How Ammonium Hydroxide Modulates Cellulose Acetate Fiber Production

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellulose Acetate Fiber Evolution and Objectives

Cellulose acetate fiber production has undergone significant evolution since its inception in the early 20th century. Initially developed as a more stable alternative to cellulose nitrate, cellulose acetate quickly gained prominence in various industries, particularly in textiles and cigarette filters. The journey of cellulose acetate fiber production has been marked by continuous improvements in manufacturing processes, aimed at enhancing fiber quality, production efficiency, and environmental sustainability.

The early production methods relied heavily on acetylation of cellulose using acetic anhydride and sulfuric acid as a catalyst. This process, while effective, posed challenges in terms of environmental impact and production costs. As the industry progressed, researchers and manufacturers sought ways to optimize the acetylation process and improve fiber properties. The introduction of new solvents and catalysts played a crucial role in this evolution, with ammonium hydroxide emerging as a significant modulator in modern production techniques.

The objectives of cellulose acetate fiber production have evolved in tandem with technological advancements and changing market demands. Initially, the primary focus was on producing fibers with adequate strength and durability for textile applications. However, as the industry matured, objectives expanded to include enhancing fiber properties such as moisture regain, dyeability, and thermal stability. In recent years, there has been a growing emphasis on developing sustainable production methods and improving the biodegradability of cellulose acetate fibers.

The role of ammonium hydroxide in modulating cellulose acetate fiber production represents a significant technological advancement. This compound has been found to influence various aspects of the production process, including the degree of acetylation, fiber morphology, and overall product quality. The use of ammonium hydroxide allows for greater control over the fiber's properties, enabling manufacturers to tailor their products to specific applications and market requirements.

Looking ahead, the objectives for cellulose acetate fiber production are increasingly focused on sustainability and versatility. Researchers are exploring ways to further reduce the environmental impact of production processes, develop bio-based alternatives to traditional acetylation agents, and enhance the recyclability of cellulose acetate products. Additionally, there is a growing interest in expanding the application range of cellulose acetate fibers, particularly in high-tech fields such as biomedical engineering and advanced materials science.

The ongoing research into the modulation of cellulose acetate fiber production using ammonium hydroxide and other innovative techniques is expected to drive the next phase of evolution in this field. These efforts aim to address current limitations in fiber performance, production efficiency, and environmental compatibility, paving the way for a new generation of cellulose acetate fibers that meet the complex demands of modern industries while aligning with global sustainability goals.

The early production methods relied heavily on acetylation of cellulose using acetic anhydride and sulfuric acid as a catalyst. This process, while effective, posed challenges in terms of environmental impact and production costs. As the industry progressed, researchers and manufacturers sought ways to optimize the acetylation process and improve fiber properties. The introduction of new solvents and catalysts played a crucial role in this evolution, with ammonium hydroxide emerging as a significant modulator in modern production techniques.

The objectives of cellulose acetate fiber production have evolved in tandem with technological advancements and changing market demands. Initially, the primary focus was on producing fibers with adequate strength and durability for textile applications. However, as the industry matured, objectives expanded to include enhancing fiber properties such as moisture regain, dyeability, and thermal stability. In recent years, there has been a growing emphasis on developing sustainable production methods and improving the biodegradability of cellulose acetate fibers.

The role of ammonium hydroxide in modulating cellulose acetate fiber production represents a significant technological advancement. This compound has been found to influence various aspects of the production process, including the degree of acetylation, fiber morphology, and overall product quality. The use of ammonium hydroxide allows for greater control over the fiber's properties, enabling manufacturers to tailor their products to specific applications and market requirements.

Looking ahead, the objectives for cellulose acetate fiber production are increasingly focused on sustainability and versatility. Researchers are exploring ways to further reduce the environmental impact of production processes, develop bio-based alternatives to traditional acetylation agents, and enhance the recyclability of cellulose acetate products. Additionally, there is a growing interest in expanding the application range of cellulose acetate fibers, particularly in high-tech fields such as biomedical engineering and advanced materials science.

The ongoing research into the modulation of cellulose acetate fiber production using ammonium hydroxide and other innovative techniques is expected to drive the next phase of evolution in this field. These efforts aim to address current limitations in fiber performance, production efficiency, and environmental compatibility, paving the way for a new generation of cellulose acetate fibers that meet the complex demands of modern industries while aligning with global sustainability goals.

Market Analysis for Ammonium Hydroxide-Modified Fibers

The market for ammonium hydroxide-modified cellulose acetate fibers is experiencing significant growth, driven by increasing demand for sustainable and high-performance materials across various industries. These modified fibers offer enhanced properties such as improved moisture absorption, increased tensile strength, and better chemical resistance compared to traditional cellulose acetate fibers.

