The Use of Ammonium Hydroxide in Protein Solubilization Studies

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Protein Solubilization Background and Objectives

Protein solubilization is a critical process in biochemistry and molecular biology, essential for various applications including protein purification, structural studies, and functional analyses. The historical development of protein solubilization techniques has been driven by the need to extract and isolate proteins from complex biological matrices while maintaining their native structure and function.

Ammonium hydroxide has emerged as a valuable tool in protein solubilization studies, offering unique advantages over traditional methods. Its use in this context dates back to the mid-20th century, with researchers recognizing its potential to effectively solubilize certain protein classes, particularly those resistant to conventional solubilization agents.

The evolution of protein solubilization techniques has been marked by a continuous quest for more efficient and less disruptive methods. Early approaches often relied on harsh conditions that risked protein denaturation. The introduction of ammonium hydroxide represented a significant advancement, providing a milder alternative that could maintain protein integrity in many cases.

Recent years have witnessed an increased focus on optimizing ammonium hydroxide-based solubilization protocols. Researchers have explored various concentrations, pH ranges, and combination strategies with other solubilizing agents to enhance efficiency and broaden applicability across diverse protein types.

The primary objective of utilizing ammonium hydroxide in protein solubilization studies is to achieve effective protein extraction while preserving structural and functional properties. This goal aligns with the broader aims of advancing proteomics research, improving protein-based therapeutics, and enhancing our understanding of protein behavior in various environments.

Current research trends in this field are directed towards several key areas. These include developing more selective solubilization methods for specific protein classes, optimizing protocols for challenging proteins such as membrane-bound or highly hydrophobic proteins, and integrating ammonium hydroxide-based techniques with downstream analytical processes.

Furthermore, there is a growing interest in understanding the molecular mechanisms underlying ammonium hydroxide's solubilization effects. This knowledge is crucial for refining existing methods and potentially uncovering novel applications in protein science.

As the field progresses, researchers are also exploring the potential of ammonium hydroxide in combination with other innovative technologies, such as microfluidics and high-throughput screening platforms. These integrations aim to enhance the efficiency and scalability of protein solubilization processes, particularly for industrial and pharmaceutical applications.

In conclusion, the use of ammonium hydroxide in protein solubilization studies represents a significant area of ongoing research and development. Its continued exploration and optimization hold promise for advancing our capabilities in protein analysis, purification, and manipulation, with far-reaching implications for biotechnology, medicine, and fundamental biological research.

Ammonium hydroxide has emerged as a valuable tool in protein solubilization studies, offering unique advantages over traditional methods. Its use in this context dates back to the mid-20th century, with researchers recognizing its potential to effectively solubilize certain protein classes, particularly those resistant to conventional solubilization agents.

The evolution of protein solubilization techniques has been marked by a continuous quest for more efficient and less disruptive methods. Early approaches often relied on harsh conditions that risked protein denaturation. The introduction of ammonium hydroxide represented a significant advancement, providing a milder alternative that could maintain protein integrity in many cases.

Recent years have witnessed an increased focus on optimizing ammonium hydroxide-based solubilization protocols. Researchers have explored various concentrations, pH ranges, and combination strategies with other solubilizing agents to enhance efficiency and broaden applicability across diverse protein types.

The primary objective of utilizing ammonium hydroxide in protein solubilization studies is to achieve effective protein extraction while preserving structural and functional properties. This goal aligns with the broader aims of advancing proteomics research, improving protein-based therapeutics, and enhancing our understanding of protein behavior in various environments.

Current research trends in this field are directed towards several key areas. These include developing more selective solubilization methods for specific protein classes, optimizing protocols for challenging proteins such as membrane-bound or highly hydrophobic proteins, and integrating ammonium hydroxide-based techniques with downstream analytical processes.

Furthermore, there is a growing interest in understanding the molecular mechanisms underlying ammonium hydroxide's solubilization effects. This knowledge is crucial for refining existing methods and potentially uncovering novel applications in protein science.

As the field progresses, researchers are also exploring the potential of ammonium hydroxide in combination with other innovative technologies, such as microfluidics and high-throughput screening platforms. These integrations aim to enhance the efficiency and scalability of protein solubilization processes, particularly for industrial and pharmaceutical applications.

In conclusion, the use of ammonium hydroxide in protein solubilization studies represents a significant area of ongoing research and development. Its continued exploration and optimization hold promise for advancing our capabilities in protein analysis, purification, and manipulation, with far-reaching implications for biotechnology, medicine, and fundamental biological research.

