How Ammonium Hydroxide Enhances Antimicrobial Properties in Coatings

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide Antimicrobial Coatings: Background and Objectives

Ammonium hydroxide has emerged as a significant component in the development of antimicrobial coatings, marking a notable advancement in surface protection technologies. The evolution of this field can be traced back to the early 20th century when the antimicrobial properties of various chemical compounds began to be systematically studied. However, it was not until recent decades that the potential of ammonium hydroxide in enhancing antimicrobial efficacy in coatings gained substantial attention.

The journey of incorporating ammonium hydroxide into antimicrobial coatings has been driven by the increasing demand for more effective and sustainable solutions to combat microbial growth on various surfaces. This demand has been particularly pronounced in healthcare, food processing, and public spaces, where maintaining hygienic conditions is paramount. The rise of antibiotic-resistant bacteria and the global focus on preventing the spread of infectious diseases have further accelerated research in this area.

Ammonium hydroxide, a solution of ammonia in water, has been known for its cleaning and disinfecting properties for centuries. Its integration into coating technologies represents a convergence of traditional knowledge and modern materials science. The key breakthrough came with the realization that ammonium hydroxide could not only provide immediate antimicrobial action but also potentially create a long-lasting protective environment when properly incorporated into coating matrices.

The technical objectives in this field are multifaceted and ambitious. Researchers and industry professionals are striving to develop coatings that exhibit broad-spectrum antimicrobial activity, long-term effectiveness, and minimal environmental impact. The goal is to create surfaces that can actively resist microbial colonization and biofilm formation, thereby reducing the risk of pathogen transmission and enhancing overall hygiene standards.

One of the primary technical challenges lies in optimizing the concentration and release mechanism of ammonium hydroxide within the coating. The aim is to achieve a balance where the antimicrobial effect is potent enough to be effective against a wide range of microorganisms, yet controlled enough to ensure longevity and prevent rapid depletion of the active component. Additionally, there is a focus on developing formulations that are compatible with various substrate materials and can withstand different environmental conditions without compromising their antimicrobial efficacy.

As research in this area progresses, there is an increasing emphasis on understanding the molecular mechanisms by which ammonium hydroxide enhances antimicrobial properties. This includes investigating its interactions with microbial cell membranes, its role in disrupting cellular processes, and its synergistic effects with other antimicrobial agents. The ultimate objective is to leverage these insights to design next-generation coatings that offer superior protection against a broad spectrum of pathogens while meeting stringent safety and environmental standards.

The journey of incorporating ammonium hydroxide into antimicrobial coatings has been driven by the increasing demand for more effective and sustainable solutions to combat microbial growth on various surfaces. This demand has been particularly pronounced in healthcare, food processing, and public spaces, where maintaining hygienic conditions is paramount. The rise of antibiotic-resistant bacteria and the global focus on preventing the spread of infectious diseases have further accelerated research in this area.

Ammonium hydroxide, a solution of ammonia in water, has been known for its cleaning and disinfecting properties for centuries. Its integration into coating technologies represents a convergence of traditional knowledge and modern materials science. The key breakthrough came with the realization that ammonium hydroxide could not only provide immediate antimicrobial action but also potentially create a long-lasting protective environment when properly incorporated into coating matrices.

The technical objectives in this field are multifaceted and ambitious. Researchers and industry professionals are striving to develop coatings that exhibit broad-spectrum antimicrobial activity, long-term effectiveness, and minimal environmental impact. The goal is to create surfaces that can actively resist microbial colonization and biofilm formation, thereby reducing the risk of pathogen transmission and enhancing overall hygiene standards.

One of the primary technical challenges lies in optimizing the concentration and release mechanism of ammonium hydroxide within the coating. The aim is to achieve a balance where the antimicrobial effect is potent enough to be effective against a wide range of microorganisms, yet controlled enough to ensure longevity and prevent rapid depletion of the active component. Additionally, there is a focus on developing formulations that are compatible with various substrate materials and can withstand different environmental conditions without compromising their antimicrobial efficacy.

As research in this area progresses, there is an increasing emphasis on understanding the molecular mechanisms by which ammonium hydroxide enhances antimicrobial properties. This includes investigating its interactions with microbial cell membranes, its role in disrupting cellular processes, and its synergistic effects with other antimicrobial agents. The ultimate objective is to leverage these insights to design next-generation coatings that offer superior protection against a broad spectrum of pathogens while meeting stringent safety and environmental standards.

