How Decane Encapsulates Active Agents for Medicine Delivery

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane Encapsulation Background and Objectives

Decane encapsulation for medicine delivery represents a significant advancement in drug delivery systems, offering a novel approach to enhance the efficacy and targeted release of active pharmaceutical ingredients. This technology leverages the unique properties of decane, a saturated hydrocarbon, to create a protective barrier around therapeutic agents, potentially improving their stability, bioavailability, and controlled release characteristics.

The development of decane encapsulation techniques stems from the ongoing challenges in pharmaceutical formulation, particularly in addressing issues such as poor drug solubility, rapid metabolism, and undesired side effects. As the pharmaceutical industry continues to develop increasingly complex and sensitive therapeutic molecules, there is a growing need for sophisticated delivery systems that can protect these agents from degradation and ensure their targeted delivery to specific sites within the body.

The primary objective of decane encapsulation research is to create a versatile and efficient drug delivery platform that can be adapted to a wide range of active agents. This technology aims to overcome limitations associated with conventional drug formulations, such as premature drug release, poor absorption, and rapid clearance from the body. By encapsulating drugs within decane-based structures, researchers seek to enhance the pharmacokinetic profile of therapeutic compounds, potentially leading to improved treatment outcomes and reduced dosing frequency.

Another key goal of decane encapsulation is to enable the delivery of hydrophobic drugs, which traditionally pose significant challenges in formulation and administration. The hydrophobic nature of decane makes it particularly suitable for encapsulating lipophilic compounds, potentially expanding the range of drugs that can be effectively delivered using this system. This could open new avenues for the development of treatments for various diseases, including cancer, neurological disorders, and infectious diseases.

Furthermore, decane encapsulation technology aims to provide a platform for the development of smart drug delivery systems. These advanced systems could potentially respond to specific physiological conditions or external stimuli, allowing for precise control over the release of active agents. Such capabilities could revolutionize personalized medicine, enabling tailored drug release profiles based on individual patient needs and disease characteristics.

As research in this field progresses, scientists and pharmaceutical companies are exploring various techniques to optimize decane encapsulation processes. This includes investigating different methods of forming decane-based capsules, studying the interactions between decane and various drug molecules, and developing strategies to functionalize the surface of decane capsules for targeted delivery. The ultimate aim is to create a robust and versatile technology that can be readily adapted to a wide range of therapeutic applications, potentially transforming the landscape of drug delivery and improving patient outcomes across multiple disease areas.

The development of decane encapsulation techniques stems from the ongoing challenges in pharmaceutical formulation, particularly in addressing issues such as poor drug solubility, rapid metabolism, and undesired side effects. As the pharmaceutical industry continues to develop increasingly complex and sensitive therapeutic molecules, there is a growing need for sophisticated delivery systems that can protect these agents from degradation and ensure their targeted delivery to specific sites within the body.

The primary objective of decane encapsulation research is to create a versatile and efficient drug delivery platform that can be adapted to a wide range of active agents. This technology aims to overcome limitations associated with conventional drug formulations, such as premature drug release, poor absorption, and rapid clearance from the body. By encapsulating drugs within decane-based structures, researchers seek to enhance the pharmacokinetic profile of therapeutic compounds, potentially leading to improved treatment outcomes and reduced dosing frequency.

Another key goal of decane encapsulation is to enable the delivery of hydrophobic drugs, which traditionally pose significant challenges in formulation and administration. The hydrophobic nature of decane makes it particularly suitable for encapsulating lipophilic compounds, potentially expanding the range of drugs that can be effectively delivered using this system. This could open new avenues for the development of treatments for various diseases, including cancer, neurological disorders, and infectious diseases.

Furthermore, decane encapsulation technology aims to provide a platform for the development of smart drug delivery systems. These advanced systems could potentially respond to specific physiological conditions or external stimuli, allowing for precise control over the release of active agents. Such capabilities could revolutionize personalized medicine, enabling tailored drug release profiles based on individual patient needs and disease characteristics.

