Ammonium Hydroxide in Tinplate Surface Treatment for Corrosion Resistance

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tinplate Corrosion Protection: Background and Objectives

Tinplate, a thin steel sheet coated with a layer of tin, has been widely used in the packaging industry for decades due to its excellent corrosion resistance and food safety properties. The background of tinplate corrosion protection can be traced back to the early 20th century when the need for durable and safe food packaging became increasingly important. As the demand for canned foods grew, so did the necessity for improved corrosion resistance in tinplate materials.

The evolution of tinplate corrosion protection has been driven by both technological advancements and regulatory requirements. Initially, the focus was primarily on increasing the thickness of the tin coating to enhance corrosion resistance. However, this approach proved to be costly and inefficient. As a result, researchers began exploring alternative methods to improve the corrosion resistance of tinplate while maintaining cost-effectiveness.

One of the key developments in tinplate corrosion protection was the introduction of passivation treatments. These treatments involve the application of a thin, protective layer on the tinplate surface to enhance its resistance to corrosion. Among the various passivation methods, the use of chromium-based compounds gained significant popularity due to their excellent corrosion inhibition properties. However, environmental and health concerns associated with chromium compounds have led to a shift towards more sustainable alternatives.

In recent years, the focus has shifted towards developing environmentally friendly and cost-effective corrosion protection methods for tinplate. This has led to increased interest in alternative passivation treatments, including the use of ammonium hydroxide. The objective of researching ammonium hydroxide in tinplate surface treatment for corrosion resistance is to develop a sustainable and efficient method that can replace traditional chromium-based passivation treatments.

The primary goals of this research include understanding the mechanism of corrosion protection provided by ammonium hydroxide, optimizing the treatment process parameters, and evaluating the long-term performance of treated tinplate surfaces. Additionally, the research aims to assess the environmental impact and cost-effectiveness of ammonium hydroxide-based treatments compared to existing methods.

By exploring the potential of ammonium hydroxide in tinplate surface treatment, researchers hope to address the growing demand for eco-friendly packaging materials while maintaining or improving the corrosion resistance properties of tinplate. This research aligns with the broader industry trend towards sustainable packaging solutions and the development of innovative surface treatment technologies.

The evolution of tinplate corrosion protection has been driven by both technological advancements and regulatory requirements. Initially, the focus was primarily on increasing the thickness of the tin coating to enhance corrosion resistance. However, this approach proved to be costly and inefficient. As a result, researchers began exploring alternative methods to improve the corrosion resistance of tinplate while maintaining cost-effectiveness.

One of the key developments in tinplate corrosion protection was the introduction of passivation treatments. These treatments involve the application of a thin, protective layer on the tinplate surface to enhance its resistance to corrosion. Among the various passivation methods, the use of chromium-based compounds gained significant popularity due to their excellent corrosion inhibition properties. However, environmental and health concerns associated with chromium compounds have led to a shift towards more sustainable alternatives.

In recent years, the focus has shifted towards developing environmentally friendly and cost-effective corrosion protection methods for tinplate. This has led to increased interest in alternative passivation treatments, including the use of ammonium hydroxide. The objective of researching ammonium hydroxide in tinplate surface treatment for corrosion resistance is to develop a sustainable and efficient method that can replace traditional chromium-based passivation treatments.

The primary goals of this research include understanding the mechanism of corrosion protection provided by ammonium hydroxide, optimizing the treatment process parameters, and evaluating the long-term performance of treated tinplate surfaces. Additionally, the research aims to assess the environmental impact and cost-effectiveness of ammonium hydroxide-based treatments compared to existing methods.

By exploring the potential of ammonium hydroxide in tinplate surface treatment, researchers hope to address the growing demand for eco-friendly packaging materials while maintaining or improving the corrosion resistance properties of tinplate. This research aligns with the broader industry trend towards sustainable packaging solutions and the development of innovative surface treatment technologies.

Market Analysis for Corrosion-Resistant Tinplate

The global market for corrosion-resistant tinplate has been experiencing steady growth, driven by increasing demand from various end-use industries such as food and beverage packaging, aerosol cans, and automotive components. The market is expected to continue its upward trajectory due to the rising need for sustainable and durable packaging solutions.

The food and beverage industry remains the largest consumer of corrosion-resistant tinplate, accounting for a significant portion of the market share. This sector's demand is fueled by the growing population, changing consumer lifestyles, and the need for extended shelf life of packaged products. The convenience and recyclability of tinplate packaging further contribute to its popularity in this industry.