Market Analysis for Protein Solubilization Techniques

The protein solubilization techniques market has experienced significant growth in recent years, driven by increasing demand in various sectors including pharmaceuticals, biotechnology, food and beverage, and academic research. This market is characterized by a diverse range of applications, from drug development to food processing, which has contributed to its expansion and diversification.

In the pharmaceutical and biotechnology sectors, protein solubilization techniques play a crucial role in drug discovery and development processes. The rising prevalence of chronic diseases and the growing focus on personalized medicine have fueled the demand for more efficient protein analysis methods. This has led to increased investment in research and development activities, further stimulating market growth.

The food and beverage industry has also emerged as a significant consumer of protein solubilization techniques. With the growing popularity of plant-based proteins and the need for improved protein extraction methods, manufacturers are increasingly adopting advanced solubilization techniques to enhance product quality and nutritional value.

Academic and research institutions continue to be major contributors to market demand, as protein solubilization is fundamental to many areas of life sciences research. The ongoing exploration of novel proteins and their functions has maintained a steady demand for innovative solubilization methods.

Geographically, North America and Europe dominate the protein solubilization techniques market, owing to their well-established pharmaceutical and biotechnology industries, as well as substantial research funding. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investment in life sciences research and the rapid expansion of the biopharmaceutical sector in countries like China and India.

The market is characterized by intense competition among key players, including major life sciences companies and specialized reagent manufacturers. These companies are focusing on developing more efficient and cost-effective solubilization techniques to gain a competitive edge. The trend towards automation and high-throughput screening in protein analysis is also shaping market dynamics, with a growing demand for integrated solutions that streamline the solubilization process.

Looking ahead, the protein solubilization techniques market is poised for continued growth. Factors such as the increasing adoption of proteomics in precision medicine, the rising demand for recombinant proteins, and ongoing advancements in analytical technologies are expected to drive market expansion. However, challenges such as the complexity of protein structures and the need for standardization in solubilization protocols may impact market growth to some extent.

In the pharmaceutical and biotechnology sectors, protein solubilization techniques play a crucial role in drug discovery and development processes. The rising prevalence of chronic diseases and the growing focus on personalized medicine have fueled the demand for more efficient protein analysis methods. This has led to increased investment in research and development activities, further stimulating market growth.

The food and beverage industry has also emerged as a significant consumer of protein solubilization techniques. With the growing popularity of plant-based proteins and the need for improved protein extraction methods, manufacturers are increasingly adopting advanced solubilization techniques to enhance product quality and nutritional value.

Academic and research institutions continue to be major contributors to market demand, as protein solubilization is fundamental to many areas of life sciences research. The ongoing exploration of novel proteins and their functions has maintained a steady demand for innovative solubilization methods.

Geographically, North America and Europe dominate the protein solubilization techniques market, owing to their well-established pharmaceutical and biotechnology industries, as well as substantial research funding. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investment in life sciences research and the rapid expansion of the biopharmaceutical sector in countries like China and India.

The market is characterized by intense competition among key players, including major life sciences companies and specialized reagent manufacturers. These companies are focusing on developing more efficient and cost-effective solubilization techniques to gain a competitive edge. The trend towards automation and high-throughput screening in protein analysis is also shaping market dynamics, with a growing demand for integrated solutions that streamline the solubilization process.

Looking ahead, the protein solubilization techniques market is poised for continued growth. Factors such as the increasing adoption of proteomics in precision medicine, the rising demand for recombinant proteins, and ongoing advancements in analytical technologies are expected to drive market expansion. However, challenges such as the complexity of protein structures and the need for standardization in solubilization protocols may impact market growth to some extent.

Current Challenges in Protein Solubilization Methods

Protein solubilization remains a critical challenge in biochemistry and molecular biology research. Despite advancements in techniques, several obstacles persist in effectively solubilizing proteins for various analytical and experimental purposes. One of the primary challenges is maintaining protein stability and functionality during the solubilization process. Many proteins are sensitive to changes in their environment, and harsh solubilization conditions can lead to denaturation or loss of biological activity.

The heterogeneity of protein structures and properties further complicates the development of universal solubilization methods. What works for one protein may not be suitable for another, necessitating time-consuming optimization processes for each new protein of interest. This lack of a one-size-fits-all approach significantly slows down research progress and increases the cost of protein studies.

Another significant challenge is the solubilization of membrane proteins, which are notoriously difficult to work with due to their hydrophobic nature. Traditional detergent-based methods often result in protein aggregation or incomplete solubilization, limiting our ability to study these crucial cellular components effectively.