In the textile industry, ammonium hydroxide-modified fibers are gaining traction due to their superior moisture management capabilities, making them ideal for sportswear and performance apparel. The global sportswear market, valued at over $170 billion in 2021, is expected to grow at a CAGR of 5.1% from 2022 to 2030, presenting a substantial opportunity for these advanced fibers.

The automotive sector is another key market for ammonium hydroxide-modified cellulose acetate fibers. As automakers focus on lightweight materials to improve fuel efficiency and reduce emissions, these fibers are being increasingly used in interior components and upholstery. The automotive textiles market is projected to reach $29 billion by 2025, with a growing emphasis on sustainable and high-performance materials.

In the filtration industry, ammonium hydroxide-modified fibers are finding applications in air and liquid filtration systems due to their improved chemical resistance and durability. The global filtration market, valued at $89 billion in 2020, is expected to grow at a CAGR of 7.2% from 2021 to 2028, driven by increasing environmental regulations and growing awareness of air and water quality.

The packaging industry is also showing interest in these modified fibers for their potential in creating biodegradable and compostable packaging solutions. With the global sustainable packaging market projected to reach $412 billion by 2027, growing at a CAGR of 6.1%, there is a significant opportunity for ammonium hydroxide-modified cellulose acetate fibers in this sector.

Geographically, North America and Europe are currently the leading markets for ammonium hydroxide-modified fibers, owing to stringent environmental regulations and a strong focus on sustainable materials. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing awareness of eco-friendly products.

Despite the promising market outlook, challenges such as higher production costs compared to conventional fibers and the need for specialized manufacturing processes may hinder widespread adoption. However, ongoing research and development efforts are expected to address these challenges and further expand the market potential of ammonium hydroxide-modified cellulose acetate fibers across various industries.

In the textile industry, ammonium hydroxide-modified fibers are gaining traction due to their superior moisture management capabilities, making them ideal for sportswear and performance apparel. The global sportswear market, valued at over $170 billion in 2021, is expected to grow at a CAGR of 5.1% from 2022 to 2030, presenting a substantial opportunity for these advanced fibers.

The automotive sector is another key market for ammonium hydroxide-modified cellulose acetate fibers. As automakers focus on lightweight materials to improve fuel efficiency and reduce emissions, these fibers are being increasingly used in interior components and upholstery. The automotive textiles market is projected to reach $29 billion by 2025, with a growing emphasis on sustainable and high-performance materials.

In the filtration industry, ammonium hydroxide-modified fibers are finding applications in air and liquid filtration systems due to their improved chemical resistance and durability. The global filtration market, valued at $89 billion in 2020, is expected to grow at a CAGR of 7.2% from 2021 to 2028, driven by increasing environmental regulations and growing awareness of air and water quality.

The packaging industry is also showing interest in these modified fibers for their potential in creating biodegradable and compostable packaging solutions. With the global sustainable packaging market projected to reach $412 billion by 2027, growing at a CAGR of 6.1%, there is a significant opportunity for ammonium hydroxide-modified cellulose acetate fibers in this sector.

Geographically, North America and Europe are currently the leading markets for ammonium hydroxide-modified fibers, owing to stringent environmental regulations and a strong focus on sustainable materials. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing awareness of eco-friendly products.

Despite the promising market outlook, challenges such as higher production costs compared to conventional fibers and the need for specialized manufacturing processes may hinder widespread adoption. However, ongoing research and development efforts are expected to address these challenges and further expand the market potential of ammonium hydroxide-modified cellulose acetate fibers across various industries.

Current Challenges in Cellulose Acetate Production

The production of cellulose acetate fibers faces several significant challenges in the current manufacturing landscape. One of the primary issues is the environmental impact of traditional production methods. The use of acetic acid and other harsh chemicals in the acetylation process raises concerns about waste management and ecological sustainability. Manufacturers are under increasing pressure to develop more environmentally friendly production techniques that reduce chemical usage and minimize harmful emissions.

Another major challenge is the energy-intensive nature of cellulose acetate production. The process requires high temperatures and prolonged reaction times, leading to substantial energy consumption and increased production costs. This energy dependency not only affects the economic viability of production but also contributes to the industry's carbon footprint, further exacerbating environmental concerns.

Quality control and consistency in fiber properties present ongoing difficulties for producers. Variations in the source of cellulose, fluctuations in reaction conditions, and inconsistencies in the acetylation process can lead to irregularities in fiber quality. Achieving uniform fiber characteristics, such as tensile strength, elasticity, and moisture absorption, remains a persistent challenge that impacts the final product's performance and market acceptance.

The limited solubility of cellulose in common solvents poses a significant obstacle in the production process. This constraint necessitates the use of specialized and often expensive solvents, which can increase production costs and complexity. Finding more efficient and cost-effective solvent systems is crucial for improving the overall production efficiency and reducing expenses.

