V8 Engine Role in Redefining Vehicle Performance Standards

JUL 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Performance Objectives

The V8 engine has played a pivotal role in shaping automotive performance standards since its inception in the early 20th century. This powerful and versatile engine configuration has undergone significant evolution, continuously pushing the boundaries of vehicle performance and efficiency. The journey of V8 engines reflects the broader trends in automotive engineering, from the pursuit of raw power to the integration of advanced technologies for improved efficiency and environmental sustainability.

Initially developed for high-performance applications, V8 engines quickly became synonymous with American muscle cars and luxury vehicles. Their ability to deliver substantial power and torque made them ideal for a wide range of automotive applications, from sports cars to heavy-duty trucks. As the automotive industry progressed, so did the objectives for V8 engine development, shifting from pure horsepower gains to a more balanced approach that considers fuel efficiency, emissions reduction, and overall vehicle dynamics.

The evolution of V8 engines has been marked by several key technological advancements. The introduction of fuel injection systems in the 1980s significantly improved fuel efficiency and power delivery. Subsequently, variable valve timing and cylinder deactivation technologies further enhanced the V8's versatility, allowing engines to operate more efficiently under varying load conditions. More recently, the integration of turbocharging and direct injection has enabled V8 engines to achieve remarkable power outputs while meeting increasingly stringent emissions standards.

Current performance objectives for V8 engines focus on achieving a delicate balance between power, efficiency, and environmental responsibility. Manufacturers are exploring innovative ways to extract maximum performance from smaller displacement V8s, utilizing advanced materials and precision engineering to reduce weight and friction. The advent of hybrid and electric powertrains has also influenced V8 development, with some automakers incorporating electric assistance to boost performance while reducing fuel consumption.

Looking ahead, the future of V8 engines in redefining vehicle performance standards lies in their ability to adapt to changing regulatory landscapes and consumer preferences. Research and development efforts are concentrated on further improving thermal efficiency, reducing emissions through advanced aftertreatment systems, and exploring alternative fuels such as hydrogen and synthetic fuels. The integration of artificial intelligence and machine learning in engine management systems promises to optimize V8 performance in real-time, adapting to driving conditions and user preferences seamlessly.

Initially developed for high-performance applications, V8 engines quickly became synonymous with American muscle cars and luxury vehicles. Their ability to deliver substantial power and torque made them ideal for a wide range of automotive applications, from sports cars to heavy-duty trucks. As the automotive industry progressed, so did the objectives for V8 engine development, shifting from pure horsepower gains to a more balanced approach that considers fuel efficiency, emissions reduction, and overall vehicle dynamics.

The evolution of V8 engines has been marked by several key technological advancements. The introduction of fuel injection systems in the 1980s significantly improved fuel efficiency and power delivery. Subsequently, variable valve timing and cylinder deactivation technologies further enhanced the V8's versatility, allowing engines to operate more efficiently under varying load conditions. More recently, the integration of turbocharging and direct injection has enabled V8 engines to achieve remarkable power outputs while meeting increasingly stringent emissions standards.

Current performance objectives for V8 engines focus on achieving a delicate balance between power, efficiency, and environmental responsibility. Manufacturers are exploring innovative ways to extract maximum performance from smaller displacement V8s, utilizing advanced materials and precision engineering to reduce weight and friction. The advent of hybrid and electric powertrains has also influenced V8 development, with some automakers incorporating electric assistance to boost performance while reducing fuel consumption.

Looking ahead, the future of V8 engines in redefining vehicle performance standards lies in their ability to adapt to changing regulatory landscapes and consumer preferences. Research and development efforts are concentrated on further improving thermal efficiency, reducing emissions through advanced aftertreatment systems, and exploring alternative fuels such as hydrogen and synthetic fuels. The integration of artificial intelligence and machine learning in engine management systems promises to optimize V8 performance in real-time, adapting to driving conditions and user preferences seamlessly.

Market Demand for High-Performance Vehicles

The market demand for high-performance vehicles has been steadily growing over the past decade, driven by a combination of factors including economic prosperity, technological advancements, and shifting consumer preferences. This segment of the automotive industry has shown remarkable resilience, even in the face of global economic uncertainties and increasing environmental concerns.

