adhesives creates uncertainty for manufacturers and consumers alike. Navigating diverse regulatory landscapes across different regions adds complexity to product development and marketing efforts.

Lastly, the integration of ammonium hydroxide in biodegradable adhesive synthesis introduces specific challenges. While ammonium hydroxide can enhance certain properties, such as pH control and crosslinking, its volatile nature and potential environmental impact require careful consideration. Balancing the benefits of ammonium hydroxide with its drawbacks in terms of safety, odor, and long-term stability remains a significant challenge for researchers and manufacturers in this field.

Existing Ammonium Hydroxide-based Synthesis Methods

01 Biodegradability of ammonium hydroxide in wastewater treatment

Ammonium hydroxide is generally considered biodegradable in wastewater treatment processes. It can be broken down by microorganisms in activated sludge systems, contributing to the removal of nitrogen compounds from wastewater. The biodegradation process involves nitrification, where ammonia is converted to nitrite and then nitrate by specific bacteria.- Biodegradability of ammonium hydroxide in wastewater treatment: Ammonium hydroxide is generally considered biodegradable in wastewater treatment processes. It can be broken down by microorganisms in activated sludge systems, contributing to the removal of nitrogen compounds from wastewater. The biodegradation process involves nitrification, where ammonia is converted to nitrite and then nitrate by specific bacteria.

- Environmental impact of ammonium hydroxide: While ammonium hydroxide is biodegradable, its release into the environment in large quantities can have negative impacts. It can contribute to eutrophication in water bodies and affect aquatic life. However, when properly managed and treated, the environmental impact can be minimized. Some studies focus on developing eco-friendly alternatives or optimizing its use to reduce environmental concerns.

- Use of ammonium hydroxide in industrial processes: Ammonium hydroxide is widely used in various industrial processes, including cleaning, textile manufacturing, and chemical synthesis. Its biodegradability is an important factor in these applications, as it affects waste management and environmental compliance. Some patents describe methods to improve the efficiency of ammonium hydroxide use while considering its biodegradability and environmental impact.

- Biodegradation mechanisms and enhancement: Research has been conducted on understanding and enhancing the biodegradation mechanisms of ammonium hydroxide. This includes studying the microbial communities involved in its breakdown, optimizing environmental conditions for biodegradation, and developing novel treatment technologies. Some innovations focus on accelerating the biodegradation process or improving its efficiency in various applications.

- Monitoring and assessment of ammonium hydroxide biodegradability: Methods for monitoring and assessing the biodegradability of ammonium hydroxide in different environments have been developed. These include analytical techniques for measuring ammonia concentrations, evaluating biodegradation rates, and assessing the impact on microbial communities. Such methods are crucial for ensuring proper management and treatment of ammonium hydroxide-containing waste streams.

02 Environmental impact of ammonium hydroxide

While ammonium hydroxide is biodegradable, its release into the environment can have potential impacts. In aquatic ecosystems, it can lead to increased algal growth and eutrophication. However, when properly managed and treated, the environmental risks associated with ammonium hydroxide can be minimized.Expand Specific Solutions03 Use of ammonium hydroxide in biodegradable products

Ammonium hydroxide is utilized in the production of certain biodegradable materials and products. Its biodegradability makes it suitable for incorporation into environmentally friendly formulations, such as cleaning products or industrial processes where the end products or waste streams need to be easily broken down in the environment.Expand Specific Solutions04 Biodegradation rate and factors affecting it

The biodegradation rate of ammonium hydroxide can vary depending on environmental conditions such as temperature, pH, and the presence of specific microorganisms. In optimal conditions, the biodegradation process can be relatively rapid. Factors like oxygen availability and the concentration of other nutrients can also influence the rate of biodegradation.Expand Specific Solutions05 Methods for enhancing biodegradability of ammonium hydroxide