Scalability and process optimization continue to be areas of concern for manufacturers. As demand for cellulose acetate fibers grows, particularly in emerging markets, producers face the challenge of scaling up production while maintaining quality and cost-effectiveness. Optimizing reaction kinetics, improving solvent recovery systems, and enhancing overall process efficiency are critical areas requiring ongoing research and development.

The integration of ammonium hydroxide into the production process, while offering potential benefits, introduces its own set of challenges. Balancing the modulating effects of ammonium hydroxide with existing production parameters requires careful calibration and process adjustments. Manufacturers must navigate the complexities of incorporating this additional component without compromising the established production workflow or final product quality.

Lastly, the industry faces increasing competition from alternative materials and synthetic fibers. To remain competitive, cellulose acetate producers must continually innovate to improve fiber properties, reduce production costs, and expand application possibilities. This ongoing need for innovation places additional pressure on research and development efforts, driving the search for novel production techniques and material enhancements.

Another major challenge is the energy-intensive nature of cellulose acetate production. The process requires high temperatures and prolonged reaction times, leading to substantial energy consumption and increased production costs. This energy dependency not only affects the economic viability of production but also contributes to the industry's carbon footprint, further exacerbating environmental concerns.

Quality control and consistency in fiber properties present ongoing difficulties for producers. Variations in the source of cellulose, fluctuations in reaction conditions, and inconsistencies in the acetylation process can lead to irregularities in fiber quality. Achieving uniform fiber characteristics, such as tensile strength, elasticity, and moisture absorption, remains a persistent challenge that impacts the final product's performance and market acceptance.

The limited solubility of cellulose in common solvents poses a significant obstacle in the production process. This constraint necessitates the use of specialized and often expensive solvents, which can increase production costs and complexity. Finding more efficient and cost-effective solvent systems is crucial for improving the overall production efficiency and reducing expenses.

Scalability and process optimization continue to be areas of concern for manufacturers. As demand for cellulose acetate fibers grows, particularly in emerging markets, producers face the challenge of scaling up production while maintaining quality and cost-effectiveness. Optimizing reaction kinetics, improving solvent recovery systems, and enhancing overall process efficiency are critical areas requiring ongoing research and development.

The integration of ammonium hydroxide into the production process, while offering potential benefits, introduces its own set of challenges. Balancing the modulating effects of ammonium hydroxide with existing production parameters requires careful calibration and process adjustments. Manufacturers must navigate the complexities of incorporating this additional component without compromising the established production workflow or final product quality.

Lastly, the industry faces increasing competition from alternative materials and synthetic fibers. To remain competitive, cellulose acetate producers must continually innovate to improve fiber properties, reduce production costs, and expand application possibilities. This ongoing need for innovation places additional pressure on research and development efforts, driving the search for novel production techniques and material enhancements.

Existing Ammonium Hydroxide Modulation Techniques

01 Spinning process optimization

Improvements in the spinning process for cellulose acetate fiber production, including adjustments to spinning conditions, solvent systems, and coagulation baths. These optimizations aim to enhance fiber quality, uniformity, and production efficiency.- Cellulose acetate fiber spinning process: The production of cellulose acetate fibers involves a spinning process where the cellulose acetate solution is extruded through spinnerets into a coagulation bath. This process can be optimized by controlling factors such as solution concentration, spinning temperature, and coagulation conditions to achieve desired fiber properties.

- Solvent recovery and recycling: Efficient solvent recovery and recycling systems are crucial in cellulose acetate fiber production. These systems help reduce environmental impact and production costs by reclaiming and purifying solvents used in the spinning process, allowing for their reuse in subsequent production cycles.

- Fiber modification and treatment: Various modification and treatment techniques can be applied to cellulose acetate fibers to enhance their properties. These may include surface treatments, incorporation of additives, or post-spinning processes to improve characteristics such as strength, durability, or functionality for specific applications.

- Sustainable production methods: Developing sustainable production methods for cellulose acetate fibers is a growing focus. This includes using bio-based raw materials, implementing energy-efficient processes, and reducing waste generation throughout the production cycle to minimize environmental impact.

- Quality control and characterization: Implementing robust quality control measures and advanced characterization techniques is essential in cellulose acetate fiber production. This involves monitoring and analyzing various fiber properties such as diameter, tensile strength, and chemical composition to ensure consistent product quality and performance.

