How Digital Twins Enhance V8 Engine Development Lifecycles?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Digital Twin Evolution and Objectives

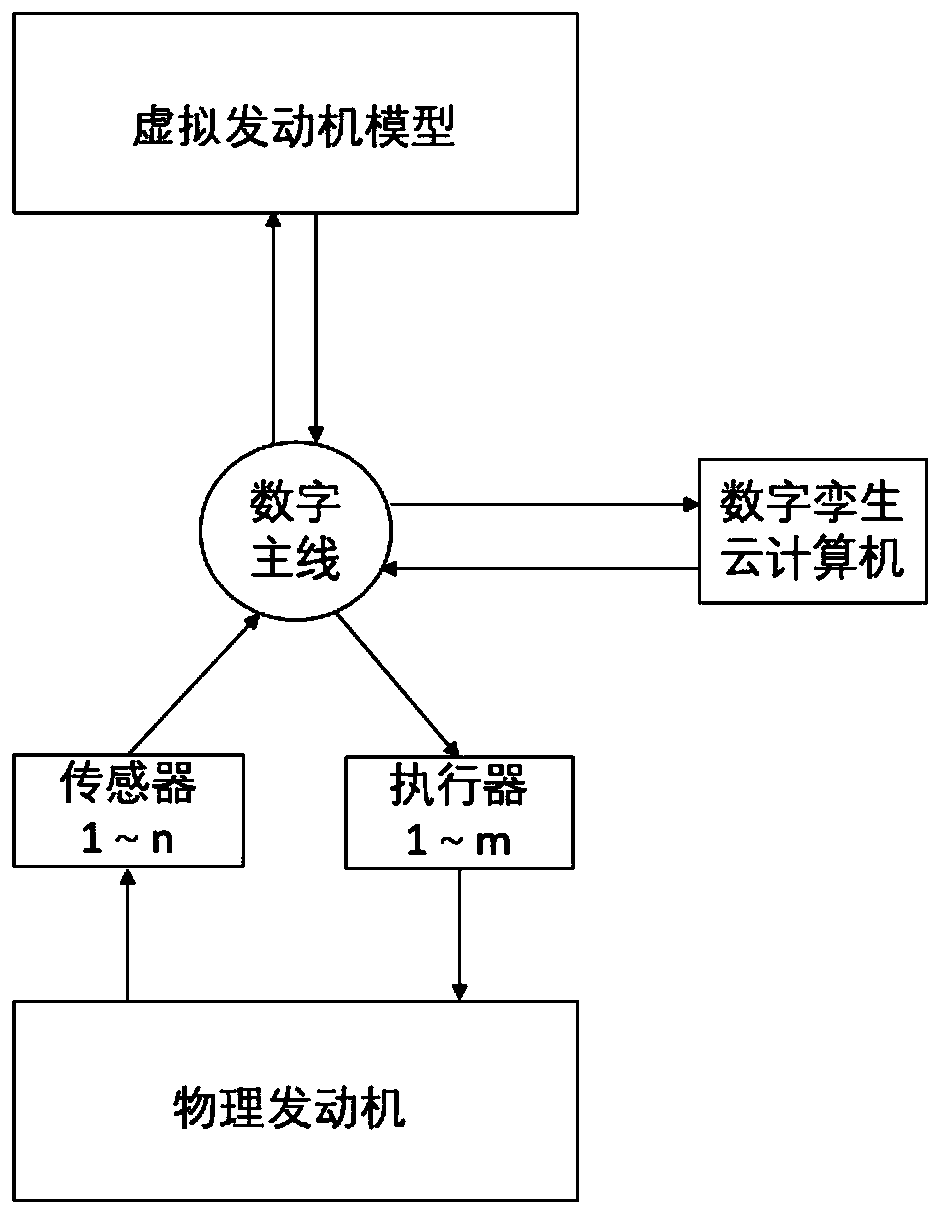

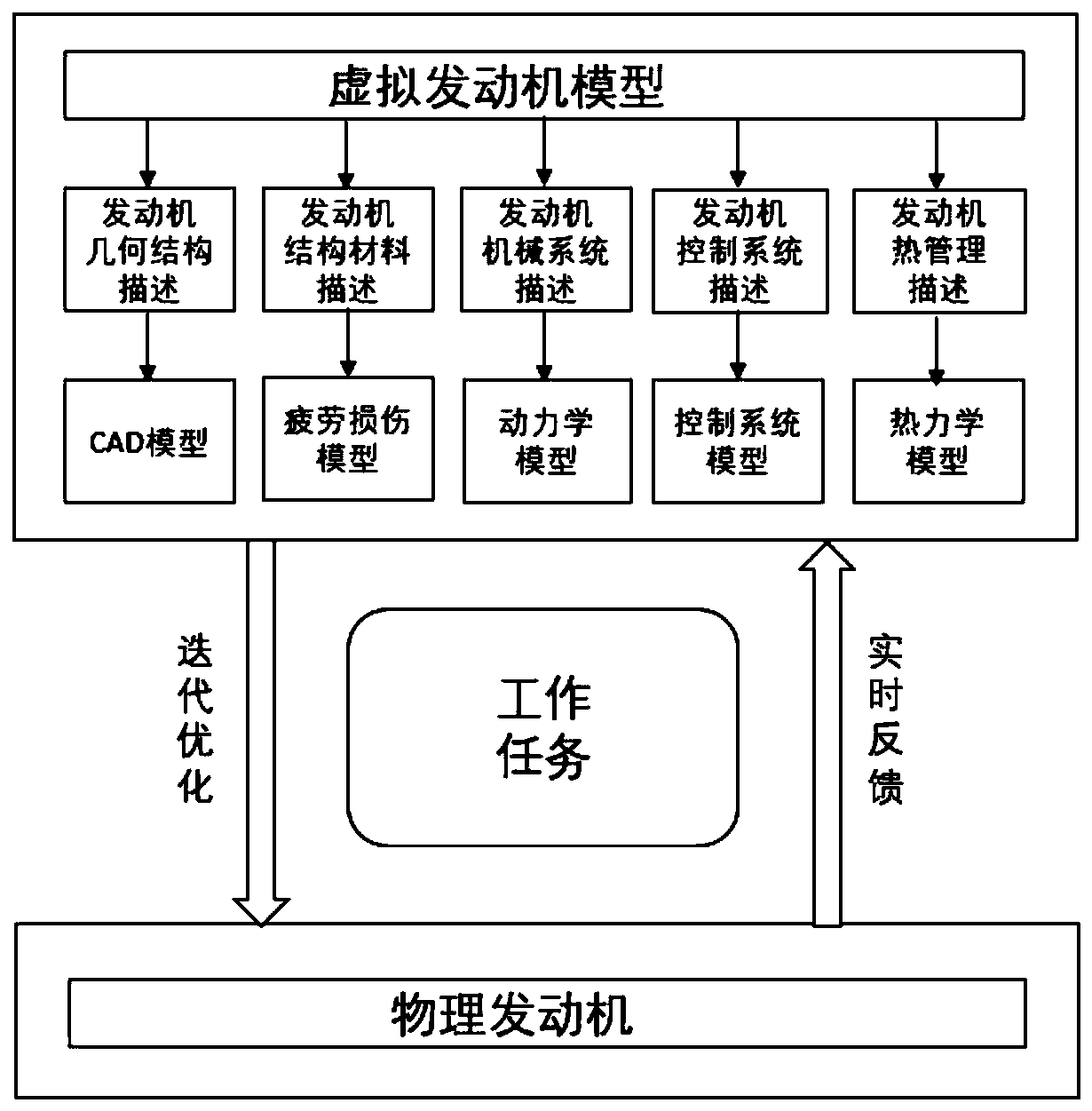

Digital twins have revolutionized the development lifecycle of V8 engines, marking a significant milestone in automotive engineering. This technology has evolved from simple 3D models to sophisticated virtual replicas that mirror the physical engine in real-time. The journey began with basic computer-aided design (CAD) models in the 1990s, progressing to more complex simulations in the early 2000s. By the 2010s, the integration of Internet of Things (IoT) sensors and big data analytics paved the way for true digital twins.