Various techniques can be employed to enhance the biodegradability of ammonium hydroxide in industrial and environmental applications. These may include the use of specialized microbial cultures, optimizing environmental conditions, or combining ammonium hydroxide with other compounds that promote its breakdown. Such methods can improve the efficiency of wastewater treatment and reduce environmental impact.Expand Specific Solutions

Key Players in Sustainable Adhesive Industry

The development of biodegradable adhesives using ammonium hydroxide is in an emerging stage, with a growing market driven by increasing environmental concerns. The global biodegradable adhesives market is expected to expand significantly in the coming years, though it remains a niche segment within the broader adhesives industry. Technologically, the field is still evolving, with companies like Henkel, Bayer, and BIOTEC Biologische Naturverpackungen at the forefront of research and development. These firms are investing in innovative formulations and production processes to enhance the performance and cost-effectiveness of biodegradable adhesives. However, challenges remain in achieving comparable strength and durability to traditional petroleum-based adhesives while maintaining biodegradability.

BIOTEC Biologische Naturverpackungen GmbH & Co. KG

Technical Solution: BIOTEC has developed an innovative approach to synthesizing biodegradable adhesives using ammonium hydroxide as a key processing aid. Their method focuses on the extraction and modification of plant-based polysaccharides, particularly starch and cellulose derivatives. Ammonium hydroxide is used in a controlled alkaline treatment process to partially depolymerize these polysaccharides, increasing their solubility and reactivity[10]. The company has optimized a grafting technique where ammonium hydroxide facilitates the attachment of biodegradable synthetic polymers to the polysaccharide backbone, creating a hybrid adhesive with enhanced performance[11]. BIOTEC's process also incorporates a final neutralization step using ammonium hydroxide to fine-tune the adhesive's pH and viscosity, ensuring optimal application properties[12].

Strengths: Highly biodegradable, derived from renewable resources, and suitable for food packaging applications. Weaknesses: May have limited moisture resistance and potentially lower bond strength compared to synthetic alternatives.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a novel approach to synthesizing biodegradable adhesives using ammonium hydroxide as a key component. Their process involves the alkaline deacetylation of chitin using ammonium hydroxide to produce chitosan, which serves as the base for their biodegradable adhesive formulation[1]. The company has optimized the concentration of ammonium hydroxide and reaction conditions to achieve a high degree of deacetylation, resulting in improved adhesive properties. Henkel's method also incorporates a cross-linking step using natural aldehydes to enhance the adhesive's strength and water resistance while maintaining biodegradability[2]. The resulting adhesive demonstrates excellent bonding capabilities on various substrates, including paper, wood, and certain plastics, making it suitable for packaging and consumer goods applications[3].

Strengths: Utilizes renewable resources, achieves high biodegradability, and offers strong adhesion properties. Weaknesses: May have limited resistance to extreme environmental conditions and potentially higher production costs compared to traditional synthetic adhesives.

Innovations in Ammonium Hydroxide Utilization

Eco-friendly biodegradable adhesive composition

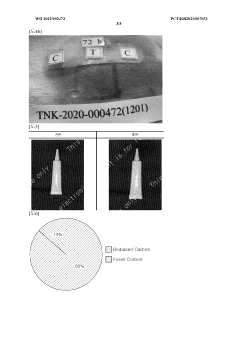

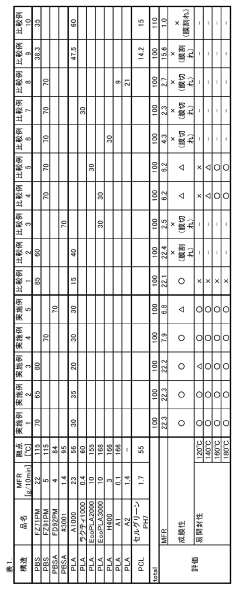

PatentWO2022092473A1

Innovation

- A bio-biodegradable adhesive composition using naturally derived saccharide and polyol compounds, specifically dextrin and glycerin, which are water-soluble and form a viscoelastic adhesive layer for easy separation without caustic substances, maintaining adhesion strength and stability.

