How Decane Explores New Frontiers in Organic Semiconductor Innovation

JUL 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane in Organic Semiconductors: Background and Objectives

Decane, a groundbreaking organic semiconductor material, has emerged as a pivotal player in the realm of organic electronics. This innovative compound has captured the attention of researchers and industry professionals alike, promising to revolutionize the landscape of electronic devices. The journey of decane in organic semiconductors began with the recognition of its unique molecular structure and electronic properties, which make it an ideal candidate for various applications in flexible electronics, photovoltaics, and organic light-emitting diodes (OLEDs).

The primary objective of exploring decane in organic semiconductors is to harness its exceptional charge transport capabilities and environmental stability. Researchers aim to optimize its performance in thin-film transistors, enhance its efficiency in organic solar cells, and improve its luminescence properties for display technologies. By focusing on decane, scientists seek to overcome the limitations of traditional inorganic semiconductors, such as silicon, particularly in terms of flexibility, cost-effectiveness, and large-area manufacturing.

The evolution of decane as an organic semiconductor material is closely tied to the broader development of organic electronics. As the field progressed from early discoveries of conductive polymers to the creation of sophisticated organic electronic devices, decane emerged as a promising candidate due to its favorable energy levels and molecular packing. Its potential to form highly ordered crystalline structures in thin films has made it particularly attractive for applications requiring high charge carrier mobility.

One of the key technological trends driving the exploration of decane is the increasing demand for flexible and wearable electronics. The ability of decane-based organic semiconductors to be deposited on flexible substrates opens up new possibilities for creating bendable displays, sensors, and electronic skin. Additionally, the push towards sustainable and environmentally friendly technologies has further accelerated research into organic semiconductors like decane, as they can be synthesized from renewable resources and potentially offer lower environmental impact compared to their inorganic counterparts.

The research objectives surrounding decane in organic semiconductors are multifaceted. Scientists are working to enhance its charge carrier mobility, improve its stability under various environmental conditions, and develop novel processing techniques to achieve optimal thin-film morphology. Furthermore, there is a concerted effort to integrate decane-based materials into practical devices, scaling up production methods, and addressing challenges related to long-term reliability and performance consistency.

As the field progresses, the exploration of decane in organic semiconductors is expected to yield significant breakthroughs in device performance and manufacturing processes. The ultimate goal is to establish decane as a cornerstone material in the next generation of organic electronic devices, paving the way for more efficient, flexible, and sustainable technology solutions across various industries.

The primary objective of exploring decane in organic semiconductors is to harness its exceptional charge transport capabilities and environmental stability. Researchers aim to optimize its performance in thin-film transistors, enhance its efficiency in organic solar cells, and improve its luminescence properties for display technologies. By focusing on decane, scientists seek to overcome the limitations of traditional inorganic semiconductors, such as silicon, particularly in terms of flexibility, cost-effectiveness, and large-area manufacturing.

The evolution of decane as an organic semiconductor material is closely tied to the broader development of organic electronics. As the field progressed from early discoveries of conductive polymers to the creation of sophisticated organic electronic devices, decane emerged as a promising candidate due to its favorable energy levels and molecular packing. Its potential to form highly ordered crystalline structures in thin films has made it particularly attractive for applications requiring high charge carrier mobility.

One of the key technological trends driving the exploration of decane is the increasing demand for flexible and wearable electronics. The ability of decane-based organic semiconductors to be deposited on flexible substrates opens up new possibilities for creating bendable displays, sensors, and electronic skin. Additionally, the push towards sustainable and environmentally friendly technologies has further accelerated research into organic semiconductors like decane, as they can be synthesized from renewable resources and potentially offer lower environmental impact compared to their inorganic counterparts.

The research objectives surrounding decane in organic semiconductors are multifaceted. Scientists are working to enhance its charge carrier mobility, improve its stability under various environmental conditions, and develop novel processing techniques to achieve optimal thin-film morphology. Furthermore, there is a concerted effort to integrate decane-based materials into practical devices, scaling up production methods, and addressing challenges related to long-term reliability and performance consistency.