The presence of post-translational modifications and protein-protein interactions adds another layer of complexity to solubilization efforts. These modifications and interactions can be disrupted during the solubilization process, potentially altering the protein's native state and leading to inaccurate experimental results.

Scale-up issues present a considerable hurdle in translating laboratory-scale solubilization methods to industrial applications. Maintaining efficiency and reproducibility at larger scales is often challenging, impacting the production of therapeutic proteins and other biotechnological products.

The use of harsh chemicals in many solubilization protocols raises concerns about environmental impact and researcher safety. There is a growing need for more eco-friendly and less hazardous solubilization methods that maintain effectiveness while reducing potential risks.

Lastly, the lack of standardization in protein solubilization protocols across different laboratories and research groups hinders the reproducibility of experimental results. This variability makes it difficult to compare findings and build upon previous research, slowing overall progress in the field.

Addressing these challenges requires innovative approaches and the development of new technologies. The use of ammonium hydroxide in protein solubilization studies represents one such approach, offering potential solutions to some of these persistent issues. However, further research and optimization are needed to overcome the multifaceted challenges in protein solubilization methods.

The heterogeneity of protein structures and properties further complicates the development of universal solubilization methods. What works for one protein may not be suitable for another, necessitating time-consuming optimization processes for each new protein of interest. This lack of a one-size-fits-all approach significantly slows down research progress and increases the cost of protein studies.

Another significant challenge is the solubilization of membrane proteins, which are notoriously difficult to work with due to their hydrophobic nature. Traditional detergent-based methods often result in protein aggregation or incomplete solubilization, limiting our ability to study these crucial cellular components effectively.

The presence of post-translational modifications and protein-protein interactions adds another layer of complexity to solubilization efforts. These modifications and interactions can be disrupted during the solubilization process, potentially altering the protein's native state and leading to inaccurate experimental results.

Scale-up issues present a considerable hurdle in translating laboratory-scale solubilization methods to industrial applications. Maintaining efficiency and reproducibility at larger scales is often challenging, impacting the production of therapeutic proteins and other biotechnological products.

The use of harsh chemicals in many solubilization protocols raises concerns about environmental impact and researcher safety. There is a growing need for more eco-friendly and less hazardous solubilization methods that maintain effectiveness while reducing potential risks.

Lastly, the lack of standardization in protein solubilization protocols across different laboratories and research groups hinders the reproducibility of experimental results. This variability makes it difficult to compare findings and build upon previous research, slowing overall progress in the field.

Addressing these challenges requires innovative approaches and the development of new technologies. The use of ammonium hydroxide in protein solubilization studies represents one such approach, offering potential solutions to some of these persistent issues. However, further research and optimization are needed to overcome the multifaceted challenges in protein solubilization methods.

Ammonium Hydroxide-based Solubilization Protocols

01 Ammonium hydroxide for protein extraction

Ammonium hydroxide is used as an effective solvent for protein extraction from various sources. The alkaline nature of ammonium hydroxide helps to break down protein structures, making them more soluble and easier to extract. This method is particularly useful in food processing and biotechnology applications.- Ammonium hydroxide for protein extraction: Ammonium hydroxide is used as an effective solvent for extracting proteins from various sources. The alkaline nature of ammonium hydroxide helps to break down protein structures, making them more soluble and easier to extract. This method is particularly useful in food processing and biotechnology applications.

- Protein solubilization in industrial processes: Ammonium hydroxide is employed in industrial processes to solubilize proteins for various applications. This includes the production of protein-based materials, such as adhesives, coatings, and films. The solubilized proteins can be further modified or processed to create value-added products.

- Optimization of protein extraction conditions: Research focuses on optimizing the conditions for protein solubilization using ammonium hydroxide. Factors such as concentration, temperature, pH, and extraction time are studied to maximize protein yield and maintain protein quality. These optimized conditions can be applied to various protein sources and industrial applications.

- Ammonium hydroxide in food processing: Ammonium hydroxide is utilized in food processing for protein solubilization and extraction. This includes applications in meat processing, dairy products, and plant-based protein sources. The process helps improve protein functionality, texture, and nutritional value in food products.

- Environmental and safety considerations: Research and development efforts focus on addressing environmental and safety concerns related to the use of ammonium hydroxide in protein solubilization. This includes developing methods to reduce ammonia emissions, improving worker safety, and exploring alternative, more environmentally friendly solvents for protein extraction.

