How Decane Governs Polymer Chain Extension in Advanced Manufacturing

JUL 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane Polymer Extension Background

Decane polymer chain extension has emerged as a critical process in advanced manufacturing, particularly in the development of high-performance materials. This technique involves the use of decane, a hydrocarbon molecule, to manipulate and extend polymer chains, resulting in enhanced material properties. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of using small organic molecules to influence polymer behavior.

The primary goal of decane-governed polymer chain extension is to achieve precise control over the molecular structure and properties of polymeric materials. This technology aims to overcome limitations in traditional polymer synthesis methods, such as insufficient molecular weight control and limited ability to tailor specific material characteristics. By leveraging the unique properties of decane, researchers and manufacturers seek to develop polymers with improved mechanical strength, thermal stability, and chemical resistance.

The development of decane-governed polymer chain extension has been driven by the increasing demand for advanced materials in various industries, including aerospace, automotive, and electronics. As these sectors push the boundaries of material performance, there is a growing need for polymers that can withstand extreme conditions while maintaining their structural integrity and functionality.

One of the key milestones in the evolution of this technology was the discovery of decane's ability to act as a chain extender in specific polymer systems. This breakthrough opened up new possibilities for controlling polymer architecture and properties at the molecular level. Subsequent research focused on optimizing the interaction between decane and various polymer types, leading to the development of more efficient and versatile extension processes.

The technological trajectory of decane-governed polymer chain extension has been characterized by continuous improvements in process control and scalability. Early experiments were limited to laboratory-scale applications, but advancements in reaction engineering and process optimization have enabled the transition to industrial-scale production. This scaling up has been crucial in making the technology commercially viable and accessible to a broader range of manufacturers.

Recent trends in this field include the integration of decane-governed polymer chain extension with other advanced manufacturing techniques, such as 3D printing and nanocomposite fabrication. These combinations have led to the creation of novel materials with unprecedented properties, further expanding the potential applications of this technology.

As research in this area progresses, the focus is shifting towards developing more sustainable and environmentally friendly processes. This includes exploring bio-based alternatives to decane and optimizing reaction conditions to reduce energy consumption and waste generation. These efforts align with the growing emphasis on green chemistry and sustainable manufacturing practices in the polymer industry.

The primary goal of decane-governed polymer chain extension is to achieve precise control over the molecular structure and properties of polymeric materials. This technology aims to overcome limitations in traditional polymer synthesis methods, such as insufficient molecular weight control and limited ability to tailor specific material characteristics. By leveraging the unique properties of decane, researchers and manufacturers seek to develop polymers with improved mechanical strength, thermal stability, and chemical resistance.

The development of decane-governed polymer chain extension has been driven by the increasing demand for advanced materials in various industries, including aerospace, automotive, and electronics. As these sectors push the boundaries of material performance, there is a growing need for polymers that can withstand extreme conditions while maintaining their structural integrity and functionality.

One of the key milestones in the evolution of this technology was the discovery of decane's ability to act as a chain extender in specific polymer systems. This breakthrough opened up new possibilities for controlling polymer architecture and properties at the molecular level. Subsequent research focused on optimizing the interaction between decane and various polymer types, leading to the development of more efficient and versatile extension processes.

The technological trajectory of decane-governed polymer chain extension has been characterized by continuous improvements in process control and scalability. Early experiments were limited to laboratory-scale applications, but advancements in reaction engineering and process optimization have enabled the transition to industrial-scale production. This scaling up has been crucial in making the technology commercially viable and accessible to a broader range of manufacturers.

Recent trends in this field include the integration of decane-governed polymer chain extension with other advanced manufacturing techniques, such as 3D printing and nanocomposite fabrication. These combinations have led to the creation of novel materials with unprecedented properties, further expanding the potential applications of this technology.

As research in this area progresses, the focus is shifting towards developing more sustainable and environmentally friendly processes. This includes exploring bio-based alternatives to decane and optimizing reaction conditions to reduce energy consumption and waste generation. These efforts align with the growing emphasis on green chemistry and sustainable manufacturing practices in the polymer industry.

Market Analysis Advanced Manufacturing

The advanced manufacturing sector has witnessed significant growth in recent years, driven by the increasing demand for high-performance polymers and innovative materials. The market for polymer chain extension technologies, particularly those involving decane as a key component, has shown promising potential across various industries.

