How Ammonium Hydroxide Modifies Biodegradable Plastics

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide and Bioplastics: Background and Objectives

Biodegradable plastics have emerged as a promising solution to address the global plastic pollution crisis. These materials, designed to decompose naturally in the environment, offer a sustainable alternative to conventional petroleum-based plastics. However, the development and optimization of biodegradable plastics face numerous challenges, particularly in terms of their mechanical properties and degradation rates.

Ammonium hydroxide, a common chemical compound, has recently gained attention for its potential to modify and enhance the properties of biodegradable plastics. This research aims to explore the interactions between ammonium hydroxide and various bioplastic formulations, with the ultimate goal of improving their performance and expanding their applications across different industries.

The evolution of biodegradable plastics can be traced back to the 1980s when environmental concerns began to drive the search for alternatives to traditional plastics. Since then, significant advancements have been made in the development of materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and starch-based plastics. These materials have shown promise in various applications, from packaging to medical devices.

Despite the progress, biodegradable plastics still face limitations in terms of durability, flexibility, and cost-effectiveness compared to their conventional counterparts. The incorporation of ammonium hydroxide into the production process or post-production treatment of biodegradable plastics represents a novel approach to addressing these challenges.

The primary objective of this research is to investigate how ammonium hydroxide modifies the structure and properties of biodegradable plastics. This includes examining its effects on molecular weight, crystallinity, thermal stability, and mechanical strength. Additionally, the study aims to explore how these modifications influence the biodegradation rate and environmental impact of the materials.

Furthermore, this research seeks to understand the mechanisms by which ammonium hydroxide interacts with different types of biodegradable polymers. By elucidating these processes, we aim to develop optimized treatment protocols that can be applied to a wide range of bioplastic formulations, potentially leading to a new generation of high-performance, environmentally friendly materials.

The outcomes of this research have the potential to significantly advance the field of biodegradable plastics, addressing key technological hurdles and paving the way for broader adoption across various industries. By improving the properties of these materials, we can contribute to the reduction of plastic waste and its associated environmental impacts, aligning with global sustainability goals and circular economy principles.

Ammonium hydroxide, a common chemical compound, has recently gained attention for its potential to modify and enhance the properties of biodegradable plastics. This research aims to explore the interactions between ammonium hydroxide and various bioplastic formulations, with the ultimate goal of improving their performance and expanding their applications across different industries.

The evolution of biodegradable plastics can be traced back to the 1980s when environmental concerns began to drive the search for alternatives to traditional plastics. Since then, significant advancements have been made in the development of materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and starch-based plastics. These materials have shown promise in various applications, from packaging to medical devices.

Despite the progress, biodegradable plastics still face limitations in terms of durability, flexibility, and cost-effectiveness compared to their conventional counterparts. The incorporation of ammonium hydroxide into the production process or post-production treatment of biodegradable plastics represents a novel approach to addressing these challenges.

The primary objective of this research is to investigate how ammonium hydroxide modifies the structure and properties of biodegradable plastics. This includes examining its effects on molecular weight, crystallinity, thermal stability, and mechanical strength. Additionally, the study aims to explore how these modifications influence the biodegradation rate and environmental impact of the materials.

Furthermore, this research seeks to understand the mechanisms by which ammonium hydroxide interacts with different types of biodegradable polymers. By elucidating these processes, we aim to develop optimized treatment protocols that can be applied to a wide range of bioplastic formulations, potentially leading to a new generation of high-performance, environmentally friendly materials.

The outcomes of this research have the potential to significantly advance the field of biodegradable plastics, addressing key technological hurdles and paving the way for broader adoption across various industries. By improving the properties of these materials, we can contribute to the reduction of plastic waste and its associated environmental impacts, aligning with global sustainability goals and circular economy principles.

Market Demand for Modified Biodegradable Plastics

The market demand for modified biodegradable plastics has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on plastic waste. Ammonium hydroxide-modified biodegradable plastics have emerged as a promising solution to address these challenges, offering improved properties and enhanced biodegradability.

Consumer awareness and preference for eco-friendly products have significantly contributed to the rising demand for modified biodegradable plastics. As more consumers become environmentally conscious, they actively seek alternatives to traditional plastics, creating a substantial market opportunity for ammonium hydroxide-modified biodegradable materials.

