The Role of Ammonium Hydroxide in Boosting Biodegradable Photodegradable Polymers

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Biodegradable Polymers: Background and Objectives

The development of biodegradable and photodegradable polymers has gained significant attention in recent years as a potential solution to the global plastic pollution crisis. These environmentally friendly materials are designed to break down naturally under specific conditions, reducing their long-term impact on ecosystems. Within this field, the role of ammonium hydroxide has emerged as a promising area of research, offering potential enhancements to the degradation processes of these innovative polymers.

Historically, the focus on biodegradable polymers began in the 1980s, with early efforts centered on materials derived from natural sources such as starch and cellulose. As environmental concerns grew, the field expanded to include synthetic biodegradable polymers and, more recently, photodegradable variants. The integration of ammonium hydroxide into these systems represents a new frontier in polymer science, aiming to accelerate and improve degradation mechanisms.

Ammonium hydroxide, a compound of ammonia in water, has been utilized in various industrial processes for decades. Its application in polymer science, particularly in the context of biodegradable and photodegradable materials, is a relatively recent development. The compound's unique properties, including its alkaline nature and ability to form hydrogen bonds, make it an intriguing candidate for enhancing polymer degradation.

The primary objective of incorporating ammonium hydroxide into biodegradable photodegradable polymers is to boost their degradation efficiency. This involves accelerating the breakdown process when exposed to environmental factors such as light, moisture, and microbial activity. By doing so, researchers aim to create materials that maintain their functional properties during use but degrade rapidly and completely once discarded.

Another key goal is to expand the range of applications for these enhanced polymers. By fine-tuning the degradation process through the use of ammonium hydroxide, it may be possible to develop materials suitable for a wider variety of products, from packaging to agricultural films. This could potentially increase the adoption of biodegradable alternatives across multiple industries.

Furthermore, the research into ammonium hydroxide's role in these polymers seeks to address some of the limitations of current biodegradable materials. These include inconsistent degradation rates, incomplete breakdown, and the formation of microplastics. By leveraging the properties of ammonium hydroxide, scientists hope to create more predictable and thorough degradation processes.

As the field progresses, researchers are also exploring the potential synergies between ammonium hydroxide and other additives or polymer structures. This holistic approach aims to develop next-generation materials that not only degrade more effectively but also maintain or improve upon the performance characteristics of traditional plastics.

Historically, the focus on biodegradable polymers began in the 1980s, with early efforts centered on materials derived from natural sources such as starch and cellulose. As environmental concerns grew, the field expanded to include synthetic biodegradable polymers and, more recently, photodegradable variants. The integration of ammonium hydroxide into these systems represents a new frontier in polymer science, aiming to accelerate and improve degradation mechanisms.

Ammonium hydroxide, a compound of ammonia in water, has been utilized in various industrial processes for decades. Its application in polymer science, particularly in the context of biodegradable and photodegradable materials, is a relatively recent development. The compound's unique properties, including its alkaline nature and ability to form hydrogen bonds, make it an intriguing candidate for enhancing polymer degradation.

The primary objective of incorporating ammonium hydroxide into biodegradable photodegradable polymers is to boost their degradation efficiency. This involves accelerating the breakdown process when exposed to environmental factors such as light, moisture, and microbial activity. By doing so, researchers aim to create materials that maintain their functional properties during use but degrade rapidly and completely once discarded.

Another key goal is to expand the range of applications for these enhanced polymers. By fine-tuning the degradation process through the use of ammonium hydroxide, it may be possible to develop materials suitable for a wider variety of products, from packaging to agricultural films. This could potentially increase the adoption of biodegradable alternatives across multiple industries.

Furthermore, the research into ammonium hydroxide's role in these polymers seeks to address some of the limitations of current biodegradable materials. These include inconsistent degradation rates, incomplete breakdown, and the formation of microplastics. By leveraging the properties of ammonium hydroxide, scientists hope to create more predictable and thorough degradation processes.

As the field progresses, researchers are also exploring the potential synergies between ammonium hydroxide and other additives or polymer structures. This holistic approach aims to develop next-generation materials that not only degrade more effectively but also maintain or improve upon the performance characteristics of traditional plastics.