02 Fiber modification techniques

Various methods for modifying cellulose acetate fibers to improve their properties, such as strength, elasticity, or functionality. This may include chemical treatments, blending with other materials, or surface modifications to enhance the fiber's performance in specific applications.Expand Specific Solutions03 Sustainable production methods

Development of eco-friendly and sustainable approaches to cellulose acetate fiber production, focusing on reducing environmental impact, using renewable resources, and improving energy efficiency in the manufacturing process.Expand Specific Solutions04 Solvent recovery and recycling

Techniques for efficient recovery and recycling of solvents used in cellulose acetate fiber production, aiming to reduce waste, lower production costs, and minimize environmental impact. This includes advanced separation and purification methods for solvent reuse.Expand Specific Solutions05 Fiber property enhancement

Methods for improving specific properties of cellulose acetate fibers, such as flame retardancy, moisture absorption, or dyeability. This involves the incorporation of additives, surface treatments, or modifications to the cellulose acetate structure to achieve desired characteristics.Expand Specific Solutions

Key Industry Players and Competitors

The development of ammonium hydroxide modulation in cellulose acetate fiber production is in a mature stage, with established market players and ongoing research. The global cellulose acetate market size is projected to reach $7.2 billion by 2027, driven by demand in textiles, cigarette filters, and packaging. Key players like Lenzing AG, DuPont, and Daicel Corp. have advanced technologies in this field. Research institutions such as Nanjing University of Science & Technology and South China University of Technology are contributing to technological advancements. The industry is characterized by a mix of large multinational corporations and specialized regional manufacturers, indicating a competitive and innovation-driven landscape.

Lenzing AG

Technical Solution: Lenzing AG has developed an innovative process for cellulose acetate fiber production using ammonium hydroxide as a key modulator. Their method involves treating cellulose with a mixture of acetic anhydride and ammonium hydroxide, which results in a more controlled acetylation process[1]. This approach allows for precise adjustment of the degree of substitution in cellulose acetate, leading to fibers with tailored properties. The company has also implemented a closed-loop system that recycles ammonium hydroxide, reducing waste and improving process efficiency[3]. Additionally, Lenzing's technology incorporates a novel spinning technique that utilizes ammonium hydroxide-based coagulation baths, resulting in fibers with enhanced uniformity and strength[5].

Strengths: Precise control over fiber properties, environmentally friendly closed-loop process, improved fiber uniformity. Weaknesses: Potentially higher initial investment costs, may require specialized equipment for ammonium hydroxide handling.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a proprietary cellulose acetate fiber production process that leverages ammonium hydroxide as a key modulator. Their approach involves a two-stage acetylation process, where ammonium hydroxide is introduced in the second stage to fine-tune the acetylation degree[2]. This method allows for the production of cellulose acetate fibers with customizable properties, such as improved moisture absorption and enhanced dyeability. DuPont's technology also incorporates a novel solvent recovery system that efficiently recycles ammonium hydroxide, reducing environmental impact and operational costs[4]. Furthermore, the company has patented a unique fiber spinning technique that utilizes ammonium hydroxide-based solutions to create fibers with superior tensile strength and elongation properties[6].

Strengths: Highly customizable fiber properties, efficient solvent recovery system, improved fiber mechanical properties. Weaknesses: Complex multi-stage process may increase production time, potential safety concerns with large-scale ammonium hydroxide use.

