Ammonium Hydroxide's Role in Enhancing Antimicrobial Surface Coatings

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NH4OH in Antimicrobials

Ammonium hydroxide (NH4OH) has emerged as a significant component in enhancing the efficacy of antimicrobial surface coatings. This compound, also known as aqueous ammonia, plays a crucial role in improving the adhesion, durability, and overall performance of antimicrobial coatings applied to various surfaces.

The use of NH4OH in antimicrobial coatings can be traced back to the early 2000s when researchers began exploring its potential as a pH regulator and stabilizing agent. Since then, its application has expanded significantly, with notable advancements in the past decade. The evolution of NH4OH's role in antimicrobial coatings has been driven by the increasing demand for more effective and long-lasting protection against harmful microorganisms in various settings, including healthcare facilities, food processing plants, and public spaces.

One of the primary functions of NH4OH in antimicrobial coatings is to create an alkaline environment that inhibits the growth of many bacteria, fungi, and other microorganisms. This alkaline condition disrupts the cell membranes of microbes, leading to their inactivation or death. Additionally, NH4OH acts as a powerful cleaning agent, helping to remove organic matter and other contaminants that could potentially harbor pathogens.

Recent technological advancements have focused on optimizing the concentration and delivery methods of NH4OH in antimicrobial coatings. Researchers have developed novel formulations that allow for the slow release of ammonia over extended periods, ensuring long-term antimicrobial activity. This controlled release mechanism has significantly improved the durability and effectiveness of antimicrobial coatings, addressing previous limitations related to the volatility of ammonia.

Furthermore, the integration of NH4OH with other antimicrobial agents, such as silver nanoparticles or quaternary ammonium compounds, has led to synergistic effects, enhancing the overall antimicrobial properties of the coatings. These combinations have shown promising results in combating a broader spectrum of microorganisms, including antibiotic-resistant strains.

The future trajectory of NH4OH in antimicrobial surface coatings is expected to focus on developing more environmentally friendly and sustainable formulations. This includes exploring bio-based sources of ammonia and optimizing coating processes to minimize environmental impact while maintaining high antimicrobial efficacy.

The use of NH4OH in antimicrobial coatings can be traced back to the early 2000s when researchers began exploring its potential as a pH regulator and stabilizing agent. Since then, its application has expanded significantly, with notable advancements in the past decade. The evolution of NH4OH's role in antimicrobial coatings has been driven by the increasing demand for more effective and long-lasting protection against harmful microorganisms in various settings, including healthcare facilities, food processing plants, and public spaces.

One of the primary functions of NH4OH in antimicrobial coatings is to create an alkaline environment that inhibits the growth of many bacteria, fungi, and other microorganisms. This alkaline condition disrupts the cell membranes of microbes, leading to their inactivation or death. Additionally, NH4OH acts as a powerful cleaning agent, helping to remove organic matter and other contaminants that could potentially harbor pathogens.

Recent technological advancements have focused on optimizing the concentration and delivery methods of NH4OH in antimicrobial coatings. Researchers have developed novel formulations that allow for the slow release of ammonia over extended periods, ensuring long-term antimicrobial activity. This controlled release mechanism has significantly improved the durability and effectiveness of antimicrobial coatings, addressing previous limitations related to the volatility of ammonia.

Furthermore, the integration of NH4OH with other antimicrobial agents, such as silver nanoparticles or quaternary ammonium compounds, has led to synergistic effects, enhancing the overall antimicrobial properties of the coatings. These combinations have shown promising results in combating a broader spectrum of microorganisms, including antibiotic-resistant strains.

The future trajectory of NH4OH in antimicrobial surface coatings is expected to focus on developing more environmentally friendly and sustainable formulations. This includes exploring bio-based sources of ammonia and optimizing coating processes to minimize environmental impact while maintaining high antimicrobial efficacy.