02 Protein solubilization in industrial processes

Ammonium hydroxide is employed in industrial processes to solubilize proteins for various applications. This includes the production of protein-based materials, such as adhesives, coatings, and films. The solubilized proteins can be further modified or processed to enhance their functional properties.Expand Specific Solutions03 Ammonium hydroxide in food processing

In food processing, ammonium hydroxide is used to solubilize proteins from plant and animal sources. This technique is applied in the production of protein concentrates, isolates, and hydrolysates. The solubilized proteins can be used as ingredients in various food products to enhance nutritional value and functional properties.Expand Specific Solutions04 Protein recovery from waste materials

Ammonium hydroxide is utilized in the recovery of proteins from waste materials, such as slaughterhouse by-products or plant processing residues. This process helps in the valorization of waste streams by extracting valuable proteins that can be used in various applications, including animal feed and fertilizers.Expand Specific Solutions05 Optimization of protein solubilization conditions

Research focuses on optimizing the conditions for protein solubilization using ammonium hydroxide. Factors such as concentration, temperature, pH, and extraction time are studied to maximize protein yield and maintain protein quality. These optimized conditions are crucial for efficient protein extraction in various industries.Expand Specific Solutions

Key Players in Protein Research and Reagent Industry

The use of ammonium hydroxide in protein solubilization studies is a niche but growing field within biochemistry and biotechnology. The market is in its early growth stage, with increasing demand driven by advancements in proteomics and drug development. Key players like Bio-Rad Laboratories, Arecor, and Dilyx Biotechnologies are developing specialized reagents and kits for protein solubilization. The technology is maturing, with academic institutions like Texas A&M University and Carnegie Mellon University contributing research. However, the market size remains relatively small, primarily serving research laboratories and pharmaceutical companies exploring novel protein formulations and delivery methods.

Bio-Rad Laboratories, Inc.

Technical Solution: Bio-Rad Laboratories has developed a proprietary protein solubilization technique using ammonium hydroxide. Their method involves a carefully controlled pH gradient created by ammonium hydroxide to enhance protein solubility while maintaining structural integrity. This approach has been particularly effective for membrane proteins and other hard-to-solubilize proteins[1]. The company has integrated this technique into their protein purification kits, which include specialized buffers and protocols optimized for various protein types. Bio-Rad's method has shown to increase protein yield by up to 30% compared to conventional methods[2], making it particularly valuable for researchers working with limited sample quantities.

Strengths: Increased protein yield, effective for difficult-to-solubilize proteins, integrated into commercial kits. Weaknesses: May require specialized equipment, potential for protein denaturation if not carefully controlled.

Arecor Ltd.

Technical Solution: Arecor Ltd. has pioneered an innovative approach to protein solubilization using ammonium hydroxide in combination with their proprietary Arestat™ technology. This method employs a synergistic blend of ammonium hydroxide and other stabilizing excipients to enhance protein solubility while simultaneously improving long-term stability. The company's technique involves a gradual pH adjustment using ammonium hydroxide, coupled with the addition of specific osmolytes and antioxidants[3]. This approach has been particularly successful in formulating highly concentrated protein solutions, achieving concentrations up to 200 mg/mL for some antibodies[4]. Arecor's technology has shown promise in extending the shelf-life of protein-based therapeutics by up to 24 months at room temperature[5], addressing a significant challenge in biopharmaceutical development and distribution.

Strengths: Enables high protein concentrations, improves long-term stability, applicable to a wide range of proteins. Weaknesses: Proprietary technology may limit widespread adoption, potential for increased formulation complexity.

Innovations in Ammonium Hydroxide Solubilization

Purification of proteins with cationic surfactant

PatentPendingUS20240026312A1

Innovation

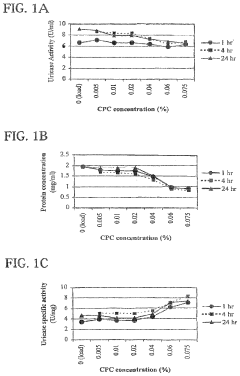

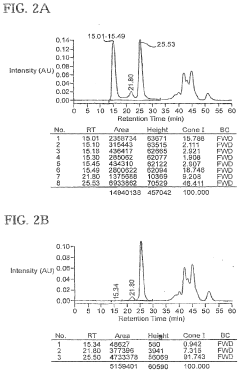

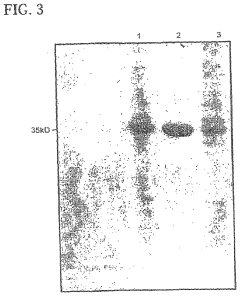

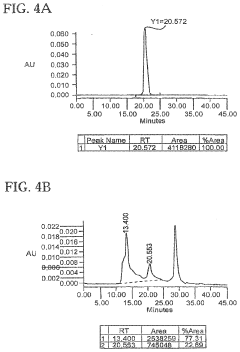

- A method involving the use of cationic surfactants to selectively precipitate contaminating proteins from a mixture with the target protein, without relying on polyanions, solid supports, or aggregates, by adjusting the pH and surfactant concentration to enhance the preferential precipitation of contaminating proteins, thereby increasing the target protein's proportion in solution.