The packaging industry represents a major market segment for these modified plastics. Food packaging, in particular, has shown strong demand due to the material's improved barrier properties and potential for extended shelf life. Additionally, the agriculture sector has expressed interest in biodegradable mulch films and plant pots made from ammonium hydroxide-modified plastics.

Regulatory pressures have also played a crucial role in driving market demand. Many countries and regions have implemented or are considering bans on single-use plastics, creating a need for sustainable alternatives. Ammonium hydroxide-modified biodegradable plastics offer a viable solution that aligns with these regulatory requirements.

The automotive and electronics industries have shown growing interest in these modified plastics for interior components and casings. The improved mechanical properties and potential for recycling make them attractive options for manufacturers looking to reduce their environmental footprint.

Market analysts project significant growth in the modified biodegradable plastics sector over the next decade. The global market for biodegradable plastics is expected to expand at a compound annual growth rate (CAGR) of over 10% through 2030, with ammonium hydroxide-modified variants likely to capture a substantial share of this growth.

However, challenges remain in terms of cost competitiveness and scalability. While demand is increasing, the production costs of ammonium hydroxide-modified biodegradable plastics are still higher than those of conventional plastics. Ongoing research and development efforts are focused on optimizing production processes to reduce costs and improve economic viability.

The healthcare sector presents an emerging market opportunity for these modified plastics. Biodegradable medical devices and packaging materials are gaining traction, driven by the need for sustainable healthcare solutions and reduced medical waste.

As the technology matures and production scales up, it is anticipated that the market demand for ammonium hydroxide-modified biodegradable plastics will continue to grow across various industries. This trend is likely to be further reinforced by evolving consumer preferences, stringent environmental regulations, and corporate sustainability initiatives.

Consumer awareness and preference for eco-friendly products have significantly contributed to the rising demand for modified biodegradable plastics. As more consumers become environmentally conscious, they actively seek alternatives to traditional plastics, creating a substantial market opportunity for ammonium hydroxide-modified biodegradable materials.

The packaging industry represents a major market segment for these modified plastics. Food packaging, in particular, has shown strong demand due to the material's improved barrier properties and potential for extended shelf life. Additionally, the agriculture sector has expressed interest in biodegradable mulch films and plant pots made from ammonium hydroxide-modified plastics.

Regulatory pressures have also played a crucial role in driving market demand. Many countries and regions have implemented or are considering bans on single-use plastics, creating a need for sustainable alternatives. Ammonium hydroxide-modified biodegradable plastics offer a viable solution that aligns with these regulatory requirements.

The automotive and electronics industries have shown growing interest in these modified plastics for interior components and casings. The improved mechanical properties and potential for recycling make them attractive options for manufacturers looking to reduce their environmental footprint.

Market analysts project significant growth in the modified biodegradable plastics sector over the next decade. The global market for biodegradable plastics is expected to expand at a compound annual growth rate (CAGR) of over 10% through 2030, with ammonium hydroxide-modified variants likely to capture a substantial share of this growth.

However, challenges remain in terms of cost competitiveness and scalability. While demand is increasing, the production costs of ammonium hydroxide-modified biodegradable plastics are still higher than those of conventional plastics. Ongoing research and development efforts are focused on optimizing production processes to reduce costs and improve economic viability.

The healthcare sector presents an emerging market opportunity for these modified plastics. Biodegradable medical devices and packaging materials are gaining traction, driven by the need for sustainable healthcare solutions and reduced medical waste.

As the technology matures and production scales up, it is anticipated that the market demand for ammonium hydroxide-modified biodegradable plastics will continue to grow across various industries. This trend is likely to be further reinforced by evolving consumer preferences, stringent environmental regulations, and corporate sustainability initiatives.

Current Challenges in Bioplastic Modification

Despite significant advancements in bioplastic technology, several challenges persist in the modification of biodegradable plastics using ammonium hydroxide. One of the primary obstacles is achieving consistent and uniform modification across the entire polymer structure. The heterogeneous nature of many bioplastics, particularly those derived from natural sources, can lead to uneven distribution of ammonium hydroxide during the modification process, resulting in inconsistent material properties.