In the automotive sector, the demand for lightweight yet durable materials has led to a surge in the adoption of advanced polymers. The ability of decane to govern polymer chain extension has opened new avenues for developing materials with enhanced mechanical properties and reduced weight. This trend is expected to continue as automakers strive to meet stringent fuel efficiency and emission standards.

The aerospace industry has also emerged as a significant market for decane-governed polymer chain extension technologies. The need for materials that can withstand extreme conditions while maintaining structural integrity has driven the adoption of advanced polymers in aircraft manufacturing. The market in this sector is projected to grow steadily as the global air traffic increases and the demand for more efficient aircraft rises.

In the electronics industry, the miniaturization trend has created a demand for polymers with precise control over their properties. Decane's role in governing polymer chain extension has enabled the development of materials suitable for flexible electronics, wearable devices, and advanced packaging solutions. This market segment is expected to experience rapid growth as consumer electronics continue to evolve and diversify.

The medical device industry has shown increasing interest in advanced polymers for applications such as implants, drug delivery systems, and diagnostic equipment. The ability to tailor polymer properties through decane-governed chain extension has opened up new possibilities for biocompatible and biodegradable materials. This market is anticipated to expand as the healthcare sector embraces personalized medicine and minimally invasive procedures.

The construction industry has also begun to explore the potential of advanced polymers in developing high-performance building materials. Decane-governed polymer chain extension technologies offer opportunities for creating materials with improved durability, thermal insulation, and weather resistance. While this market segment is still in its early stages, it shows promise for significant growth as sustainable construction practices gain traction.

As the global focus on sustainability intensifies, the market for recyclable and biodegradable polymers is expected to grow. Decane's role in polymer chain extension could play a crucial part in developing eco-friendly materials that maintain the desired performance characteristics. This trend is likely to drive innovation and create new market opportunities across various industries.

In the automotive sector, the demand for lightweight yet durable materials has led to a surge in the adoption of advanced polymers. The ability of decane to govern polymer chain extension has opened new avenues for developing materials with enhanced mechanical properties and reduced weight. This trend is expected to continue as automakers strive to meet stringent fuel efficiency and emission standards.

The aerospace industry has also emerged as a significant market for decane-governed polymer chain extension technologies. The need for materials that can withstand extreme conditions while maintaining structural integrity has driven the adoption of advanced polymers in aircraft manufacturing. The market in this sector is projected to grow steadily as the global air traffic increases and the demand for more efficient aircraft rises.

In the electronics industry, the miniaturization trend has created a demand for polymers with precise control over their properties. Decane's role in governing polymer chain extension has enabled the development of materials suitable for flexible electronics, wearable devices, and advanced packaging solutions. This market segment is expected to experience rapid growth as consumer electronics continue to evolve and diversify.

The medical device industry has shown increasing interest in advanced polymers for applications such as implants, drug delivery systems, and diagnostic equipment. The ability to tailor polymer properties through decane-governed chain extension has opened up new possibilities for biocompatible and biodegradable materials. This market is anticipated to expand as the healthcare sector embraces personalized medicine and minimally invasive procedures.

The construction industry has also begun to explore the potential of advanced polymers in developing high-performance building materials. Decane-governed polymer chain extension technologies offer opportunities for creating materials with improved durability, thermal insulation, and weather resistance. While this market segment is still in its early stages, it shows promise for significant growth as sustainable construction practices gain traction.

As the global focus on sustainability intensifies, the market for recyclable and biodegradable polymers is expected to grow. Decane's role in polymer chain extension could play a crucial part in developing eco-friendly materials that maintain the desired performance characteristics. This trend is likely to drive innovation and create new market opportunities across various industries.

Decane Polymer Challenges

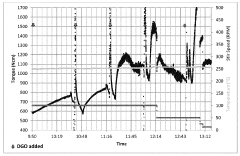

The development of advanced manufacturing techniques for polymer chain extension faces several significant challenges when working with decane as a key component. One of the primary obstacles is controlling the reaction kinetics between decane and polymer chains. The rate at which decane molecules interact with and extend polymer chains can be highly sensitive to environmental conditions, making it difficult to achieve consistent results across different manufacturing batches.

Temperature control presents another major challenge in decane-based polymer chain extension processes. The optimal temperature range for effective chain extension is often narrow, and maintaining precise temperature control throughout the manufacturing process can be technically demanding. Fluctuations in temperature can lead to uneven chain extension or unwanted side reactions, compromising the quality and properties of the final polymer product.