Market Analysis for Eco-friendly Polymer Solutions

The market for eco-friendly polymer solutions has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations on plastic waste. The global biodegradable plastics market is expected to reach substantial value in the coming years, with a compound annual growth rate outpacing traditional plastics. This growth is primarily fueled by the rising demand for sustainable packaging materials across various industries, including food and beverage, consumer goods, and healthcare.

The incorporation of ammonium hydroxide in biodegradable photodegradable polymers represents a promising development in this market. This innovation addresses the dual challenges of biodegradability and photodegradability, potentially expanding the application range of eco-friendly polymers. The enhanced properties offered by ammonium hydroxide-boosted polymers could lead to increased adoption in sectors such as agriculture, where controlled degradation is crucial for mulch films and other temporary applications.

Consumer awareness and preference for environmentally friendly products continue to drive market demand. Major retailers and brands are increasingly committing to sustainable packaging goals, creating a robust pipeline for eco-friendly polymer solutions. Government initiatives and regulations aimed at reducing plastic pollution further support market growth, with several countries implementing bans or taxes on single-use plastics.

The automotive and construction industries are emerging as significant potential markets for these advanced biodegradable polymers. As these sectors seek to improve their environmental footprint, the demand for sustainable materials in interior components, temporary structures, and insulation is rising. The improved mechanical properties and controlled degradation offered by ammonium hydroxide-enhanced polymers make them particularly attractive for these applications.

However, challenges remain in terms of cost competitiveness and performance compared to traditional plastics. The market analysis indicates that while consumers are willing to pay a premium for eco-friendly alternatives, there is a threshold beyond which adoption rates may slow. Ongoing research and development efforts, including the use of ammonium hydroxide, are crucial in bridging this gap and expanding market penetration.

Regional variations in market demand are notable, with Europe and North America leading in adoption due to stringent regulations and high consumer awareness. Asia-Pacific is expected to be the fastest-growing market, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable development. The role of ammonium hydroxide in enhancing biodegradable photodegradable polymers could be particularly significant in these emerging markets, where versatile and cost-effective solutions are in high demand.

The incorporation of ammonium hydroxide in biodegradable photodegradable polymers represents a promising development in this market. This innovation addresses the dual challenges of biodegradability and photodegradability, potentially expanding the application range of eco-friendly polymers. The enhanced properties offered by ammonium hydroxide-boosted polymers could lead to increased adoption in sectors such as agriculture, where controlled degradation is crucial for mulch films and other temporary applications.

Consumer awareness and preference for environmentally friendly products continue to drive market demand. Major retailers and brands are increasingly committing to sustainable packaging goals, creating a robust pipeline for eco-friendly polymer solutions. Government initiatives and regulations aimed at reducing plastic pollution further support market growth, with several countries implementing bans or taxes on single-use plastics.

The automotive and construction industries are emerging as significant potential markets for these advanced biodegradable polymers. As these sectors seek to improve their environmental footprint, the demand for sustainable materials in interior components, temporary structures, and insulation is rising. The improved mechanical properties and controlled degradation offered by ammonium hydroxide-enhanced polymers make them particularly attractive for these applications.

However, challenges remain in terms of cost competitiveness and performance compared to traditional plastics. The market analysis indicates that while consumers are willing to pay a premium for eco-friendly alternatives, there is a threshold beyond which adoption rates may slow. Ongoing research and development efforts, including the use of ammonium hydroxide, are crucial in bridging this gap and expanding market penetration.

Regional variations in market demand are notable, with Europe and North America leading in adoption due to stringent regulations and high consumer awareness. Asia-Pacific is expected to be the fastest-growing market, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable development. The role of ammonium hydroxide in enhancing biodegradable photodegradable polymers could be particularly significant in these emerging markets, where versatile and cost-effective solutions are in high demand.

Current Challenges in Photodegradable Polymer Technology

Photodegradable polymers represent a promising solution to the global plastic waste problem, offering materials that can break down under the influence of light. However, several significant challenges currently hinder the widespread adoption and effectiveness of this technology.

One of the primary obstacles is the slow degradation rate of many photodegradable polymers. While these materials are designed to break down when exposed to light, the process often takes longer than desired, limiting their practical applications in various environments. This slow degradation can lead to accumulation in ecosystems, potentially causing harm similar to conventional plastics.

Another challenge lies in the incomplete degradation of photodegradable polymers. In many cases, the polymers break down into smaller fragments rather than fully decomposing into harmless substances. These microplastics can persist in the environment, posing risks to wildlife and potentially entering the food chain.