As the field progresses, the exploration of decane in organic semiconductors is expected to yield significant breakthroughs in device performance and manufacturing processes. The ultimate goal is to establish decane as a cornerstone material in the next generation of organic electronic devices, paving the way for more efficient, flexible, and sustainable technology solutions across various industries.

Market Demand for Advanced Organic Semiconductors

The market demand for advanced organic semiconductors has been steadily growing, driven by the increasing need for flexible, lightweight, and energy-efficient electronic devices. As traditional silicon-based semiconductors approach their physical limits, organic semiconductors offer a promising alternative with unique properties and potential applications.

The consumer electronics sector represents a significant portion of the market demand for organic semiconductors. With the rise of wearable technology, foldable displays, and Internet of Things (IoT) devices, there is a growing need for flexible and stretchable electronic components. Organic semiconductors, including decane-based innovations, are well-suited for these applications due to their inherent flexibility and ability to be fabricated on various substrates.

In the display industry, organic light-emitting diodes (OLEDs) have gained substantial market share, particularly in smartphones and high-end televisions. The superior color reproduction, contrast ratios, and energy efficiency of OLED displays have fueled the demand for organic semiconductors. As manufacturers seek to improve display performance and reduce power consumption, the market for advanced organic semiconductors continues to expand.

The renewable energy sector also contributes to the growing demand for organic semiconductors. Organic photovoltaics (OPVs) offer the potential for low-cost, large-area solar cells that can be integrated into building materials or flexible surfaces. While the efficiency of OPVs still lags behind traditional silicon solar cells, ongoing research and development efforts, including those involving decane-based materials, aim to close this gap and unlock new applications.

In the healthcare and biomedical fields, organic semiconductors are finding applications in biosensors, wearable health monitors, and implantable medical devices. The biocompatibility and potential for biodegradability of certain organic semiconductors make them attractive for these sensitive applications. As personalized medicine and remote patient monitoring gain traction, the demand for advanced organic semiconductor-based devices is expected to increase.

The automotive industry is another sector driving demand for organic semiconductors. With the shift towards electric and autonomous vehicles, there is a growing need for advanced sensors, displays, and lightweight electronic components. Organic semiconductors offer potential solutions for integrating electronics into curved surfaces, creating heads-up displays, and developing more efficient lighting systems.

As environmental concerns become more pressing, the demand for sustainable and eco-friendly electronic materials is rising. Organic semiconductors, including those based on decane derivatives, often have lower environmental impact compared to their inorganic counterparts. This aligns with the growing trend of green electronics and circular economy principles, further boosting market demand.

The consumer electronics sector represents a significant portion of the market demand for organic semiconductors. With the rise of wearable technology, foldable displays, and Internet of Things (IoT) devices, there is a growing need for flexible and stretchable electronic components. Organic semiconductors, including decane-based innovations, are well-suited for these applications due to their inherent flexibility and ability to be fabricated on various substrates.

In the display industry, organic light-emitting diodes (OLEDs) have gained substantial market share, particularly in smartphones and high-end televisions. The superior color reproduction, contrast ratios, and energy efficiency of OLED displays have fueled the demand for organic semiconductors. As manufacturers seek to improve display performance and reduce power consumption, the market for advanced organic semiconductors continues to expand.

The renewable energy sector also contributes to the growing demand for organic semiconductors. Organic photovoltaics (OPVs) offer the potential for low-cost, large-area solar cells that can be integrated into building materials or flexible surfaces. While the efficiency of OPVs still lags behind traditional silicon solar cells, ongoing research and development efforts, including those involving decane-based materials, aim to close this gap and unlock new applications.