The solubility of decane in various polymer systems also poses challenges for manufacturers. Ensuring uniform distribution of decane molecules throughout the polymer matrix is crucial for achieving consistent chain extension. However, the solubility of decane can vary significantly depending on the polymer type and processing conditions, necessitating careful formulation and process optimization for each specific polymer system.

Another significant challenge lies in managing the volatility of decane during the manufacturing process. Decane's relatively low boiling point can lead to evaporation losses during high-temperature processing steps, potentially altering the intended stoichiometry of the reaction and affecting the final product properties. This volatility also raises safety concerns, requiring robust ventilation systems and handling protocols to minimize exposure risks.

The potential for side reactions between decane and other components in the polymer system presents additional complications. These unintended reactions can lead to the formation of byproducts that may negatively impact the mechanical, thermal, or chemical properties of the extended polymer chains. Identifying and mitigating these side reactions often requires extensive research and development efforts.

Scalability of decane-based polymer chain extension processes from laboratory to industrial scale is another significant challenge. Maintaining the precise control over reaction conditions and achieving uniform chain extension becomes increasingly difficult as production volumes increase. This scaling challenge often necessitates substantial engineering efforts to design and optimize large-scale manufacturing equipment and processes.

Lastly, the environmental and regulatory considerations surrounding the use of decane in polymer manufacturing pose challenges for industry adoption. As environmental regulations become more stringent, manufacturers must address concerns related to volatile organic compound (VOC) emissions and develop strategies for minimizing the environmental impact of decane-based processes.

Temperature control presents another major challenge in decane-based polymer chain extension processes. The optimal temperature range for effective chain extension is often narrow, and maintaining precise temperature control throughout the manufacturing process can be technically demanding. Fluctuations in temperature can lead to uneven chain extension or unwanted side reactions, compromising the quality and properties of the final polymer product.

The solubility of decane in various polymer systems also poses challenges for manufacturers. Ensuring uniform distribution of decane molecules throughout the polymer matrix is crucial for achieving consistent chain extension. However, the solubility of decane can vary significantly depending on the polymer type and processing conditions, necessitating careful formulation and process optimization for each specific polymer system.

Another significant challenge lies in managing the volatility of decane during the manufacturing process. Decane's relatively low boiling point can lead to evaporation losses during high-temperature processing steps, potentially altering the intended stoichiometry of the reaction and affecting the final product properties. This volatility also raises safety concerns, requiring robust ventilation systems and handling protocols to minimize exposure risks.

The potential for side reactions between decane and other components in the polymer system presents additional complications. These unintended reactions can lead to the formation of byproducts that may negatively impact the mechanical, thermal, or chemical properties of the extended polymer chains. Identifying and mitigating these side reactions often requires extensive research and development efforts.

Scalability of decane-based polymer chain extension processes from laboratory to industrial scale is another significant challenge. Maintaining the precise control over reaction conditions and achieving uniform chain extension becomes increasingly difficult as production volumes increase. This scaling challenge often necessitates substantial engineering efforts to design and optimize large-scale manufacturing equipment and processes.

Lastly, the environmental and regulatory considerations surrounding the use of decane in polymer manufacturing pose challenges for industry adoption. As environmental regulations become more stringent, manufacturers must address concerns related to volatile organic compound (VOC) emissions and develop strategies for minimizing the environmental impact of decane-based processes.

Current Decane Extension Solutions

01 Synthesis of decane-based polymers

Various methods for synthesizing decane-based polymers through chain extension reactions. These processes often involve the use of specific catalysts, reaction conditions, and monomers to achieve desired polymer properties and structures.- Synthesis of decane-based polymers: Various methods for synthesizing decane-based polymers are described, including chain extension techniques. These processes often involve the use of specific catalysts and reaction conditions to control the polymer chain length and properties.

- Chain extension of polyurethanes using decane derivatives: Decane-based compounds are utilized as chain extenders in polyurethane synthesis. This approach can improve the mechanical properties and thermal stability of the resulting polymers, making them suitable for various applications.

- Modification of polymer properties through decane incorporation: The incorporation of decane or its derivatives into polymer chains can modify the physical and chemical properties of the resulting materials. This includes changes in hydrophobicity, flexibility, and thermal characteristics.

- Decane-based copolymers and block copolymers: Techniques for creating copolymers and block copolymers using decane-based monomers or oligomers are explored. These methods allow for the development of materials with tailored properties for specific applications.

