Ammonium Hydroxide in the Recycling of Electronic Waste

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

E-Waste Recycling Background and Objectives

Electronic waste, or e-waste, has become a significant global concern as the rapid advancement of technology leads to shorter product lifecycles and increased disposal of electronic devices. The recycling of e-waste is crucial for resource conservation, environmental protection, and sustainable development. This research focuses on the use of ammonium hydroxide in e-waste recycling, aiming to explore innovative and efficient methods for recovering valuable materials from discarded electronic products.

The evolution of e-waste recycling technologies has seen significant progress over the past decades. Initially, rudimentary methods such as open burning and acid leaching were prevalent, causing severe environmental and health hazards. As awareness grew, more sophisticated techniques emerged, including mechanical separation, pyrometallurgical processes, and hydrometallurgical methods. The use of ammonium hydroxide in hydrometallurgical processes represents a promising direction in this technological evolution, offering potential advantages in terms of efficiency and environmental impact.

The primary objective of this research is to investigate the effectiveness of ammonium hydroxide in extracting valuable metals from e-waste, particularly focusing on its application in leaching processes. This study aims to optimize the use of ammonium hydroxide in terms of concentration, temperature, and reaction time to maximize metal recovery while minimizing environmental impact. Additionally, the research seeks to compare the efficiency and sustainability of ammonium hydroxide-based methods with conventional recycling techniques.

Another key goal is to assess the scalability and economic viability of implementing ammonium hydroxide-based recycling processes in industrial settings. This includes evaluating the potential for integrating this method into existing recycling infrastructures and analyzing the cost-effectiveness compared to current practices. The research also aims to identify any potential challenges or limitations in using ammonium hydroxide for e-waste recycling and propose strategies to overcome these obstacles.

Furthermore, this study intends to explore the broader implications of adopting ammonium hydroxide-based recycling methods. This includes examining the potential environmental benefits, such as reduced emissions and waste generation, as well as the impact on the circular economy of electronic products. The research will also consider the regulatory landscape and how the use of ammonium hydroxide aligns with current and future environmental policies and standards in e-waste management.

By addressing these objectives, this research aims to contribute to the advancement of e-waste recycling technologies, potentially offering a more efficient and environmentally friendly approach to recovering valuable resources from electronic waste. The findings could have significant implications for the electronics industry, recycling sector, and environmental sustainability efforts worldwide.

The evolution of e-waste recycling technologies has seen significant progress over the past decades. Initially, rudimentary methods such as open burning and acid leaching were prevalent, causing severe environmental and health hazards. As awareness grew, more sophisticated techniques emerged, including mechanical separation, pyrometallurgical processes, and hydrometallurgical methods. The use of ammonium hydroxide in hydrometallurgical processes represents a promising direction in this technological evolution, offering potential advantages in terms of efficiency and environmental impact.

The primary objective of this research is to investigate the effectiveness of ammonium hydroxide in extracting valuable metals from e-waste, particularly focusing on its application in leaching processes. This study aims to optimize the use of ammonium hydroxide in terms of concentration, temperature, and reaction time to maximize metal recovery while minimizing environmental impact. Additionally, the research seeks to compare the efficiency and sustainability of ammonium hydroxide-based methods with conventional recycling techniques.

Another key goal is to assess the scalability and economic viability of implementing ammonium hydroxide-based recycling processes in industrial settings. This includes evaluating the potential for integrating this method into existing recycling infrastructures and analyzing the cost-effectiveness compared to current practices. The research also aims to identify any potential challenges or limitations in using ammonium hydroxide for e-waste recycling and propose strategies to overcome these obstacles.

Furthermore, this study intends to explore the broader implications of adopting ammonium hydroxide-based recycling methods. This includes examining the potential environmental benefits, such as reduced emissions and waste generation, as well as the impact on the circular economy of electronic products. The research will also consider the regulatory landscape and how the use of ammonium hydroxide aligns with current and future environmental policies and standards in e-waste management.