Emerging economies, particularly in Asia-Pacific and Latin America, are witnessing rapid industrialization and urbanization, leading to increased consumption of packaged goods. This trend is driving the demand for corrosion-resistant tinplate in these regions. China, in particular, has become a major player in both production and consumption of tinplate, influencing global market dynamics.

The automotive industry is another key driver for the corrosion-resistant tinplate market. As vehicle manufacturers focus on lightweight materials to improve fuel efficiency and reduce emissions, tinplate is increasingly being used in various automotive components due to its corrosion resistance and strength-to-weight ratio.

Environmental concerns and stringent regulations regarding packaging materials have also positively impacted the market for corrosion-resistant tinplate. Its recyclability and eco-friendly nature make it a preferred choice over plastic packaging in many applications, aligning with the global push towards sustainable packaging solutions.

However, the market faces challenges from alternative packaging materials such as aluminum and plastic. These materials offer certain advantages in terms of cost and weight, posing competition to tinplate in some applications. Additionally, fluctuations in raw material prices, particularly steel, can impact the overall market growth and profitability of tinplate manufacturers.

Technological advancements in surface treatment processes, including the use of ammonium hydroxide, are expected to enhance the corrosion resistance properties of tinplate further. This innovation is likely to open up new application areas and strengthen tinplate's position in existing markets, potentially leading to market expansion and increased adoption across industries.

The food and beverage industry remains the largest consumer of corrosion-resistant tinplate, accounting for a significant portion of the market share. This sector's demand is fueled by the growing population, changing consumer lifestyles, and the need for extended shelf life of packaged products. The convenience and recyclability of tinplate packaging further contribute to its popularity in this industry.

Emerging economies, particularly in Asia-Pacific and Latin America, are witnessing rapid industrialization and urbanization, leading to increased consumption of packaged goods. This trend is driving the demand for corrosion-resistant tinplate in these regions. China, in particular, has become a major player in both production and consumption of tinplate, influencing global market dynamics.

The automotive industry is another key driver for the corrosion-resistant tinplate market. As vehicle manufacturers focus on lightweight materials to improve fuel efficiency and reduce emissions, tinplate is increasingly being used in various automotive components due to its corrosion resistance and strength-to-weight ratio.

Environmental concerns and stringent regulations regarding packaging materials have also positively impacted the market for corrosion-resistant tinplate. Its recyclability and eco-friendly nature make it a preferred choice over plastic packaging in many applications, aligning with the global push towards sustainable packaging solutions.

However, the market faces challenges from alternative packaging materials such as aluminum and plastic. These materials offer certain advantages in terms of cost and weight, posing competition to tinplate in some applications. Additionally, fluctuations in raw material prices, particularly steel, can impact the overall market growth and profitability of tinplate manufacturers.

Technological advancements in surface treatment processes, including the use of ammonium hydroxide, are expected to enhance the corrosion resistance properties of tinplate further. This innovation is likely to open up new application areas and strengthen tinplate's position in existing markets, potentially leading to market expansion and increased adoption across industries.

Current Challenges in Tinplate Surface Treatment

The surface treatment of tinplate faces several significant challenges in the current technological landscape. One of the primary issues is the need for more environmentally friendly and sustainable processes. Traditional surface treatment methods often involve the use of hazardous chemicals, which pose risks to both workers and the environment. This has led to increased regulatory pressure and a growing demand for greener alternatives.

Another challenge lies in achieving consistent and uniform coating quality across large production volumes. Variations in surface treatment can lead to inconsistencies in corrosion resistance, affecting the overall quality and longevity of tinplate products. This is particularly critical in industries such as food packaging, where even minor defects can have significant consequences.

The optimization of energy consumption during the surface treatment process remains a persistent challenge. Current methods often require high temperatures and extended processing times, resulting in substantial energy costs. Developing more energy-efficient techniques without compromising the quality of surface treatment is a key area of focus for researchers and industry professionals.

Adhesion between the tin coating and the steel substrate is another critical issue. Poor adhesion can lead to flaking or peeling of the protective layer, compromising the corrosion resistance of the tinplate. Improving the bonding strength while maintaining the desired surface properties is an ongoing challenge that requires innovative solutions.

The increasing demand for tinplate with enhanced functional properties presents additional challenges. There is a growing need for surfaces that not only provide corrosion resistance but also offer properties such as improved printability, better lacquer adhesion, or antimicrobial characteristics. Developing multi-functional surface treatments that can meet these diverse requirements without significantly increasing production costs is a complex task.