As research in this field progresses, scientists and pharmaceutical companies are exploring various techniques to optimize decane encapsulation processes. This includes investigating different methods of forming decane-based capsules, studying the interactions between decane and various drug molecules, and developing strategies to functionalize the surface of decane capsules for targeted delivery. The ultimate aim is to create a robust and versatile technology that can be readily adapted to a wide range of therapeutic applications, potentially transforming the landscape of drug delivery and improving patient outcomes across multiple disease areas.

Market Analysis for Decane-based Drug Delivery Systems

The market for decane-based drug delivery systems is experiencing significant growth, driven by the increasing demand for targeted and controlled release medications. This innovative approach to drug delivery offers several advantages over traditional methods, including improved bioavailability, reduced side effects, and enhanced patient compliance. The global market for advanced drug delivery systems, which includes decane-based technologies, is projected to reach substantial value in the coming years.

Decane-based drug delivery systems are particularly attractive in the pharmaceutical industry due to their versatility and compatibility with a wide range of active pharmaceutical ingredients (APIs). These systems can be tailored to deliver drugs to specific target sites within the body, making them especially valuable for treating complex diseases such as cancer, neurological disorders, and chronic inflammatory conditions.

The market for decane-based drug delivery systems is segmented based on the type of formulation, route of administration, and therapeutic area. Nanoparticle-based formulations using decane as a carrier have gained significant traction, especially in oncology applications. Oral and injectable routes of administration dominate the market, with transdermal and pulmonary delivery systems showing promising growth potential.

Geographically, North America and Europe currently lead the market for decane-based drug delivery systems, owing to their advanced healthcare infrastructure, high R&D investments, and favorable regulatory environment. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing healthcare expenditure, growing prevalence of chronic diseases, and rising adoption of advanced medical technologies.

Key factors driving the market growth include the rising prevalence of chronic diseases, increasing focus on personalized medicine, and advancements in nanotechnology. The ability of decane-based systems to improve drug solubility and enhance the therapeutic index of poorly soluble drugs is particularly valuable in addressing the challenges associated with many new chemical entities in drug development pipelines.

However, the market also faces certain challenges, including high development costs, stringent regulatory requirements, and potential safety concerns associated with nanoparticle-based delivery systems. These factors may slow down market growth to some extent and require ongoing research and development efforts to address.

In conclusion, the market for decane-based drug delivery systems presents significant opportunities for pharmaceutical companies, biotechnology firms, and research institutions. As the technology continues to evolve and demonstrate its efficacy in clinical settings, it is expected to play an increasingly important role in the future of drug delivery and personalized medicine.

Decane-based drug delivery systems are particularly attractive in the pharmaceutical industry due to their versatility and compatibility with a wide range of active pharmaceutical ingredients (APIs). These systems can be tailored to deliver drugs to specific target sites within the body, making them especially valuable for treating complex diseases such as cancer, neurological disorders, and chronic inflammatory conditions.

The market for decane-based drug delivery systems is segmented based on the type of formulation, route of administration, and therapeutic area. Nanoparticle-based formulations using decane as a carrier have gained significant traction, especially in oncology applications. Oral and injectable routes of administration dominate the market, with transdermal and pulmonary delivery systems showing promising growth potential.

Geographically, North America and Europe currently lead the market for decane-based drug delivery systems, owing to their advanced healthcare infrastructure, high R&D investments, and favorable regulatory environment. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing healthcare expenditure, growing prevalence of chronic diseases, and rising adoption of advanced medical technologies.

Key factors driving the market growth include the rising prevalence of chronic diseases, increasing focus on personalized medicine, and advancements in nanotechnology. The ability of decane-based systems to improve drug solubility and enhance the therapeutic index of poorly soluble drugs is particularly valuable in addressing the challenges associated with many new chemical entities in drug development pipelines.