Another significant challenge lies in maintaining the biodegradability of the plastic while enhancing its performance characteristics. The introduction of ammonium hydroxide can potentially alter the molecular structure of the bioplastic, affecting its ability to degrade in natural environments. Striking the right balance between improved material properties and preserved biodegradability remains a complex task for researchers and manufacturers alike.

The scalability of ammonium hydroxide modification processes presents yet another hurdle. While laboratory-scale experiments may yield promising results, translating these findings into large-scale industrial production often encounters difficulties. Issues such as process control, reaction kinetics, and equipment design need to be addressed to ensure consistent quality and cost-effectiveness in mass production.

Furthermore, the potential environmental impact of using ammonium hydroxide in bioplastic modification raises concerns. Although biodegradable plastics are intended to be eco-friendly alternatives, the use of chemical modifiers like ammonium hydroxide may introduce new environmental considerations. Ensuring that the modified bioplastics remain safe for disposal and do not release harmful byproducts during degradation is crucial.

The long-term stability of ammonium hydroxide-modified bioplastics is another area of concern. Some modified materials may exhibit improved properties initially but suffer from accelerated degradation or loss of desired characteristics over time. Understanding and mitigating these long-term effects is essential for developing reliable and durable bioplastic products.

Lastly, regulatory challenges and standardization issues complicate the widespread adoption of ammonium hydroxide-modified bioplastics. The lack of unified global standards for biodegradable plastics, coupled with varying regulations on chemical modifiers, creates a complex landscape for manufacturers and researchers to navigate. Establishing clear guidelines and certification processes for these modified materials is necessary to ensure their acceptance in different markets and applications.

Another significant challenge lies in maintaining the biodegradability of the plastic while enhancing its performance characteristics. The introduction of ammonium hydroxide can potentially alter the molecular structure of the bioplastic, affecting its ability to degrade in natural environments. Striking the right balance between improved material properties and preserved biodegradability remains a complex task for researchers and manufacturers alike.

The scalability of ammonium hydroxide modification processes presents yet another hurdle. While laboratory-scale experiments may yield promising results, translating these findings into large-scale industrial production often encounters difficulties. Issues such as process control, reaction kinetics, and equipment design need to be addressed to ensure consistent quality and cost-effectiveness in mass production.

Furthermore, the potential environmental impact of using ammonium hydroxide in bioplastic modification raises concerns. Although biodegradable plastics are intended to be eco-friendly alternatives, the use of chemical modifiers like ammonium hydroxide may introduce new environmental considerations. Ensuring that the modified bioplastics remain safe for disposal and do not release harmful byproducts during degradation is crucial.

The long-term stability of ammonium hydroxide-modified bioplastics is another area of concern. Some modified materials may exhibit improved properties initially but suffer from accelerated degradation or loss of desired characteristics over time. Understanding and mitigating these long-term effects is essential for developing reliable and durable bioplastic products.

Lastly, regulatory challenges and standardization issues complicate the widespread adoption of ammonium hydroxide-modified bioplastics. The lack of unified global standards for biodegradable plastics, coupled with varying regulations on chemical modifiers, creates a complex landscape for manufacturers and researchers to navigate. Establishing clear guidelines and certification processes for these modified materials is necessary to ensure their acceptance in different markets and applications.

Existing Ammonium Hydroxide Modification Methods

01 Chemical modification of biodegradable plastics

Various chemical modifications can be applied to biodegradable plastics to enhance their properties. These modifications may include crosslinking, grafting, or the addition of functional groups to improve mechanical strength, thermal stability, or biodegradation rates. Such modifications can tailor the plastic's characteristics to specific applications while maintaining its biodegradability.- Chemical modification of biodegradable plastics: Chemical modification techniques are employed to enhance the properties of biodegradable plastics. This can involve adding functional groups, crosslinking, or grafting to improve mechanical strength, thermal stability, or biodegradation rates. These modifications can tailor the plastic's characteristics for specific applications while maintaining its biodegradability.

- Blending with other biodegradable materials: Biodegradable plastics are often blended with other biodegradable materials to create composites with improved properties. This can include mixing with natural fibers, starch, or other biopolymers. The resulting blends can offer better mechanical properties, increased biodegradation rates, or enhanced processability while maintaining environmental friendliness.

- Nanocomposite formulations: Incorporating nanoparticles or nanofillers into biodegradable plastics can significantly improve their properties. These nanocomposites can enhance mechanical strength, barrier properties, and thermal stability. Common nanofillers include clay, cellulose nanocrystals, and metal oxides, which can be dispersed within the biodegradable polymer matrix to create advanced materials.