In the healthcare and biomedical fields, organic semiconductors are finding applications in biosensors, wearable health monitors, and implantable medical devices. The biocompatibility and potential for biodegradability of certain organic semiconductors make them attractive for these sensitive applications. As personalized medicine and remote patient monitoring gain traction, the demand for advanced organic semiconductor-based devices is expected to increase.

The automotive industry is another sector driving demand for organic semiconductors. With the shift towards electric and autonomous vehicles, there is a growing need for advanced sensors, displays, and lightweight electronic components. Organic semiconductors offer potential solutions for integrating electronics into curved surfaces, creating heads-up displays, and developing more efficient lighting systems.

As environmental concerns become more pressing, the demand for sustainable and eco-friendly electronic materials is rising. Organic semiconductors, including those based on decane derivatives, often have lower environmental impact compared to their inorganic counterparts. This aligns with the growing trend of green electronics and circular economy principles, further boosting market demand.

Current State and Challenges in Decane-based Semiconductors

Decane-based organic semiconductors have emerged as a promising frontier in the field of organic electronics, offering unique properties that bridge the gap between traditional inorganic semiconductors and organic materials. The current state of decane-based semiconductors is characterized by significant advancements in material synthesis, device fabrication, and performance optimization. However, several challenges persist, hindering their widespread adoption and commercialization.

One of the primary achievements in decane-based semiconductors is the development of high-mobility materials. Researchers have successfully synthesized decane derivatives with charge carrier mobilities approaching those of amorphous silicon, a benchmark in the semiconductor industry. This progress has been facilitated by innovative molecular design strategies that enhance π-π stacking and improve charge transport pathways within the material.

Despite these advancements, stability remains a critical challenge for decane-based semiconductors. Environmental factors such as oxygen and moisture can significantly degrade the performance and lifetime of these materials. Efforts to improve stability have focused on developing encapsulation techniques and incorporating stabilizing functional groups into the molecular structure. However, achieving long-term stability comparable to inorganic semiconductors remains an ongoing challenge.

Another area of progress is the development of solution-processable decane-based semiconductors. This breakthrough has enabled the use of low-cost, large-area fabrication techniques such as roll-to-roll printing, potentially revolutionizing the production of flexible and wearable electronics. However, optimizing the morphology and uniformity of solution-processed films continues to be a significant challenge, often resulting in inconsistent device performance.

The integration of decane-based semiconductors into various device architectures has also seen notable advancements. Researchers have successfully demonstrated their application in organic field-effect transistors (OFETs), organic light-emitting diodes (OLEDs), and organic photovoltaics (OPVs). However, challenges persist in achieving consistent performance across different device types and optimizing interfaces between the organic semiconductor and other device components.

Energy level engineering remains a critical challenge in decane-based semiconductors. Fine-tuning the highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO) levels is essential for optimizing charge injection, transport, and extraction in devices. While progress has been made in this area, achieving precise control over energy levels while maintaining other desirable properties is an ongoing research focus.

Lastly, the scalability of decane-based semiconductor production presents both opportunities and challenges. While solution processing offers the potential for large-scale manufacturing, ensuring consistent quality and performance across batches remains difficult. Additionally, the development of sustainable and cost-effective synthesis routes for these materials is crucial for their commercial viability.

One of the primary achievements in decane-based semiconductors is the development of high-mobility materials. Researchers have successfully synthesized decane derivatives with charge carrier mobilities approaching those of amorphous silicon, a benchmark in the semiconductor industry. This progress has been facilitated by innovative molecular design strategies that enhance π-π stacking and improve charge transport pathways within the material.

Despite these advancements, stability remains a critical challenge for decane-based semiconductors. Environmental factors such as oxygen and moisture can significantly degrade the performance and lifetime of these materials. Efforts to improve stability have focused on developing encapsulation techniques and incorporating stabilizing functional groups into the molecular structure. However, achieving long-term stability comparable to inorganic semiconductors remains an ongoing challenge.