However, the market also faces certain challenges, including high development costs, stringent regulatory requirements, and potential safety concerns associated with nanoparticle-based delivery systems. These factors may slow down market growth to some extent and require ongoing research and development efforts to address.

In conclusion, the market for decane-based drug delivery systems presents significant opportunities for pharmaceutical companies, biotechnology firms, and research institutions. As the technology continues to evolve and demonstrate its efficacy in clinical settings, it is expected to play an increasingly important role in the future of drug delivery and personalized medicine.

Current Challenges in Decane Encapsulation Technology

Decane encapsulation technology for medicine delivery faces several significant challenges that hinder its widespread adoption and efficacy. One of the primary obstacles is achieving consistent and uniform encapsulation of active agents within decane molecules. The hydrophobic nature of decane can lead to uneven distribution of hydrophilic drugs, resulting in variable drug release profiles and reduced therapeutic efficacy.

Another major challenge lies in controlling the release kinetics of encapsulated agents. While decane provides a stable encapsulation medium, fine-tuning the release rate to match specific therapeutic needs remains complex. Factors such as temperature, pH, and enzymatic activity in the body can significantly affect the release profile, making it difficult to achieve precise and predictable drug delivery.

The stability of decane-encapsulated formulations during storage and administration poses additional challenges. Decane's volatility can lead to changes in the encapsulation structure over time, potentially compromising the integrity of the drug delivery system. This instability may result in premature drug release or alterations in the pharmacokinetic properties of the encapsulated agents.

Biocompatibility and biodegradability concerns also present significant hurdles. While decane is generally considered safe, its long-term effects on biological systems when used as a drug carrier are not fully understood. Ensuring complete elimination of decane from the body without adverse effects is crucial for the safety and efficacy of this delivery method.

Scale-up and manufacturing challenges further complicate the development of decane-based drug delivery systems. Maintaining consistent encapsulation quality and drug loading efficiency during large-scale production is technically demanding. Variations in production parameters can lead to batch-to-batch inconsistencies, affecting the overall reliability of the drug delivery system.

Regulatory hurdles and approval processes present additional obstacles. The novel nature of decane encapsulation technology may require extensive safety and efficacy studies to meet regulatory standards. Demonstrating the long-term safety and superiority of this approach over existing drug delivery methods is essential for gaining regulatory approval and market acceptance.

Lastly, the cost-effectiveness of decane encapsulation technology compared to conventional drug delivery methods remains a challenge. The complexity of the encapsulation process and the need for specialized equipment and expertise can increase production costs, potentially limiting its commercial viability for certain therapeutic applications.

Another major challenge lies in controlling the release kinetics of encapsulated agents. While decane provides a stable encapsulation medium, fine-tuning the release rate to match specific therapeutic needs remains complex. Factors such as temperature, pH, and enzymatic activity in the body can significantly affect the release profile, making it difficult to achieve precise and predictable drug delivery.

The stability of decane-encapsulated formulations during storage and administration poses additional challenges. Decane's volatility can lead to changes in the encapsulation structure over time, potentially compromising the integrity of the drug delivery system. This instability may result in premature drug release or alterations in the pharmacokinetic properties of the encapsulated agents.

Biocompatibility and biodegradability concerns also present significant hurdles. While decane is generally considered safe, its long-term effects on biological systems when used as a drug carrier are not fully understood. Ensuring complete elimination of decane from the body without adverse effects is crucial for the safety and efficacy of this delivery method.

Scale-up and manufacturing challenges further complicate the development of decane-based drug delivery systems. Maintaining consistent encapsulation quality and drug loading efficiency during large-scale production is technically demanding. Variations in production parameters can lead to batch-to-batch inconsistencies, affecting the overall reliability of the drug delivery system.

Regulatory hurdles and approval processes present additional obstacles. The novel nature of decane encapsulation technology may require extensive safety and efficacy studies to meet regulatory standards. Demonstrating the long-term safety and superiority of this approach over existing drug delivery methods is essential for gaining regulatory approval and market acceptance.