Furthermore, the industry faces challenges in adapting to new substrate materials and alloy compositions. As manufacturers explore alternative materials to improve performance or reduce costs, surface treatment processes must be flexible enough to accommodate these changes while maintaining effectiveness.

Lastly, the integration of surface treatment processes into high-speed production lines poses significant technical challenges. Developing methods that can deliver high-quality surface treatments at increased production speeds, without sacrificing uniformity or effectiveness, is crucial for meeting the growing demand for tinplate products in various industries.

Another challenge lies in achieving consistent and uniform coating quality across large production volumes. Variations in surface treatment can lead to inconsistencies in corrosion resistance, affecting the overall quality and longevity of tinplate products. This is particularly critical in industries such as food packaging, where even minor defects can have significant consequences.

The optimization of energy consumption during the surface treatment process remains a persistent challenge. Current methods often require high temperatures and extended processing times, resulting in substantial energy costs. Developing more energy-efficient techniques without compromising the quality of surface treatment is a key area of focus for researchers and industry professionals.

Adhesion between the tin coating and the steel substrate is another critical issue. Poor adhesion can lead to flaking or peeling of the protective layer, compromising the corrosion resistance of the tinplate. Improving the bonding strength while maintaining the desired surface properties is an ongoing challenge that requires innovative solutions.

The increasing demand for tinplate with enhanced functional properties presents additional challenges. There is a growing need for surfaces that not only provide corrosion resistance but also offer properties such as improved printability, better lacquer adhesion, or antimicrobial characteristics. Developing multi-functional surface treatments that can meet these diverse requirements without significantly increasing production costs is a complex task.

Furthermore, the industry faces challenges in adapting to new substrate materials and alloy compositions. As manufacturers explore alternative materials to improve performance or reduce costs, surface treatment processes must be flexible enough to accommodate these changes while maintaining effectiveness.

Lastly, the integration of surface treatment processes into high-speed production lines poses significant technical challenges. Developing methods that can deliver high-quality surface treatments at increased production speeds, without sacrificing uniformity or effectiveness, is crucial for meeting the growing demand for tinplate products in various industries.

Ammonium Hydroxide-Based Surface Treatment Solutions

01 Corrosion-resistant coatings

Specialized coatings can be applied to surfaces to protect against ammonium hydroxide corrosion. These coatings often include polymer-based or epoxy materials that create a barrier between the corrosive substance and the underlying material. The coatings may also incorporate additives that enhance their resistance to alkaline environments.- Corrosion-resistant coatings: Specialized coatings can be applied to surfaces to protect against ammonium hydroxide corrosion. These coatings often include polymer-based or epoxy materials that form a barrier between the corrosive substance and the underlying material. The coatings may also incorporate additives that enhance their resistance to alkaline environments.

- Material selection for ammonium hydroxide resistance: Choosing appropriate materials that inherently resist ammonium hydroxide corrosion is crucial. Certain metals, alloys, and polymers exhibit better resistance to alkaline environments. These materials may include stainless steel grades, nickel-based alloys, or specific thermoplastics that maintain their integrity when exposed to ammonium hydroxide.

- Inhibitor additives for corrosion prevention: Chemical inhibitors can be added to ammonium hydroxide solutions or incorporated into materials to reduce corrosion. These additives work by forming protective films on surfaces or by altering the electrochemical properties of the solution to minimize corrosive effects. Organic and inorganic compounds may be used as inhibitors depending on the specific application.

- Surface treatment techniques: Various surface treatment methods can enhance the corrosion resistance of materials exposed to ammonium hydroxide. These techniques may include passivation, anodizing, or chemical conversion coatings. Such treatments modify the surface properties of the material, creating a more resistant layer that protects against alkaline attack.

- Corrosion monitoring and maintenance strategies: Implementing effective monitoring systems and maintenance protocols is essential for managing ammonium hydroxide corrosion. This may involve regular inspections, the use of corrosion sensors, and the development of predictive maintenance schedules. Additionally, proper cleaning procedures and neutralization techniques can help mitigate corrosion risks in equipment and storage facilities.