The primary objective of V8 engine digital twins is to enhance the entire development process, from initial design to final production and beyond. These virtual counterparts aim to reduce time-to-market, minimize physical prototyping costs, and improve overall engine performance and reliability. By creating a digital representation that can be tested, analyzed, and optimized in a virtual environment, engineers can identify and resolve potential issues before they manifest in the physical product.

Another crucial goal is to enable predictive maintenance and real-time monitoring of V8 engines in operation. Digital twins collect and process data from sensors embedded in physical engines, allowing for continuous performance analysis and early detection of potential failures. This proactive approach significantly reduces downtime and maintenance costs while extending the engine's lifespan.

The evolution of V8 engine digital twins has been driven by advancements in computing power, data analytics, and simulation technologies. Modern digital twins incorporate machine learning algorithms that can predict engine behavior under various conditions, optimize performance parameters, and even suggest design improvements. The integration of augmented reality (AR) and virtual reality (VR) technologies has further enhanced the visualization and interaction capabilities of these digital models.

Looking ahead, the objectives for V8 engine digital twins include achieving even greater fidelity between the virtual and physical worlds. This involves developing more accurate simulation models, incorporating a wider range of environmental factors, and improving the real-time synchronization between the digital twin and its physical counterpart. Additionally, there is a push towards creating a more collaborative development environment, where engineers from different disciplines can work simultaneously on the same digital model, streamlining the design process and fostering innovation.

The primary objective of V8 engine digital twins is to enhance the entire development process, from initial design to final production and beyond. These virtual counterparts aim to reduce time-to-market, minimize physical prototyping costs, and improve overall engine performance and reliability. By creating a digital representation that can be tested, analyzed, and optimized in a virtual environment, engineers can identify and resolve potential issues before they manifest in the physical product.

Another crucial goal is to enable predictive maintenance and real-time monitoring of V8 engines in operation. Digital twins collect and process data from sensors embedded in physical engines, allowing for continuous performance analysis and early detection of potential failures. This proactive approach significantly reduces downtime and maintenance costs while extending the engine's lifespan.

The evolution of V8 engine digital twins has been driven by advancements in computing power, data analytics, and simulation technologies. Modern digital twins incorporate machine learning algorithms that can predict engine behavior under various conditions, optimize performance parameters, and even suggest design improvements. The integration of augmented reality (AR) and virtual reality (VR) technologies has further enhanced the visualization and interaction capabilities of these digital models.

Looking ahead, the objectives for V8 engine digital twins include achieving even greater fidelity between the virtual and physical worlds. This involves developing more accurate simulation models, incorporating a wider range of environmental factors, and improving the real-time synchronization between the digital twin and its physical counterpart. Additionally, there is a push towards creating a more collaborative development environment, where engineers from different disciplines can work simultaneously on the same digital model, streamlining the design process and fostering innovation.

Market Demand for Advanced V8 Engine Development

The market demand for advanced V8 engine development has been steadily growing, driven by the automotive industry's pursuit of higher performance, improved fuel efficiency, and reduced emissions. As environmental regulations become more stringent and consumer preferences evolve, manufacturers are increasingly turning to innovative technologies to enhance their V8 engine offerings.

In the high-performance vehicle segment, there is a persistent demand for V8 engines that deliver exceptional power and torque. Sports car enthusiasts and luxury vehicle buyers continue to seek the distinctive sound and driving experience associated with V8 engines. This market segment values cutting-edge technology that can extract maximum performance while meeting emissions standards.

Simultaneously, there is a growing demand for more fuel-efficient V8 engines in the light truck and SUV markets. As these vehicles remain popular, especially in North America, manufacturers are under pressure to improve fuel economy without sacrificing the power and capability that consumers expect from V8-equipped vehicles.

The commercial vehicle sector also contributes to the demand for advanced V8 engine development. Heavy-duty trucks and specialized industrial equipment often rely on V8 engines for their power and durability. In this segment, there is a strong focus on enhancing reliability, extending service intervals, and reducing total cost of ownership.

Racing and motorsports continue to be significant drivers of V8 engine innovation. The constant push for higher performance in competitive environments leads to technological advancements that often trickle down to production vehicles. This creates a cycle of innovation and market demand for increasingly sophisticated V8 engines.