Market Analysis

The market for antimicrobial surface coatings has experienced significant growth in recent years, driven by increasing awareness of hygiene and the need for infection control across various industries. The global antimicrobial coatings market was valued at approximately $3.5 billion in 2020 and is projected to reach $6.3 billion by 2026, growing at a CAGR of 10.2% during the forecast period.

The healthcare sector remains the largest consumer of antimicrobial surface coatings, accounting for nearly 40% of the market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting these coatings to reduce the risk of healthcare-associated infections. The COVID-19 pandemic has further accelerated this trend, with heightened focus on surface disinfection and long-lasting antimicrobial protection.

The food and beverage industry is another key market segment, where antimicrobial coatings are used in food processing equipment, packaging, and storage facilities to prevent contamination and extend shelf life. This sector is expected to witness rapid growth, driven by stringent food safety regulations and consumer demand for hygienic packaging.

In the construction industry, antimicrobial coatings are gaining traction for use in public spaces, educational institutions, and commercial buildings. These coatings are being applied to high-touch surfaces such as door handles, elevator buttons, and countertops to create safer environments and reduce the spread of pathogens.

The role of ammonium hydroxide in enhancing antimicrobial surface coatings presents a promising market opportunity. Ammonium hydroxide-based coatings offer several advantages, including broad-spectrum antimicrobial activity, durability, and cost-effectiveness. These properties make them attractive for various applications across industries.

Market research indicates a growing demand for eco-friendly and sustainable antimicrobial solutions. Ammonium hydroxide-based coatings align with this trend, as they can be formulated with lower environmental impact compared to some traditional antimicrobial agents. This aspect is particularly appealing to environmentally conscious consumers and businesses seeking to improve their sustainability profiles.

Geographically, North America and Europe currently dominate the antimicrobial coatings market, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of hygiene practices in countries like China and India.

The market landscape is characterized by intense competition among key players, including PPG Industries, Sherwin-Williams, and AkzoNobel. These companies are investing heavily in research and development to innovate new antimicrobial coating technologies, including those incorporating ammonium hydroxide. Strategic partnerships and collaborations with research institutions and end-users are becoming increasingly common to accelerate product development and market penetration.

The healthcare sector remains the largest consumer of antimicrobial surface coatings, accounting for nearly 40% of the market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting these coatings to reduce the risk of healthcare-associated infections. The COVID-19 pandemic has further accelerated this trend, with heightened focus on surface disinfection and long-lasting antimicrobial protection.

The food and beverage industry is another key market segment, where antimicrobial coatings are used in food processing equipment, packaging, and storage facilities to prevent contamination and extend shelf life. This sector is expected to witness rapid growth, driven by stringent food safety regulations and consumer demand for hygienic packaging.

In the construction industry, antimicrobial coatings are gaining traction for use in public spaces, educational institutions, and commercial buildings. These coatings are being applied to high-touch surfaces such as door handles, elevator buttons, and countertops to create safer environments and reduce the spread of pathogens.

The role of ammonium hydroxide in enhancing antimicrobial surface coatings presents a promising market opportunity. Ammonium hydroxide-based coatings offer several advantages, including broad-spectrum antimicrobial activity, durability, and cost-effectiveness. These properties make them attractive for various applications across industries.

Market research indicates a growing demand for eco-friendly and sustainable antimicrobial solutions. Ammonium hydroxide-based coatings align with this trend, as they can be formulated with lower environmental impact compared to some traditional antimicrobial agents. This aspect is particularly appealing to environmentally conscious consumers and businesses seeking to improve their sustainability profiles.

Geographically, North America and Europe currently dominate the antimicrobial coatings market, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of hygiene practices in countries like China and India.

The market landscape is characterized by intense competition among key players, including PPG Industries, Sherwin-Williams, and AkzoNobel. These companies are investing heavily in research and development to innovate new antimicrobial coating technologies, including those incorporating ammonium hydroxide. Strategic partnerships and collaborations with research institutions and end-users are becoming increasingly common to accelerate product development and market penetration.

