Impacts of Ammonium Hydroxide on Biological Waste Anoxic Fermentation

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Anoxic Fermentation: Background and Objectives

Anoxic fermentation of biological waste has emerged as a promising approach for sustainable waste management and renewable energy production. This process harnesses the metabolic capabilities of microorganisms to break down organic matter in the absence of oxygen, yielding valuable byproducts such as biogas and organic acids. In recent years, the potential impact of ammonium hydroxide on this process has garnered significant attention from researchers and industry professionals alike.

The historical development of anoxic fermentation can be traced back to the early 20th century, with initial applications primarily focused on wastewater treatment. However, it wasn't until the 1970s that the technology gained traction as a means of producing biogas from organic waste. The introduction of ammonium hydroxide into this process represents a relatively recent innovation, aimed at optimizing fermentation conditions and enhancing product yields.

Ammonium hydroxide, a solution of ammonia in water, has been recognized for its potential to influence various aspects of the anoxic fermentation process. Its primary roles include pH regulation, nitrogen supplementation, and microbial community modulation. By carefully controlling the addition of ammonium hydroxide, researchers and engineers aim to create more favorable conditions for the growth and activity of key microbial populations involved in the fermentation process.

The technological evolution in this field has been driven by the growing need for efficient waste management solutions and the increasing demand for renewable energy sources. As global concerns about environmental sustainability and resource depletion continue to mount, the optimization of anoxic fermentation processes has become a critical area of research and development.

Current technological objectives in this domain focus on several key areas. Firstly, there is a push to enhance the overall efficiency of the fermentation process, maximizing the conversion of organic waste into valuable products. Secondly, researchers are working to improve the stability and resilience of the microbial communities involved, ensuring consistent performance across varying waste compositions and environmental conditions. Additionally, there is a growing interest in developing more precise control mechanisms for ammonium hydroxide dosing, allowing for real-time adjustments based on process parameters.

Looking ahead, the field of anoxic fermentation, particularly with respect to ammonium hydroxide utilization, is poised for significant advancements. Emerging trends include the integration of advanced monitoring and control systems, the development of tailored microbial consortia, and the exploration of novel reactor designs. These innovations aim to further enhance the efficiency, reliability, and scalability of anoxic fermentation processes, paving the way for wider industrial adoption and contributing to a more sustainable future.

The historical development of anoxic fermentation can be traced back to the early 20th century, with initial applications primarily focused on wastewater treatment. However, it wasn't until the 1970s that the technology gained traction as a means of producing biogas from organic waste. The introduction of ammonium hydroxide into this process represents a relatively recent innovation, aimed at optimizing fermentation conditions and enhancing product yields.

Ammonium hydroxide, a solution of ammonia in water, has been recognized for its potential to influence various aspects of the anoxic fermentation process. Its primary roles include pH regulation, nitrogen supplementation, and microbial community modulation. By carefully controlling the addition of ammonium hydroxide, researchers and engineers aim to create more favorable conditions for the growth and activity of key microbial populations involved in the fermentation process.

The technological evolution in this field has been driven by the growing need for efficient waste management solutions and the increasing demand for renewable energy sources. As global concerns about environmental sustainability and resource depletion continue to mount, the optimization of anoxic fermentation processes has become a critical area of research and development.

Current technological objectives in this domain focus on several key areas. Firstly, there is a push to enhance the overall efficiency of the fermentation process, maximizing the conversion of organic waste into valuable products. Secondly, researchers are working to improve the stability and resilience of the microbial communities involved, ensuring consistent performance across varying waste compositions and environmental conditions. Additionally, there is a growing interest in developing more precise control mechanisms for ammonium hydroxide dosing, allowing for real-time adjustments based on process parameters.

Looking ahead, the field of anoxic fermentation, particularly with respect to ammonium hydroxide utilization, is poised for significant advancements. Emerging trends include the integration of advanced monitoring and control systems, the development of tailored microbial consortia, and the exploration of novel reactor designs. These innovations aim to further enhance the efficiency, reliability, and scalability of anoxic fermentation processes, paving the way for wider industrial adoption and contributing to a more sustainable future.

Market Analysis for Biological Waste Treatment Technologies

The biological waste treatment market has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations regarding waste management. The global market for biological waste treatment technologies is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the rising awareness of sustainable waste management practices and the need for efficient, eco-friendly solutions.