The integration of digital technologies in engine development has opened new avenues for advancement. Digital twins, in particular, have emerged as a powerful tool for optimizing V8 engine design and performance. The market is showing increased interest in engines developed using these advanced simulation techniques, as they promise faster development cycles and more refined end products.

Lastly, there is a growing niche market for modernized classic vehicles, where advanced V8 engines are in demand for restomod projects. This segment seeks engines that combine modern performance and efficiency with the character of traditional V8 designs, driving innovation in aftermarket and specialty engine development.

In the high-performance vehicle segment, there is a persistent demand for V8 engines that deliver exceptional power and torque. Sports car enthusiasts and luxury vehicle buyers continue to seek the distinctive sound and driving experience associated with V8 engines. This market segment values cutting-edge technology that can extract maximum performance while meeting emissions standards.

Simultaneously, there is a growing demand for more fuel-efficient V8 engines in the light truck and SUV markets. As these vehicles remain popular, especially in North America, manufacturers are under pressure to improve fuel economy without sacrificing the power and capability that consumers expect from V8-equipped vehicles.

The commercial vehicle sector also contributes to the demand for advanced V8 engine development. Heavy-duty trucks and specialized industrial equipment often rely on V8 engines for their power and durability. In this segment, there is a strong focus on enhancing reliability, extending service intervals, and reducing total cost of ownership.

Racing and motorsports continue to be significant drivers of V8 engine innovation. The constant push for higher performance in competitive environments leads to technological advancements that often trickle down to production vehicles. This creates a cycle of innovation and market demand for increasingly sophisticated V8 engines.

The integration of digital technologies in engine development has opened new avenues for advancement. Digital twins, in particular, have emerged as a powerful tool for optimizing V8 engine design and performance. The market is showing increased interest in engines developed using these advanced simulation techniques, as they promise faster development cycles and more refined end products.

Lastly, there is a growing niche market for modernized classic vehicles, where advanced V8 engines are in demand for restomod projects. This segment seeks engines that combine modern performance and efficiency with the character of traditional V8 designs, driving innovation in aftermarket and specialty engine development.

Digital Twin Challenges in V8 Engine Simulation

Digital twin technology faces several significant challenges in V8 engine simulation, primarily due to the complexity of the engine system and the high fidelity required for accurate representation. One of the main obstacles is the integration of multi-physics simulations, which must account for thermodynamics, fluid dynamics, structural mechanics, and combustion processes simultaneously. This integration is computationally intensive and requires sophisticated algorithms to manage the interactions between different physical domains.

Data acquisition and synchronization pose another major challenge. V8 engines operate at high speeds and temperatures, making it difficult to collect real-time data from all critical components. Sensors must be carefully placed to avoid interference with engine operation while still capturing essential information. The sheer volume of data generated during engine operation also presents challenges in terms of storage, processing, and analysis.

Model fidelity and accuracy are crucial for effective digital twin implementation in V8 engine development. Creating high-fidelity models that accurately represent the complex geometries and material properties of engine components is a time-consuming and resource-intensive process. Moreover, these models must be continuously updated to reflect wear, degradation, and modifications throughout the engine's lifecycle.

Real-time simulation capabilities are essential for digital twins to provide meaningful insights during engine operation. However, achieving real-time performance while maintaining high accuracy is challenging, especially when simulating complex phenomena such as combustion dynamics and thermal management. This often requires a balance between model complexity and computational efficiency.

Validation and verification of digital twin models present another significant challenge. Ensuring that the digital representation accurately reflects the physical engine across a wide range of operating conditions requires extensive testing and correlation with experimental data. This process can be time-consuming and expensive, particularly for high-performance V8 engines with wide operating envelopes.

Interoperability and standardization issues also hinder the widespread adoption of digital twins in V8 engine development. Different simulation tools and data formats used across the development lifecycle may not be fully compatible, leading to integration challenges and potential loss of fidelity when transferring data between systems.

Lastly, cybersecurity concerns are paramount when implementing digital twins, as they involve sensitive design and operational data. Protecting this information from unauthorized access or manipulation while still allowing necessary data sharing among development teams and suppliers is a complex challenge that requires robust security protocols and infrastructure.