Lastly, the cost-effectiveness of decane encapsulation technology compared to conventional drug delivery methods remains a challenge. The complexity of the encapsulation process and the need for specialized equipment and expertise can increase production costs, potentially limiting its commercial viability for certain therapeutic applications.

Existing Decane Encapsulation Techniques

01 Encapsulation methods for decane

Various techniques are employed to encapsulate decane, including the use of polymeric materials and nanostructures. These methods aim to improve the stability, controlled release, and functionality of decane in different applications. Encapsulation can enhance the performance of decane-based products and protect the compound from environmental factors.- Encapsulation of decane in polymer matrices: Decane can be encapsulated within various polymer matrices to create stable and functional materials. This process often involves the formation of microcapsules or nanoparticles, which can be used for controlled release applications or to improve material properties.

- Use of decane encapsulation in energy storage devices: Encapsulated decane is utilized in energy storage devices, particularly in lithium-ion batteries and other electrochemical cells. The encapsulation helps improve the stability and performance of these devices by acting as a protective or functional component within the cell structure.

- Decane encapsulation for phase change materials: Encapsulating decane as a phase change material (PCM) is employed in thermal management applications. The encapsulated decane can absorb, store, and release thermal energy, making it useful in temperature regulation systems and energy-efficient building materials.

- Microencapsulation techniques for decane: Various microencapsulation techniques are used to encapsulate decane, including interfacial polymerization, in-situ polymerization, and emulsion-based methods. These techniques allow for the creation of microcapsules with specific properties tailored for different applications.

- Applications of encapsulated decane in coatings and films: Encapsulated decane is incorporated into coatings and films to enhance their properties. This can include improving water resistance, thermal insulation, or creating smart materials that respond to environmental changes. The encapsulation allows for controlled release or activation of the decane within the coating or film matrix.

02 Applications of encapsulated decane in energy storage

Encapsulated decane finds applications in energy storage systems, particularly in phase change materials (PCMs) for thermal energy storage. The encapsulation of decane allows for improved heat transfer efficiency, thermal stability, and cycle life in energy storage devices. This technology is relevant to renewable energy systems and building energy management.Expand Specific Solutions03 Use of decane encapsulation in electronic devices

Encapsulated decane is utilized in electronic devices, particularly in the field of organic light-emitting diodes (OLEDs) and other display technologies. The encapsulation process helps to protect sensitive electronic components from moisture and oxygen, thereby enhancing device longevity and performance. This technology contributes to the development of more durable and efficient electronic displays.Expand Specific Solutions04 Decane encapsulation for chemical and pharmaceutical applications

In the chemical and pharmaceutical industries, decane encapsulation is employed to improve the stability, solubility, and controlled release of active ingredients. This technique can enhance the efficacy of drug delivery systems, protect sensitive compounds from degradation, and modify the release profile of various substances. The encapsulation of decane plays a role in formulation development for diverse products.Expand Specific Solutions05 Novel materials and processes for decane encapsulation

Research and development efforts focus on creating new materials and processes for more effective decane encapsulation. This includes the exploration of advanced polymers, nanocomposites, and hybrid materials that can offer improved encapsulation efficiency, controlled release properties, and environmental sustainability. Novel encapsulation techniques aim to expand the potential applications of decane across various industries.Expand Specific Solutions

Key Players in Decane Encapsulation Research

The field of decane encapsulation for active agent delivery in medicine is in a nascent stage of development, characterized by emerging technologies and growing market potential. The market size is expanding as pharmaceutical companies recognize the benefits of this approach for improving drug efficacy and targeted delivery. While the technology is still evolving, several key players are making significant strides. Companies like Rani Therapeutics and Entrega are pioneering innovative oral delivery systems, while established pharmaceutical giants such as Novartis and Takeda are likely investing in research and development. Academic institutions like MIT and Northwestern University are contributing fundamental research. The competitive landscape is diverse, with both startups and large corporations vying to develop and commercialize decane-based drug delivery systems.