02 Material selection for ammonium hydroxide resistance

Choosing appropriate materials that inherently resist ammonium hydroxide corrosion is crucial. Certain metals, alloys, and polymers exhibit better resistance to alkaline environments. These materials may include stainless steel grades, nickel alloys, or specific thermoplastics that maintain their integrity when exposed to ammonium hydroxide.Expand Specific Solutions03 Inhibitors and additives for corrosion prevention

Chemical inhibitors and additives can be incorporated into materials or solutions to enhance resistance to ammonium hydroxide corrosion. These substances work by forming protective films on surfaces or altering the chemical properties of the corrosive environment, thereby reducing the rate of corrosion.Expand Specific Solutions04 Surface treatment techniques

Various surface treatment methods can be employed to improve the corrosion resistance of materials exposed to ammonium hydroxide. These techniques may include passivation, anodizing, or chemical conversion coatings that modify the surface properties of the material to enhance its resistance to alkaline attack.Expand Specific Solutions05 Monitoring and maintenance strategies

Implementing effective monitoring and maintenance strategies is essential for managing ammonium hydroxide corrosion. This includes regular inspections, corrosion rate measurements, and the use of corrosion monitoring techniques. Proper maintenance procedures, such as cleaning and reapplication of protective coatings, can significantly extend the life of equipment exposed to ammonium hydroxide.Expand Specific Solutions

Key Players in Tinplate and Surface Treatment Industry

The research on ammonium hydroxide in tinplate surface treatment for corrosion resistance is at a mature stage, with significant market potential due to the growing demand for corrosion-resistant materials in various industries. The global tinplate market is expected to expand, driven by packaging and automotive sectors. Key players like Henkel AG & Co. KGaA, JFE Steel Corp., and Baoshan Iron & Steel Co., Ltd. are actively involved in developing advanced surface treatment technologies. These companies, along with others such as ThyssenKrupp Rasselstein GmbH and Tata Steel Europe Limited, are investing in R&D to enhance the effectiveness of ammonium hydroxide-based treatments, focusing on improving corrosion resistance while meeting environmental regulations.

Henkel AG & Co. KGaA

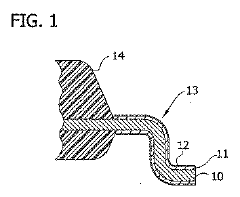

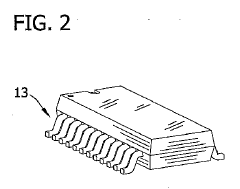

Technical Solution: Henkel has developed an innovative ammonium hydroxide-based surface treatment for tinplate corrosion resistance. Their process involves applying a thin layer of ammonium hydroxide solution to the tinplate surface, which reacts with the tin to form a protective oxide layer. This layer significantly enhances the corrosion resistance of the tinplate[1]. The treatment is followed by a controlled drying process to ensure uniform coverage and optimal adhesion. Henkel's method also incorporates nano-scale additives to further improve the barrier properties of the protective layer[3].

Strengths: Environmentally friendly, cost-effective, and provides excellent corrosion resistance. Weaknesses: May require specialized equipment for application and careful control of process parameters.

JFE Steel Corp.

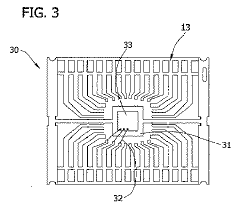

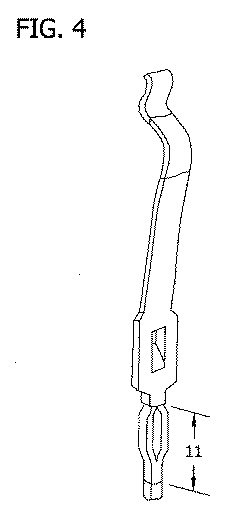

Technical Solution: JFE Steel has pioneered a multi-stage ammonium hydroxide treatment for tinplate surface protection. Their process begins with a pre-cleaning step to remove any contaminants, followed by the application of a high-concentration ammonium hydroxide solution. This solution is then subjected to a controlled electrolysis process, which promotes the formation of a dense, uniform protective layer on the tinplate surface[2]. JFE Steel's method also incorporates a post-treatment step involving the application of a proprietary organic sealant, which further enhances the corrosion resistance and durability of the treated tinplate[4].

Strengths: Highly effective corrosion resistance, suitable for a wide range of tinplate products. Weaknesses: Complex multi-stage process may increase production time and costs.

Innovations in Ammonium Hydroxide Surface Treatment

Improved corrosion resistance of tin surface

PatentInactiveJP2008501861A

Innovation

- Applying a composition comprising phosphonic acid compounds and water to form a phosphorous-based film on tin-based surfaces, which inhibits corrosion and maintains solderability without high temperatures, using concentrations between 0.01 to 10% weight/volume with optional organic solvents up to 30% by volume.