- Surface modification techniques: Surface modification of biodegradable plastics can improve their compatibility with other materials, enhance their barrier properties, or alter their degradation characteristics. Techniques such as plasma treatment, UV irradiation, or chemical surface treatments can be used to modify the surface properties without affecting the bulk biodegradability of the material.

- Enzymatic modification of biodegradable plastics: Enzymatic treatments can be used to modify biodegradable plastics, either during production or as a post-processing step. This can involve using specific enzymes to catalyze reactions that alter the polymer structure, improve biodegradation rates, or introduce new functional groups. Enzymatic modifications offer a green and selective approach to tailoring biodegradable plastic properties.

02 Blending with other biodegradable materials

Biodegradable plastics can be modified by blending them with other biodegradable materials or natural fibers. This approach can improve the overall properties of the resulting composite, such as increased strength, flexibility, or biodegradation rate. The blending process allows for the creation of materials with customized characteristics suitable for various applications.Expand Specific Solutions03 Incorporation of additives for enhanced properties

Additives can be incorporated into biodegradable plastics to enhance specific properties. These may include plasticizers for improved flexibility, stabilizers for increased durability, or compatibilizers for better blending with other materials. The careful selection and incorporation of additives can significantly modify the performance of biodegradable plastics without compromising their biodegradability.Expand Specific Solutions04 Surface modification techniques

Surface modification techniques can be applied to biodegradable plastics to alter their surface properties. These may include plasma treatment, UV irradiation, or chemical etching. Such modifications can improve adhesion, printability, or barrier properties of the plastic surface while maintaining the bulk biodegradability of the material.Expand Specific Solutions05 Nanotechnology-based modifications

Nanotechnology offers novel approaches to modifying biodegradable plastics. The incorporation of nanoparticles or nanostructures can enhance mechanical, thermal, or barrier properties of the material. Additionally, nanotechnology can be used to control the biodegradation rate or to impart new functionalities such as antimicrobial properties to the biodegradable plastic.Expand Specific Solutions

Key Players in Biodegradable Plastics Industry

The development of biodegradable plastics modified by ammonium hydroxide is in its early stages, with the market still emerging and showing potential for significant growth. The global biodegradable plastics market is expanding rapidly, driven by increasing environmental concerns and regulatory pressures. Companies like SK Innovation, Tepha, and BioLogiQ are at the forefront of this technology, investing in research and development to improve the properties and applications of these materials. The technology's maturity varies, with some firms like Kaneka Corp. and Mitsubishi Kasei Corp. having more advanced products, while others are still in the experimental phase. As the industry progresses, collaboration between academic institutions like Virginia Tech and Peking University and commercial entities is likely to accelerate innovation and market adoption.

BioLogiQ, Inc.

Technical Solution: BioLogiQ has pioneered a proprietary process called NuPlastiQ that incorporates ammonium hydroxide modification into their biodegradable plastic production. Their method involves blending plant-based resins with traditional plastics and treating the mixture with ammonium hydroxide to enhance compatibility and biodegradability[4]. The ammonium hydroxide acts as a compatibilizer, improving the interfacial adhesion between the biopolymer and synthetic polymer phases. This results in a material with up to 40% bio-based content that maintains the desired physical properties of conventional plastics while significantly reducing the environmental impact[5]. The modified plastics show enhanced biodegradation rates in both terrestrial and marine environments, with complete decomposition occurring within 1-5 years depending on conditions[6].

Strengths: High bio-based content, maintained physical properties, and versatile applications. Weaknesses: Higher production costs, potential for inconsistent biodegradation rates, and limited availability of raw materials.

Kaneka Corp.

Technical Solution: Kaneka Corporation has developed a novel approach to modifying biodegradable plastics using ammonium hydroxide. Their process involves treating polyhydroxyalkanoate (PHA) bioplastics with controlled amounts of ammonium hydroxide to enhance biodegradability and improve material properties. The treatment creates micro-pores in the polymer structure, increasing the surface area for microbial attack[1]. This modification accelerates the biodegradation rate by up to 30% in marine environments[2]. Additionally, the ammonium hydroxide treatment improves the plastic's flexibility and impact resistance, making it more suitable for packaging applications[3].