Innovative Approaches in Fiber Modulation

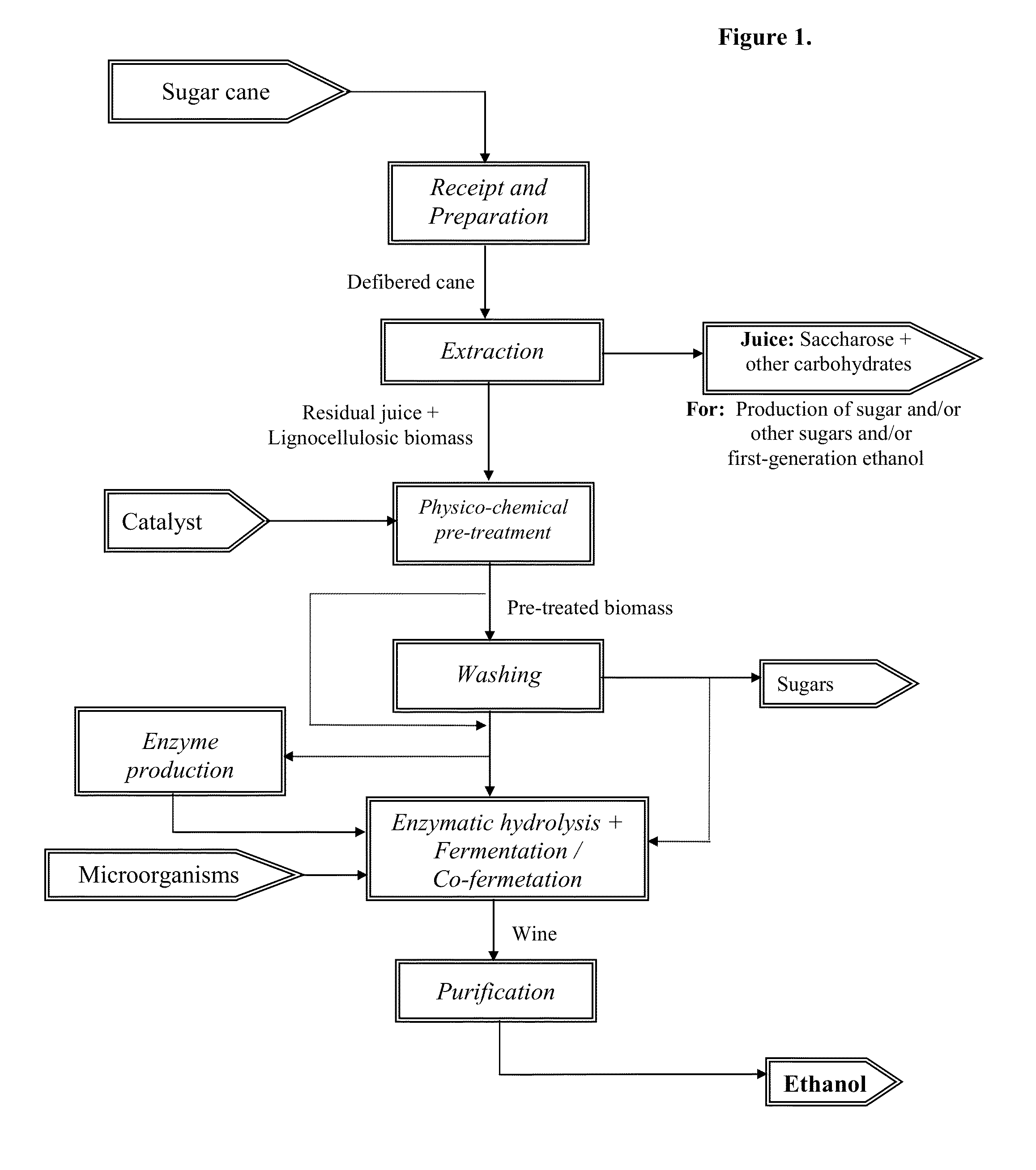

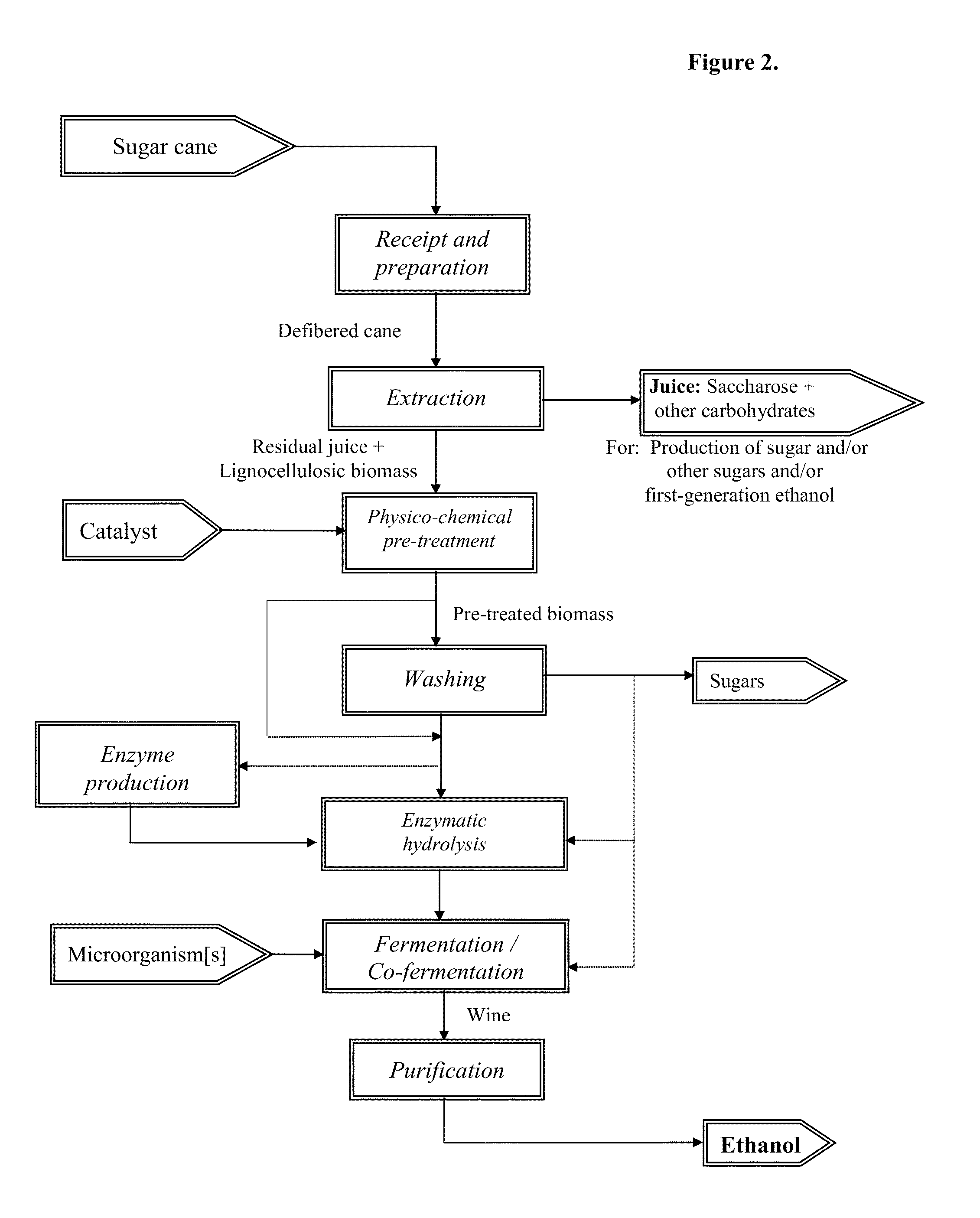

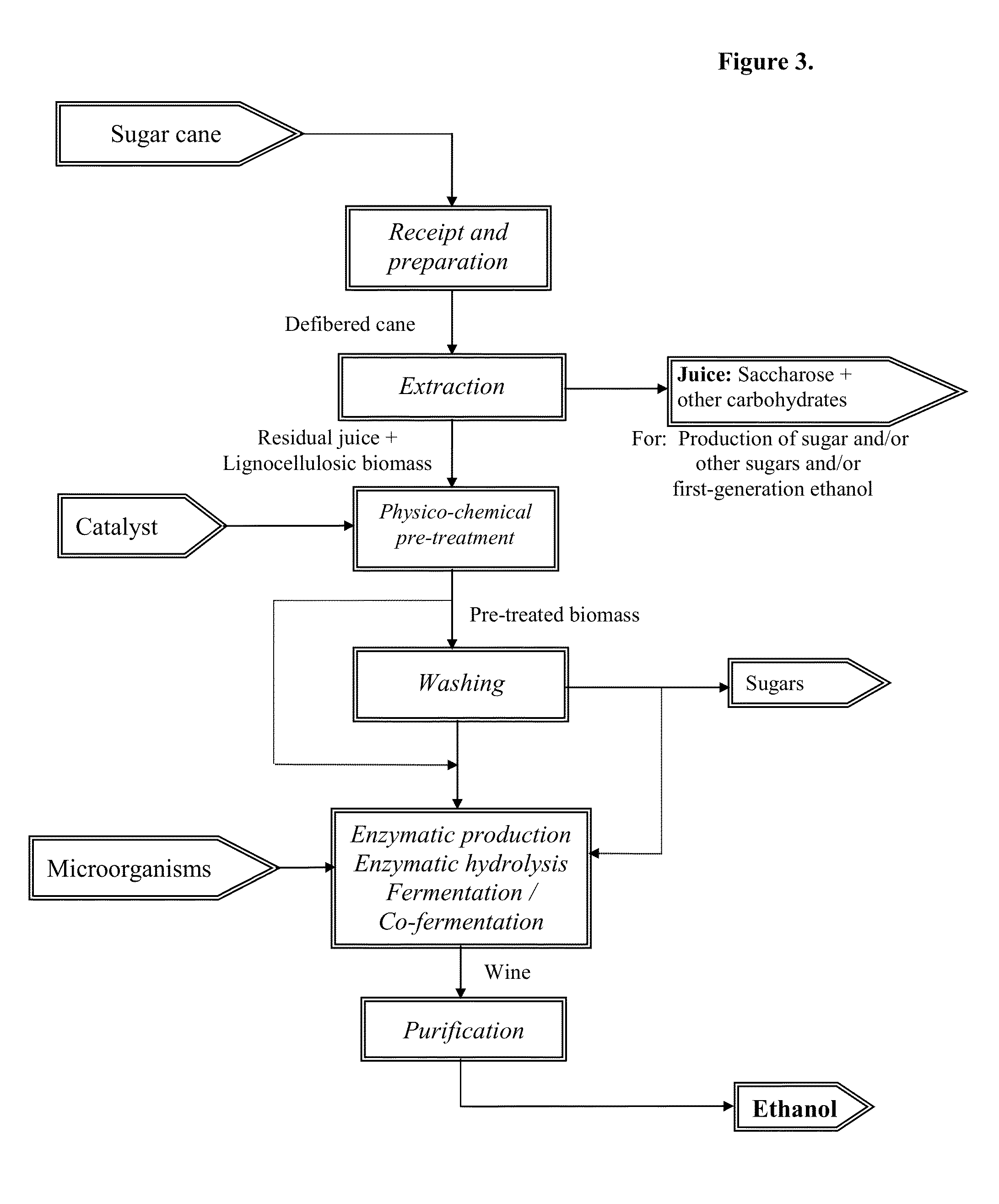

Method for processing vegetable biomass

PatentActiveUS20140053827A1

Innovation

- A process involving defibration of sugar cane biomass followed by a simplified three-roller milling configuration and moderate chemical treatment to extract juice, combined with enzymatic hydrolysis and fermentation, reduces energy demand and enhances the accessibility of cellulose to hydrolytic agents, allowing for the production of both first- and second-generation ethanol.