Biodegradable adhesive and sheet

PatentInactiveJP2020176230A

Innovation

- The biodegradable adhesive combines polybutylene succinate/polybutylene succinate adipate with polylactic acid in specific ratios to achieve both adhesive strength and easy openability.

- The use of polylactic acid with a specific melt flow rate and low melting point enables low-temperature heat sealing while maintaining adhesive performance.

- The formulation achieves a balance between adhesive strength and easy openability, addressing a common challenge in biodegradable adhesives.

Environmental Impact Assessment of Synthesis Process

The synthesis of biodegradable adhesives using ammonium hydroxide presents both opportunities and challenges from an environmental perspective. The process involves chemical reactions that can have varying impacts on the ecosystem, necessitating a comprehensive environmental impact assessment.

Ammonium hydroxide, a key component in this synthesis, is a strong base that can potentially alter the pH of aquatic environments if released untreated. This pH change could disrupt local ecosystems, affecting aquatic life and vegetation. However, when properly managed, the use of ammonium hydroxide in controlled industrial settings poses minimal risk to the environment.

The synthesis process itself may consume significant energy, contributing to greenhouse gas emissions if non-renewable energy sources are used. Implementing energy-efficient technologies and transitioning to renewable energy sources could substantially mitigate this impact. Additionally, the production of raw materials for the adhesive synthesis may involve resource extraction, which could lead to habitat disruption and biodiversity loss if not managed sustainably.

Water usage is another critical factor to consider. The synthesis process may require substantial amounts of water for reactions and cleaning. Implementing water recycling systems and optimizing water use efficiency can help reduce the overall water footprint of the production process.

On the positive side, the biodegradable nature of the resulting adhesives offers significant environmental benefits. Unlike traditional petroleum-based adhesives, these biodegradable alternatives decompose naturally, reducing long-term environmental pollution and waste accumulation. This characteristic aligns well with circular economy principles and can contribute to reducing plastic pollution in ecosystems.

The production of biodegradable adhesives may also result in fewer toxic by-products compared to conventional adhesive manufacturing processes. This reduction in hazardous waste generation can lead to decreased soil and water contamination risks associated with disposal.

To fully assess the environmental impact, a life cycle analysis (LCA) should be conducted. This analysis would consider all stages of the adhesive's life, from raw material extraction to disposal or biodegradation. The LCA would provide a comprehensive view of the environmental footprint, including carbon emissions, water usage, and potential toxicity impacts throughout the product's lifecycle.

Implementing green chemistry principles in the synthesis process can further enhance its environmental profile. This approach involves designing chemical products and processes that reduce or eliminate the use and generation of hazardous substances, thereby minimizing environmental impact from the outset of production.

Ammonium hydroxide, a key component in this synthesis, is a strong base that can potentially alter the pH of aquatic environments if released untreated. This pH change could disrupt local ecosystems, affecting aquatic life and vegetation. However, when properly managed, the use of ammonium hydroxide in controlled industrial settings poses minimal risk to the environment.

The synthesis process itself may consume significant energy, contributing to greenhouse gas emissions if non-renewable energy sources are used. Implementing energy-efficient technologies and transitioning to renewable energy sources could substantially mitigate this impact. Additionally, the production of raw materials for the adhesive synthesis may involve resource extraction, which could lead to habitat disruption and biodiversity loss if not managed sustainably.

Water usage is another critical factor to consider. The synthesis process may require substantial amounts of water for reactions and cleaning. Implementing water recycling systems and optimizing water use efficiency can help reduce the overall water footprint of the production process.

On the positive side, the biodegradable nature of the resulting adhesives offers significant environmental benefits. Unlike traditional petroleum-based adhesives, these biodegradable alternatives decompose naturally, reducing long-term environmental pollution and waste accumulation. This characteristic aligns well with circular economy principles and can contribute to reducing plastic pollution in ecosystems.

The production of biodegradable adhesives may also result in fewer toxic by-products compared to conventional adhesive manufacturing processes. This reduction in hazardous waste generation can lead to decreased soil and water contamination risks associated with disposal.