Data acquisition and synchronization pose another major challenge. V8 engines operate at high speeds and temperatures, making it difficult to collect real-time data from all critical components. Sensors must be carefully placed to avoid interference with engine operation while still capturing essential information. The sheer volume of data generated during engine operation also presents challenges in terms of storage, processing, and analysis.

Model fidelity and accuracy are crucial for effective digital twin implementation in V8 engine development. Creating high-fidelity models that accurately represent the complex geometries and material properties of engine components is a time-consuming and resource-intensive process. Moreover, these models must be continuously updated to reflect wear, degradation, and modifications throughout the engine's lifecycle.

Real-time simulation capabilities are essential for digital twins to provide meaningful insights during engine operation. However, achieving real-time performance while maintaining high accuracy is challenging, especially when simulating complex phenomena such as combustion dynamics and thermal management. This often requires a balance between model complexity and computational efficiency.

Validation and verification of digital twin models present another significant challenge. Ensuring that the digital representation accurately reflects the physical engine across a wide range of operating conditions requires extensive testing and correlation with experimental data. This process can be time-consuming and expensive, particularly for high-performance V8 engines with wide operating envelopes.

Interoperability and standardization issues also hinder the widespread adoption of digital twins in V8 engine development. Different simulation tools and data formats used across the development lifecycle may not be fully compatible, leading to integration challenges and potential loss of fidelity when transferring data between systems.

Lastly, cybersecurity concerns are paramount when implementing digital twins, as they involve sensitive design and operational data. Protecting this information from unauthorized access or manipulation while still allowing necessary data sharing among development teams and suppliers is a complex challenge that requires robust security protocols and infrastructure.

Current Digital Twin Approaches for V8 Engines

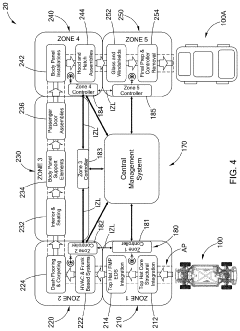

01 Digital Twin Creation and Initialization

The process of creating and initializing digital twins involves gathering data from physical assets, setting up virtual models, and establishing connections between the physical and digital realms. This phase includes defining the scope, objectives, and key performance indicators for the digital twin.- Digital Twin Creation and Modeling: This phase involves creating a virtual representation of a physical asset or system. It includes data collection, 3D modeling, and establishing connections between the physical and digital entities. The process often utilizes advanced technologies such as IoT sensors, AI, and machine learning to ensure accurate representation and real-time data synchronization.

- Simulation and Analysis: Once created, digital twins are used for simulation and analysis. This stage involves running various scenarios, predicting outcomes, and optimizing performance. It allows for testing different conditions without risking the physical asset, enabling better decision-making and risk management in real-world applications.

- Integration and Deployment: This phase focuses on integrating the digital twin into existing systems and processes. It involves connecting the digital twin to relevant databases, enterprise systems, and other digital platforms. The deployment process ensures that the digital twin can effectively communicate with and enhance the performance of physical assets in real-time operations.

- Maintenance and Updating: Maintaining and updating digital twins is crucial for their long-term effectiveness. This includes regular data updates, refining models based on new information, and adapting to changes in the physical asset or environment. Continuous improvement ensures that the digital twin remains an accurate and valuable representation of its physical counterpart.

- Lifecycle Management and Decommissioning: This final phase encompasses the overall management of the digital twin throughout its lifecycle, including eventual decommissioning. It involves monitoring the twin's performance, assessing its continued relevance, and making decisions about upgrades or retirement. Proper lifecycle management ensures optimal resource allocation and maintains the value of the digital twin initiative over time.