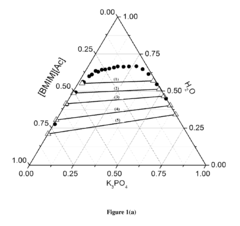

Ionic liquid pretreatment of cellulosic biomass: enzymatic hydrolysis and ionic liquid recycle

PatentInactiveUS20130252285A1

Innovation

- The use of ionic liquids in combination with a kosmotropic anion in an aqueous solution to form a biphasic system, allowing for the separation and recycling of the ionic liquid phase, which pretreats biomass to create a cellulose-rich solid phase that can be enzymatically hydrolyzed effectively.

Environmental Impact Assessment

The environmental impact of cellulose acetate fiber production using ammonium hydroxide as a modulating agent is a critical consideration in the manufacturing process. This assessment focuses on the potential effects on air, water, and soil quality, as well as the overall ecological footprint of the production method.

Ammonium hydroxide, while an effective modulator in cellulose acetate fiber production, poses several environmental concerns. Its volatile nature contributes to air pollution, primarily through the release of ammonia gas. This can lead to the formation of particulate matter and contribute to smog formation in urban areas. Additionally, ammonia emissions can cause respiratory irritation in humans and animals, and potentially harm vegetation in the surrounding ecosystem.

Water pollution is another significant concern. The use of ammonium hydroxide in the production process can result in the discharge of ammonia-rich wastewater. If not properly treated, this effluent can lead to eutrophication in aquatic ecosystems, causing algal blooms and oxygen depletion. The high pH levels associated with ammonium hydroxide can also disrupt the natural balance of aquatic habitats, affecting fish and other aquatic organisms.

Soil contamination is a potential risk, particularly in cases of accidental spills or improper disposal of production waste. Ammonium hydroxide can alter soil pH, affecting nutrient availability and microbial activity. This can have cascading effects on local flora and fauna, potentially leading to changes in biodiversity and ecosystem functioning.

The production process also has implications for energy consumption and greenhouse gas emissions. The synthesis and handling of ammonium hydroxide require significant energy inputs, contributing to the carbon footprint of the manufacturing process. Furthermore, the production of cellulose acetate fibers often involves the use of fossil fuel-derived raw materials, adding to the overall environmental impact.

Waste management is a crucial aspect of the environmental assessment. The production process generates various waste streams, including spent chemicals, off-spec fibers, and packaging materials. Proper disposal and recycling strategies are essential to minimize landfill contributions and reduce the overall environmental burden of the production process.

In light of these environmental concerns, there is a growing emphasis on developing more sustainable production methods. This includes exploring alternative modulating agents with lower environmental impacts, implementing closed-loop systems to minimize waste and emissions, and improving energy efficiency throughout the production process. Additionally, research into bio-based alternatives for cellulose acetate production is gaining traction, aiming to reduce reliance on fossil fuel-derived raw materials and decrease the overall ecological footprint of the industry.

Ammonium hydroxide, while an effective modulator in cellulose acetate fiber production, poses several environmental concerns. Its volatile nature contributes to air pollution, primarily through the release of ammonia gas. This can lead to the formation of particulate matter and contribute to smog formation in urban areas. Additionally, ammonia emissions can cause respiratory irritation in humans and animals, and potentially harm vegetation in the surrounding ecosystem.

Water pollution is another significant concern. The use of ammonium hydroxide in the production process can result in the discharge of ammonia-rich wastewater. If not properly treated, this effluent can lead to eutrophication in aquatic ecosystems, causing algal blooms and oxygen depletion. The high pH levels associated with ammonium hydroxide can also disrupt the natural balance of aquatic habitats, affecting fish and other aquatic organisms.

Soil contamination is a potential risk, particularly in cases of accidental spills or improper disposal of production waste. Ammonium hydroxide can alter soil pH, affecting nutrient availability and microbial activity. This can have cascading effects on local flora and fauna, potentially leading to changes in biodiversity and ecosystem functioning.

The production process also has implications for energy consumption and greenhouse gas emissions. The synthesis and handling of ammonium hydroxide require significant energy inputs, contributing to the carbon footprint of the manufacturing process. Furthermore, the production of cellulose acetate fibers often involves the use of fossil fuel-derived raw materials, adding to the overall environmental impact.