By addressing these objectives, this research aims to contribute to the advancement of e-waste recycling technologies, potentially offering a more efficient and environmentally friendly approach to recovering valuable resources from electronic waste. The findings could have significant implications for the electronics industry, recycling sector, and environmental sustainability efforts worldwide.

Market Analysis for E-Waste Recycling Solutions

The global electronic waste (e-waste) recycling market has been experiencing significant growth due to increasing awareness of environmental issues and the rising volume of electronic devices reaching end-of-life. The market for e-waste recycling solutions, particularly those involving ammonium hydroxide, is driven by several key factors.

Firstly, the rapid technological advancements and shorter lifecycles of electronic devices have led to a surge in e-waste generation. According to recent estimates, global e-waste production is expected to reach 74 million metric tons annually by 2030. This growing volume of e-waste presents a substantial market opportunity for recycling solutions.

The use of ammonium hydroxide in e-waste recycling has gained attention due to its effectiveness in extracting valuable metals from electronic components. This method offers a more environmentally friendly alternative to traditional acid-based extraction processes, aligning with the increasing demand for sustainable recycling technologies.

Market demand for e-waste recycling solutions is also influenced by stringent environmental regulations and government initiatives. Many countries have implemented laws mandating proper e-waste disposal and recycling, creating a regulatory framework that supports market growth. For instance, the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive has set collection, recycling, and recovery targets for all types of electrical goods.

The economic value of recovered materials from e-waste is another significant driver of market demand. Precious metals such as gold, silver, and palladium, as well as other valuable materials like copper and rare earth elements, can be extracted from e-waste using advanced recycling techniques. The potential for resource recovery makes e-waste recycling an attractive proposition for both environmental and economic reasons.

Geographically, the market for e-waste recycling solutions shows varying levels of maturity. Developed regions like North America and Europe have established recycling infrastructures and regulations, while emerging economies in Asia and Africa are experiencing rapid growth in e-waste generation and subsequent demand for recycling solutions.

The COVID-19 pandemic has had a mixed impact on the e-waste recycling market. While it initially disrupted collection and recycling operations, the increased reliance on electronic devices for remote work and education has accelerated e-waste generation, potentially driving long-term market growth.

Looking ahead, the market for e-waste recycling solutions, including those utilizing ammonium hydroxide, is expected to continue expanding. Factors such as technological advancements in recycling processes, increasing corporate responsibility initiatives, and growing consumer awareness of e-waste issues are likely to fuel this growth. The development of more efficient and cost-effective recycling technologies, particularly those that can handle complex modern electronics, will be crucial in shaping the future of this market.

Firstly, the rapid technological advancements and shorter lifecycles of electronic devices have led to a surge in e-waste generation. According to recent estimates, global e-waste production is expected to reach 74 million metric tons annually by 2030. This growing volume of e-waste presents a substantial market opportunity for recycling solutions.

The use of ammonium hydroxide in e-waste recycling has gained attention due to its effectiveness in extracting valuable metals from electronic components. This method offers a more environmentally friendly alternative to traditional acid-based extraction processes, aligning with the increasing demand for sustainable recycling technologies.

Market demand for e-waste recycling solutions is also influenced by stringent environmental regulations and government initiatives. Many countries have implemented laws mandating proper e-waste disposal and recycling, creating a regulatory framework that supports market growth. For instance, the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive has set collection, recycling, and recovery targets for all types of electrical goods.

The economic value of recovered materials from e-waste is another significant driver of market demand. Precious metals such as gold, silver, and palladium, as well as other valuable materials like copper and rare earth elements, can be extracted from e-waste using advanced recycling techniques. The potential for resource recovery makes e-waste recycling an attractive proposition for both environmental and economic reasons.

Geographically, the market for e-waste recycling solutions shows varying levels of maturity. Developed regions like North America and Europe have established recycling infrastructures and regulations, while emerging economies in Asia and Africa are experiencing rapid growth in e-waste generation and subsequent demand for recycling solutions.