Takeda Pharmaceutical Co., Ltd.

Technical Solution: Takeda has developed a proprietary decane-based encapsulation technology for targeted drug delivery. Their approach utilizes a modified decane core surrounded by a biocompatible polymer shell, creating a versatile platform for encapsulating various active agents. The company has optimized the process to achieve high drug loading capacity and controlled release profiles. Takeda's technology incorporates surface modifications to enhance the capsules' ability to cross biological barriers and target specific tissues or cell types[3]. They have successfully applied this technology to improve the delivery of both small molecule drugs and biologics, demonstrating enhanced therapeutic efficacy in preclinical studies. The company has also explored the use of stimuli-responsive decane-based capsules that can release their payload in response to specific physiological conditions or external triggers[4].

Strengths: Versatile platform suitable for various drug types, targeted delivery capabilities, and potential for stimuli-responsive release. Weaknesses: Complexity of manufacturing process and potential regulatory challenges for novel delivery systems.

Rani Therapeutics LLC

Technical Solution: Rani Therapeutics has developed a unique approach to decane encapsulation for oral delivery of biologics and other macromolecules. Their RaniPill™ technology utilizes a specialized capsule containing a decane-based microemulsion that protects the active agent from degradation in the stomach. Upon reaching the small intestine, the capsule dissolves, and the decane microemulsion transforms into a microneedle that penetrates the intestinal wall to deliver the drug directly into the bloodstream[7]. This innovative approach allows for the oral administration of drugs that traditionally require injection. Rani has optimized the decane formulation to ensure stability of various biologics, including peptides and proteins, throughout the delivery process. The company has demonstrated successful delivery of insulin, antibodies, and other large molecules in preclinical and early clinical studies[8].

Strengths: Enables oral delivery of biologics, potential to replace injections for certain therapies, and protection of sensitive molecules from degradation. Weaknesses: Complex manufacturing process and potential safety concerns related to intestinal wall penetration.

Innovative Approaches in Decane-based Drug Delivery

Drug delivery systems and methods for making and using the same

PatentActiveUS12102711B1

Innovation

- The development of nanoscale drug delivery vehicles comprising a substrate with a buffer layer, a release layer, and an encapsulant layer, allowing for the deposition, adhesion, encapsulation, and controlled release of payload active agents on a nanoscale platform, enabling on-demand production of personalized, customizable medicines with improved bioavailability and biodistribution.

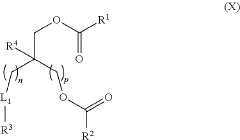

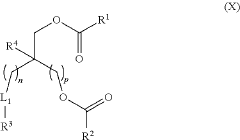

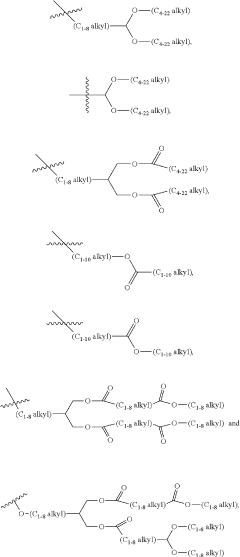

Lipids and lipid compositions for the delivery of active agents

PatentActiveUS11420933B2

Innovation

- Development of a cationic lipid scaffold with specific chemical structures that form compounds suitable for local delivery to tissues like the eye, ear, skin, lung, muscle, or subcutaneous cells, and for systemic delivery, which are designed to reduce toxicity and improve therapeutic index by incorporating degradable functionalities and optimized physical characteristics.

Regulatory Framework for Decane-based Drug Delivery

The regulatory framework for decane-based drug delivery systems is a complex and evolving landscape that requires careful navigation by pharmaceutical companies and researchers. At the core of this framework are the guidelines set forth by major regulatory bodies such as the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and other international counterparts.