Within this broader market, the segment focusing on anoxic fermentation of biological waste has gained particular attention. This process, which involves the breakdown of organic matter in the absence of oxygen, offers several advantages over traditional aerobic treatment methods. These benefits include lower energy consumption, reduced sludge production, and the potential for biogas generation. As a result, industries and municipalities are increasingly adopting anoxic fermentation technologies for waste treatment.

The impact of ammonium hydroxide on biological waste anoxic fermentation represents a niche but growing area of interest within the market. Ammonium hydroxide, when used in controlled amounts, can potentially enhance the fermentation process by regulating pH levels and providing a source of nitrogen for microbial growth. This application has sparked interest among waste treatment facility operators and technology providers, as it offers the possibility of improving process efficiency and biogas yield.

Market demand for technologies that can optimize anoxic fermentation processes is on the rise. Waste treatment facilities are seeking solutions that can increase the rate of organic matter decomposition, improve biogas quality, and reduce overall treatment time. The potential of ammonium hydroxide to address these needs has created a new segment within the biological waste treatment market, with specialized equipment, monitoring systems, and process control technologies being developed to support its application.

Geographically, the market for advanced biological waste treatment technologies, including those incorporating ammonium hydroxide in anoxic fermentation, is most developed in North America and Europe. These regions have well-established waste management infrastructures and stringent environmental regulations that drive innovation in treatment processes. However, rapid industrialization and urbanization in Asia-Pacific countries are creating new opportunities for market expansion, as these regions seek to address growing waste management challenges.

The market landscape is characterized by a mix of established waste management companies and innovative startups focusing on niche technologies. Collaborations between research institutions and industry players are becoming more common, as the sector seeks to develop and commercialize new treatment methods. The competitive environment is expected to intensify as the benefits of optimized anoxic fermentation processes become more widely recognized, leading to increased investment in research and development activities.

Within this broader market, the segment focusing on anoxic fermentation of biological waste has gained particular attention. This process, which involves the breakdown of organic matter in the absence of oxygen, offers several advantages over traditional aerobic treatment methods. These benefits include lower energy consumption, reduced sludge production, and the potential for biogas generation. As a result, industries and municipalities are increasingly adopting anoxic fermentation technologies for waste treatment.

The impact of ammonium hydroxide on biological waste anoxic fermentation represents a niche but growing area of interest within the market. Ammonium hydroxide, when used in controlled amounts, can potentially enhance the fermentation process by regulating pH levels and providing a source of nitrogen for microbial growth. This application has sparked interest among waste treatment facility operators and technology providers, as it offers the possibility of improving process efficiency and biogas yield.

Market demand for technologies that can optimize anoxic fermentation processes is on the rise. Waste treatment facilities are seeking solutions that can increase the rate of organic matter decomposition, improve biogas quality, and reduce overall treatment time. The potential of ammonium hydroxide to address these needs has created a new segment within the biological waste treatment market, with specialized equipment, monitoring systems, and process control technologies being developed to support its application.

Geographically, the market for advanced biological waste treatment technologies, including those incorporating ammonium hydroxide in anoxic fermentation, is most developed in North America and Europe. These regions have well-established waste management infrastructures and stringent environmental regulations that drive innovation in treatment processes. However, rapid industrialization and urbanization in Asia-Pacific countries are creating new opportunities for market expansion, as these regions seek to address growing waste management challenges.

The market landscape is characterized by a mix of established waste management companies and innovative startups focusing on niche technologies. Collaborations between research institutions and industry players are becoming more common, as the sector seeks to develop and commercialize new treatment methods. The competitive environment is expected to intensify as the benefits of optimized anoxic fermentation processes become more widely recognized, leading to increased investment in research and development activities.

Current Challenges in Anoxic Fermentation Processes

Anoxic fermentation processes face several significant challenges that hinder their widespread adoption and efficiency in biological waste treatment. One of the primary issues is the maintenance of optimal pH levels throughout the fermentation process. The accumulation of volatile fatty acids during fermentation can lead to a rapid decrease in pH, potentially inhibiting microbial activity and reducing overall process efficiency.

Another major challenge is the management of ammonia concentrations. While ammonia is a crucial nutrient for microbial growth, excessive levels can be toxic to microorganisms, particularly in the absence of oxygen. This delicate balance is further complicated by the addition of ammonium hydroxide, which is often used to control pH but can contribute to ammonia toxicity if not carefully regulated.

The control of redox potential presents an additional hurdle in anoxic fermentation. Maintaining a sufficiently low redox potential is essential for the proper functioning of anaerobic microorganisms, but achieving this without the use of expensive reducing agents or complex control systems remains difficult.