The COVID-19 pandemic has had a mixed impact on the e-waste recycling market. While it initially disrupted collection and recycling operations, the increased reliance on electronic devices for remote work and education has accelerated e-waste generation, potentially driving long-term market growth.

Looking ahead, the market for e-waste recycling solutions, including those utilizing ammonium hydroxide, is expected to continue expanding. Factors such as technological advancements in recycling processes, increasing corporate responsibility initiatives, and growing consumer awareness of e-waste issues are likely to fuel this growth. The development of more efficient and cost-effective recycling technologies, particularly those that can handle complex modern electronics, will be crucial in shaping the future of this market.

Ammonium Hydroxide in E-Waste: Current Status and Challenges

The use of ammonium hydroxide in electronic waste recycling has gained significant attention in recent years due to its potential to address key challenges in the industry. Currently, the e-waste recycling sector faces several obstacles, including the complexity of waste composition, environmental concerns, and the need for more efficient extraction methods. Ammonium hydroxide has emerged as a promising solution to some of these issues.

One of the primary challenges in e-waste recycling is the separation and recovery of valuable metals from complex electronic components. Traditional methods often involve harsh chemicals and energy-intensive processes. Ammonium hydroxide offers a more environmentally friendly alternative, capable of selectively leaching certain metals from e-waste without the need for extreme temperatures or highly corrosive substances.

However, the implementation of ammonium hydroxide in large-scale e-waste recycling operations faces several hurdles. The effectiveness of the process can vary depending on the specific composition of the e-waste, which is often heterogeneous. This variability necessitates careful optimization of the recycling process for different waste streams, presenting a challenge for standardization across the industry.

Another significant challenge is the recovery and reuse of ammonium hydroxide after the leaching process. While the chemical itself is relatively inexpensive, its efficient recovery is crucial for making the process economically viable and minimizing environmental impact. Current research is focused on developing closed-loop systems that can effectively regenerate and reuse the ammonium hydroxide solution.

Safety considerations also pose a challenge in the widespread adoption of ammonium hydroxide in e-waste recycling. Although it is less hazardous than some alternative chemicals, proper handling and storage protocols must be established to protect workers and the environment. This includes addressing potential ammonia emissions and ensuring adequate ventilation in processing facilities.

The scalability of ammonium hydroxide-based recycling processes remains a key area of investigation. While laboratory studies have shown promising results, translating these findings into industrial-scale operations presents its own set of challenges. Researchers are working on optimizing reactor designs and process parameters to ensure efficiency and cost-effectiveness at larger scales.

Despite these challenges, the potential benefits of using ammonium hydroxide in e-waste recycling continue to drive innovation in the field. Its ability to selectively extract valuable metals while minimizing environmental impact aligns well with the growing emphasis on sustainable and circular economy principles in waste management. As research progresses, it is expected that many of the current challenges will be addressed, paving the way for more widespread adoption of this technology in the e-waste recycling industry.

One of the primary challenges in e-waste recycling is the separation and recovery of valuable metals from complex electronic components. Traditional methods often involve harsh chemicals and energy-intensive processes. Ammonium hydroxide offers a more environmentally friendly alternative, capable of selectively leaching certain metals from e-waste without the need for extreme temperatures or highly corrosive substances.

However, the implementation of ammonium hydroxide in large-scale e-waste recycling operations faces several hurdles. The effectiveness of the process can vary depending on the specific composition of the e-waste, which is often heterogeneous. This variability necessitates careful optimization of the recycling process for different waste streams, presenting a challenge for standardization across the industry.

Another significant challenge is the recovery and reuse of ammonium hydroxide after the leaching process. While the chemical itself is relatively inexpensive, its efficient recovery is crucial for making the process economically viable and minimizing environmental impact. Current research is focused on developing closed-loop systems that can effectively regenerate and reuse the ammonium hydroxide solution.