These agencies have established specific protocols for the evaluation and approval of novel drug delivery systems, including those utilizing decane as an encapsulating agent. The FDA, for instance, requires extensive preclinical and clinical data to demonstrate the safety and efficacy of such systems. This includes comprehensive toxicology studies to assess the potential risks associated with decane and its metabolites, as well as pharmacokinetic and pharmacodynamic analyses to understand how the encapsulation affects drug absorption, distribution, metabolism, and excretion.

In the European Union, the EMA has implemented a rigorous assessment process for advanced therapy medicinal products (ATMPs), which may encompass certain decane-based delivery systems. This process involves a centralized authorization procedure and often requires long-term follow-up studies to monitor potential delayed adverse effects.

Regulatory bodies also place significant emphasis on the manufacturing processes and quality control measures for decane-based drug delivery systems. Good Manufacturing Practice (GMP) guidelines must be strictly adhered to, with particular attention paid to the purity and stability of the decane formulations. Manufacturers must demonstrate consistent production methods and implement robust quality assurance systems to ensure batch-to-batch uniformity.

Environmental considerations are increasingly becoming a part of the regulatory framework. As decane is a hydrocarbon, regulatory agencies may require environmental impact assessments and plans for proper disposal or recycling of any waste products generated during manufacturing or after use.

Intellectual property protection is another crucial aspect of the regulatory landscape. Patent offices worldwide have established guidelines for evaluating the novelty and non-obviousness of decane-based drug delivery technologies. Companies must navigate these patent regulations carefully to secure and maintain their competitive advantage in the market.

As the field of nanomedicine advances, regulatory bodies are adapting their frameworks to address the unique challenges posed by nanoparticle-based drug delivery systems, which may include decane-based formulations. This has led to the development of specific guidance documents and testing requirements for nanomedicines, focusing on aspects such as particle size distribution, surface characteristics, and potential for accumulation in tissues.

These agencies have established specific protocols for the evaluation and approval of novel drug delivery systems, including those utilizing decane as an encapsulating agent. The FDA, for instance, requires extensive preclinical and clinical data to demonstrate the safety and efficacy of such systems. This includes comprehensive toxicology studies to assess the potential risks associated with decane and its metabolites, as well as pharmacokinetic and pharmacodynamic analyses to understand how the encapsulation affects drug absorption, distribution, metabolism, and excretion.

In the European Union, the EMA has implemented a rigorous assessment process for advanced therapy medicinal products (ATMPs), which may encompass certain decane-based delivery systems. This process involves a centralized authorization procedure and often requires long-term follow-up studies to monitor potential delayed adverse effects.

Regulatory bodies also place significant emphasis on the manufacturing processes and quality control measures for decane-based drug delivery systems. Good Manufacturing Practice (GMP) guidelines must be strictly adhered to, with particular attention paid to the purity and stability of the decane formulations. Manufacturers must demonstrate consistent production methods and implement robust quality assurance systems to ensure batch-to-batch uniformity.

Environmental considerations are increasingly becoming a part of the regulatory framework. As decane is a hydrocarbon, regulatory agencies may require environmental impact assessments and plans for proper disposal or recycling of any waste products generated during manufacturing or after use.

Intellectual property protection is another crucial aspect of the regulatory landscape. Patent offices worldwide have established guidelines for evaluating the novelty and non-obviousness of decane-based drug delivery technologies. Companies must navigate these patent regulations carefully to secure and maintain their competitive advantage in the market.

As the field of nanomedicine advances, regulatory bodies are adapting their frameworks to address the unique challenges posed by nanoparticle-based drug delivery systems, which may include decane-based formulations. This has led to the development of specific guidance documents and testing requirements for nanomedicines, focusing on aspects such as particle size distribution, surface characteristics, and potential for accumulation in tissues.

Biocompatibility and Safety Considerations

The biocompatibility and safety considerations of decane-based encapsulation systems for active agent delivery in medicine are crucial aspects that require thorough evaluation. Decane, being a hydrocarbon, presents both advantages and challenges in terms of its interaction with biological systems.