02 Data Integration and Synchronization

This stage focuses on integrating various data sources and ensuring real-time synchronization between the physical asset and its digital counterpart. It involves implementing IoT sensors, data collection protocols, and establishing secure communication channels for continuous data flow.Expand Specific Solutions03 Simulation and Predictive Analysis

Digital twins enable advanced simulation capabilities and predictive analytics. This phase involves developing algorithms for scenario modeling, performance optimization, and predictive maintenance. It also includes the integration of machine learning and AI techniques to enhance forecasting accuracy.Expand Specific Solutions04 Visualization and User Interface Development

Creating intuitive and interactive user interfaces for digital twins is crucial for effective utilization. This stage involves developing 3D visualizations, dashboards, and control panels that allow users to interact with the digital twin, monitor performance, and make informed decisions.Expand Specific Solutions05 Continuous Improvement and Lifecycle Management

The ongoing management and improvement of digital twins throughout their lifecycle is essential. This includes regular updates, performance evaluations, and incorporating feedback from users and stakeholders. It also involves adapting the digital twin to evolving business needs and technological advancements.Expand Specific Solutions

Key Players in V8 Engine Digital Twin Solutions

The digital twin technology for V8 engine development is in a growth phase, with increasing market size and evolving technical maturity. The competitive landscape is characterized by a mix of established automotive manufacturers, technology companies, and research institutions. Companies like Ford Global Technologies, Volkswagen AG, and Volvo Lastvagnar AB are leveraging their industry experience to integrate digital twins into their development processes. Simultaneously, tech giants such as IBM and Siemens Industry Software are providing advanced simulation platforms. Universities like Beihang University and Northwestern Polytechnical University are contributing to research and innovation in this field, pushing the boundaries of digital twin applications in engine development.

Cummins Power Generation Ltd.

Technical Solution: Cummins Power Generation Ltd. has developed a comprehensive digital twin strategy for V8 engine development. Their approach focuses on creating accurate virtual representations of engine components and systems, enabling real-time monitoring and predictive maintenance. Cummins' digital twin platform integrates IoT sensors, big data analytics, and AI-driven simulation models to provide a holistic view of engine performance throughout its lifecycle[4]. The company has implemented a cloud-based infrastructure to support their digital twin ecosystem, allowing for scalable computing resources and remote access capabilities. Cummins has reported a 25% reduction in engine testing time and a 15% improvement in fuel efficiency through the use of digital twins[5]. Their system also incorporates advanced visualization tools, enabling engineers to analyze complex engine dynamics and optimize designs more effectively.

Strengths: Reduced testing time, improved fuel efficiency, and enhanced predictive maintenance capabilities. Weaknesses: Reliance on complex IT infrastructure and potential challenges in data integration across different engine models.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC has implemented an advanced digital twin framework for V8 engine development. Their approach leverages high-performance computing and AI-driven simulations to create accurate virtual models of engine systems. Ford's digital twin platform incorporates real-time data from test engines and production vehicles, enabling continuous validation and refinement of engine designs. The company has developed proprietary algorithms for analyzing engine performance under various operating conditions, allowing for rapid iteration and optimization[6]. Ford's digital twin system also integrates with their supply chain management, enabling better coordination with suppliers and more efficient production planning. The company has reported a 40% reduction in physical prototyping costs and a 20% improvement in engine durability through the use of digital twins[7]. Additionally, Ford has implemented augmented reality tools to enhance collaboration between design and manufacturing teams, facilitating faster problem resolution and knowledge transfer.

Strengths: Significant reduction in prototyping costs, improved engine durability, and enhanced supply chain integration. Weaknesses: Potential over-reliance on virtual testing and challenges in maintaining data accuracy across diverse vehicle platforms.

Core Innovations in V8 Engine Digital Twinning

Automobile engine control method based on digital twin technology

PatentActiveCN110454290A

Innovation

- Use digital twin technology to build a virtual engine model that is completely consistent with the physical engine, monitor operating data simultaneously in the actual and simulation environments, and dynamically update the virtual engine model through data analysis and fusion processing to obtain the optimal control strategy and realize dynamic management of the physical engine. control.

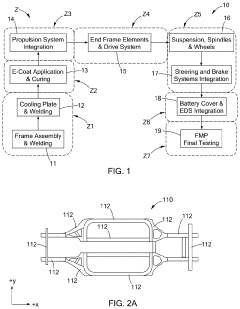

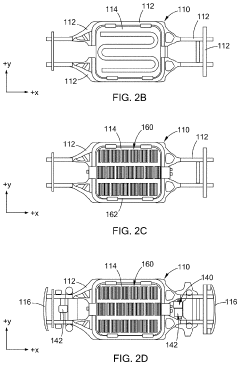

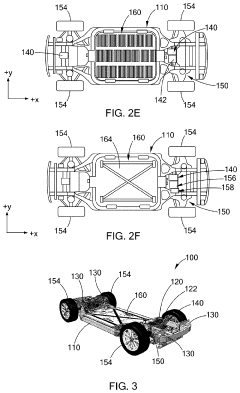

Method of storing, processing, and transmitting digital twins for flexible module platforms and vehicles