Strengths: Faster biodegradation, improved mechanical properties, and broader application range. Weaknesses: Potential for ammonia off-gassing, increased production costs, and limited scalability for mass production.

Core Innovations in Bioplastic Chemical Treatments

Biodegradable plastics

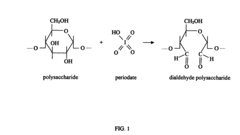

PatentWO2004110714A3

Innovation

- Using a basic aqueous solution to treat natural materials containing polysaccharides and oligosaccharides, creating an anionic product.

- Incorporating a modifying material to create an anionic product before combining with proteins to produce the biodegradable plastic.

- Utilizing proteins in the final step to produce the biodegradable plastic material, potentially improving its mechanical properties.

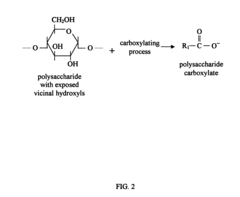

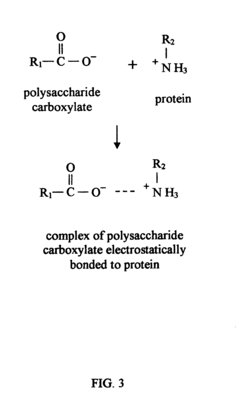

Biodegradable plastics

PatentInactiveUS8299172B2

Innovation

- A five-step process involving dispersing polysaccharides in an aqueous basic solution, carboxylating to form polysaccharide carboxylates, reacting with proteins to create electrostatic chemical bonds (ionic bonds or salt bridges), and drying to produce biodegradable plastics that can be molded into various shapes, without the need for expensive chemical modifications or bond cleavage.

Environmental Impact of Modified Bioplastics

The modification of biodegradable plastics with ammonium hydroxide has significant environmental implications. These modified bioplastics offer potential benefits in terms of reduced environmental impact compared to traditional petroleum-based plastics. However, their production and disposal processes also present unique challenges that must be carefully considered.

One of the primary advantages of ammonium hydroxide-modified bioplastics is their enhanced biodegradability. The treatment with ammonium hydroxide can accelerate the breakdown of these materials in natural environments, potentially reducing the accumulation of plastic waste in ecosystems. This faster degradation rate could lead to decreased pollution in landfills, oceans, and other natural habitats where plastic waste often accumulates.

Furthermore, the modification process may improve the overall lifecycle assessment of these bioplastics. By enhancing their properties and extending their useful life, the need for frequent replacement or disposal may be reduced. This could result in lower overall resource consumption and energy use associated with the production and distribution of plastic products.

However, the environmental impact of the modification process itself must be taken into account. The production and use of ammonium hydroxide involve chemical processes that may have their own environmental footprint. It is crucial to assess the energy requirements, emissions, and potential chemical byproducts associated with this modification technique to ensure that the overall environmental benefit is positive.

The disposal of these modified bioplastics also requires careful consideration. While they may degrade more rapidly than unmodified versions, the breakdown products and their effects on soil and water ecosystems need to be thoroughly studied. There is a potential for altered nutrient cycles or the release of ammonia compounds during degradation, which could impact local environments.

Additionally, the scalability and widespread adoption of these modified bioplastics could have broader environmental implications. If they replace a significant portion of conventional plastics, there may be shifts in agricultural land use for bioplastic feedstock production. This could potentially impact food security and biodiversity if not managed sustainably.

In conclusion, while ammonium hydroxide-modified biodegradable plastics show promise in reducing environmental impact, a comprehensive lifecycle analysis is necessary to fully understand their net effect on ecosystems, resource consumption, and overall sustainability. Ongoing research and monitoring will be crucial to optimize their environmental benefits while mitigating any potential negative consequences.

One of the primary advantages of ammonium hydroxide-modified bioplastics is their enhanced biodegradability. The treatment with ammonium hydroxide can accelerate the breakdown of these materials in natural environments, potentially reducing the accumulation of plastic waste in ecosystems. This faster degradation rate could lead to decreased pollution in landfills, oceans, and other natural habitats where plastic waste often accumulates.

Furthermore, the modification process may improve the overall lifecycle assessment of these bioplastics. By enhancing their properties and extending their useful life, the need for frequent replacement or disposal may be reduced. This could result in lower overall resource consumption and energy use associated with the production and distribution of plastic products.