Market Analysis for Antimicrobial Coating Solutions

The global market for antimicrobial coatings has experienced significant growth in recent years, driven by increasing awareness of hygiene and the need for infection control across various industries. The COVID-19 pandemic has further accelerated this trend, with a heightened focus on surface disinfection and long-lasting antimicrobial protection.

The healthcare sector remains the largest consumer of antimicrobial coatings, accounting for a substantial portion of the market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting these coatings to reduce the risk of healthcare-associated infections. The food and beverage industry is another key market, where antimicrobial coatings are used to maintain hygiene standards in processing and packaging facilities.

Construction and automotive industries are emerging as promising growth sectors for antimicrobial coatings. In construction, these coatings are being applied to high-touch surfaces in public spaces, while automotive manufacturers are exploring their use in vehicle interiors to enhance passenger safety.

Geographically, North America and Europe lead the market due to stringent regulations and high healthcare expenditure. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing healthcare investments, and growing awareness of hygiene standards.

The market is characterized by intense competition among key players, including PPG Industries, Sherwin-Williams, and AkzoNobel. These companies are investing heavily in research and development to improve the efficacy and durability of their antimicrobial coating solutions. There is a growing focus on developing environmentally friendly and non-toxic formulations to meet regulatory requirements and consumer preferences.

Ammonium hydroxide-enhanced antimicrobial coatings represent a niche but growing segment within this market. The unique properties of ammonium hydroxide, including its ability to increase pH and disrupt microbial cell membranes, make it an attractive additive for enhancing the antimicrobial efficacy of coatings. This technology is particularly relevant in applications requiring long-lasting antimicrobial activity and resistance to harsh cleaning protocols.

The healthcare sector remains the largest consumer of antimicrobial coatings, accounting for a substantial portion of the market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting these coatings to reduce the risk of healthcare-associated infections. The food and beverage industry is another key market, where antimicrobial coatings are used to maintain hygiene standards in processing and packaging facilities.

Construction and automotive industries are emerging as promising growth sectors for antimicrobial coatings. In construction, these coatings are being applied to high-touch surfaces in public spaces, while automotive manufacturers are exploring their use in vehicle interiors to enhance passenger safety.

Geographically, North America and Europe lead the market due to stringent regulations and high healthcare expenditure. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing healthcare investments, and growing awareness of hygiene standards.

The market is characterized by intense competition among key players, including PPG Industries, Sherwin-Williams, and AkzoNobel. These companies are investing heavily in research and development to improve the efficacy and durability of their antimicrobial coating solutions. There is a growing focus on developing environmentally friendly and non-toxic formulations to meet regulatory requirements and consumer preferences.

Ammonium hydroxide-enhanced antimicrobial coatings represent a niche but growing segment within this market. The unique properties of ammonium hydroxide, including its ability to increase pH and disrupt microbial cell membranes, make it an attractive additive for enhancing the antimicrobial efficacy of coatings. This technology is particularly relevant in applications requiring long-lasting antimicrobial activity and resistance to harsh cleaning protocols.

Current Challenges in Antimicrobial Coating Technology

Despite significant advancements in antimicrobial coating technology, several challenges persist in the development and application of effective coatings enhanced with ammonium hydroxide. One of the primary obstacles is achieving long-term efficacy. While ammonium hydroxide can provide initial antimicrobial properties, maintaining these effects over extended periods remains difficult. Environmental factors, such as humidity and temperature fluctuations, can degrade the coating's performance over time, necessitating frequent reapplication or maintenance.

Another challenge lies in balancing antimicrobial effectiveness with potential toxicity. Although ammonium hydroxide enhances antimicrobial properties, its concentration must be carefully controlled to avoid harmful effects on human health and the environment. This delicate balance often requires extensive testing and optimization, which can prolong development timelines and increase costs.

Compatibility issues between ammonium hydroxide and various substrate materials present another hurdle. Certain surfaces may react adversely with ammonium hydroxide, leading to discoloration, corrosion, or degradation of the underlying material. This limitation restricts the range of applications and requires tailored formulations for different substrates.