PatentActiveUS20210397164A1

Innovation

- A method is introduced to create a digital twin for vehicles by scanning and updating digital files of modular vehicle subassemblies as they move through assembly zones, allowing for efficient data management and assembly line operations, including the use of vehicle identification numbers and temporary and permanent digital files to track component assembly and integration.

Environmental Impact of Digital Twin-Driven Development

The implementation of digital twins in V8 engine development lifecycles brings significant environmental benefits, contributing to more sustainable practices in the automotive industry. By creating virtual replicas of physical engines, manufacturers can substantially reduce the need for physical prototypes, leading to a decrease in material consumption and waste generation. This shift towards digital simulation and testing minimizes the environmental impact associated with traditional development processes.

Digital twin technology enables engineers to conduct extensive virtual testing and optimization, reducing the number of physical tests required. This approach not only saves time and resources but also significantly lowers energy consumption and carbon emissions associated with physical testing facilities. The ability to simulate various operating conditions and scenarios digitally allows for more efficient design iterations without the need for multiple physical prototypes, further reducing the environmental footprint of engine development.

Moreover, digital twins facilitate the optimization of engine performance and efficiency throughout the entire lifecycle. By continuously monitoring and analyzing real-time data from operational engines, manufacturers can identify areas for improvement in fuel efficiency and emissions reduction. This data-driven approach enables more precise tuning and refinement of engine parameters, leading to cleaner and more environmentally friendly V8 engines in production vehicles.

The use of digital twins also extends to predictive maintenance strategies, which can have a positive environmental impact. By accurately predicting when maintenance is needed, unnecessary servicing can be avoided, reducing waste from premature part replacements and minimizing the use of resources for maintenance activities. This proactive approach not only extends the lifespan of engines but also ensures they operate at peak efficiency, further reducing fuel consumption and emissions over time.

Additionally, digital twin technology supports the development of more recyclable and sustainable engine designs. By simulating the entire lifecycle of an engine, including its end-of-life phase, engineers can optimize designs for easier disassembly and recycling. This focus on circular economy principles helps reduce the overall environmental impact of V8 engines by improving material recovery and reducing waste sent to landfills.

In conclusion, the integration of digital twins in V8 engine development lifecycles represents a significant step towards more environmentally sustainable practices in automotive engineering. By reducing physical prototyping, optimizing performance, enabling predictive maintenance, and supporting sustainable design principles, digital twin technology contributes to lower resource consumption, reduced emissions, and improved overall environmental performance in the automotive sector.

Digital twin technology enables engineers to conduct extensive virtual testing and optimization, reducing the number of physical tests required. This approach not only saves time and resources but also significantly lowers energy consumption and carbon emissions associated with physical testing facilities. The ability to simulate various operating conditions and scenarios digitally allows for more efficient design iterations without the need for multiple physical prototypes, further reducing the environmental footprint of engine development.

Moreover, digital twins facilitate the optimization of engine performance and efficiency throughout the entire lifecycle. By continuously monitoring and analyzing real-time data from operational engines, manufacturers can identify areas for improvement in fuel efficiency and emissions reduction. This data-driven approach enables more precise tuning and refinement of engine parameters, leading to cleaner and more environmentally friendly V8 engines in production vehicles.

The use of digital twins also extends to predictive maintenance strategies, which can have a positive environmental impact. By accurately predicting when maintenance is needed, unnecessary servicing can be avoided, reducing waste from premature part replacements and minimizing the use of resources for maintenance activities. This proactive approach not only extends the lifespan of engines but also ensures they operate at peak efficiency, further reducing fuel consumption and emissions over time.

Additionally, digital twin technology supports the development of more recyclable and sustainable engine designs. By simulating the entire lifecycle of an engine, including its end-of-life phase, engineers can optimize designs for easier disassembly and recycling. This focus on circular economy principles helps reduce the overall environmental impact of V8 engines by improving material recovery and reducing waste sent to landfills.