Safety considerations also pose a challenge in the widespread adoption of ammonium hydroxide in e-waste recycling. Although it is less hazardous than some alternative chemicals, proper handling and storage protocols must be established to protect workers and the environment. This includes addressing potential ammonia emissions and ensuring adequate ventilation in processing facilities.

The scalability of ammonium hydroxide-based recycling processes remains a key area of investigation. While laboratory studies have shown promising results, translating these findings into industrial-scale operations presents its own set of challenges. Researchers are working on optimizing reactor designs and process parameters to ensure efficiency and cost-effectiveness at larger scales.

Despite these challenges, the potential benefits of using ammonium hydroxide in e-waste recycling continue to drive innovation in the field. Its ability to selectively extract valuable metals while minimizing environmental impact aligns well with the growing emphasis on sustainable and circular economy principles in waste management. As research progresses, it is expected that many of the current challenges will be addressed, paving the way for more widespread adoption of this technology in the e-waste recycling industry.

Existing Ammonium Hydroxide-Based E-Waste Recycling Methods

01 Use in chemical processes

Ammonium hydroxide is widely used in various chemical processes, including as a reactant, pH adjuster, and neutralizing agent. It plays a crucial role in the production of different chemicals and materials, serving as a versatile compound in industrial applications.- Use in chemical processes: Ammonium hydroxide is widely used in various chemical processes, including as a reactant, pH adjuster, and neutralizing agent. It plays a crucial role in the production of certain chemicals and materials, and can be used to control the acidity or alkalinity of solutions in industrial applications.

- Application in cleaning and surface treatment: Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It can effectively remove grease, oils, and other contaminants from surfaces. Additionally, it is used in etching and polishing processes for metals and semiconductors, as well as in the treatment of textiles and leather.

- Role in agricultural and fertilizer applications: Ammonium hydroxide serves as a source of nitrogen in fertilizers and soil amendments. It can be directly applied to soil or used in the production of other nitrogen-containing fertilizers. The compound helps improve soil fertility and promotes plant growth by providing essential nutrients.

- Use in wastewater treatment: Ammonium hydroxide is employed in wastewater treatment processes for pH adjustment and nitrogen removal. It can help neutralize acidic effluents and assist in the precipitation of certain contaminants. The compound also plays a role in biological treatment systems that involve nitrification and denitrification processes.

- Application in personal care and cosmetic products: Ammonium hydroxide finds use in various personal care and cosmetic formulations. It can act as a pH adjuster in hair dyes, skin care products, and other cosmetic preparations. The compound helps stabilize certain formulations and can enhance the effectiveness of active ingredients in some beauty products.

02 Application in cleaning and surface treatment

Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing dirt, grease, and stains from various surfaces. Additionally, it can be used in etching and polishing applications for metals and semiconductors.Expand Specific Solutions03 Role in agricultural and fertilizer products

Ammonium hydroxide is an important component in the production of fertilizers and other agricultural products. It serves as a source of nitrogen for plant growth and can be used to adjust soil pH. The compound is also used in the manufacturing of certain pesticides and herbicides.Expand Specific Solutions04 Use in textile and dyeing industries

Ammonium hydroxide finds applications in textile processing and dyeing. It is used as a pH regulator in dyebaths, assists in fiber swelling for improved dye penetration, and can act as a fixing agent for certain dyes. The compound also plays a role in leather processing and treatment.Expand Specific Solutions05 Environmental and emission control applications

Ammonium hydroxide is employed in various environmental and emission control processes. It is used in flue gas treatment to reduce nitrogen oxide emissions, in wastewater treatment for pH adjustment and nitrogen removal, and in air purification systems. The compound also has applications in carbon capture and storage technologies.Expand Specific Solutions

Key Players in E-Waste Recycling Industry

The research on using Ammonium Hydroxide in electronic waste recycling is in its early stages, indicating an emerging market with significant growth potential. The industry is transitioning from traditional recycling methods to more efficient and environmentally friendly processes. Key players like Guangdong Bangpu Recycling Technology and Hunan Bangpu Recycling Technology are leading the charge in developing innovative recycling technologies. The market size is expected to expand rapidly due to increasing e-waste generation and stricter environmental regulations. While the technology is still maturing, companies such as SACHEM, Inc. and Cangzhou Sunheat Chemicals Co. Ltd. are contributing to the advancement of chemical solutions in this field, suggesting a competitive landscape with room for technological breakthroughs.