The development of resistance in microorganisms poses a significant long-term challenge. As with many antimicrobial agents, there is a risk that bacteria and other pathogens may adapt to ammonium hydroxide-enhanced coatings over time, reducing their effectiveness. This necessitates ongoing research into novel formulations and combinations of antimicrobial agents to stay ahead of evolving microbial threats.

Regulatory compliance and safety standards also present obstacles in the widespread adoption of ammonium hydroxide-enhanced antimicrobial coatings. Stringent regulations regarding the use of chemical agents in various industries, particularly in healthcare and food processing, require extensive documentation and testing to ensure safety and efficacy.

Scalability and cost-effectiveness remain significant challenges in the commercialization of these coatings. While laboratory results may demonstrate promising antimicrobial properties, translating these findings into large-scale, economically viable production processes often proves difficult. The cost of raw materials, specialized equipment, and quality control measures can impact the overall feasibility of widespread implementation.

Lastly, the environmental impact of ammonium hydroxide-enhanced coatings is a growing concern. As sustainability becomes increasingly important across industries, there is a need to develop eco-friendly formulations that maintain antimicrobial efficacy while minimizing environmental harm. This challenge requires innovative approaches to coating design and material selection.

Another challenge lies in balancing antimicrobial effectiveness with potential toxicity. Although ammonium hydroxide enhances antimicrobial properties, its concentration must be carefully controlled to avoid harmful effects on human health and the environment. This delicate balance often requires extensive testing and optimization, which can prolong development timelines and increase costs.

Compatibility issues between ammonium hydroxide and various substrate materials present another hurdle. Certain surfaces may react adversely with ammonium hydroxide, leading to discoloration, corrosion, or degradation of the underlying material. This limitation restricts the range of applications and requires tailored formulations for different substrates.

The development of resistance in microorganisms poses a significant long-term challenge. As with many antimicrobial agents, there is a risk that bacteria and other pathogens may adapt to ammonium hydroxide-enhanced coatings over time, reducing their effectiveness. This necessitates ongoing research into novel formulations and combinations of antimicrobial agents to stay ahead of evolving microbial threats.

Regulatory compliance and safety standards also present obstacles in the widespread adoption of ammonium hydroxide-enhanced antimicrobial coatings. Stringent regulations regarding the use of chemical agents in various industries, particularly in healthcare and food processing, require extensive documentation and testing to ensure safety and efficacy.

Scalability and cost-effectiveness remain significant challenges in the commercialization of these coatings. While laboratory results may demonstrate promising antimicrobial properties, translating these findings into large-scale, economically viable production processes often proves difficult. The cost of raw materials, specialized equipment, and quality control measures can impact the overall feasibility of widespread implementation.

Lastly, the environmental impact of ammonium hydroxide-enhanced coatings is a growing concern. As sustainability becomes increasingly important across industries, there is a need to develop eco-friendly formulations that maintain antimicrobial efficacy while minimizing environmental harm. This challenge requires innovative approaches to coating design and material selection.

Existing Ammonium Hydroxide-Based Coating Solutions

01 Antimicrobial compositions containing ammonium hydroxide

Ammonium hydroxide is used in various antimicrobial compositions due to its ability to inhibit or kill microorganisms. These compositions can be formulated for different applications, including disinfectants, preservatives, and sanitizers. The alkaline nature of ammonium hydroxide contributes to its antimicrobial properties by disrupting microbial cell membranes and altering cellular pH.- Antimicrobial compositions containing ammonium hydroxide: Ammonium hydroxide is used as a key component in antimicrobial compositions. These formulations leverage the alkaline properties of ammonium hydroxide to create an environment inhospitable to various microorganisms. The compositions can be applied in various settings for disinfection and sanitization purposes.

- Synergistic effects with other antimicrobial agents: Ammonium hydroxide is often combined with other antimicrobial agents to enhance its effectiveness. These combinations can result in synergistic effects, broadening the spectrum of antimicrobial activity and potentially reducing the required concentrations of individual components.

- Application in food preservation and safety: The antimicrobial properties of ammonium hydroxide are utilized in food preservation and safety applications. It can be incorporated into food processing methods or packaging materials to inhibit microbial growth and extend shelf life of various food products.

- Use in agricultural and horticultural settings: Ammonium hydroxide-based formulations are employed in agricultural and horticultural contexts for their antimicrobial properties. These applications can include seed treatments, soil amendments, or foliar sprays to control plant pathogens and promote crop health.