Substrate composition and loading rates also pose significant challenges. Heterogeneous waste streams with varying organic content can lead to inconsistent fermentation performance and unpredictable biogas production. Overloading the system with substrate can result in process instability and reduced efficiency, while underloading may lead to suboptimal resource utilization.

Temperature control is another critical factor that presents ongoing challenges. Anoxic fermentation processes are typically sensitive to temperature fluctuations, with even small deviations potentially causing significant reductions in microbial activity and process efficiency. Maintaining consistent temperatures across large-scale reactors can be both technically challenging and energy-intensive.

The formation of recalcitrant compounds during the fermentation process can inhibit further degradation and reduce overall process efficiency. These compounds, which are resistant to microbial breakdown, can accumulate over time and potentially lead to long-term performance issues in continuous fermentation systems.

Lastly, the optimization of microbial communities remains a significant challenge. Achieving and maintaining a balanced and diverse microbial ecosystem that can efficiently break down complex organic matter while producing desired end-products is an ongoing area of research and development in anoxic fermentation processes.

Another major challenge is the management of ammonia concentrations. While ammonia is a crucial nutrient for microbial growth, excessive levels can be toxic to microorganisms, particularly in the absence of oxygen. This delicate balance is further complicated by the addition of ammonium hydroxide, which is often used to control pH but can contribute to ammonia toxicity if not carefully regulated.

The control of redox potential presents an additional hurdle in anoxic fermentation. Maintaining a sufficiently low redox potential is essential for the proper functioning of anaerobic microorganisms, but achieving this without the use of expensive reducing agents or complex control systems remains difficult.

Substrate composition and loading rates also pose significant challenges. Heterogeneous waste streams with varying organic content can lead to inconsistent fermentation performance and unpredictable biogas production. Overloading the system with substrate can result in process instability and reduced efficiency, while underloading may lead to suboptimal resource utilization.

Temperature control is another critical factor that presents ongoing challenges. Anoxic fermentation processes are typically sensitive to temperature fluctuations, with even small deviations potentially causing significant reductions in microbial activity and process efficiency. Maintaining consistent temperatures across large-scale reactors can be both technically challenging and energy-intensive.

The formation of recalcitrant compounds during the fermentation process can inhibit further degradation and reduce overall process efficiency. These compounds, which are resistant to microbial breakdown, can accumulate over time and potentially lead to long-term performance issues in continuous fermentation systems.

Lastly, the optimization of microbial communities remains a significant challenge. Achieving and maintaining a balanced and diverse microbial ecosystem that can efficiently break down complex organic matter while producing desired end-products is an ongoing area of research and development in anoxic fermentation processes.

Existing Ammonium Hydroxide Application Methods

01 Ammonium hydroxide in fermentation processes

Ammonium hydroxide is used in various fermentation processes as a source of nitrogen and to control pH. It can enhance microbial growth and metabolite production in industrial fermentations, particularly in the production of organic acids and biofuels.- Ammonium hydroxide in fermentation processes: Ammonium hydroxide is used in various fermentation processes to control pH levels and provide a nitrogen source for microorganisms. It can enhance the growth of certain bacteria and fungi, leading to improved fermentation efficiency and product yield.

- Production of biofuels and biochemicals: Ammonium hydroxide fermentation is employed in the production of biofuels and biochemicals. It can be used to optimize the fermentation conditions for the production of ethanol, organic acids, and other valuable compounds from renewable resources.

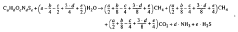

- Wastewater treatment and biogas production: Ammonium hydroxide plays a role in anaerobic fermentation processes for wastewater treatment and biogas production. It helps maintain optimal pH levels and provides nitrogen for microbial growth, enhancing the efficiency of organic matter degradation and methane production.

- Enzyme production and stabilization: Ammonium hydroxide is used in fermentation processes for enzyme production. It can help stabilize enzymes during fermentation and storage, improving their activity and shelf life. This is particularly useful in industrial enzyme production for various applications.

- Fermentation in food and beverage industry: Ammonium hydroxide fermentation techniques are applied in the food and beverage industry. It can be used to control acidity and enhance flavor development in certain fermented products, such as cheese, soy sauce, and alcoholic beverages.