- Applications of decane-extended polymers: Polymers with decane-based chain extensions find applications in various fields, including adhesives, coatings, and composite materials. The unique properties imparted by decane incorporation make these polymers suitable for specialized uses.

02 Modification of decane polymer properties

Techniques for modifying the properties of decane polymers through chain extension. This includes methods to improve mechanical strength, thermal stability, and chemical resistance by altering the polymer structure or incorporating additional functional groups.Expand Specific Solutions03 Applications of extended decane polymers

Various applications of chain-extended decane polymers in industries such as automotive, construction, and consumer goods. These polymers offer improved performance characteristics, making them suitable for specific end-use applications.Expand Specific Solutions04 Chain extension agents for decane polymers

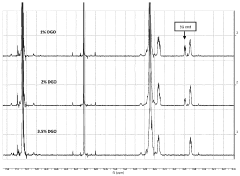

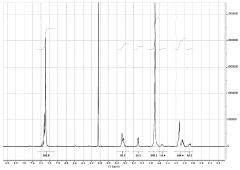

Development and use of specific chain extension agents tailored for decane polymers. These agents are designed to effectively increase molecular weight, improve polymer properties, and enhance processability of the resulting materials.Expand Specific Solutions05 Characterization of chain-extended decane polymers

Methods and techniques for characterizing chain-extended decane polymers, including analysis of molecular weight distribution, thermal properties, and mechanical behavior. These characterization techniques are essential for understanding and optimizing the polymer structure and properties.Expand Specific Solutions

Key Players Polymer Industry

The competition landscape for decane-governed polymer chain extension in advanced manufacturing is evolving rapidly. The market is in its growth phase, with increasing demand for advanced materials in various industries. The global market size for polymer chain extension technologies is projected to expand significantly in the coming years. Technological maturity varies among key players, with companies like ExxonMobil Technology & Engineering Co., BASF Corp., and 3M Innovative Properties Co. leading in research and development. Academic institutions such as Carnegie Mellon University and Tongji University are contributing to fundamental research, while specialized firms like The Lycra Co. LLC and Xiamen Sinopeg Biotech Co., Ltd. are focusing on niche applications. The competition is intensifying as more players enter the market, driving innovation and diversification in polymer chain extension techniques.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced manufacturing techniques for polymer chain extension using decane as a key component. Their approach involves precise control of decane concentration and temperature during polymerization to achieve optimal chain length and properties. The company utilizes a proprietary catalytic system that enhances the efficiency of decane-mediated chain extension, resulting in polymers with improved mechanical strength and thermal stability[1]. ExxonMobil's process also incorporates real-time monitoring and adjustment of reaction conditions, allowing for fine-tuning of polymer characteristics based on specific application requirements[3]. This technology has been successfully applied in the production of high-performance plastics for automotive and aerospace industries[5].

Strengths: Precise control over polymer properties, scalable production process, and versatility in end-product applications. Weaknesses: Potentially higher production costs due to specialized equipment and catalysts required.

BASF Corp.

Technical Solution: BASF has pioneered a novel approach to decane-governed polymer chain extension in advanced manufacturing. Their method employs a unique combination of decane and co-solvents to create a controlled reaction environment that promotes uniform chain growth[2]. The company has developed a series of custom-designed initiators that work synergistically with decane to achieve precise molecular weight distribution and branching patterns[4]. BASF's technology also incorporates sustainable practices by utilizing bio-based decane sources and implementing closed-loop recycling systems for solvent recovery[6]. This innovative approach has enabled the production of high-performance polymers with enhanced durability and chemical resistance for use in industrial coatings and membranes[8].

Strengths: Sustainable production methods, precise control over polymer architecture, and broad applicability across various industries. Weaknesses: Potential limitations in scaling up production for certain specialized polymer types.

Core Decane Extension Innovations

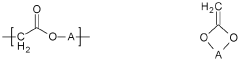

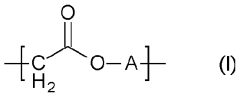

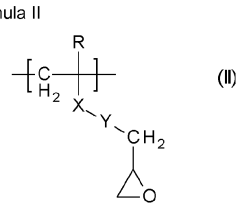

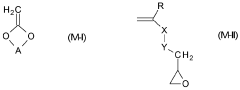

Copolymers having epoxy groups and their use as chain extenders

PatentWO2014173985A1

Innovation

- Copolymers with repeating units of specific formulae, combining monoethylenically unsaturated glycidyl monomers, provide excellent heat stability and processability while maintaining biodegradability, effectively acting as chain extenders for hydroxyl- and carboxyl-terminated polymers.