- Incorporation into cleaning and disinfecting products: The antimicrobial properties of ammonium hydroxide are leveraged in the formulation of cleaning and disinfecting products. These products can be used for household, industrial, or institutional applications to sanitize surfaces and control microbial contamination.

02 Synergistic effects with other antimicrobial agents

Ammonium hydroxide can be combined with other antimicrobial agents to enhance overall efficacy. These combinations may exhibit synergistic effects, allowing for broader spectrum antimicrobial activity or improved performance against specific pathogens. Such formulations can be particularly useful in applications requiring robust antimicrobial protection.Expand Specific Solutions03 Use in food preservation and safety

Ammonium hydroxide is utilized in food preservation and safety applications due to its antimicrobial properties. It can be incorporated into food processing methods or packaging materials to inhibit microbial growth and extend shelf life. The compound's ability to control pH also contributes to its effectiveness in food preservation.Expand Specific Solutions04 Application in personal care and hygiene products

The antimicrobial properties of ammonium hydroxide make it suitable for use in personal care and hygiene products. It can be incorporated into formulations for hand sanitizers, soaps, and other cleansing products to provide antimicrobial protection. The compound's ability to adjust pH also contributes to its effectiveness in these applications.Expand Specific Solutions05 Environmental and industrial applications

Ammonium hydroxide's antimicrobial properties are utilized in various environmental and industrial applications. These include water treatment, surface disinfection, and industrial cleaning processes. The compound's effectiveness against a wide range of microorganisms makes it valuable in maintaining hygiene and preventing microbial contamination in diverse settings.Expand Specific Solutions

Key Players in Antimicrobial Coating Industry

The antimicrobial coatings market is in a growth phase, driven by increasing demand for hygiene and safety across various industries. The global market size is projected to expand significantly, with a compound annual growth rate exceeding 10% in the coming years. Technological maturity varies among key players, with established companies like Ecolab USA, Inc., Henkel AG & Co. KGaA, and The Sherwin-Williams Co. leading in innovation and product development. Emerging players such as Nano Safe Coatings Inc and Surface Technologies GmbH & Co. KG are also contributing to advancements in the field. The integration of ammonium hydroxide in antimicrobial coatings represents a promising area for research and development, with potential applications across multiple sectors including healthcare, food processing, and consumer goods.

Ecolab USA, Inc.

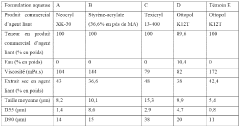

Technical Solution: Ecolab has developed an innovative coating technology that incorporates ammonium hydroxide to enhance antimicrobial properties. Their approach involves creating a stable emulsion of ammonium hydroxide within a polymer matrix, allowing for controlled release of the antimicrobial agent. This technology utilizes a proprietary blend of surfactants and stabilizers to maintain the emulsion's integrity over extended periods[1]. The coating formulation also includes additional synergistic compounds that work in conjunction with ammonium hydroxide to broaden the spectrum of antimicrobial activity[3]. Ecolab's solution has shown particular efficacy in food processing environments, where it can be applied to surfaces to prevent bacterial contamination and biofilm formation[5].

Strengths: Long-lasting antimicrobial efficacy, particularly effective in food processing environments. Weaknesses: May require periodic reapplication in high-traffic areas, potential for ammonia odor in some applications.

The Sherwin-Williams Co.

Technical Solution: Sherwin-Williams has developed an innovative antimicrobial coating system that leverages the properties of ammonium hydroxide. Their approach involves creating a multi-layered coating structure where ammonium hydroxide is incorporated into a porous intermediate layer[1]. This design allows for the gradual diffusion of the antimicrobial agent to the surface, providing sustained protection. The company has also developed a proprietary surface treatment that enhances the adhesion of the ammonium hydroxide-containing layer to various substrates, improving overall durability[3]. Additionally, Sherwin-Williams has incorporated UV-resistant additives to prevent degradation of the antimicrobial compounds when exposed to sunlight, extending the coating's effective lifespan[5].

Strengths: Multi-layered design for sustained release, improved adhesion to various substrates, UV-resistant formulation. Weaknesses: Complex application process may increase installation costs, potential for reduced efficacy in high-moisture environments.