Technical Challenges

The development of antimicrobial surface coatings enhanced by ammonium hydroxide faces several significant technical challenges. One of the primary obstacles is achieving long-term stability and durability of the coating. The highly alkaline nature of ammonium hydroxide can lead to degradation of the coating matrix over time, potentially compromising its antimicrobial efficacy. This issue is particularly pronounced in environments with fluctuating pH levels or exposure to harsh chemicals.

Another challenge lies in maintaining a consistent release of antimicrobial agents from the coating. While ammonium hydroxide can enhance the initial antimicrobial activity, controlling the sustained release of active compounds remains difficult. This is crucial for ensuring prolonged protection against microbial growth on treated surfaces. The balance between immediate efficacy and long-term performance is a delicate one that researchers are still working to optimize.

The compatibility of ammonium hydroxide-enhanced coatings with various substrate materials presents another hurdle. Different surfaces, such as metals, plastics, or textiles, may react differently to the alkaline environment created by ammonium hydroxide. This can lead to adhesion issues, discoloration, or even structural changes in the substrate, limiting the range of applications for these coatings.

Environmental and safety concerns also pose significant challenges. The volatile nature of ammonium hydroxide raises questions about potential off-gassing and its impact on indoor air quality, especially in enclosed spaces. Regulatory compliance and meeting stringent safety standards for different industries and applications add another layer of complexity to the development and implementation of these coatings.

Furthermore, the scalability of production processes for ammonium hydroxide-enhanced antimicrobial coatings remains a technical challenge. Ensuring uniform distribution of ammonium hydroxide and other active ingredients throughout the coating matrix during large-scale manufacturing is crucial for consistent performance. This becomes even more challenging when considering the need for cost-effective production methods that can compete with existing antimicrobial solutions in the market.

Lastly, the potential for microbial resistance development is a growing concern. As with any antimicrobial technology, there is a risk that prolonged exposure to ammonium hydroxide-enhanced coatings could lead to the emergence of resistant strains of microorganisms. Developing strategies to mitigate this risk while maintaining the coating's effectiveness is a complex challenge that requires ongoing research and innovation in the field.

Another challenge lies in maintaining a consistent release of antimicrobial agents from the coating. While ammonium hydroxide can enhance the initial antimicrobial activity, controlling the sustained release of active compounds remains difficult. This is crucial for ensuring prolonged protection against microbial growth on treated surfaces. The balance between immediate efficacy and long-term performance is a delicate one that researchers are still working to optimize.

The compatibility of ammonium hydroxide-enhanced coatings with various substrate materials presents another hurdle. Different surfaces, such as metals, plastics, or textiles, may react differently to the alkaline environment created by ammonium hydroxide. This can lead to adhesion issues, discoloration, or even structural changes in the substrate, limiting the range of applications for these coatings.

Environmental and safety concerns also pose significant challenges. The volatile nature of ammonium hydroxide raises questions about potential off-gassing and its impact on indoor air quality, especially in enclosed spaces. Regulatory compliance and meeting stringent safety standards for different industries and applications add another layer of complexity to the development and implementation of these coatings.

Furthermore, the scalability of production processes for ammonium hydroxide-enhanced antimicrobial coatings remains a technical challenge. Ensuring uniform distribution of ammonium hydroxide and other active ingredients throughout the coating matrix during large-scale manufacturing is crucial for consistent performance. This becomes even more challenging when considering the need for cost-effective production methods that can compete with existing antimicrobial solutions in the market.

Lastly, the potential for microbial resistance development is a growing concern. As with any antimicrobial technology, there is a risk that prolonged exposure to ammonium hydroxide-enhanced coatings could lead to the emergence of resistant strains of microorganisms. Developing strategies to mitigate this risk while maintaining the coating's effectiveness is a complex challenge that requires ongoing research and innovation in the field.