Luxury car manufacturers and sports car brands have reported consistent growth in sales of their high-performance models. For instance, Porsche's GT series and Ferrari's V8-powered models have seen increased demand, with waiting lists extending several months for some popular variants. This trend is not limited to traditional sports car manufacturers; mainstream automakers have also been expanding their high-performance offerings to capitalize on this growing market.

The demand for high-performance vehicles is particularly strong in developed markets such as North America, Europe, and parts of Asia. In the United States, the muscle car segment has experienced a renaissance, with models like the Ford Mustang GT, Chevrolet Camaro SS, and Dodge Challenger SRT Hellcat attracting enthusiasts and collectors alike. These vehicles, often equipped with powerful V8 engines, continue to be popular despite the industry's overall shift towards electrification.

Emerging markets, particularly China and the Middle East, have also shown a significant appetite for high-performance vehicles. The growing middle and upper classes in these regions view high-performance cars as status symbols, driving demand for premium and luxury brands that offer powerful engine options.

Market research indicates that consumers of high-performance vehicles prioritize factors such as acceleration, top speed, handling, and overall driving experience. The V8 engine, with its distinctive sound and power delivery characteristics, remains a key selling point for many buyers in this segment. However, there is an increasing emphasis on balancing performance with fuel efficiency and emissions compliance, leading to innovations in engine technology.

The aftermarket and tuning industry has also benefited from the demand for high-performance vehicles. Many owners seek to further enhance their vehicles' performance through modifications and upgrades, creating a thriving ecosystem of parts manufacturers and tuning specialists.

Despite the growing focus on electric vehicles, the market for high-performance internal combustion engine vehicles, particularly those with V8 engines, remains robust. This sustained demand has prompted manufacturers to continue investing in the development and refinement of V8 engine technology, seeking ways to improve performance while meeting increasingly stringent emissions regulations.

Luxury car manufacturers and sports car brands have reported consistent growth in sales of their high-performance models. For instance, Porsche's GT series and Ferrari's V8-powered models have seen increased demand, with waiting lists extending several months for some popular variants. This trend is not limited to traditional sports car manufacturers; mainstream automakers have also been expanding their high-performance offerings to capitalize on this growing market.

The demand for high-performance vehicles is particularly strong in developed markets such as North America, Europe, and parts of Asia. In the United States, the muscle car segment has experienced a renaissance, with models like the Ford Mustang GT, Chevrolet Camaro SS, and Dodge Challenger SRT Hellcat attracting enthusiasts and collectors alike. These vehicles, often equipped with powerful V8 engines, continue to be popular despite the industry's overall shift towards electrification.

Emerging markets, particularly China and the Middle East, have also shown a significant appetite for high-performance vehicles. The growing middle and upper classes in these regions view high-performance cars as status symbols, driving demand for premium and luxury brands that offer powerful engine options.

Market research indicates that consumers of high-performance vehicles prioritize factors such as acceleration, top speed, handling, and overall driving experience. The V8 engine, with its distinctive sound and power delivery characteristics, remains a key selling point for many buyers in this segment. However, there is an increasing emphasis on balancing performance with fuel efficiency and emissions compliance, leading to innovations in engine technology.

The aftermarket and tuning industry has also benefited from the demand for high-performance vehicles. Many owners seek to further enhance their vehicles' performance through modifications and upgrades, creating a thriving ecosystem of parts manufacturers and tuning specialists.

Despite the growing focus on electric vehicles, the market for high-performance internal combustion engine vehicles, particularly those with V8 engines, remains robust. This sustained demand has prompted manufacturers to continue investing in the development and refinement of V8 engine technology, seeking ways to improve performance while meeting increasingly stringent emissions regulations.

Current V8 Technology and Engineering Challenges

The current state of V8 engine technology represents a pinnacle of automotive engineering, blending power, efficiency, and sophistication. Modern V8 engines typically displace between 4.0 to 6.2 liters, producing anywhere from 300 to over 700 horsepower in production vehicles. These powerplants utilize advanced materials such as aluminum alloys for weight reduction and improved heat dissipation, while incorporating high-strength steel components in critical areas to withstand extreme pressures and temperatures.