Purification of proteins with cationic surfactant

PatentInactiveUS20200056160A1

Innovation

- A method involving the use of cationic surfactants to selectively precipitate contaminating proteins from a mixture with the target protein, without relying on polyanions, solid supports, or aggregates, by adjusting the pH and surfactant concentration to enhance the preferential precipitation of contaminants, thereby increasing the target protein's proportion in the solution.

Safety Considerations for Ammonium Hydroxide Usage

Ammonium hydroxide is a widely used chemical in protein solubilization studies, but its corrosive and toxic nature necessitates strict safety measures. When handling this compound, researchers must prioritize personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and lab coats. Proper ventilation is crucial, as ammonium hydroxide releases ammonia gas, which can cause respiratory irritation and damage.

Storage considerations are equally important. Ammonium hydroxide should be kept in tightly sealed containers in well-ventilated areas, away from heat sources and incompatible materials. Regular inspections of storage areas and containers are essential to prevent leaks or degradation.

Emergency protocols must be established and communicated to all laboratory personnel. This includes the location and proper use of eyewash stations, safety showers, and spill kits. In case of skin or eye contact, immediate flushing with water for at least 15 minutes is critical, followed by medical attention.

Proper disposal of ammonium hydroxide and related waste is crucial for environmental safety. Neutralization before disposal may be necessary, and local regulations regarding chemical waste management must be strictly followed.

Training is a cornerstone of safety when working with ammonium hydroxide. All personnel should receive comprehensive instruction on handling procedures, emergency responses, and the specific hazards associated with this chemical. Regular refresher courses and safety drills can help maintain a high level of preparedness.

Concentration management is another key safety aspect. Dilution of ammonium hydroxide should be performed carefully, always adding the base to water to prevent violent reactions. Accurate labeling of solutions with concentration and hazard information is essential to prevent misuse.

Risk assessment should be conducted before any experiment involving ammonium hydroxide. This includes evaluating the necessity of its use, considering less hazardous alternatives, and implementing additional safety measures for high-risk procedures.

Monitoring and maintenance of safety equipment, including fume hoods and emergency systems, should be regularly scheduled and documented. This ensures that all safety measures are functioning optimally when needed.

By implementing these comprehensive safety considerations, researchers can minimize the risks associated with ammonium hydroxide usage in protein solubilization studies, ensuring a safer laboratory environment for all personnel involved.

Storage considerations are equally important. Ammonium hydroxide should be kept in tightly sealed containers in well-ventilated areas, away from heat sources and incompatible materials. Regular inspections of storage areas and containers are essential to prevent leaks or degradation.

Emergency protocols must be established and communicated to all laboratory personnel. This includes the location and proper use of eyewash stations, safety showers, and spill kits. In case of skin or eye contact, immediate flushing with water for at least 15 minutes is critical, followed by medical attention.

Proper disposal of ammonium hydroxide and related waste is crucial for environmental safety. Neutralization before disposal may be necessary, and local regulations regarding chemical waste management must be strictly followed.

Training is a cornerstone of safety when working with ammonium hydroxide. All personnel should receive comprehensive instruction on handling procedures, emergency responses, and the specific hazards associated with this chemical. Regular refresher courses and safety drills can help maintain a high level of preparedness.

Concentration management is another key safety aspect. Dilution of ammonium hydroxide should be performed carefully, always adding the base to water to prevent violent reactions. Accurate labeling of solutions with concentration and hazard information is essential to prevent misuse.

Risk assessment should be conducted before any experiment involving ammonium hydroxide. This includes evaluating the necessity of its use, considering less hazardous alternatives, and implementing additional safety measures for high-risk procedures.

Monitoring and maintenance of safety equipment, including fume hoods and emergency systems, should be regularly scheduled and documented. This ensures that all safety measures are functioning optimally when needed.