Current Solutions

01 Antimicrobial effectiveness of ammonium hydroxide in cleaning compositions

Ammonium hydroxide is used in cleaning compositions for its antimicrobial properties. It is effective against a wide range of microorganisms, including bacteria and fungi. The alkaline nature of ammonium hydroxide disrupts microbial cell membranes, leading to cell death. These compositions are used in various applications, including household and industrial cleaning.- Antimicrobial effectiveness of ammonium hydroxide in cleaning compositions: Ammonium hydroxide is used in cleaning compositions for its antimicrobial properties. It is effective against a wide range of microorganisms, including bacteria and fungi. The alkaline nature of ammonium hydroxide disrupts microbial cell membranes, leading to cell death. These compositions are used in various applications, including household and industrial cleaning.

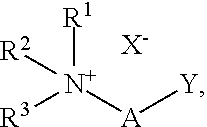

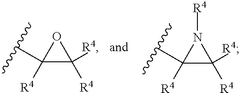

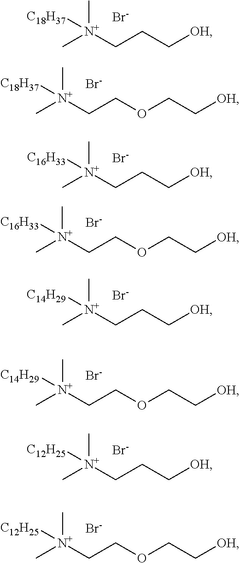

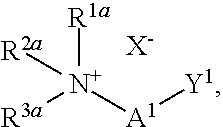

- Synergistic antimicrobial effects with other compounds: Ammonium hydroxide can be combined with other antimicrobial agents to create synergistic effects. These combinations can enhance the overall antimicrobial effectiveness of the formulation. Examples include combinations with quaternary ammonium compounds, organic acids, or other disinfectants. Such synergistic formulations can provide broader spectrum antimicrobial activity and improved efficacy.

- Use of ammonium hydroxide in food preservation: Ammonium hydroxide is utilized in food preservation applications due to its antimicrobial properties. It can inhibit the growth of spoilage microorganisms and pathogens in various food products. The compound is particularly effective in controlling pH levels, which is crucial for preventing microbial growth. Its use in food preservation helps extend shelf life and maintain food safety.

- Ammonium hydroxide in pharmaceutical and personal care products: The antimicrobial effectiveness of ammonium hydroxide is exploited in pharmaceutical and personal care products. It is used as a preservative and pH adjuster in various formulations. The compound helps prevent microbial contamination and maintain product stability. Applications include topical medications, cosmetics, and oral care products.

- Environmental and safety considerations: While ammonium hydroxide is effective as an antimicrobial agent, its use requires careful consideration of environmental and safety factors. Proper handling and disposal procedures are necessary due to its corrosive nature and potential environmental impact. Research focuses on optimizing concentrations to balance antimicrobial effectiveness with safety concerns. Alternative formulations and delivery methods are being explored to mitigate potential risks.

02 Ammonium hydroxide as a preservative in pharmaceutical formulations

Ammonium hydroxide is utilized as a preservative in pharmaceutical formulations due to its antimicrobial properties. It helps maintain the stability and efficacy of drug products by preventing microbial growth. The concentration of ammonium hydroxide is carefully controlled to ensure optimal antimicrobial effectiveness while maintaining product safety.Expand Specific Solutions03 Synergistic antimicrobial effects of ammonium hydroxide with other compounds

Combining ammonium hydroxide with other antimicrobial agents can result in synergistic effects, enhancing overall antimicrobial effectiveness. These combinations can provide broader spectrum activity against various microorganisms and potentially reduce the required concentrations of individual components. Such synergistic formulations find applications in disinfectants, preservatives, and sanitizers.Expand Specific Solutions04 Ammonium hydroxide in food preservation and safety