One of the primary engineering challenges facing V8 engines is the ongoing push for improved fuel efficiency without sacrificing performance. This has led to the widespread adoption of technologies like direct fuel injection, variable valve timing, and cylinder deactivation. Direct injection allows for more precise fuel delivery, improving combustion efficiency and power output. Variable valve timing optimizes engine breathing across the rev range, enhancing both low-end torque and high-end power. Cylinder deactivation enables V8s to operate as more efficient four-cylinder engines under light load conditions.

Turbocharging and supercharging have become increasingly common in V8 applications, allowing manufacturers to extract more power from smaller displacement engines. This "downsizing" trend helps meet stringent emissions regulations while maintaining the performance characteristics expected from a V8. However, forced induction introduces additional complexity and thermal management challenges, requiring sophisticated intercooling systems and robust engine components.

Another significant challenge is the integration of hybrid and electrification technologies with V8 engines. Many high-performance vehicles now incorporate electric motors to supplement the V8's output, resulting in improved acceleration and efficiency. This hybridization adds layers of complexity to powertrain design, requiring seamless integration of mechanical and electrical systems.

Emissions control remains a critical focus for V8 engine development. Advanced catalytic converters, particulate filters, and exhaust gas recirculation systems are employed to meet increasingly strict global emissions standards. These systems often necessitate careful tuning to maintain performance while reducing harmful exhaust emissions.

Noise, vibration, and harshness (NVH) management presents another engineering challenge, particularly as consumers expect refined performance even from high-output engines. Sophisticated engine mounts, sound-deadening materials, and active noise cancellation systems are employed to mitigate unwanted vibrations and sound while preserving the characteristic V8 exhaust note.

As the automotive industry shifts towards electrification, the role of V8 engines is evolving. Engineers are tasked with making these powerplants more efficient and environmentally friendly while still delivering the performance and emotional appeal that enthusiasts demand. This balancing act between tradition and innovation continues to drive advancements in V8 technology, ensuring its relevance in an increasingly electrified automotive landscape.

One of the primary engineering challenges facing V8 engines is the ongoing push for improved fuel efficiency without sacrificing performance. This has led to the widespread adoption of technologies like direct fuel injection, variable valve timing, and cylinder deactivation. Direct injection allows for more precise fuel delivery, improving combustion efficiency and power output. Variable valve timing optimizes engine breathing across the rev range, enhancing both low-end torque and high-end power. Cylinder deactivation enables V8s to operate as more efficient four-cylinder engines under light load conditions.

Turbocharging and supercharging have become increasingly common in V8 applications, allowing manufacturers to extract more power from smaller displacement engines. This "downsizing" trend helps meet stringent emissions regulations while maintaining the performance characteristics expected from a V8. However, forced induction introduces additional complexity and thermal management challenges, requiring sophisticated intercooling systems and robust engine components.

Another significant challenge is the integration of hybrid and electrification technologies with V8 engines. Many high-performance vehicles now incorporate electric motors to supplement the V8's output, resulting in improved acceleration and efficiency. This hybridization adds layers of complexity to powertrain design, requiring seamless integration of mechanical and electrical systems.

Emissions control remains a critical focus for V8 engine development. Advanced catalytic converters, particulate filters, and exhaust gas recirculation systems are employed to meet increasingly strict global emissions standards. These systems often necessitate careful tuning to maintain performance while reducing harmful exhaust emissions.

Noise, vibration, and harshness (NVH) management presents another engineering challenge, particularly as consumers expect refined performance even from high-output engines. Sophisticated engine mounts, sound-deadening materials, and active noise cancellation systems are employed to mitigate unwanted vibrations and sound while preserving the characteristic V8 exhaust note.

As the automotive industry shifts towards electrification, the role of V8 engines is evolving. Engineers are tasked with making these powerplants more efficient and environmentally friendly while still delivering the performance and emotional appeal that enthusiasts demand. This balancing act between tradition and innovation continues to drive advancements in V8 technology, ensuring its relevance in an increasingly electrified automotive landscape.