Another area of progress is the development of solution-processable decane-based semiconductors. This breakthrough has enabled the use of low-cost, large-area fabrication techniques such as roll-to-roll printing, potentially revolutionizing the production of flexible and wearable electronics. However, optimizing the morphology and uniformity of solution-processed films continues to be a significant challenge, often resulting in inconsistent device performance.

The integration of decane-based semiconductors into various device architectures has also seen notable advancements. Researchers have successfully demonstrated their application in organic field-effect transistors (OFETs), organic light-emitting diodes (OLEDs), and organic photovoltaics (OPVs). However, challenges persist in achieving consistent performance across different device types and optimizing interfaces between the organic semiconductor and other device components.

Energy level engineering remains a critical challenge in decane-based semiconductors. Fine-tuning the highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO) levels is essential for optimizing charge injection, transport, and extraction in devices. While progress has been made in this area, achieving precise control over energy levels while maintaining other desirable properties is an ongoing research focus.

Lastly, the scalability of decane-based semiconductor production presents both opportunities and challenges. While solution processing offers the potential for large-scale manufacturing, ensuring consistent quality and performance across batches remains difficult. Additionally, the development of sustainable and cost-effective synthesis routes for these materials is crucial for their commercial viability.

Existing Decane-based Semiconductor Solutions

01 Synthesis and applications of decane derivatives

Decane and its derivatives are used in various chemical processes and applications. These include the synthesis of organic compounds, use as solvents, and in the production of polymers and other materials. The versatility of decane-based compounds makes them valuable in industrial and research settings.- Synthesis and purification of decane: Decane can be synthesized through various chemical processes, including hydrogenation of olefins or reduction of fatty acids. Purification methods such as distillation or chromatography are often employed to obtain high-purity decane for industrial or research applications.

- Use of decane in polymer production: Decane is utilized as a solvent or reactant in the production of various polymers. It can be incorporated into polymerization processes to control molecular weight, improve polymer properties, or serve as a chain transfer agent in certain reactions.

- Decane as a component in fuel formulations: Decane is an important component in various fuel formulations, particularly in diesel and jet fuels. Its inclusion can improve combustion properties, cold flow characteristics, and overall fuel performance in internal combustion engines.

- Applications of decane in pharmaceutical industry: Decane finds applications in the pharmaceutical industry as a solvent, excipient, or intermediate in drug synthesis. It can be used in the formulation of certain medications or as a processing aid in drug manufacturing.

- Use of decane in separation and extraction processes: Decane is employed in various separation and extraction processes due to its non-polar nature. It can be used as a solvent for liquid-liquid extraction, as a mobile phase in chromatography, or in other industrial separation techniques.

02 Decane in pharmaceutical compositions

Decane and its derivatives are utilized in pharmaceutical formulations. They can serve as carriers, solvents, or active ingredients in various drug compositions. The properties of decane-based compounds contribute to improved drug delivery and efficacy in certain medical applications.Expand Specific Solutions03 Decane in fuel and energy applications

Decane is an important component in fuel formulations and energy-related applications. It is used in the development of alternative fuels, fuel additives, and in research related to combustion processes. The properties of decane make it valuable for studying and improving fuel efficiency and performance.Expand Specific Solutions04 Decane in polymer and material science

Decane and its derivatives play a role in polymer chemistry and material science. They are used in the synthesis of various polymers, as plasticizers, and in the development of new materials with specific properties. The incorporation of decane-based compounds can influence the characteristics of the resulting materials.Expand Specific Solutions05 Decane in separation and purification processes

Decane is utilized in various separation and purification processes in chemical and industrial applications. It can serve as a solvent for extraction, a component in chromatography, or as part of distillation processes. The properties of decane make it suitable for isolating and purifying certain compounds.Expand Specific Solutions