Core Innovations in Ammonium Hydroxide Antimicrobial Mechanisms

Antimicrobial coatings

PatentWO2015028513A1

Innovation

- A coating composition containing an optionally etherified amino resin, an ammonium salt, a polyacrylate polyol, a catalyst, and optional paint-typical additives and solvents, where the ammonium salt is integrated into the coating to provide sustained antimicrobial properties.

Aqueous antimicrobial composition

PatentWO2023213977A1

Innovation

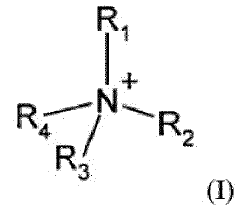

- An aqueous antimicrobial composition with a viscosity ranging from 5 to 500 mPa.s, comprising 0.05% to 5% non-polymeric quaternary ammonium salts and a polymeric binding agent with a number average particle size or droplet size greater than or equal to 7 μm, allowing for surface deposition via various techniques like spraying, impregnation, or printing.

Environmental Impact of Ammonium Hydroxide Coatings

The environmental impact of ammonium hydroxide coatings is a critical consideration in their application and development. These coatings, while effective in enhancing antimicrobial properties, can have both positive and negative effects on the environment.

One of the primary environmental benefits of ammonium hydroxide coatings is their potential to reduce the use of traditional, more harmful antimicrobial agents. By providing a long-lasting antimicrobial effect, these coatings can decrease the need for frequent application of chemical disinfectants, thereby reducing overall chemical exposure in the environment.

However, the production and application of ammonium hydroxide coatings are not without environmental concerns. The manufacturing process of these coatings may involve the use of volatile organic compounds (VOCs) and other potentially harmful chemicals. These substances can contribute to air pollution and pose risks to both human health and ecosystems if not properly managed.

The disposal of products treated with ammonium hydroxide coatings also presents environmental challenges. As these coatings wear off or degrade over time, they may release ammonia and other compounds into the environment. This can lead to increased nitrogen levels in soil and water systems, potentially contributing to eutrophication in aquatic environments.

Furthermore, the persistence of antimicrobial agents in the environment raises concerns about the development of antimicrobial resistance. While ammonium hydroxide coatings aim to inhibit microbial growth, their widespread use could potentially lead to the evolution of resistant microbial strains, which could have far-reaching ecological consequences.

On the other hand, the use of ammonium hydroxide coatings in certain applications can indirectly benefit the environment. For instance, in food packaging, these coatings can extend the shelf life of products, potentially reducing food waste and the associated environmental impacts of food production and disposal.

The environmental impact of these coatings also depends on their specific formulation and application method. Advances in coating technology are focusing on developing more environmentally friendly versions, such as water-based formulations with lower VOC content and improved biodegradability.

Regulatory bodies are increasingly scrutinizing the environmental impact of antimicrobial coatings. This has led to stricter guidelines for their production, use, and disposal, encouraging manufacturers to invest in more sustainable alternatives and improved lifecycle assessments of their products.

In conclusion, while ammonium hydroxide coatings offer significant antimicrobial benefits, their environmental impact is complex and multifaceted. Balancing their efficacy with environmental sustainability remains a key challenge for researchers and manufacturers in this field.

One of the primary environmental benefits of ammonium hydroxide coatings is their potential to reduce the use of traditional, more harmful antimicrobial agents. By providing a long-lasting antimicrobial effect, these coatings can decrease the need for frequent application of chemical disinfectants, thereby reducing overall chemical exposure in the environment.

However, the production and application of ammonium hydroxide coatings are not without environmental concerns. The manufacturing process of these coatings may involve the use of volatile organic compounds (VOCs) and other potentially harmful chemicals. These substances can contribute to air pollution and pose risks to both human health and ecosystems if not properly managed.

The disposal of products treated with ammonium hydroxide coatings also presents environmental challenges. As these coatings wear off or degrade over time, they may release ammonia and other compounds into the environment. This can lead to increased nitrogen levels in soil and water systems, potentially contributing to eutrophication in aquatic environments.

Furthermore, the persistence of antimicrobial agents in the environment raises concerns about the development of antimicrobial resistance. While ammonium hydroxide coatings aim to inhibit microbial growth, their widespread use could potentially lead to the evolution of resistant microbial strains, which could have far-reaching ecological consequences.