Corrosion protective cleaning agent for tin-plated steel

PatentInactiveEP0817871A1

Innovation

- An aqueous cleaning solution containing 100-400 ppm complex fluorides of boron, titanium, or hafnium, 100-2000 ppm nonionic surfactants, 100-1000 ppm corrosion inhibitors, and aluminum ions, with a pH of 3-6, is used to clean and provide corrosion protection to tinplate cans in a single step, preventing surface corrosion and ensuring good paint adhesion.

Environmental Impact of Ammonium Hydroxide Treatments

The use of ammonium hydroxide in tinplate surface treatment for corrosion resistance has significant environmental implications that warrant careful consideration. While this treatment method offers enhanced protection against corrosion, its environmental impact must be thoroughly assessed to ensure sustainable practices in the tinplate industry.

Ammonium hydroxide, when released into the environment, can have detrimental effects on aquatic ecosystems. The compound can raise the pH levels of water bodies, potentially harming fish and other aquatic organisms. Additionally, the nitrogen content in ammonium hydroxide can contribute to eutrophication, leading to excessive algal growth and oxygen depletion in water systems.

Air quality is another concern associated with ammonium hydroxide treatments. The volatile nature of the compound can result in ammonia emissions, which contribute to air pollution and may pose respiratory risks to workers and nearby communities. These emissions can also participate in the formation of particulate matter, further impacting air quality.

The production and transportation of ammonium hydroxide for tinplate treatment also carry environmental risks. Accidental spills or leaks during these processes can contaminate soil and water resources, potentially affecting local ecosystems and human health. Moreover, the energy-intensive production of ammonium hydroxide contributes to greenhouse gas emissions, exacerbating climate change concerns.

Waste management is a critical aspect of the environmental impact assessment. Proper disposal of ammonium hydroxide-containing waste from tinplate treatment facilities is essential to prevent soil and groundwater contamination. Inadequate handling or disposal practices can lead to long-term environmental degradation and potential health hazards for surrounding communities.

However, it is important to note that advancements in treatment technologies and waste management practices have the potential to mitigate some of these environmental concerns. Closed-loop systems, which recycle and reuse ammonium hydroxide, can significantly reduce emissions and waste generation. Additionally, the development of more environmentally friendly alternatives to ammonium hydroxide is an active area of research in the tinplate industry.

Regulatory compliance and environmental monitoring play crucial roles in managing the environmental impact of ammonium hydroxide treatments. Stringent regulations on emissions, waste disposal, and workplace safety help ensure that the use of this compound in tinplate surface treatment is conducted responsibly and with minimal environmental harm.

Ammonium hydroxide, when released into the environment, can have detrimental effects on aquatic ecosystems. The compound can raise the pH levels of water bodies, potentially harming fish and other aquatic organisms. Additionally, the nitrogen content in ammonium hydroxide can contribute to eutrophication, leading to excessive algal growth and oxygen depletion in water systems.

Air quality is another concern associated with ammonium hydroxide treatments. The volatile nature of the compound can result in ammonia emissions, which contribute to air pollution and may pose respiratory risks to workers and nearby communities. These emissions can also participate in the formation of particulate matter, further impacting air quality.

The production and transportation of ammonium hydroxide for tinplate treatment also carry environmental risks. Accidental spills or leaks during these processes can contaminate soil and water resources, potentially affecting local ecosystems and human health. Moreover, the energy-intensive production of ammonium hydroxide contributes to greenhouse gas emissions, exacerbating climate change concerns.

Waste management is a critical aspect of the environmental impact assessment. Proper disposal of ammonium hydroxide-containing waste from tinplate treatment facilities is essential to prevent soil and groundwater contamination. Inadequate handling or disposal practices can lead to long-term environmental degradation and potential health hazards for surrounding communities.

However, it is important to note that advancements in treatment technologies and waste management practices have the potential to mitigate some of these environmental concerns. Closed-loop systems, which recycle and reuse ammonium hydroxide, can significantly reduce emissions and waste generation. Additionally, the development of more environmentally friendly alternatives to ammonium hydroxide is an active area of research in the tinplate industry.

Regulatory compliance and environmental monitoring play crucial roles in managing the environmental impact of ammonium hydroxide treatments. Stringent regulations on emissions, waste disposal, and workplace safety help ensure that the use of this compound in tinplate surface treatment is conducted responsibly and with minimal environmental harm.