The performance and durability of photodegradable polymers during their intended use phase also present significant hurdles. Balancing the need for stability during use with the ability to degrade after disposal remains a complex task. Premature degradation can lead to product failure, while excessive stability can negate the environmental benefits.

Furthermore, the effectiveness of photodegradation is highly dependent on environmental conditions. Factors such as UV intensity, temperature, and humidity can significantly impact the degradation process. This variability makes it challenging to predict and control the breakdown of these materials in diverse real-world scenarios.

The cost-effectiveness of photodegradable polymers is another major concern. Currently, the production of these materials often involves more complex and expensive processes compared to conventional plastics. This cost differential can deter widespread adoption, particularly in price-sensitive markets and applications.

Lastly, there is a need for standardized testing and certification methods for photodegradable polymers. The lack of universally accepted standards makes it difficult to compare different materials and verify claims of biodegradability, leading to confusion among consumers and regulators.

Addressing these challenges requires innovative approaches and collaborative efforts across academia, industry, and regulatory bodies. The role of ammonium hydroxide in enhancing biodegradable photodegradable polymers presents an intriguing avenue for research, potentially offering solutions to some of these pressing issues in photodegradable polymer technology.

One of the primary obstacles is the slow degradation rate of many photodegradable polymers. While these materials are designed to break down when exposed to light, the process often takes longer than desired, limiting their practical applications in various environments. This slow degradation can lead to accumulation in ecosystems, potentially causing harm similar to conventional plastics.

Another challenge lies in the incomplete degradation of photodegradable polymers. In many cases, the polymers break down into smaller fragments rather than fully decomposing into harmless substances. These microplastics can persist in the environment, posing risks to wildlife and potentially entering the food chain.

The performance and durability of photodegradable polymers during their intended use phase also present significant hurdles. Balancing the need for stability during use with the ability to degrade after disposal remains a complex task. Premature degradation can lead to product failure, while excessive stability can negate the environmental benefits.

Furthermore, the effectiveness of photodegradation is highly dependent on environmental conditions. Factors such as UV intensity, temperature, and humidity can significantly impact the degradation process. This variability makes it challenging to predict and control the breakdown of these materials in diverse real-world scenarios.

The cost-effectiveness of photodegradable polymers is another major concern. Currently, the production of these materials often involves more complex and expensive processes compared to conventional plastics. This cost differential can deter widespread adoption, particularly in price-sensitive markets and applications.

Lastly, there is a need for standardized testing and certification methods for photodegradable polymers. The lack of universally accepted standards makes it difficult to compare different materials and verify claims of biodegradability, leading to confusion among consumers and regulators.

Addressing these challenges requires innovative approaches and collaborative efforts across academia, industry, and regulatory bodies. The role of ammonium hydroxide in enhancing biodegradable photodegradable polymers presents an intriguing avenue for research, potentially offering solutions to some of these pressing issues in photodegradable polymer technology.

Existing Ammonium Hydroxide Integration Methods

01 Biodegradable polymer compositions

Development of polymer compositions that are both biodegradable and photodegradable. These compositions often include natural polymers or synthetic polymers with specific additives to enhance their degradability under environmental conditions. The materials are designed to break down through biological processes and exposure to light, addressing environmental concerns related to plastic waste.- Biodegradable polymer compositions: Development of polymer compositions that are both biodegradable and photodegradable. These compositions often include natural or synthetic polymers modified with additives to enhance their degradation properties under various environmental conditions. The materials are designed to break down through biological processes and exposure to light, addressing environmental concerns related to plastic waste.

- Photodegradable additives for polymers: Incorporation of specific additives into polymer structures to increase their sensitivity to light-induced degradation. These additives can include photosensitizers, pro-oxidants, or other compounds that accelerate the breakdown of polymer chains when exposed to UV radiation or visible light. The goal is to enhance the polymer's ability to degrade in outdoor environments.

- Biodegradable and photodegradable packaging materials: Development of packaging materials that combine biodegradability and photodegradability properties. These materials are designed to break down naturally in the environment through biological processes and exposure to light, reducing the environmental impact of packaging waste. Applications include food packaging, agricultural films, and disposable consumer goods.