On the other hand, the use of ammonium hydroxide coatings in certain applications can indirectly benefit the environment. For instance, in food packaging, these coatings can extend the shelf life of products, potentially reducing food waste and the associated environmental impacts of food production and disposal.

The environmental impact of these coatings also depends on their specific formulation and application method. Advances in coating technology are focusing on developing more environmentally friendly versions, such as water-based formulations with lower VOC content and improved biodegradability.

Regulatory bodies are increasingly scrutinizing the environmental impact of antimicrobial coatings. This has led to stricter guidelines for their production, use, and disposal, encouraging manufacturers to invest in more sustainable alternatives and improved lifecycle assessments of their products.

In conclusion, while ammonium hydroxide coatings offer significant antimicrobial benefits, their environmental impact is complex and multifaceted. Balancing their efficacy with environmental sustainability remains a key challenge for researchers and manufacturers in this field.

Regulatory Framework for Antimicrobial Coating Products

The regulatory framework for antimicrobial coating products is a complex and evolving landscape that plays a crucial role in ensuring the safety and efficacy of these innovative materials. In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing antimicrobial coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). This act requires manufacturers to register their products and provide extensive data on their safety and effectiveness before they can be marketed.

The EPA's review process for antimicrobial coatings is rigorous, often taking several years to complete. It involves a thorough assessment of the product's chemical composition, including the role of ammonium hydroxide in enhancing antimicrobial properties. Manufacturers must demonstrate that their coatings are effective against specific microorganisms and that they do not pose unreasonable risks to human health or the environment.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antimicrobial coatings. This regulation aims to harmonize the market for biocidal products while ensuring a high level of protection for humans and the environment. Under the BPR, active substances used in antimicrobial coatings must be approved at the EU level before products containing them can be authorized for use in individual member states.

The regulatory framework also addresses labeling requirements for antimicrobial coating products. In both the US and EU, manufacturers must provide clear and accurate information about the product's intended use, active ingredients, and potential risks. This includes specific guidelines on how to make antimicrobial claims without misleading consumers or overstating the product's capabilities.

As the technology behind antimicrobial coatings advances, regulatory bodies are continually updating their frameworks to keep pace. This includes developing new testing protocols to evaluate the long-term effectiveness of coatings and their potential for contributing to antimicrobial resistance. The use of ammonium hydroxide in these coatings is subject to ongoing scrutiny, with regulators assessing its safety profile and environmental impact.

International standards organizations, such as ISO and ASTM, also play a role in shaping the regulatory landscape. These organizations develop standardized testing methods and performance criteria for antimicrobial coatings, which are often incorporated into national and regional regulations. This helps ensure consistency in product evaluation across different jurisdictions and facilitates global trade in antimicrobial coating products.

The EPA's review process for antimicrobial coatings is rigorous, often taking several years to complete. It involves a thorough assessment of the product's chemical composition, including the role of ammonium hydroxide in enhancing antimicrobial properties. Manufacturers must demonstrate that their coatings are effective against specific microorganisms and that they do not pose unreasonable risks to human health or the environment.

In the European Union, the Biocidal Products Regulation (BPR) governs the use of antimicrobial coatings. This regulation aims to harmonize the market for biocidal products while ensuring a high level of protection for humans and the environment. Under the BPR, active substances used in antimicrobial coatings must be approved at the EU level before products containing them can be authorized for use in individual member states.

The regulatory framework also addresses labeling requirements for antimicrobial coating products. In both the US and EU, manufacturers must provide clear and accurate information about the product's intended use, active ingredients, and potential risks. This includes specific guidelines on how to make antimicrobial claims without misleading consumers or overstating the product's capabilities.

As the technology behind antimicrobial coatings advances, regulatory bodies are continually updating their frameworks to keep pace. This includes developing new testing protocols to evaluate the long-term effectiveness of coatings and their potential for contributing to antimicrobial resistance. The use of ammonium hydroxide in these coatings is subject to ongoing scrutiny, with regulators assessing its safety profile and environmental impact.

International standards organizations, such as ISO and ASTM, also play a role in shaping the regulatory landscape. These organizations develop standardized testing methods and performance criteria for antimicrobial coatings, which are often incorporated into national and regional regulations. This helps ensure consistency in product evaluation across different jurisdictions and facilitates global trade in antimicrobial coating products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!