Cost-Benefit Analysis of Ammonium Hydroxide Application

The application of ammonium hydroxide in tinplate surface treatment for corrosion resistance presents a complex cost-benefit scenario that warrants careful analysis. Initial investment costs for implementing ammonium hydroxide-based treatments are relatively low compared to alternative corrosion prevention methods. The chemical itself is inexpensive and readily available, reducing procurement expenses.

Equipment modifications required for ammonium hydroxide application are typically minimal, further containing capital expenditures. Operational costs associated with the treatment process are also favorable, as ammonium hydroxide can be applied efficiently with existing tinplate production lines, minimizing disruptions to manufacturing workflows.

From a benefits perspective, ammonium hydroxide treatment significantly enhances the corrosion resistance of tinplate surfaces. This improvement in product quality can lead to extended shelf life for canned goods and reduced product losses due to corrosion-related failures. Such enhancements may justify premium pricing for treated tinplate products, potentially increasing profit margins.

The environmental impact of ammonium hydroxide usage is generally lower than that of many alternative corrosion inhibitors. This can result in reduced waste management costs and improved compliance with environmental regulations, potentially avoiding fines and penalties associated with more hazardous substances.

However, there are some drawbacks to consider. While ammonium hydroxide is less toxic than many alternatives, proper handling and safety measures are still required, incurring some additional training and equipment costs. Ventilation systems may need upgrades to manage ammonia fumes, representing a potential capital expense.

Long-term exposure of workers to ammonia vapors, even at low levels, may lead to health issues, potentially resulting in increased healthcare costs or worker compensation claims. Regular monitoring and maintenance of air quality in the production environment add to operational expenses.

The effectiveness of ammonium hydroxide treatment may vary depending on specific tinplate compositions and intended applications. In some cases, additional or complementary treatments might be necessary to achieve desired corrosion resistance levels, potentially offsetting some of the cost advantages.

Market acceptance of ammonium hydroxide-treated tinplate products must also be considered. While the treatment is generally viewed favorably, some customers may have concerns about potential ammonia residues or odors, necessitating additional quality assurance measures or marketing efforts to address these perceptions.

In conclusion, the cost-benefit analysis of ammonium hydroxide application in tinplate surface treatment for corrosion resistance generally leans positive. The relatively low implementation and operational costs, combined with significant improvements in product quality and potential market advantages, often outweigh the associated risks and additional expenses. However, a thorough assessment of specific production environments, regulatory landscapes, and market demands is crucial for determining the overall economic viability of this treatment method.

Equipment modifications required for ammonium hydroxide application are typically minimal, further containing capital expenditures. Operational costs associated with the treatment process are also favorable, as ammonium hydroxide can be applied efficiently with existing tinplate production lines, minimizing disruptions to manufacturing workflows.

From a benefits perspective, ammonium hydroxide treatment significantly enhances the corrosion resistance of tinplate surfaces. This improvement in product quality can lead to extended shelf life for canned goods and reduced product losses due to corrosion-related failures. Such enhancements may justify premium pricing for treated tinplate products, potentially increasing profit margins.

The environmental impact of ammonium hydroxide usage is generally lower than that of many alternative corrosion inhibitors. This can result in reduced waste management costs and improved compliance with environmental regulations, potentially avoiding fines and penalties associated with more hazardous substances.

However, there are some drawbacks to consider. While ammonium hydroxide is less toxic than many alternatives, proper handling and safety measures are still required, incurring some additional training and equipment costs. Ventilation systems may need upgrades to manage ammonia fumes, representing a potential capital expense.

Long-term exposure of workers to ammonia vapors, even at low levels, may lead to health issues, potentially resulting in increased healthcare costs or worker compensation claims. Regular monitoring and maintenance of air quality in the production environment add to operational expenses.

The effectiveness of ammonium hydroxide treatment may vary depending on specific tinplate compositions and intended applications. In some cases, additional or complementary treatments might be necessary to achieve desired corrosion resistance levels, potentially offsetting some of the cost advantages.

Market acceptance of ammonium hydroxide-treated tinplate products must also be considered. While the treatment is generally viewed favorably, some customers may have concerns about potential ammonia residues or odors, necessitating additional quality assurance measures or marketing efforts to address these perceptions.

In conclusion, the cost-benefit analysis of ammonium hydroxide application in tinplate surface treatment for corrosion resistance generally leans positive. The relatively low implementation and operational costs, combined with significant improvements in product quality and potential market advantages, often outweigh the associated risks and additional expenses. However, a thorough assessment of specific production environments, regulatory landscapes, and market demands is crucial for determining the overall economic viability of this treatment method.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!