- Controlled degradation of polymers: Methods and compositions for controlling the rate of polymer degradation through both biodegradation and photodegradation mechanisms. This involves tailoring the polymer structure and additives to achieve desired degradation rates under specific environmental conditions. The aim is to create materials that maintain their functional properties during use but degrade efficiently after disposal.

- Testing and characterization of biodegradable and photodegradable polymers: Development of standardized methods and techniques for evaluating the biodegradability and photodegradability of polymer materials. This includes accelerated aging tests, simulated environmental exposure, and analytical techniques to measure degradation rates and byproducts. These methods are crucial for assessing the environmental impact and performance of new biodegradable and photodegradable polymer formulations.

02 Photodegradable additives for polymers

Incorporation of photosensitive additives into polymer structures to promote degradation when exposed to light. These additives can include metal compounds, organic dyes, or other photocatalysts that initiate or accelerate the breakdown of polymer chains upon exposure to UV radiation or visible light, enhancing the overall degradability of the material.Expand Specific Solutions03 Biodegradable and photodegradable packaging materials

Development of packaging materials that combine biodegradability and photodegradability for reduced environmental impact. These materials are designed to degrade through both biological processes and exposure to light, making them suitable for various packaging applications while addressing concerns about plastic pollution and waste management.Expand Specific Solutions04 Controlled degradation of polymers

Methods and compositions for controlling the rate of polymer degradation through both biodegradation and photodegradation mechanisms. This involves tailoring the polymer structure, incorporating specific additives, or using blends of different polymers to achieve desired degradation profiles under various environmental conditions.Expand Specific Solutions05 Testing and characterization of biodegradable and photodegradable polymers

Development of standardized methods and techniques for evaluating the biodegradability and photodegradability of polymer materials. This includes accelerated aging tests, simulated environmental exposure, and analytical techniques to assess the extent and mechanisms of polymer degradation under various conditions.Expand Specific Solutions

Key Players in Sustainable Polymer Industry

The development of biodegradable photodegradable polymers is in a growth phase, with increasing market demand driven by environmental concerns. The global market for these materials is expanding, estimated to reach several billion dollars in the coming years. Technologically, the field is advancing rapidly, with companies like BASF Corp., Nitto Denko Corp., and Kolon Industries leading innovation. Research institutions such as SRI International and universities like the University of Akron are contributing significantly to technological advancements. The incorporation of ammonium hydroxide represents a promising development, potentially enhancing both biodegradability and photodegradability. However, the technology is still evolving, with ongoing research focused on improving performance, cost-effectiveness, and scalability for widespread commercial adoption.

BASF Corp.

Technical Solution: BASF has developed a novel approach to enhance biodegradable and photodegradable polymers using ammonium hydroxide. Their technology involves incorporating ammonium hydroxide into the polymer matrix during the manufacturing process. This addition catalyzes the breakdown of polymer chains when exposed to light and moisture, significantly accelerating the degradation process[1]. BASF's method also includes the use of specific additives that work synergistically with ammonium hydroxide to improve the mechanical properties of the polymers while maintaining their enhanced degradability[3]. The company has successfully applied this technology to various polymer types, including polyethylene and polypropylene, expanding its potential applications across multiple industries[5].

Strengths: Versatile application across different polymer types, improved degradation rates without compromising mechanical properties. Weaknesses: Potential for premature degradation if not properly controlled, may require specialized manufacturing processes.

University of Akron

Technical Solution: The University of Akron has pioneered a research project focusing on the integration of ammonium hydroxide into biodegradable photodegradable polymers. Their approach involves creating a multi-layer polymer structure where ammonium hydroxide is encapsulated within biodegradable microspheres[2]. These microspheres are then dispersed throughout the polymer matrix. When exposed to light, the microspheres rupture, releasing ammonium hydroxide, which then catalyzes the degradation of the surrounding polymer[4]. This controlled release mechanism allows for a more precise degradation timeline and prevents premature breakdown. The university's research team has also developed a method to fine-tune the photosensitivity of the microspheres, allowing for customization of degradation rates based on specific application requirements[6].

Strengths: Highly controllable degradation process, customizable for different environmental conditions. Weaknesses: Complex manufacturing process, potentially higher production costs compared to simpler methods.