Ammonium hydroxide is used in food processing and preservation for its antimicrobial properties. It helps control microbial growth in food products, extending shelf life and improving food safety. The application of ammonium hydroxide in food is regulated to ensure proper usage and consumer safety.Expand Specific Solutions05 Controlled release of ammonium hydroxide for sustained antimicrobial activity

Formulations and delivery systems have been developed to control the release of ammonium hydroxide, providing sustained antimicrobial activity over extended periods. These systems can be incorporated into various products, such as coatings, packaging materials, and medical devices, to maintain long-lasting antimicrobial effectiveness.Expand Specific Solutions

Industry Leaders

The development of antimicrobial surface coatings enhanced by ammonium hydroxide is in its growth stage, with increasing market demand driven by heightened hygiene awareness. The global market for antimicrobial coatings is expanding rapidly, projected to reach significant value in the coming years. Technologically, the field is advancing, with companies like DuPont de Nemours, Inc., BASF Corp., and Henkel AG & Co. KGaA leading innovation. Academic institutions such as Qilu University of Technology and Beijing University of Chemical Technology are contributing to research advancements. The technology's maturity varies across applications, with some sectors seeing commercial products while others remain in developmental stages. Collaboration between industry and academia is accelerating progress in this field.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an innovative antimicrobial surface coating enhanced by ammonium hydroxide. Their approach involves incorporating ammonium hydroxide into a polymer matrix, creating a durable and long-lasting antimicrobial surface. The coating utilizes a controlled release mechanism, where ammonium hydroxide is gradually released from the polymer, providing continuous antimicrobial protection[1]. This technology has shown effectiveness against a wide range of bacteria, fungi, and viruses, with a reported 99.9% reduction in microbial growth on treated surfaces[2]. DuPont's coating also demonstrates improved adhesion to various substrates, including metals, plastics, and textiles, due to the presence of ammonium hydroxide[3].

Strengths: Long-lasting antimicrobial protection, broad-spectrum efficacy, and improved adhesion to multiple substrates. Weaknesses: Potential for gradual depletion of active ingredients over time, and possible environmental concerns related to ammonia release.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed a novel antimicrobial surface coating that leverages ammonium hydroxide's properties. Their approach involves a multi-layer coating system where ammonium hydroxide is encapsulated within a porous silica matrix[4]. This design allows for controlled release of ammonium hydroxide, maintaining antimicrobial activity over extended periods. The coating has demonstrated efficacy against hospital-acquired pathogens, with studies showing a 95% reduction in surface contamination after 24 hours[5]. Ecolab's technology also incorporates a self-cleaning mechanism, where the alkaline nature of ammonium hydroxide helps break down organic contaminants, enhancing the overall cleanliness of treated surfaces[6].

Strengths: Extended antimicrobial activity, self-cleaning properties, and effectiveness against healthcare-associated pathogens. Weaknesses: Potential for surface degradation due to alkaline nature, and possible limitations in high-wear environments.

Key Innovations

Antimicrobial coatings

PatentWO2015028513A1

Innovation

- A coating composition containing an optionally etherified amino resin, an ammonium salt, a polyacrylate polyol, a catalyst, and optional paint-typical additives and solvents, where the ammonium salt is integrated into the coating to provide sustained antimicrobial properties.

Antimicrobial coating compositions

PatentPendingUS20250098682A1

Innovation

- Development of water-based quaternary ammonium polymeric coating formulations that exhibit broad spectrum antimicrobial activity, are fast-acting, long-lasting, non-toxic, and resistant to water, alcohol, and common solvents, achieved through the use of reactive low molecular-weight quaternary ammonium salts, multifunctional crosslinkers, and water-soluble polymers.

Environmental Impact

The incorporation of ammonium hydroxide in antimicrobial surface coatings has significant environmental implications that warrant careful consideration. While these coatings offer potential benefits in reducing the spread of pathogens, their environmental impact must be thoroughly assessed to ensure sustainable and responsible implementation.