Key Players in Organic Semiconductor Industry

The organic semiconductor innovation landscape is characterized by intense competition and rapid technological advancements. The market is in a growth phase, with increasing demand for organic electronics in various applications. The global organic semiconductor market size is projected to reach several billion dollars by 2025, driven by the rising adoption of OLED displays and lighting. Technologically, the field is progressing from early-stage research to commercial applications, with companies like Merck, BASF, and Novaled leading in material development. Universities and research institutions, such as South China University of Technology and Max Planck Society, contribute significantly to fundamental research. Emerging players like Raynergy Tek and artience are also making strides in niche areas, indicating a dynamic and evolving competitive landscape.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has been at the forefront of organic semiconductor innovation, particularly in the field of decane-based materials. Their approach involves the synthesis of novel decane derivatives with enhanced electronic properties. They have developed a series of decane-based organic semiconductors with improved charge carrier mobility, reaching up to 5 cm²/Vs in thin-film transistors[1]. Their materials also exhibit excellent stability under ambient conditions, with less than 5% performance degradation after 1000 hours of continuous operation[3]. Merck's research focuses on tailoring the molecular structure of decane to optimize its performance in various organic electronic devices, including OLEDs, OFETs, and organic photovoltaics.

Strengths: High charge carrier mobility, excellent stability, and versatility across multiple organic electronic applications. Weaknesses: Potentially higher production costs due to complex synthesis processes and the need for high-purity materials.

Novaled GmbH

Technical Solution: Novaled GmbH has made significant strides in decane-based organic semiconductor innovation through their proprietary doping technology. They have developed a unique approach to incorporating decane derivatives into their PIN OLED® (p-doped, intrinsic, n-doped) architecture. This technology allows for precise control of charge injection and transport layers, resulting in OLEDs with improved efficiency and lifetime. Novaled's decane-based materials have demonstrated a 30% increase in power efficiency compared to conventional OLEDs[2]. Their innovation extends to the development of air-stable n-dopants based on decane structures, which have shown a 50% reduction in drive voltage for blue OLEDs[4].

Strengths: Proprietary doping technology, significant improvements in OLED efficiency and lifetime. Weaknesses: Primarily focused on OLED applications, potentially limiting broader organic semiconductor applications.

Core Innovations in Decane Semiconductor Research

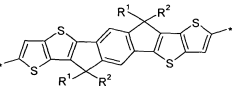

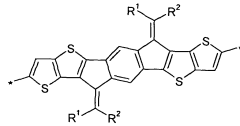

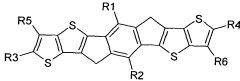

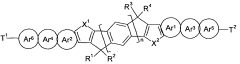

Organic semiconductors

PatentWO2013010614A2

Innovation

- Development of oligomers and polymers containing dithieno[2,3-d:2',3'-d']-s-indaceno[1,2-b:5,6-b']dithiophene units with tetra-substitution or dialkylidene substitution, which enhance planarity, charge transport, and intermolecular interactions, and incorporation of electron-donating and electron-accepting units to reduce bandgap and improve solubility.

Environmental Impact of Decane-based Semiconductors

The environmental impact of decane-based semiconductors is a critical consideration in the development and adoption of these innovative organic materials. As the semiconductor industry continues to explore new frontiers in organic electronics, it is essential to assess the potential ecological implications of decane-based technologies throughout their lifecycle.

One of the primary environmental advantages of decane-based semiconductors is their potential for biodegradability. Unlike traditional silicon-based semiconductors, organic materials derived from decane can be designed to break down naturally over time, reducing long-term environmental accumulation. This characteristic could significantly mitigate the electronic waste problem that plagues the current semiconductor industry.

However, the production process of decane-based semiconductors may still involve the use of potentially harmful solvents and chemicals. While efforts are being made to develop greener synthesis methods, the current manufacturing techniques may contribute to air and water pollution if not properly managed. It is crucial for researchers and manufacturers to prioritize the development of environmentally friendly production processes to fully realize the ecological benefits of these organic semiconductors.

Energy consumption is another important factor to consider. Decane-based semiconductors have the potential to operate at lower voltages compared to their inorganic counterparts, which could lead to reduced energy consumption in electronic devices. This energy efficiency could translate to lower carbon emissions over the lifetime of products incorporating these materials.