In conclusion, the integration of digital twins in V8 engine development lifecycles represents a significant step towards more environmentally sustainable practices in automotive engineering. By reducing physical prototyping, optimizing performance, enabling predictive maintenance, and supporting sustainable design principles, digital twin technology contributes to lower resource consumption, reduced emissions, and improved overall environmental performance in the automotive sector.

Cost-Benefit Analysis of Digital Twin Implementation

Implementing digital twins in V8 engine development lifecycles requires a comprehensive cost-benefit analysis to justify the investment and maximize returns. The initial costs of digital twin implementation can be substantial, including software licenses, hardware infrastructure, and specialized personnel training. However, these upfront expenses are often outweighed by long-term benefits and cost savings throughout the engine development process.

One of the primary benefits of digital twins is the significant reduction in physical prototyping costs. By creating accurate virtual models, engineers can conduct extensive simulations and testing without the need for multiple physical prototypes. This not only reduces material costs but also accelerates the development timeline, potentially saving millions in development expenses.

Digital twins also enhance the efficiency of the design process, allowing for rapid iterations and optimizations. This increased speed-to-market can provide a competitive advantage and potentially increase market share, translating to higher revenues. Furthermore, the ability to predict and address issues early in the development cycle minimizes costly redesigns and recalls, substantially reducing overall project costs.

Improved quality control is another significant benefit of digital twin implementation. By continuously monitoring and analyzing engine performance data, manufacturers can identify potential issues before they escalate, leading to reduced warranty claims and improved customer satisfaction. This proactive approach to quality management can result in substantial cost savings over the product lifecycle.

The implementation of digital twins also facilitates more efficient resource allocation. By providing accurate insights into engine performance and maintenance needs, manufacturers can optimize their supply chain and inventory management, reducing overhead costs and improving operational efficiency.

While the initial investment in digital twin technology may be significant, the long-term return on investment (ROI) is often compelling. Studies have shown that companies implementing digital twins in complex engineering projects can achieve cost savings of up to 30% in development and manufacturing processes. Additionally, the improved product quality and performance can lead to increased customer loyalty and brand value, further enhancing the overall financial benefits.

However, it is crucial to consider the ongoing costs associated with maintaining and updating digital twin systems. This includes regular software updates, data management, and the potential need for cloud computing resources. Organizations must also factor in the costs of change management and employee training to ensure successful adoption and utilization of digital twin technology.

One of the primary benefits of digital twins is the significant reduction in physical prototyping costs. By creating accurate virtual models, engineers can conduct extensive simulations and testing without the need for multiple physical prototypes. This not only reduces material costs but also accelerates the development timeline, potentially saving millions in development expenses.

Digital twins also enhance the efficiency of the design process, allowing for rapid iterations and optimizations. This increased speed-to-market can provide a competitive advantage and potentially increase market share, translating to higher revenues. Furthermore, the ability to predict and address issues early in the development cycle minimizes costly redesigns and recalls, substantially reducing overall project costs.

Improved quality control is another significant benefit of digital twin implementation. By continuously monitoring and analyzing engine performance data, manufacturers can identify potential issues before they escalate, leading to reduced warranty claims and improved customer satisfaction. This proactive approach to quality management can result in substantial cost savings over the product lifecycle.

The implementation of digital twins also facilitates more efficient resource allocation. By providing accurate insights into engine performance and maintenance needs, manufacturers can optimize their supply chain and inventory management, reducing overhead costs and improving operational efficiency.

While the initial investment in digital twin technology may be significant, the long-term return on investment (ROI) is often compelling. Studies have shown that companies implementing digital twins in complex engineering projects can achieve cost savings of up to 30% in development and manufacturing processes. Additionally, the improved product quality and performance can lead to increased customer loyalty and brand value, further enhancing the overall financial benefits.

However, it is crucial to consider the ongoing costs associated with maintaining and updating digital twin systems. This includes regular software updates, data management, and the potential need for cloud computing resources. Organizations must also factor in the costs of change management and employee training to ensure successful adoption and utilization of digital twin technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!