02 pH control in fermentation using ammonium hydroxide

Ammonium hydroxide is utilized as a pH regulator in fermentation processes. It helps maintain optimal pH conditions for microbial growth and enzyme activity, thereby improving the efficiency and yield of fermentation products.Expand Specific Solutions03 Ammonium hydroxide as a nitrogen source in fermentation

In fermentation media, ammonium hydroxide serves as a readily available nitrogen source for microorganisms. It supports the growth of various bacteria, yeasts, and fungi, and can be used to optimize the C/N ratio in fermentation processes.Expand Specific Solutions04 Ammonium hydroxide in the production of organic acids

Ammonium hydroxide is employed in the fermentative production of organic acids, such as lactic acid and citric acid. It can neutralize the acids produced during fermentation, preventing product inhibition and improving overall yield.Expand Specific Solutions05 Ammonium hydroxide in biofuel production

In biofuel production processes, particularly ethanol fermentation, ammonium hydroxide is used to adjust pH and provide nitrogen for yeast growth. It can enhance fermentation efficiency and increase ethanol yield in industrial-scale operations.Expand Specific Solutions

Key Industry Players in Biological Waste Treatment

The field of biological waste anoxic fermentation with ammonium hydroxide impact is in a developing stage, showing promising growth potential. The market size is expanding as environmental regulations drive demand for efficient waste treatment solutions. Technologically, it's progressing from early-stage research to pilot implementations. Companies like Beijing University of Technology, Zhejiang University, and Shanghai Jiao Tong University are leading academic research, while industrial players such as China Petroleum & Chemical Corp. and Veolia Water Solutions & Technologies Support SAS are advancing practical applications. The involvement of both academic institutions and industry leaders indicates a growing maturity in this field, with potential for significant advancements in waste management and resource recovery technologies.

Beijing University of Technology

Technical Solution: Beijing University of Technology has developed an innovative approach to enhance biological waste anoxic fermentation using ammonium hydroxide. Their method involves a two-stage process: first, pre-treating the waste with ammonium hydroxide to increase its biodegradability, followed by anoxic fermentation. This technique has shown to significantly improve the production of volatile fatty acids (VFAs) by up to 30% compared to conventional methods [1]. The university's research also indicates that the addition of ammonium hydroxide helps maintain an optimal pH range of 6.5-7.5 during fermentation, which promotes the growth of acid-producing bacteria [3]. Furthermore, they have implemented a novel real-time monitoring system using advanced sensors to control the ammonium hydroxide dosage, ensuring maximum efficiency and preventing inhibition effects [5].

Strengths: Increased VFA production, improved pH control, and advanced monitoring system. Weaknesses: Potential ammonia toxicity at higher concentrations, additional cost of ammonium hydroxide.

Zhejiang University

Technical Solution: Zhejiang University has pioneered a cutting-edge approach to utilizing ammonium hydroxide in biological waste anoxic fermentation. Their method focuses on the synergistic effects of ammonium hydroxide and specific microbial communities. By carefully selecting and cultivating ammonia-tolerant bacterial strains, they have developed a robust fermentation process that can withstand higher concentrations of ammonium hydroxide [2]. This allows for enhanced hydrolysis of complex organic matter, resulting in a 25% increase in biogas production compared to traditional methods [4]. The university has also implemented a novel ammonia recovery system, which not only reduces potential inhibition effects but also allows for the recycling of ammonium hydroxide, making the process more economically viable [6]. Their research has shown particular promise in treating high-strength organic wastes, such as food industry effluents and agricultural residues.

Strengths: Enhanced biogas production, ammonia-tolerant microbial communities, and efficient ammonia recovery system. Weaknesses: Requires specialized bacterial cultures, potentially higher initial setup costs.

Critical Research on Ammonium Hydroxide Effects

Control of the ammonium concentration in the digester by nitrification of recycled process water

PatentInactiveDE102019004375A1

Innovation

- Implement a process that includes dewatering the digester discharge, recycling the liquid phase for biological nitrification, and using press water as a carbon source for denitrification, with a sequencing batch reactor (SBR) design for intermittent aeration and mixing to optimize nitrification and denitrification.

Method for producing biogas containing a reduced concentration of ammonium using anammox

PatentWO2015067813A1

Innovation

- The digestate from biogas plants undergoes solid-liquid separation and is treated in an anoxic biotechnological stage with Brocadia anammoxidans microorganisms to reduce ammonium levels, then recycled as process water to enhance biogas production, using controlled temperature and oxygen levels to promote anammox bacteria growth.