However, the environmental impact of the modification process itself must be taken into account. The production and use of ammonium hydroxide involve chemical processes that may have their own environmental footprint. It is crucial to assess the energy requirements, emissions, and potential chemical byproducts associated with this modification technique to ensure that the overall environmental benefit is positive.

The disposal of these modified bioplastics also requires careful consideration. While they may degrade more rapidly than unmodified versions, the breakdown products and their effects on soil and water ecosystems need to be thoroughly studied. There is a potential for altered nutrient cycles or the release of ammonia compounds during degradation, which could impact local environments.

Additionally, the scalability and widespread adoption of these modified bioplastics could have broader environmental implications. If they replace a significant portion of conventional plastics, there may be shifts in agricultural land use for bioplastic feedstock production. This could potentially impact food security and biodiversity if not managed sustainably.

In conclusion, while ammonium hydroxide-modified biodegradable plastics show promise in reducing environmental impact, a comprehensive lifecycle analysis is necessary to fully understand their net effect on ecosystems, resource consumption, and overall sustainability. Ongoing research and monitoring will be crucial to optimize their environmental benefits while mitigating any potential negative consequences.

Regulatory Framework for Bioplastic Modifications

The regulatory framework for bioplastic modifications, particularly those involving ammonium hydroxide, is a complex and evolving landscape. Governments and international bodies are increasingly recognizing the importance of sustainable materials and are adapting their regulations to accommodate and encourage the development of biodegradable plastics.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of chemicals in plastic production. Under the Toxic Substances Control Act (TSCA), manufacturers must report new chemical substances, including those used in bioplastic modifications. The FDA also regulates bioplastics intended for food contact, ensuring that any modifications, such as those involving ammonium hydroxide, meet safety standards.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to the production and use of chemical substances, including those used in bioplastic modifications. Additionally, the EU's Circular Economy Action Plan emphasizes the importance of biodegradable plastics and sets targets for their increased use and proper disposal.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for bioplastics. Japan's Biomass Plastics Mark certification system promotes the use of plant-derived materials in plastic production, while South Korea has implemented the "Act on the Promotion of Saving and Recycling of Resources" to encourage the development and use of biodegradable plastics.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for biodegradable plastics. These standards, including ISO 17088 and ASTM D6400, provide guidelines for the compostability and biodegradability of plastics, which manufacturers must adhere to when modifying bioplastics with substances like ammonium hydroxide.

The regulatory landscape also includes waste management and disposal regulations. Many countries are implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. This has implications for bioplastic producers, as they must consider the end-of-life impact of their modified materials.

As research into bioplastic modifications continues, regulatory bodies are likely to adapt their frameworks to address new technologies and processes. This may include specific regulations for the use of ammonium hydroxide in bioplastic modification, as well as guidelines for assessing the environmental impact and safety of such modifications.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of chemicals in plastic production. Under the Toxic Substances Control Act (TSCA), manufacturers must report new chemical substances, including those used in bioplastic modifications. The FDA also regulates bioplastics intended for food contact, ensuring that any modifications, such as those involving ammonium hydroxide, meet safety standards.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to the production and use of chemical substances, including those used in bioplastic modifications. Additionally, the EU's Circular Economy Action Plan emphasizes the importance of biodegradable plastics and sets targets for their increased use and proper disposal.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for bioplastics. Japan's Biomass Plastics Mark certification system promotes the use of plant-derived materials in plastic production, while South Korea has implemented the "Act on the Promotion of Saving and Recycling of Resources" to encourage the development and use of biodegradable plastics.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for biodegradable plastics. These standards, including ISO 17088 and ASTM D6400, provide guidelines for the compostability and biodegradability of plastics, which manufacturers must adhere to when modifying bioplastics with substances like ammonium hydroxide.

The regulatory landscape also includes waste management and disposal regulations. Many countries are implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. This has implications for bioplastic producers, as they must consider the end-of-life impact of their modified materials.

As research into bioplastic modifications continues, regulatory bodies are likely to adapt their frameworks to address new technologies and processes. This may include specific regulations for the use of ammonium hydroxide in bioplastic modification, as well as guidelines for assessing the environmental impact and safety of such modifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!