Guangdong Bangpu Recycling Technology Co., Ltd.

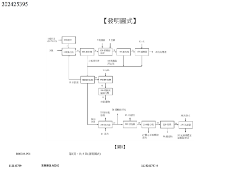

Technical Solution: Guangdong Bangpu has developed an innovative process for recycling electronic waste using ammonium hydroxide. Their method involves a two-step leaching process: first, using ammonium hydroxide to selectively dissolve copper and precious metals from e-waste; then, employing a secondary leaching step with stronger reagents to recover remaining metals. This approach allows for efficient recovery of valuable metals while minimizing environmental impact[1][3]. The company has also implemented a closed-loop system that recycles the ammonium hydroxide solution, reducing chemical consumption and waste generation. Their technology can process various types of e-waste, including printed circuit boards, mobile phones, and computer components, with a reported metal recovery rate of over 95%[2].

Strengths: High metal recovery rate, environmentally friendly process, versatility in handling different e-waste types. Weaknesses: Potential for ammonia emissions if not properly controlled, may require significant initial investment for implementation.

Guangdong University of Technology

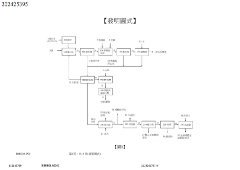

Technical Solution: Researchers at Guangdong University of Technology have developed a novel approach to e-waste recycling using ammonium hydroxide in conjunction with electrochemical processes. Their method involves pre-treating e-waste with ammonium hydroxide to selectively dissolve target metals, followed by an electrochemical recovery step. This process has shown particular efficacy in recovering copper and precious metals from printed circuit boards. The team has also explored the use of ultrasound-assisted leaching to enhance the dissolution kinetics, reporting a 30% increase in leaching efficiency compared to conventional methods[4][5]. Additionally, they have investigated the use of complexing agents in combination with ammonium hydroxide to improve selectivity and reduce processing time.

Strengths: Enhanced leaching efficiency, potential for selective metal recovery, integration with electrochemical processes for improved sustainability. Weaknesses: May require specialized equipment, potential scalability challenges for industrial implementation.

Innovations in Ammonium Hydroxide E-Waste Treatment

Recycling of electronic waste to recover lithium

PatentPendingTW202425395A

Innovation

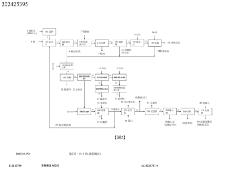

- The method uses ammonium sulfate as a leaching agent in the presence of an oxidizing agent to recover lithium and other metals from electronic waste.

- The process allows for the simultaneous recovery of copper and lithium ions from electronic waste, particularly from waste lithium-ion batteries.

- The invention addresses the growing demand for sustainable metal recovery from the increasing volume of electronic waste, especially lithium-ion batteries.

Method for removing copper and aluminum from an electrode material, and process for recycling electrode material from waste lithium-ion batteries

PatentActiveUS20160049700A1

Innovation

- A method involving an aqueous solution with a pH higher than 10, containing a base, oxidizing agent, and complexing agent is used to dissolve copper and aluminum from electrode materials, preserving the chemical and physical state of the transition-metal oxides, specifically using lithium hydroxide, dissolved oxygen, and ammonium hydroxide to effectively remove contaminants.

Environmental Impact Assessment

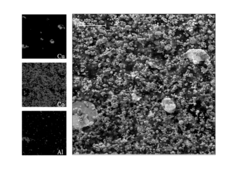

The use of ammonium hydroxide in electronic waste recycling presents both environmental benefits and potential risks that require careful assessment. On the positive side, this process can significantly reduce the amount of electronic waste sent to landfills, conserving valuable resources and minimizing soil and water contamination. Ammonium hydroxide's ability to selectively dissolve certain metals allows for more efficient recovery of precious and rare earth elements, reducing the need for environmentally damaging mining operations.