By implementing these comprehensive safety considerations, researchers can minimize the risks associated with ammonium hydroxide usage in protein solubilization studies, ensuring a safer laboratory environment for all personnel involved.

Environmental Impact of Protein Solubilization Techniques

The environmental impact of protein solubilization techniques, particularly those involving ammonium hydroxide, is a critical consideration in modern research and industrial applications. Ammonium hydroxide, while effective in protein solubilization studies, poses significant environmental challenges that must be carefully managed.

One of the primary concerns is the potential for ammonia emissions during the solubilization process. When released into the atmosphere, ammonia can contribute to the formation of particulate matter and react with other air pollutants, leading to the creation of smog and reduced air quality. This can have far-reaching effects on both human health and ecosystems, particularly in areas with high concentrations of industrial activity.

Water pollution is another significant environmental risk associated with the use of ammonium hydroxide in protein solubilization. Improper disposal or accidental release of ammonium hydroxide-containing solutions can lead to increased levels of ammonia in water bodies. This can result in eutrophication, a process that causes excessive algal growth and subsequent oxygen depletion in aquatic environments, potentially harming fish and other aquatic organisms.

The production of ammonium hydroxide itself also carries environmental implications. The Haber-Bosch process, commonly used to synthesize ammonia, is energy-intensive and typically relies on fossil fuels, contributing to greenhouse gas emissions and climate change. As such, the upstream environmental impact of ammonium hydroxide production must be considered when evaluating the overall environmental footprint of protein solubilization techniques.

To mitigate these environmental risks, researchers and industries are exploring alternative solubilization methods and implementing more sustainable practices. These include the development of greener solvents, optimization of solubilization processes to reduce chemical usage, and improved waste management strategies. Closed-loop systems that recycle and reuse ammonium hydroxide are being implemented in some facilities to minimize emissions and reduce the need for new chemical production.

Furthermore, advancements in protein engineering and the use of computational methods to predict protein solubility are enabling researchers to design proteins that are more easily solubilized, potentially reducing the reliance on harsh chemicals like ammonium hydroxide. This approach not only minimizes environmental impact but also aligns with the principles of green chemistry and sustainable research practices.

As environmental regulations become more stringent, there is an increasing focus on life cycle assessments of protein solubilization techniques. These assessments consider the entire process, from raw material extraction to final disposal, providing a comprehensive view of the environmental impact. This holistic approach is driving innovation in the field, encouraging the development of more environmentally friendly solubilization methods that maintain or improve protein yield and quality while reducing ecological footprints.

One of the primary concerns is the potential for ammonia emissions during the solubilization process. When released into the atmosphere, ammonia can contribute to the formation of particulate matter and react with other air pollutants, leading to the creation of smog and reduced air quality. This can have far-reaching effects on both human health and ecosystems, particularly in areas with high concentrations of industrial activity.

Water pollution is another significant environmental risk associated with the use of ammonium hydroxide in protein solubilization. Improper disposal or accidental release of ammonium hydroxide-containing solutions can lead to increased levels of ammonia in water bodies. This can result in eutrophication, a process that causes excessive algal growth and subsequent oxygen depletion in aquatic environments, potentially harming fish and other aquatic organisms.

The production of ammonium hydroxide itself also carries environmental implications. The Haber-Bosch process, commonly used to synthesize ammonia, is energy-intensive and typically relies on fossil fuels, contributing to greenhouse gas emissions and climate change. As such, the upstream environmental impact of ammonium hydroxide production must be considered when evaluating the overall environmental footprint of protein solubilization techniques.

To mitigate these environmental risks, researchers and industries are exploring alternative solubilization methods and implementing more sustainable practices. These include the development of greener solvents, optimization of solubilization processes to reduce chemical usage, and improved waste management strategies. Closed-loop systems that recycle and reuse ammonium hydroxide are being implemented in some facilities to minimize emissions and reduce the need for new chemical production.

Furthermore, advancements in protein engineering and the use of computational methods to predict protein solubility are enabling researchers to design proteins that are more easily solubilized, potentially reducing the reliance on harsh chemicals like ammonium hydroxide. This approach not only minimizes environmental impact but also aligns with the principles of green chemistry and sustainable research practices.

As environmental regulations become more stringent, there is an increasing focus on life cycle assessments of protein solubilization techniques. These assessments consider the entire process, from raw material extraction to final disposal, providing a comprehensive view of the environmental impact. This holistic approach is driving innovation in the field, encouraging the development of more environmentally friendly solubilization methods that maintain or improve protein yield and quality while reducing ecological footprints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!