One of the primary concerns is the potential toxicity of decane itself. While decane is generally considered to have low acute toxicity, long-term exposure or high concentrations may lead to adverse effects. Therefore, it is essential to assess the release kinetics of decane from the encapsulation system and ensure that the levels remain within safe limits throughout the drug delivery process.

The interaction between decane and the encapsulated active agents must also be carefully studied. Some active pharmaceutical ingredients may be susceptible to degradation or alteration when in contact with hydrocarbons, potentially affecting their efficacy or safety profile. Comprehensive stability studies are necessary to guarantee that the therapeutic properties of the encapsulated agents remain intact throughout the shelf life of the formulation.

Another critical aspect is the potential for immune system reactions to decane-based carriers. While hydrocarbons are not typically recognized as foreign by the immune system, the presence of decane in novel nanostructures or formulations may trigger unexpected immune responses. Extensive in vitro and in vivo immunogenicity studies are required to evaluate the risk of allergic reactions or other immune-mediated adverse events.

The biodegradability and elimination pathways of decane-based systems also warrant careful consideration. The body's ability to metabolize and excrete decane and its potential breakdown products must be thoroughly investigated to prevent accumulation and associated toxicities. This is particularly important for applications involving repeated or long-term administration of decane-encapsulated medicines.

Furthermore, the potential for decane to interact with biological membranes and cellular structures needs to be assessed. While its lipophilic nature may enhance penetration of certain barriers, it could also disrupt cellular membranes or interfere with normal physiological processes. Detailed studies on the impact of decane-based carriers on cell viability, membrane integrity, and cellular function are essential to ensure safety at the cellular level.

Regulatory considerations play a significant role in the development of decane-based drug delivery systems. Compliance with guidelines set by regulatory bodies such as the FDA and EMA regarding the use of novel excipients in pharmaceutical formulations is crucial. Extensive toxicological studies and safety data will be required to support regulatory submissions and gain approval for clinical use.

One of the primary concerns is the potential toxicity of decane itself. While decane is generally considered to have low acute toxicity, long-term exposure or high concentrations may lead to adverse effects. Therefore, it is essential to assess the release kinetics of decane from the encapsulation system and ensure that the levels remain within safe limits throughout the drug delivery process.

The interaction between decane and the encapsulated active agents must also be carefully studied. Some active pharmaceutical ingredients may be susceptible to degradation or alteration when in contact with hydrocarbons, potentially affecting their efficacy or safety profile. Comprehensive stability studies are necessary to guarantee that the therapeutic properties of the encapsulated agents remain intact throughout the shelf life of the formulation.

Another critical aspect is the potential for immune system reactions to decane-based carriers. While hydrocarbons are not typically recognized as foreign by the immune system, the presence of decane in novel nanostructures or formulations may trigger unexpected immune responses. Extensive in vitro and in vivo immunogenicity studies are required to evaluate the risk of allergic reactions or other immune-mediated adverse events.

The biodegradability and elimination pathways of decane-based systems also warrant careful consideration. The body's ability to metabolize and excrete decane and its potential breakdown products must be thoroughly investigated to prevent accumulation and associated toxicities. This is particularly important for applications involving repeated or long-term administration of decane-encapsulated medicines.

Furthermore, the potential for decane to interact with biological membranes and cellular structures needs to be assessed. While its lipophilic nature may enhance penetration of certain barriers, it could also disrupt cellular membranes or interfere with normal physiological processes. Detailed studies on the impact of decane-based carriers on cell viability, membrane integrity, and cellular function are essential to ensure safety at the cellular level.

Regulatory considerations play a significant role in the development of decane-based drug delivery systems. Compliance with guidelines set by regulatory bodies such as the FDA and EMA regarding the use of novel excipients in pharmaceutical formulations is crucial. Extensive toxicological studies and safety data will be required to support regulatory submissions and gain approval for clinical use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!