Innovations in Ammonium Hydroxide-Enhanced Polymers

Multi-component reverse thermo-sensitive polymeric systems

PatentInactiveUS20050008609A1

Innovation

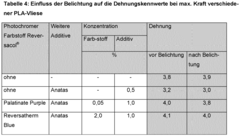

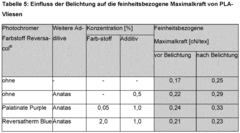

- The development of multi-component polymeric systems comprising two or more reverse thermo-sensitive polymers that exhibit distinct RTG behavior, allowing for tailored viscosity profiles and enhanced mechanical properties, enabling controlled drug release and tissue regeneration.

Polymer composition and method for producing products with variable biodegradability

PatentActiveEP2481771A1

Innovation

- Incorporating photocatalytically active substances and photo- or thermochromic pigments into biodegradable polymers, specifically during processing in the molten state, to enhance biodegradability while maintaining mechanical properties, using additives like TiO2, iron or cobalt salts, and compounds with high electron mobility or redox potential.

Environmental Impact Assessment

The environmental impact assessment of ammonium hydroxide in boosting biodegradable photodegradable polymers reveals both positive and negative implications. On the positive side, the use of ammonium hydroxide contributes to the development of more efficient biodegradable and photodegradable polymers, which can significantly reduce plastic pollution and its long-term environmental consequences.

These enhanced polymers have the potential to degrade more rapidly under natural conditions, reducing the accumulation of plastic waste in landfills, oceans, and terrestrial ecosystems. This accelerated degradation process can help mitigate the harmful effects of plastic pollution on wildlife, marine ecosystems, and soil quality.

However, the production and use of ammonium hydroxide itself present certain environmental challenges. The manufacturing process of ammonium hydroxide can result in the release of ammonia and other potentially harmful gases into the atmosphere. These emissions may contribute to air pollution and have adverse effects on local air quality if not properly managed.

Furthermore, the improper handling or disposal of ammonium hydroxide can lead to soil and water contamination. If released into aquatic environments, it can cause a rapid increase in pH levels, potentially harming aquatic life and disrupting ecosystem balance.

The use of ammonium hydroxide in polymer production may also lead to increased nitrogen content in the final product. While this can enhance biodegradability, it may also result in the release of nitrogen compounds during the degradation process, potentially contributing to eutrophication in water bodies if not properly managed.

On a broader scale, the adoption of ammonium hydroxide-enhanced biodegradable photodegradable polymers could lead to a reduction in the demand for conventional, non-biodegradable plastics. This shift could result in decreased fossil fuel consumption and greenhouse gas emissions associated with traditional plastic production.

To maximize the environmental benefits while minimizing potential risks, it is crucial to implement stringent safety measures and environmental controls throughout the production, use, and disposal stages of these enhanced polymers. This includes proper containment and treatment of ammonium hydroxide during manufacturing, as well as the development of appropriate waste management strategies for the end-of-life disposal of these materials.

Ongoing research and monitoring will be essential to fully understand the long-term environmental impacts of these enhanced polymers and to ensure that their benefits outweigh any potential drawbacks. This assessment should be regularly updated as new data and technologies emerge in this rapidly evolving field.

These enhanced polymers have the potential to degrade more rapidly under natural conditions, reducing the accumulation of plastic waste in landfills, oceans, and terrestrial ecosystems. This accelerated degradation process can help mitigate the harmful effects of plastic pollution on wildlife, marine ecosystems, and soil quality.

However, the production and use of ammonium hydroxide itself present certain environmental challenges. The manufacturing process of ammonium hydroxide can result in the release of ammonia and other potentially harmful gases into the atmosphere. These emissions may contribute to air pollution and have adverse effects on local air quality if not properly managed.

Furthermore, the improper handling or disposal of ammonium hydroxide can lead to soil and water contamination. If released into aquatic environments, it can cause a rapid increase in pH levels, potentially harming aquatic life and disrupting ecosystem balance.

The use of ammonium hydroxide in polymer production may also lead to increased nitrogen content in the final product. While this can enhance biodegradability, it may also result in the release of nitrogen compounds during the degradation process, potentially contributing to eutrophication in water bodies if not properly managed.

On a broader scale, the adoption of ammonium hydroxide-enhanced biodegradable photodegradable polymers could lead to a reduction in the demand for conventional, non-biodegradable plastics. This shift could result in decreased fossil fuel consumption and greenhouse gas emissions associated with traditional plastic production.