To fully assess the environmental impact, a life cycle analysis (LCA) should be conducted. This analysis would consider all stages of the adhesive's life, from raw material extraction to disposal or biodegradation. The LCA would provide a comprehensive view of the environmental footprint, including carbon emissions, water usage, and potential toxicity impacts throughout the product's lifecycle.

Implementing green chemistry principles in the synthesis process can further enhance its environmental profile. This approach involves designing chemical products and processes that reduce or eliminate the use and generation of hazardous substances, thereby minimizing environmental impact from the outset of production.

Regulatory Framework for Green Adhesive Production

The regulatory framework for green adhesive production is a critical aspect of the biodegradable adhesives industry, particularly concerning the use of ammonium hydroxide in synthesis processes. Governments and international organizations have established various guidelines and standards to ensure the safety and environmental sustainability of these products.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the production and use of green adhesives. The Toxic Substances Control Act (TSCA) provides the EPA with authority to require reporting, record-keeping, and testing requirements for chemical substances and mixtures, including those used in biodegradable adhesives. The EPA also enforces the Resource Conservation and Recovery Act (RCRA), which governs the management of hazardous waste generated during the production process.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which aims to protect human health and the environment from the risks posed by chemicals. Under REACH, manufacturers and importers of chemical substances, including those used in green adhesives, must register their substances with the European Chemicals Agency (ECHA) and provide safety information.

International standards, such as ISO 14001 for environmental management systems, provide a framework for organizations to minimize their environmental impact. The ISO 14001 certification is increasingly important for companies producing green adhesives, as it demonstrates their commitment to sustainable practices.

Specific to ammonium hydroxide, its use in biodegradable adhesive synthesis is subject to occupational safety regulations. In the United States, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits and requires proper handling and storage procedures. Similarly, the EU's Directive 98/24/EC on chemical agents at work outlines measures to protect workers from risks related to chemical agents, including ammonium hydroxide.

The Global Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. This system is particularly relevant for the labeling and packaging of ammonium hydroxide and other chemicals used in green adhesive production.

As the industry evolves, regulatory bodies are increasingly focusing on the entire lifecycle of biodegradable adhesives. This includes regulations on raw material sourcing, production processes, product performance, and end-of-life disposal. The EU's Circular Economy Action Plan, for instance, emphasizes the importance of designing products for recyclability and biodegradability, which directly impacts the development of green adhesives.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the production and use of green adhesives. The Toxic Substances Control Act (TSCA) provides the EPA with authority to require reporting, record-keeping, and testing requirements for chemical substances and mixtures, including those used in biodegradable adhesives. The EPA also enforces the Resource Conservation and Recovery Act (RCRA), which governs the management of hazardous waste generated during the production process.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which aims to protect human health and the environment from the risks posed by chemicals. Under REACH, manufacturers and importers of chemical substances, including those used in green adhesives, must register their substances with the European Chemicals Agency (ECHA) and provide safety information.

International standards, such as ISO 14001 for environmental management systems, provide a framework for organizations to minimize their environmental impact. The ISO 14001 certification is increasingly important for companies producing green adhesives, as it demonstrates their commitment to sustainable practices.

Specific to ammonium hydroxide, its use in biodegradable adhesive synthesis is subject to occupational safety regulations. In the United States, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits and requires proper handling and storage procedures. Similarly, the EU's Directive 98/24/EC on chemical agents at work outlines measures to protect workers from risks related to chemical agents, including ammonium hydroxide.

The Global Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. This system is particularly relevant for the labeling and packaging of ammonium hydroxide and other chemicals used in green adhesive production.

As the industry evolves, regulatory bodies are increasingly focusing on the entire lifecycle of biodegradable adhesives. This includes regulations on raw material sourcing, production processes, product performance, and end-of-life disposal. The EU's Circular Economy Action Plan, for instance, emphasizes the importance of designing products for recyclability and biodegradability, which directly impacts the development of green adhesives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!