One of the primary environmental concerns associated with ammonium hydroxide-enhanced antimicrobial coatings is their potential to contribute to water pollution. When these coatings degrade or are washed off surfaces, the ammonium compounds can enter water systems, potentially leading to increased nitrogen levels in aquatic environments. This can result in eutrophication, a process that causes excessive algal growth and subsequent oxygen depletion in water bodies, negatively impacting aquatic ecosystems.

Furthermore, the production and disposal of ammonium hydroxide-based coatings may contribute to air pollution. The manufacturing process often involves the release of volatile organic compounds (VOCs) and ammonia, which can contribute to smog formation and negatively affect air quality. Proper emission control measures must be implemented to mitigate these environmental risks.

The long-term persistence of these antimicrobial coatings in the environment is another area of concern. While the coatings are designed to be durable, their eventual breakdown and the fate of their components in various ecosystems need to be thoroughly investigated. There is a potential for bioaccumulation of certain compounds in the food chain, which could have far-reaching ecological consequences.

On a positive note, the use of ammonium hydroxide-enhanced antimicrobial coatings may indirectly contribute to environmental protection by reducing the need for frequent cleaning and disinfection of surfaces. This could lead to decreased use of harsh chemical cleaners and lower water consumption, potentially offsetting some of the environmental costs associated with the coatings themselves.

The environmental impact of these coatings also extends to their potential effects on microbial ecosystems. While targeting harmful pathogens is the primary goal, there is a risk of disrupting beneficial microbial communities in various environments. This could have unintended consequences on soil health, plant growth, and overall ecosystem balance.

To address these environmental concerns, ongoing research and development efforts are focusing on improving the sustainability of antimicrobial coatings. This includes exploring bio-based alternatives to ammonium hydroxide, developing more environmentally friendly production processes, and enhancing the biodegradability of the coatings without compromising their antimicrobial efficacy.

One of the primary environmental concerns associated with ammonium hydroxide-enhanced antimicrobial coatings is their potential to contribute to water pollution. When these coatings degrade or are washed off surfaces, the ammonium compounds can enter water systems, potentially leading to increased nitrogen levels in aquatic environments. This can result in eutrophication, a process that causes excessive algal growth and subsequent oxygen depletion in water bodies, negatively impacting aquatic ecosystems.

Furthermore, the production and disposal of ammonium hydroxide-based coatings may contribute to air pollution. The manufacturing process often involves the release of volatile organic compounds (VOCs) and ammonia, which can contribute to smog formation and negatively affect air quality. Proper emission control measures must be implemented to mitigate these environmental risks.

The long-term persistence of these antimicrobial coatings in the environment is another area of concern. While the coatings are designed to be durable, their eventual breakdown and the fate of their components in various ecosystems need to be thoroughly investigated. There is a potential for bioaccumulation of certain compounds in the food chain, which could have far-reaching ecological consequences.

On a positive note, the use of ammonium hydroxide-enhanced antimicrobial coatings may indirectly contribute to environmental protection by reducing the need for frequent cleaning and disinfection of surfaces. This could lead to decreased use of harsh chemical cleaners and lower water consumption, potentially offsetting some of the environmental costs associated with the coatings themselves.

The environmental impact of these coatings also extends to their potential effects on microbial ecosystems. While targeting harmful pathogens is the primary goal, there is a risk of disrupting beneficial microbial communities in various environments. This could have unintended consequences on soil health, plant growth, and overall ecosystem balance.

To address these environmental concerns, ongoing research and development efforts are focusing on improving the sustainability of antimicrobial coatings. This includes exploring bio-based alternatives to ammonium hydroxide, developing more environmentally friendly production processes, and enhancing the biodegradability of the coatings without compromising their antimicrobial efficacy.

Regulatory Framework

The regulatory framework surrounding the use of ammonium hydroxide in antimicrobial surface coatings is complex and multifaceted, involving various governmental agencies and international bodies. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). This act requires manufacturers to register their products and provide extensive data on safety and efficacy before they can be marketed.