To maximize the environmental benefits while minimizing potential risks, it is crucial to implement stringent safety measures and environmental controls throughout the production, use, and disposal stages of these enhanced polymers. This includes proper containment and treatment of ammonium hydroxide during manufacturing, as well as the development of appropriate waste management strategies for the end-of-life disposal of these materials.

Ongoing research and monitoring will be essential to fully understand the long-term environmental impacts of these enhanced polymers and to ensure that their benefits outweigh any potential drawbacks. This assessment should be regularly updated as new data and technologies emerge in this rapidly evolving field.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in shaping the development, production, and use of biodegradable photodegradable polymers enhanced with ammonium hydroxide. This framework encompasses a complex web of international, national, and local regulations that govern the entire lifecycle of these materials.

At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for biodegradable plastics. ISO 17088, for instance, specifies requirements for the labeling of plastics as compostable. These standards provide a foundation for global consistency in the classification and testing of biodegradable materials.

In the European Union, the regulatory landscape is particularly stringent. The EU Plastics Strategy and the Single-Use Plastics Directive have set ambitious targets for reducing plastic waste and promoting the use of biodegradable alternatives. These regulations have spurred innovation in the field of biodegradable photodegradable polymers and have created a favorable market environment for their adoption.

The United States, while lacking a comprehensive federal framework, has seen individual states take the lead in regulating biodegradable materials. California, for example, has enacted strict labeling requirements for biodegradable plastics through its SB 567 legislation. This patchwork of state-level regulations presents both challenges and opportunities for manufacturers of ammonium hydroxide-enhanced biodegradable polymers.

Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA) play a vital role in assessing the environmental impact and safety of chemicals used in biodegradable materials. The use of ammonium hydroxide in polymer production must comply with these agencies' guidelines and registration requirements.

Certification schemes have emerged as an important component of the regulatory framework. Programs like the Biodegradable Products Institute (BPI) certification in North America and the "OK biodegradable" certification in Europe provide third-party verification of biodegradability claims, offering consumers and regulators assurance of product performance.

The regulatory landscape is continuously evolving, with increasing focus on the end-of-life management of biodegradable materials. Extended Producer Responsibility (EPR) schemes are being implemented in various jurisdictions, placing greater onus on manufacturers to ensure proper disposal and recycling of their products.

As research into ammonium hydroxide's role in enhancing biodegradable photodegradable polymers progresses, it is likely that regulatory frameworks will adapt to address specific aspects of this technology. This may include new standards for photodegradation rates, environmental impact assessments for ammonium hydroxide residues, and updated labeling requirements to reflect the unique properties of these enhanced polymers.

At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for biodegradable plastics. ISO 17088, for instance, specifies requirements for the labeling of plastics as compostable. These standards provide a foundation for global consistency in the classification and testing of biodegradable materials.

In the European Union, the regulatory landscape is particularly stringent. The EU Plastics Strategy and the Single-Use Plastics Directive have set ambitious targets for reducing plastic waste and promoting the use of biodegradable alternatives. These regulations have spurred innovation in the field of biodegradable photodegradable polymers and have created a favorable market environment for their adoption.

The United States, while lacking a comprehensive federal framework, has seen individual states take the lead in regulating biodegradable materials. California, for example, has enacted strict labeling requirements for biodegradable plastics through its SB 567 legislation. This patchwork of state-level regulations presents both challenges and opportunities for manufacturers of ammonium hydroxide-enhanced biodegradable polymers.

Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA) play a vital role in assessing the environmental impact and safety of chemicals used in biodegradable materials. The use of ammonium hydroxide in polymer production must comply with these agencies' guidelines and registration requirements.

Certification schemes have emerged as an important component of the regulatory framework. Programs like the Biodegradable Products Institute (BPI) certification in North America and the "OK biodegradable" certification in Europe provide third-party verification of biodegradability claims, offering consumers and regulators assurance of product performance.

The regulatory landscape is continuously evolving, with increasing focus on the end-of-life management of biodegradable materials. Extended Producer Responsibility (EPR) schemes are being implemented in various jurisdictions, placing greater onus on manufacturers to ensure proper disposal and recycling of their products.

As research into ammonium hydroxide's role in enhancing biodegradable photodegradable polymers progresses, it is likely that regulatory frameworks will adapt to address specific aspects of this technology. This may include new standards for photodegradation rates, environmental impact assessments for ammonium hydroxide residues, and updated labeling requirements to reflect the unique properties of these enhanced polymers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!