Waste management is a crucial aspect of the environmental assessment. The production process generates various waste streams, including spent chemicals, off-spec fibers, and packaging materials. Proper disposal and recycling strategies are essential to minimize landfill contributions and reduce the overall environmental burden of the production process.

In light of these environmental concerns, there is a growing emphasis on developing more sustainable production methods. This includes exploring alternative modulating agents with lower environmental impacts, implementing closed-loop systems to minimize waste and emissions, and improving energy efficiency throughout the production process. Additionally, research into bio-based alternatives for cellulose acetate production is gaining traction, aiming to reduce reliance on fossil fuel-derived raw materials and decrease the overall ecological footprint of the industry.

Quality Control and Standardization

Quality control and standardization are crucial aspects of cellulose acetate fiber production, especially when ammonium hydroxide is used as a modulating agent. The implementation of robust quality control measures ensures consistency in fiber properties and performance across production batches. Standardization of processes and parameters is essential for maintaining product quality and meeting industry specifications.

To achieve effective quality control, manufacturers must establish comprehensive testing protocols for raw materials, intermediate products, and finished fibers. These protocols typically include assessments of chemical composition, physical properties, and mechanical characteristics. For instance, the concentration and purity of ammonium hydroxide used in the production process must be carefully monitored to ensure optimal modulation of cellulose acetate properties.

Standardization of production processes involves the development and adherence to detailed standard operating procedures (SOPs). These SOPs should cover all aspects of fiber production, from raw material handling to final product packaging. In the context of ammonium hydroxide modulation, standardization efforts focus on parameters such as reaction time, temperature, pressure, and mixing ratios.

Advanced analytical techniques play a vital role in quality control and standardization efforts. Spectroscopic methods, such as Fourier-transform infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR), can be employed to analyze the chemical structure and composition of cellulose acetate fibers. These techniques help ensure that the desired modifications induced by ammonium hydroxide are consistently achieved.

Statistical process control (SPC) methods are widely used to monitor and control variability in fiber production. By implementing SPC, manufacturers can detect and address process deviations in real-time, minimizing the production of out-of-specification fibers. Key performance indicators (KPIs) related to fiber quality, such as tensile strength, elongation, and moisture regain, are continuously monitored and analyzed using statistical tools.

Certification and compliance with international standards are essential for ensuring the quality and reliability of cellulose acetate fibers produced using ammonium hydroxide modulation. Organizations such as the International Organization for Standardization (ISO) and ASTM International provide guidelines and standards for fiber testing and quality assurance. Adherence to these standards not only ensures product quality but also facilitates global trade and customer confidence.

Continuous improvement initiatives are integral to quality control and standardization efforts. Regular audits, both internal and external, help identify areas for improvement in production processes and quality management systems. Feedback from customers and end-users is also valuable in refining quality control measures and adapting to evolving market requirements.

To achieve effective quality control, manufacturers must establish comprehensive testing protocols for raw materials, intermediate products, and finished fibers. These protocols typically include assessments of chemical composition, physical properties, and mechanical characteristics. For instance, the concentration and purity of ammonium hydroxide used in the production process must be carefully monitored to ensure optimal modulation of cellulose acetate properties.

Standardization of production processes involves the development and adherence to detailed standard operating procedures (SOPs). These SOPs should cover all aspects of fiber production, from raw material handling to final product packaging. In the context of ammonium hydroxide modulation, standardization efforts focus on parameters such as reaction time, temperature, pressure, and mixing ratios.

Advanced analytical techniques play a vital role in quality control and standardization efforts. Spectroscopic methods, such as Fourier-transform infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR), can be employed to analyze the chemical structure and composition of cellulose acetate fibers. These techniques help ensure that the desired modifications induced by ammonium hydroxide are consistently achieved.

Statistical process control (SPC) methods are widely used to monitor and control variability in fiber production. By implementing SPC, manufacturers can detect and address process deviations in real-time, minimizing the production of out-of-specification fibers. Key performance indicators (KPIs) related to fiber quality, such as tensile strength, elongation, and moisture regain, are continuously monitored and analyzed using statistical tools.

Certification and compliance with international standards are essential for ensuring the quality and reliability of cellulose acetate fibers produced using ammonium hydroxide modulation. Organizations such as the International Organization for Standardization (ISO) and ASTM International provide guidelines and standards for fiber testing and quality assurance. Adherence to these standards not only ensures product quality but also facilitates global trade and customer confidence.

Continuous improvement initiatives are integral to quality control and standardization efforts. Regular audits, both internal and external, help identify areas for improvement in production processes and quality management systems. Feedback from customers and end-users is also valuable in refining quality control measures and adapting to evolving market requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!