Contemporary V8 Engine Design Solutions

01 Engine performance testing and measurement

V8 engine performance standards involve various testing and measurement methods to evaluate engine efficiency, power output, and overall performance. These methods may include dynamometer testing, fuel consumption analysis, and emissions measurements. Advanced sensors and data acquisition systems are often used to collect and analyze performance data.- Engine performance testing and measurement: V8 engine performance standards involve various testing and measurement methods to evaluate engine efficiency, power output, and overall performance. These methods may include dynamometer testing, fuel consumption analysis, and emissions measurements. Advanced sensors and data acquisition systems are often used to collect and analyze performance data.

- Combustion optimization and fuel efficiency: Improving combustion efficiency and fuel economy is a key aspect of V8 engine performance standards. This involves optimizing fuel injection systems, valve timing, and air-fuel mixture ratios. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation may be employed to enhance engine efficiency and reduce fuel consumption.

- Emissions control and environmental standards: V8 engine performance standards must comply with increasingly stringent emissions regulations. This involves the development and implementation of advanced exhaust aftertreatment systems, such as catalytic converters and particulate filters. Engine management systems are also optimized to reduce harmful emissions while maintaining performance.

- Engine durability and reliability testing: Ensuring the longevity and reliability of V8 engines is an important aspect of performance standards. This involves extensive durability testing, including long-term endurance runs, thermal cycling, and accelerated wear testing. Advanced materials and manufacturing techniques may be employed to improve engine durability and reduce wear.

- Engine control and management systems: Advanced engine control and management systems play a crucial role in meeting V8 engine performance standards. These systems utilize sophisticated algorithms and real-time data processing to optimize engine performance, fuel efficiency, and emissions control. Features such as adaptive learning, predictive control, and over-the-air updates may be incorporated to continuously improve engine performance.

02 Combustion optimization and fuel efficiency

Improving combustion efficiency and fuel economy is a key aspect of V8 engine performance standards. This involves optimizing fuel injection systems, valve timing, and air-fuel mixture ratios. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation may be employed to enhance engine performance while reducing fuel consumption.Expand Specific Solutions03 Emissions control and environmental standards

V8 engine performance standards must comply with increasingly stringent emissions regulations. This involves the development and implementation of advanced exhaust aftertreatment systems, such as catalytic converters and particulate filters. Engine management systems are also optimized to reduce harmful emissions while maintaining performance.Expand Specific Solutions04 Durability and reliability testing

Ensuring the longevity and reliability of V8 engines is an essential aspect of performance standards. This involves extensive durability testing, including long-term endurance runs, thermal cycling, and accelerated wear testing. Materials selection and component design are optimized to withstand the high stresses and temperatures associated with high-performance V8 engines.Expand Specific Solutions05 Advanced materials and manufacturing techniques

The use of advanced materials and manufacturing techniques plays a crucial role in meeting V8 engine performance standards. This may include the application of lightweight alloys, composite materials, and advanced coatings to reduce weight and improve thermal efficiency. Precision manufacturing techniques, such as 3D printing and advanced machining processes, are employed to produce complex engine components with tight tolerances.Expand Specific Solutions

Major Automotive Manufacturers in V8 Production

The V8 engine market is in a mature stage, with established players and ongoing innovation. The global market size for V8 engines is substantial, driven by demand in high-performance vehicles and luxury segments. Technologically, V8 engines are well-developed, but companies are focusing on improving efficiency and performance. Key players like GM Global Technology Operations, BMW, Toyota, and Ford Global Technologies are investing in R&D to enhance V8 engine capabilities. These companies are exploring advanced materials, fuel injection systems, and hybrid technologies to meet stringent emissions standards while maintaining power output. The competitive landscape is characterized by a mix of traditional automakers and specialized powertrain companies, each striving to differentiate through technological advancements and performance metrics.