However, the environmental impact of using ammonium hydroxide in e-waste recycling is not without concerns. The production and handling of ammonium hydroxide itself can contribute to air pollution if not properly managed. Ammonia emissions from the recycling process may lead to local air quality issues and potentially contribute to the formation of particulate matter. Additionally, if not properly contained, ammonium hydroxide can contaminate water sources, potentially harming aquatic ecosystems and affecting water quality for human consumption.

The recycling process also consumes energy, which indirectly contributes to greenhouse gas emissions if the energy source is not renewable. However, this impact is generally outweighed by the energy savings from reduced raw material extraction and processing. Proper waste management practices are crucial to mitigate potential environmental risks associated with the recycling process, including the safe disposal of any residual chemicals and byproducts.

Long-term environmental effects of ammonium hydroxide use in e-waste recycling are still being studied. While the immediate benefits of resource recovery are clear, potential cumulative impacts on soil and water quality in recycling facility areas need ongoing monitoring. The development of closed-loop systems and improved chemical recovery techniques could further reduce environmental risks and enhance the sustainability of this recycling method.

Comparative life cycle assessments have shown that ammonium hydroxide-based recycling generally has a lower environmental footprint than traditional e-waste disposal methods or pyrometallurgical recycling processes. However, the specific environmental impact can vary depending on factors such as the scale of operations, the efficiency of chemical recovery and reuse, and the implementation of pollution control measures.

To maximize environmental benefits and minimize risks, ongoing research is focused on optimizing the recycling process, improving chemical recovery rates, and developing more environmentally friendly alternatives to ammonium hydroxide. Regulatory frameworks and industry standards play a crucial role in ensuring that e-waste recycling operations using ammonium hydroxide adhere to strict environmental protection guidelines, including proper emissions control, wastewater treatment, and worker safety protocols.

However, the environmental impact of using ammonium hydroxide in e-waste recycling is not without concerns. The production and handling of ammonium hydroxide itself can contribute to air pollution if not properly managed. Ammonia emissions from the recycling process may lead to local air quality issues and potentially contribute to the formation of particulate matter. Additionally, if not properly contained, ammonium hydroxide can contaminate water sources, potentially harming aquatic ecosystems and affecting water quality for human consumption.

The recycling process also consumes energy, which indirectly contributes to greenhouse gas emissions if the energy source is not renewable. However, this impact is generally outweighed by the energy savings from reduced raw material extraction and processing. Proper waste management practices are crucial to mitigate potential environmental risks associated with the recycling process, including the safe disposal of any residual chemicals and byproducts.

Long-term environmental effects of ammonium hydroxide use in e-waste recycling are still being studied. While the immediate benefits of resource recovery are clear, potential cumulative impacts on soil and water quality in recycling facility areas need ongoing monitoring. The development of closed-loop systems and improved chemical recovery techniques could further reduce environmental risks and enhance the sustainability of this recycling method.

Comparative life cycle assessments have shown that ammonium hydroxide-based recycling generally has a lower environmental footprint than traditional e-waste disposal methods or pyrometallurgical recycling processes. However, the specific environmental impact can vary depending on factors such as the scale of operations, the efficiency of chemical recovery and reuse, and the implementation of pollution control measures.

To maximize environmental benefits and minimize risks, ongoing research is focused on optimizing the recycling process, improving chemical recovery rates, and developing more environmentally friendly alternatives to ammonium hydroxide. Regulatory frameworks and industry standards play a crucial role in ensuring that e-waste recycling operations using ammonium hydroxide adhere to strict environmental protection guidelines, including proper emissions control, wastewater treatment, and worker safety protocols.