The Food and Drug Administration (FDA) also has jurisdiction over antimicrobial coatings, particularly when they are used in food contact surfaces or medical devices. The FDA's regulations focus on ensuring that these coatings do not pose health risks to consumers or patients. In Europe, the European Chemicals Agency (ECHA) oversees the registration, evaluation, authorization, and restriction of chemicals, including those used in antimicrobial coatings.

Globally, the World Health Organization (WHO) provides guidelines on the use of antimicrobial agents, which can influence national policies and regulations. These guidelines often emphasize the importance of responsible use to prevent the development of antimicrobial resistance.

Specific to ammonium hydroxide, its use in antimicrobial coatings must comply with concentration limits set by regulatory bodies. For instance, the Occupational Safety and Health Administration (OSHA) in the U.S. has established permissible exposure limits for workers handling ammonium hydroxide. Similarly, the European Union has set maximum residue levels for ammonium hydroxide in various applications through its regulations on food additives and biocidal products.

Manufacturers of antimicrobial coatings containing ammonium hydroxide must also adhere to labeling requirements. These typically include clear instructions for use, safety precautions, and disposal methods. In many jurisdictions, products must undergo rigorous testing to demonstrate their effectiveness against specific microorganisms and to ensure they do not pose unacceptable risks to human health or the environment.

The regulatory landscape is continually evolving, with increasing focus on sustainable and environmentally friendly solutions. This has led to stricter regulations on the use of certain chemicals and a push towards greener alternatives. Manufacturers and researchers working with ammonium hydroxide in antimicrobial coatings must stay abreast of these changes and adapt their formulations and processes accordingly.

Compliance with these regulations often requires significant investment in research, testing, and documentation. However, adherence to these standards is crucial for ensuring product safety, maintaining consumer trust, and accessing global markets. As the field of antimicrobial coatings continues to advance, it is likely that regulatory frameworks will further evolve to address new technologies and emerging concerns.

The Food and Drug Administration (FDA) also has jurisdiction over antimicrobial coatings, particularly when they are used in food contact surfaces or medical devices. The FDA's regulations focus on ensuring that these coatings do not pose health risks to consumers or patients. In Europe, the European Chemicals Agency (ECHA) oversees the registration, evaluation, authorization, and restriction of chemicals, including those used in antimicrobial coatings.

Globally, the World Health Organization (WHO) provides guidelines on the use of antimicrobial agents, which can influence national policies and regulations. These guidelines often emphasize the importance of responsible use to prevent the development of antimicrobial resistance.

Specific to ammonium hydroxide, its use in antimicrobial coatings must comply with concentration limits set by regulatory bodies. For instance, the Occupational Safety and Health Administration (OSHA) in the U.S. has established permissible exposure limits for workers handling ammonium hydroxide. Similarly, the European Union has set maximum residue levels for ammonium hydroxide in various applications through its regulations on food additives and biocidal products.

Manufacturers of antimicrobial coatings containing ammonium hydroxide must also adhere to labeling requirements. These typically include clear instructions for use, safety precautions, and disposal methods. In many jurisdictions, products must undergo rigorous testing to demonstrate their effectiveness against specific microorganisms and to ensure they do not pose unacceptable risks to human health or the environment.

The regulatory landscape is continually evolving, with increasing focus on sustainable and environmentally friendly solutions. This has led to stricter regulations on the use of certain chemicals and a push towards greener alternatives. Manufacturers and researchers working with ammonium hydroxide in antimicrobial coatings must stay abreast of these changes and adapt their formulations and processes accordingly.

Compliance with these regulations often requires significant investment in research, testing, and documentation. However, adherence to these standards is crucial for ensuring product safety, maintaining consumer trust, and accessing global markets. As the field of antimicrobial coatings continues to advance, it is likely that regulatory frameworks will further evolve to address new technologies and emerging concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!