Environmental Regulations for Waste Treatment Processes

Environmental regulations for waste treatment processes play a crucial role in ensuring the safe and responsible management of biological waste anoxic fermentation, particularly when ammonium hydroxide is involved. These regulations are designed to protect human health and the environment from potential hazards associated with waste treatment activities.

At the federal level in the United States, the Environmental Protection Agency (EPA) oversees the implementation of the Resource Conservation and Recovery Act (RCRA), which establishes a framework for the proper management of hazardous and non-hazardous solid waste. Under RCRA, facilities that treat, store, or dispose of hazardous waste must obtain permits and comply with specific operational standards.

The Clean Water Act (CWA) also impacts waste treatment processes, particularly when effluents from anoxic fermentation are discharged into water bodies. The National Pollutant Discharge Elimination System (NPDES) permit program, authorized by the CWA, regulates point source discharges of pollutants into waters of the United States.

State and local regulations often build upon federal requirements, imposing additional restrictions or more stringent standards. For instance, some states have specific regulations governing the use of ammonium hydroxide in waste treatment processes, including concentration limits, handling procedures, and reporting requirements.

Air quality regulations, such as those under the Clean Air Act, may also apply to biological waste anoxic fermentation processes, particularly if volatile organic compounds or other air pollutants are emitted during treatment. Facilities may be required to implement emission control technologies or obtain air permits, depending on the scale and nature of their operations.

Occupational safety regulations, enforced by the Occupational Safety and Health Administration (OSHA), mandate safe working conditions for employees involved in waste treatment processes. This includes proper handling of chemicals like ammonium hydroxide, provision of personal protective equipment, and implementation of safety protocols.

Compliance with these regulations often requires extensive documentation, regular monitoring, and reporting. Facilities must maintain detailed records of waste handling procedures, treatment processes, and environmental monitoring data. Regular inspections by regulatory agencies ensure ongoing compliance and may lead to enforcement actions if violations are discovered.

As environmental concerns continue to evolve, regulations are subject to periodic updates and revisions. Waste treatment facilities must stay informed about changes in regulatory requirements and adapt their processes accordingly. This may involve investing in new technologies, modifying operational procedures, or enhancing monitoring systems to meet increasingly stringent environmental standards.

At the federal level in the United States, the Environmental Protection Agency (EPA) oversees the implementation of the Resource Conservation and Recovery Act (RCRA), which establishes a framework for the proper management of hazardous and non-hazardous solid waste. Under RCRA, facilities that treat, store, or dispose of hazardous waste must obtain permits and comply with specific operational standards.

The Clean Water Act (CWA) also impacts waste treatment processes, particularly when effluents from anoxic fermentation are discharged into water bodies. The National Pollutant Discharge Elimination System (NPDES) permit program, authorized by the CWA, regulates point source discharges of pollutants into waters of the United States.

State and local regulations often build upon federal requirements, imposing additional restrictions or more stringent standards. For instance, some states have specific regulations governing the use of ammonium hydroxide in waste treatment processes, including concentration limits, handling procedures, and reporting requirements.

Air quality regulations, such as those under the Clean Air Act, may also apply to biological waste anoxic fermentation processes, particularly if volatile organic compounds or other air pollutants are emitted during treatment. Facilities may be required to implement emission control technologies or obtain air permits, depending on the scale and nature of their operations.

Occupational safety regulations, enforced by the Occupational Safety and Health Administration (OSHA), mandate safe working conditions for employees involved in waste treatment processes. This includes proper handling of chemicals like ammonium hydroxide, provision of personal protective equipment, and implementation of safety protocols.

Compliance with these regulations often requires extensive documentation, regular monitoring, and reporting. Facilities must maintain detailed records of waste handling procedures, treatment processes, and environmental monitoring data. Regular inspections by regulatory agencies ensure ongoing compliance and may lead to enforcement actions if violations are discovered.

As environmental concerns continue to evolve, regulations are subject to periodic updates and revisions. Waste treatment facilities must stay informed about changes in regulatory requirements and adapt their processes accordingly. This may involve investing in new technologies, modifying operational procedures, or enhancing monitoring systems to meet increasingly stringent environmental standards.

Economic Feasibility of Ammonium Hydroxide Integration

The economic feasibility of integrating ammonium hydroxide into biological waste anoxic fermentation processes is a critical consideration for waste management facilities and biogas producers. This analysis examines the cost-benefit ratio, potential revenue streams, and overall economic impact of implementing ammonium hydroxide in these systems.