Regulatory Framework for E-Waste Chemical Recycling

The regulatory framework for e-waste chemical recycling is a complex and evolving landscape that plays a crucial role in shaping the industry's practices and standards. At the global level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal serves as the primary international treaty governing e-waste management. This convention establishes guidelines for the responsible handling and disposal of electronic waste, including chemical recycling processes.

In the United States, the Environmental Protection Agency (EPA) oversees e-waste management under the Resource Conservation and Recovery Act (RCRA). The RCRA provides a framework for the proper management of hazardous waste, including electronic waste. Specifically, the use of ammonium hydroxide in e-waste recycling falls under the purview of the EPA's regulations on hazardous waste treatment, storage, and disposal facilities.

The European Union has implemented the Waste Electrical and Electronic Equipment (WEEE) Directive, which sets collection, recycling, and recovery targets for all types of electrical goods. This directive also addresses the use of chemicals in e-waste recycling processes, requiring member states to ensure that hazardous substances are properly managed and disposed of.

China, a major player in e-waste recycling, has introduced regulations such as the Administrative Measure on the Control of Pollution Caused by Electronic Information Products. This measure aims to reduce the environmental impact of e-waste recycling operations, including those involving chemical processes like the use of ammonium hydroxide.

Many countries have adopted Extended Producer Responsibility (EPR) policies, which hold manufacturers accountable for the entire lifecycle of their products, including end-of-life management. These policies often include provisions for the safe and environmentally responsible recycling of electronic waste, including chemical recycling methods.

Regulatory bodies are increasingly focusing on the circular economy concept, promoting the development of more efficient and sustainable recycling technologies. This shift is driving research into innovative chemical recycling methods, such as the use of ammonium hydroxide, which can potentially recover a higher percentage of valuable materials from e-waste while minimizing environmental impact.

As the e-waste recycling industry continues to evolve, regulatory frameworks are expected to adapt to new technologies and processes. Future regulations may place greater emphasis on the recovery of critical raw materials, the reduction of hazardous emissions, and the overall sustainability of recycling operations. This evolving regulatory landscape will likely shape the future direction of research and development in e-waste chemical recycling technologies, including the use of ammonium hydroxide and other innovative approaches.

In the United States, the Environmental Protection Agency (EPA) oversees e-waste management under the Resource Conservation and Recovery Act (RCRA). The RCRA provides a framework for the proper management of hazardous waste, including electronic waste. Specifically, the use of ammonium hydroxide in e-waste recycling falls under the purview of the EPA's regulations on hazardous waste treatment, storage, and disposal facilities.

The European Union has implemented the Waste Electrical and Electronic Equipment (WEEE) Directive, which sets collection, recycling, and recovery targets for all types of electrical goods. This directive also addresses the use of chemicals in e-waste recycling processes, requiring member states to ensure that hazardous substances are properly managed and disposed of.

China, a major player in e-waste recycling, has introduced regulations such as the Administrative Measure on the Control of Pollution Caused by Electronic Information Products. This measure aims to reduce the environmental impact of e-waste recycling operations, including those involving chemical processes like the use of ammonium hydroxide.

Many countries have adopted Extended Producer Responsibility (EPR) policies, which hold manufacturers accountable for the entire lifecycle of their products, including end-of-life management. These policies often include provisions for the safe and environmentally responsible recycling of electronic waste, including chemical recycling methods.

Regulatory bodies are increasingly focusing on the circular economy concept, promoting the development of more efficient and sustainable recycling technologies. This shift is driving research into innovative chemical recycling methods, such as the use of ammonium hydroxide, which can potentially recover a higher percentage of valuable materials from e-waste while minimizing environmental impact.

As the e-waste recycling industry continues to evolve, regulatory frameworks are expected to adapt to new technologies and processes. Future regulations may place greater emphasis on the recovery of critical raw materials, the reduction of hazardous emissions, and the overall sustainability of recycling operations. This evolving regulatory landscape will likely shape the future direction of research and development in e-waste chemical recycling technologies, including the use of ammonium hydroxide and other innovative approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!