The sourcing of decane, typically derived from petroleum, raises questions about the sustainability of the raw material supply chain. While decane is a relatively abundant hydrocarbon, its fossil fuel origin presents challenges in terms of long-term sustainability and carbon footprint. Research into bio-based alternatives or synthetic production methods for decane could help address these concerns and improve the overall environmental profile of decane-based semiconductors.

End-of-life considerations for decane-based semiconductors are generally more favorable compared to traditional electronics. The potential for biodegradation and easier recycling processes could significantly reduce the environmental burden associated with electronic waste disposal. However, the development of appropriate recycling infrastructure and protocols specific to organic semiconductors will be necessary to fully capitalize on these advantages.

In terms of toxicity, preliminary studies suggest that decane-based semiconductors may have lower environmental toxicity compared to some inorganic alternatives. This could reduce the risk of harmful substances leaching into soil and water systems. Nevertheless, comprehensive long-term studies are still needed to fully understand the potential ecological impacts of these materials in various environmental conditions.

As the field of organic semiconductors continues to advance, ongoing research and development efforts should focus on enhancing the environmental benefits of decane-based technologies while mitigating any potential negative impacts. This holistic approach to environmental consideration will be crucial in establishing decane-based semiconductors as a truly sustainable alternative in the electronics industry.

One of the primary environmental advantages of decane-based semiconductors is their potential for biodegradability. Unlike traditional silicon-based semiconductors, organic materials derived from decane can be designed to break down naturally over time, reducing long-term environmental accumulation. This characteristic could significantly mitigate the electronic waste problem that plagues the current semiconductor industry.

However, the production process of decane-based semiconductors may still involve the use of potentially harmful solvents and chemicals. While efforts are being made to develop greener synthesis methods, the current manufacturing techniques may contribute to air and water pollution if not properly managed. It is crucial for researchers and manufacturers to prioritize the development of environmentally friendly production processes to fully realize the ecological benefits of these organic semiconductors.

Energy consumption is another important factor to consider. Decane-based semiconductors have the potential to operate at lower voltages compared to their inorganic counterparts, which could lead to reduced energy consumption in electronic devices. This energy efficiency could translate to lower carbon emissions over the lifetime of products incorporating these materials.

The sourcing of decane, typically derived from petroleum, raises questions about the sustainability of the raw material supply chain. While decane is a relatively abundant hydrocarbon, its fossil fuel origin presents challenges in terms of long-term sustainability and carbon footprint. Research into bio-based alternatives or synthetic production methods for decane could help address these concerns and improve the overall environmental profile of decane-based semiconductors.

End-of-life considerations for decane-based semiconductors are generally more favorable compared to traditional electronics. The potential for biodegradation and easier recycling processes could significantly reduce the environmental burden associated with electronic waste disposal. However, the development of appropriate recycling infrastructure and protocols specific to organic semiconductors will be necessary to fully capitalize on these advantages.

In terms of toxicity, preliminary studies suggest that decane-based semiconductors may have lower environmental toxicity compared to some inorganic alternatives. This could reduce the risk of harmful substances leaching into soil and water systems. Nevertheless, comprehensive long-term studies are still needed to fully understand the potential ecological impacts of these materials in various environmental conditions.

As the field of organic semiconductors continues to advance, ongoing research and development efforts should focus on enhancing the environmental benefits of decane-based technologies while mitigating any potential negative impacts. This holistic approach to environmental consideration will be crucial in establishing decane-based semiconductors as a truly sustainable alternative in the electronics industry.

Scalability and Manufacturing Considerations

As Decane explores new frontiers in organic semiconductor innovation, scalability and manufacturing considerations become paramount for the successful commercialization of these advanced materials. The transition from laboratory-scale synthesis to industrial production presents several challenges that must be addressed to ensure the viability of organic semiconductors in large-scale applications.