Process for the production of a high molecular weight polyester (CO)polymer

PatentWO2024094633A1

Innovation

- A process involving the use of diphenyl oxalate ester as a molecular weight booster, which reacts with polyester chains to increase molecular weight without being incorporated into the polymer structure, allowing for higher molecular weights to be achieved under milder conditions and enabling recycling without altering the polymer's physical properties.

Environmental Impact Assessment

The environmental impact of decane-governed polymer chain extension in advanced manufacturing processes is a critical consideration for sustainable industrial practices. This process, while offering significant advantages in material properties and manufacturing efficiency, also presents potential environmental challenges that must be carefully assessed and mitigated.

One of the primary environmental concerns is the use of decane itself, a hydrocarbon derived from petroleum sources. The extraction, processing, and transportation of decane contribute to carbon emissions and potential ecosystem disruption. However, the extended lifespan and improved performance of polymers produced through this method may offset some of these impacts by reducing the frequency of replacement and overall material consumption.

Emissions from the manufacturing process are another key area of environmental impact. The volatility of decane can lead to the release of volatile organic compounds (VOCs) during production. These emissions can contribute to air pollution and the formation of ground-level ozone, potentially affecting local air quality and human health. Implementing advanced emission control technologies and closed-loop systems can significantly reduce these environmental risks.

Water usage and potential contamination are also important factors to consider. The polymer chain extension process may require substantial amounts of water for cooling and cleaning purposes. Proper water management systems, including treatment and recycling facilities, are essential to minimize water consumption and prevent the release of contaminated effluents into local water bodies.

Energy consumption is a significant aspect of the environmental footprint of this manufacturing process. The precise control required for decane-governed polymer chain extension often necessitates energy-intensive equipment and conditions. Improving energy efficiency through process optimization and the use of renewable energy sources can help mitigate this impact.

Waste generation and management are crucial considerations. While the process aims to improve material efficiency, there may still be by-products and waste materials that require proper disposal or recycling. Developing effective waste management strategies, including the potential for circular economy approaches, can minimize the environmental burden of these materials.

The end-of-life considerations for products manufactured using this technique are also important. The enhanced properties of the polymers may affect their biodegradability or recyclability. Research into environmentally friendly disposal methods or innovative recycling techniques specific to these materials is essential for reducing their long-term environmental impact.

In conclusion, while decane-governed polymer chain extension offers significant benefits in advanced manufacturing, a comprehensive environmental impact assessment is crucial. This assessment should guide the development of mitigation strategies and sustainable practices to ensure that the advantages of this technology are not outweighed by its environmental costs.

One of the primary environmental concerns is the use of decane itself, a hydrocarbon derived from petroleum sources. The extraction, processing, and transportation of decane contribute to carbon emissions and potential ecosystem disruption. However, the extended lifespan and improved performance of polymers produced through this method may offset some of these impacts by reducing the frequency of replacement and overall material consumption.

Emissions from the manufacturing process are another key area of environmental impact. The volatility of decane can lead to the release of volatile organic compounds (VOCs) during production. These emissions can contribute to air pollution and the formation of ground-level ozone, potentially affecting local air quality and human health. Implementing advanced emission control technologies and closed-loop systems can significantly reduce these environmental risks.

Water usage and potential contamination are also important factors to consider. The polymer chain extension process may require substantial amounts of water for cooling and cleaning purposes. Proper water management systems, including treatment and recycling facilities, are essential to minimize water consumption and prevent the release of contaminated effluents into local water bodies.

Energy consumption is a significant aspect of the environmental footprint of this manufacturing process. The precise control required for decane-governed polymer chain extension often necessitates energy-intensive equipment and conditions. Improving energy efficiency through process optimization and the use of renewable energy sources can help mitigate this impact.

Waste generation and management are crucial considerations. While the process aims to improve material efficiency, there may still be by-products and waste materials that require proper disposal or recycling. Developing effective waste management strategies, including the potential for circular economy approaches, can minimize the environmental burden of these materials.

The end-of-life considerations for products manufactured using this technique are also important. The enhanced properties of the polymers may affect their biodegradability or recyclability. Research into environmentally friendly disposal methods or innovative recycling techniques specific to these materials is essential for reducing their long-term environmental impact.