Initial investment costs for ammonium hydroxide integration are relatively low compared to other chemical additives. The infrastructure required for storage and dosing is minimal, consisting primarily of storage tanks, pumps, and dosing equipment. These components are readily available and can be easily incorporated into existing fermentation systems with minimal disruption to operations.

Operational costs associated with ammonium hydroxide usage are generally favorable. The chemical itself is relatively inexpensive, and its high efficiency in pH control means that smaller quantities are required compared to other alkaline agents. This translates to lower ongoing material costs and reduced transportation expenses.

One of the primary economic benefits of ammonium hydroxide integration is the potential increase in biogas production. By optimizing pH levels and reducing ammonia inhibition, fermentation efficiency can be significantly improved. Studies have shown biogas yield increases of up to 20-30% in some cases, which directly translates to higher energy output and increased revenue from biogas sales or on-site energy generation.

The use of ammonium hydroxide can also lead to reduced operational downtime. Its rapid action in pH control helps prevent system imbalances that could otherwise lead to process interruptions. This improved stability translates to more consistent biogas production and reduced maintenance costs over time.

Another economic advantage is the potential for improved digestate quality. The controlled addition of ammonium hydroxide can result in a more balanced nutrient profile in the fermentation end-product. This enhanced digestate may command higher prices in agricultural markets as a fertilizer, opening up additional revenue streams for waste treatment facilities.

However, it is important to consider potential economic drawbacks. The handling and storage of ammonium hydroxide require adherence to safety regulations, which may incur additional training and equipment costs. There is also the possibility of increased nitrogen content in effluents, which could necessitate additional treatment steps in some jurisdictions, potentially offsetting some of the economic gains.

Long-term economic projections for ammonium hydroxide integration are generally positive. As waste management regulations become more stringent and the demand for renewable energy sources grows, the ability to optimize fermentation processes becomes increasingly valuable. Facilities that implement efficient and cost-effective solutions like ammonium hydroxide are likely to gain a competitive edge in the market.

In conclusion, the economic feasibility of ammonium hydroxide integration in biological waste anoxic fermentation appears promising. The combination of low implementation costs, improved process efficiency, and potential for increased revenue streams presents a compelling case for its adoption in many waste treatment scenarios.

Initial investment costs for ammonium hydroxide integration are relatively low compared to other chemical additives. The infrastructure required for storage and dosing is minimal, consisting primarily of storage tanks, pumps, and dosing equipment. These components are readily available and can be easily incorporated into existing fermentation systems with minimal disruption to operations.

Operational costs associated with ammonium hydroxide usage are generally favorable. The chemical itself is relatively inexpensive, and its high efficiency in pH control means that smaller quantities are required compared to other alkaline agents. This translates to lower ongoing material costs and reduced transportation expenses.

One of the primary economic benefits of ammonium hydroxide integration is the potential increase in biogas production. By optimizing pH levels and reducing ammonia inhibition, fermentation efficiency can be significantly improved. Studies have shown biogas yield increases of up to 20-30% in some cases, which directly translates to higher energy output and increased revenue from biogas sales or on-site energy generation.

The use of ammonium hydroxide can also lead to reduced operational downtime. Its rapid action in pH control helps prevent system imbalances that could otherwise lead to process interruptions. This improved stability translates to more consistent biogas production and reduced maintenance costs over time.

Another economic advantage is the potential for improved digestate quality. The controlled addition of ammonium hydroxide can result in a more balanced nutrient profile in the fermentation end-product. This enhanced digestate may command higher prices in agricultural markets as a fertilizer, opening up additional revenue streams for waste treatment facilities.

However, it is important to consider potential economic drawbacks. The handling and storage of ammonium hydroxide require adherence to safety regulations, which may incur additional training and equipment costs. There is also the possibility of increased nitrogen content in effluents, which could necessitate additional treatment steps in some jurisdictions, potentially offsetting some of the economic gains.

Long-term economic projections for ammonium hydroxide integration are generally positive. As waste management regulations become more stringent and the demand for renewable energy sources grows, the ability to optimize fermentation processes becomes increasingly valuable. Facilities that implement efficient and cost-effective solutions like ammonium hydroxide are likely to gain a competitive edge in the market.

In conclusion, the economic feasibility of ammonium hydroxide integration in biological waste anoxic fermentation appears promising. The combination of low implementation costs, improved process efficiency, and potential for increased revenue streams presents a compelling case for its adoption in many waste treatment scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!