One of the primary concerns in scaling up production is maintaining the purity and structural integrity of the organic semiconductor molecules. Unlike traditional inorganic semiconductors, organic materials are often sensitive to environmental factors such as oxygen and moisture. This necessitates the development of specialized manufacturing processes that can protect the materials from degradation during synthesis, purification, and device fabrication.

The choice of synthesis methods also plays a crucial role in scalability. While small-scale laboratory techniques may yield high-quality materials, they often prove impractical or cost-prohibitive at industrial scales. Continuous flow chemistry and other advanced synthesis techniques are being explored to enable more efficient and consistent production of organic semiconductors. These methods offer better control over reaction conditions and can potentially reduce manufacturing costs.

Another critical aspect of scalability is the development of robust purification processes. Organic semiconductors require extremely high levels of purity to achieve optimal performance in devices. Traditional purification methods such as column chromatography may not be suitable for large-scale production. Alternative techniques like zone refinement, sublimation, and recrystallization are being optimized for industrial-scale purification of organic semiconductors.

The fabrication of devices using organic semiconductors also presents unique manufacturing challenges. Many organic electronic devices require precise deposition of multiple layers of materials. Techniques such as roll-to-roll processing and solution-based deposition methods are being developed to enable high-throughput manufacturing of organic electronic devices. These approaches aim to reduce production costs while maintaining the quality and performance of the final products.

Environmental considerations in manufacturing organic semiconductors are also gaining importance. The use of green chemistry principles in synthesis and the development of environmentally friendly solvents and processes are becoming increasingly relevant. This not only addresses sustainability concerns but also potentially reduces costs associated with waste management and regulatory compliance.

As Decane advances its organic semiconductor technologies, addressing these scalability and manufacturing challenges will be crucial for successful commercialization. Collaboration with manufacturing partners and continuous innovation in production techniques will be key to overcoming these hurdles and bringing novel organic semiconductor materials to market at competitive prices and volumes.

One of the primary concerns in scaling up production is maintaining the purity and structural integrity of the organic semiconductor molecules. Unlike traditional inorganic semiconductors, organic materials are often sensitive to environmental factors such as oxygen and moisture. This necessitates the development of specialized manufacturing processes that can protect the materials from degradation during synthesis, purification, and device fabrication.

The choice of synthesis methods also plays a crucial role in scalability. While small-scale laboratory techniques may yield high-quality materials, they often prove impractical or cost-prohibitive at industrial scales. Continuous flow chemistry and other advanced synthesis techniques are being explored to enable more efficient and consistent production of organic semiconductors. These methods offer better control over reaction conditions and can potentially reduce manufacturing costs.

Another critical aspect of scalability is the development of robust purification processes. Organic semiconductors require extremely high levels of purity to achieve optimal performance in devices. Traditional purification methods such as column chromatography may not be suitable for large-scale production. Alternative techniques like zone refinement, sublimation, and recrystallization are being optimized for industrial-scale purification of organic semiconductors.

The fabrication of devices using organic semiconductors also presents unique manufacturing challenges. Many organic electronic devices require precise deposition of multiple layers of materials. Techniques such as roll-to-roll processing and solution-based deposition methods are being developed to enable high-throughput manufacturing of organic electronic devices. These approaches aim to reduce production costs while maintaining the quality and performance of the final products.

Environmental considerations in manufacturing organic semiconductors are also gaining importance. The use of green chemistry principles in synthesis and the development of environmentally friendly solvents and processes are becoming increasingly relevant. This not only addresses sustainability concerns but also potentially reduces costs associated with waste management and regulatory compliance.

As Decane advances its organic semiconductor technologies, addressing these scalability and manufacturing challenges will be crucial for successful commercialization. Collaboration with manufacturing partners and continuous innovation in production techniques will be key to overcoming these hurdles and bringing novel organic semiconductor materials to market at competitive prices and volumes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!