In conclusion, while decane-governed polymer chain extension offers significant benefits in advanced manufacturing, a comprehensive environmental impact assessment is crucial. This assessment should guide the development of mitigation strategies and sustainable practices to ensure that the advantages of this technology are not outweighed by its environmental costs.

Regulatory Compliance Manufacturing

In the realm of advanced manufacturing, regulatory compliance plays a crucial role in ensuring the safety, quality, and environmental sustainability of polymer production processes. The governance of decane in polymer chain extension is subject to various regulatory frameworks that manufacturers must adhere to. These regulations are designed to address potential risks associated with the use of decane and other hydrocarbons in manufacturing processes.

One of the primary regulatory bodies overseeing the use of decane in polymer production is the Environmental Protection Agency (EPA). The EPA has established guidelines for the handling, storage, and disposal of volatile organic compounds (VOCs) like decane. Manufacturers must implement proper emission control systems to minimize the release of decane into the atmosphere, as it can contribute to the formation of ground-level ozone and smog.

The Occupational Safety and Health Administration (OSHA) also imposes strict regulations on the use of decane in manufacturing environments. These regulations focus on worker safety, requiring proper ventilation systems, personal protective equipment, and safety protocols to prevent exposure to decane vapors. Manufacturers must conduct regular risk assessments and provide adequate training to employees working with decane and related substances.

In addition to federal regulations, many states and local jurisdictions have their own set of rules governing the use of hydrocarbons in manufacturing processes. These regulations may include permitting requirements, emission limits, and reporting obligations. Manufacturers must stay informed about the specific regulations applicable to their location and ensure compliance with all relevant standards.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also impacts the use of decane in polymer production. Under REACH, manufacturers and importers are required to register substances like decane and provide information on their properties, hazards, and safe use. This regulation aims to protect human health and the environment by promoting the responsible use of chemicals in manufacturing processes.

To ensure compliance with these regulations, manufacturers must implement robust quality management systems and maintain detailed documentation of their processes. This includes keeping records of decane usage, conducting regular audits, and implementing continuous improvement initiatives to reduce environmental impact and enhance worker safety.

As the field of advanced manufacturing continues to evolve, regulatory frameworks are likely to adapt to address new challenges and technologies. Manufacturers must stay vigilant and proactive in monitoring regulatory changes and updating their compliance strategies accordingly. This may involve investing in new technologies for emission control, exploring alternative substances to replace decane, or developing innovative processes that minimize the use of volatile organic compounds.

One of the primary regulatory bodies overseeing the use of decane in polymer production is the Environmental Protection Agency (EPA). The EPA has established guidelines for the handling, storage, and disposal of volatile organic compounds (VOCs) like decane. Manufacturers must implement proper emission control systems to minimize the release of decane into the atmosphere, as it can contribute to the formation of ground-level ozone and smog.

The Occupational Safety and Health Administration (OSHA) also imposes strict regulations on the use of decane in manufacturing environments. These regulations focus on worker safety, requiring proper ventilation systems, personal protective equipment, and safety protocols to prevent exposure to decane vapors. Manufacturers must conduct regular risk assessments and provide adequate training to employees working with decane and related substances.

In addition to federal regulations, many states and local jurisdictions have their own set of rules governing the use of hydrocarbons in manufacturing processes. These regulations may include permitting requirements, emission limits, and reporting obligations. Manufacturers must stay informed about the specific regulations applicable to their location and ensure compliance with all relevant standards.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also impacts the use of decane in polymer production. Under REACH, manufacturers and importers are required to register substances like decane and provide information on their properties, hazards, and safe use. This regulation aims to protect human health and the environment by promoting the responsible use of chemicals in manufacturing processes.

To ensure compliance with these regulations, manufacturers must implement robust quality management systems and maintain detailed documentation of their processes. This includes keeping records of decane usage, conducting regular audits, and implementing continuous improvement initiatives to reduce environmental impact and enhance worker safety.

As the field of advanced manufacturing continues to evolve, regulatory frameworks are likely to adapt to address new challenges and technologies. Manufacturers must stay vigilant and proactive in monitoring regulatory changes and updating their compliance strategies accordingly. This may involve investing in new technologies for emission control, exploring alternative substances to replace decane, or developing innovative processes that minimize the use of volatile organic compounds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!