GM Global Technology Operations LLC

Technical Solution: GM's V8 engine technology focuses on advanced combustion strategies and materials to redefine vehicle performance standards. Their latest V8 engines incorporate Dynamic Fuel Management (DFM) system, which can operate on as few as two cylinders to optimize efficiency[1]. The engines also feature direct injection and variable valve timing, improving both power output and fuel economy. GM has developed a new aluminum alloy for engine blocks that can withstand higher cylinder pressures, allowing for increased compression ratios and better thermal efficiency[2]. Additionally, GM's V8 engines utilize advanced friction-reducing technologies, such as low-tension piston rings and polymer-coated bearings, to minimize internal losses and enhance overall performance[3].

Strengths: Cutting-edge fuel management system, advanced materials for improved durability and efficiency, comprehensive approach to friction reduction. Weaknesses: Potential complexity in DFM system, higher production costs for advanced materials.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to V8 engine technology focuses on combining high performance with improved efficiency. Their latest V8 engines feature TwinPower Turbo technology, which uses two twin-scroll turbochargers for rapid response and high power output[1]. BMW has implemented a cross-bank exhaust manifold, improving thermal management and turbocharger efficiency[2]. The company also utilizes a high-precision direct injection system operating at pressures up to 350 bar, ensuring optimal fuel atomization and combustion[3]. BMW's Valvetronic fully variable valve control system and Double-VANOS variable camshaft timing work in tandem to optimize engine breathing and reduce pumping losses across the entire rev range[4]. Additionally, BMW has integrated a 48V mild-hybrid system in some V8 models, providing an electric boost to enhance performance and efficiency[5].

Strengths: Advanced turbocharging technology, high-precision fuel injection, comprehensive valve control systems, integration of mild-hybrid technology. Weaknesses: Complexity of multiple advanced systems may impact long-term reliability and maintenance costs.

Key Innovations in V8 Engine Technology

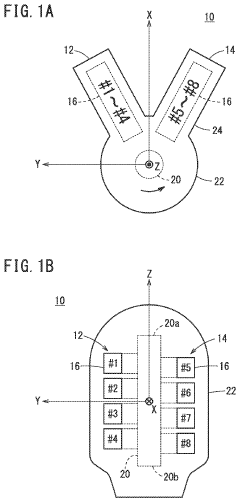

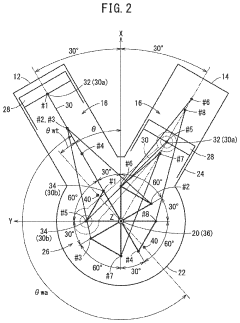

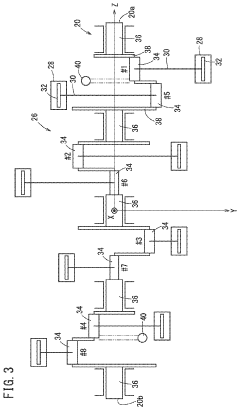

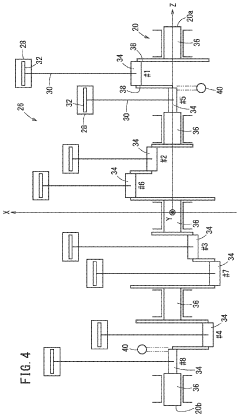

V8 engine

PatentWO2021171405A1

Innovation

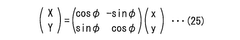

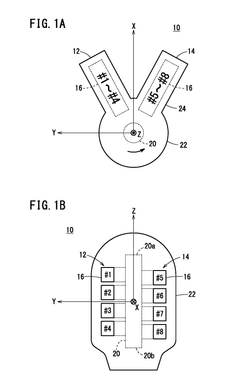

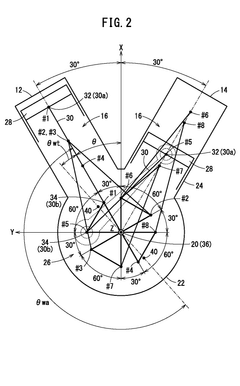

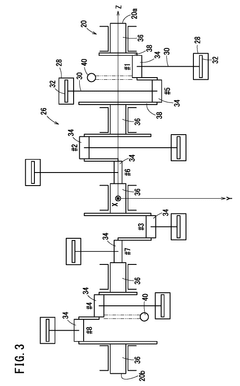

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Environmental Impact of V8 Engines

The environmental impact of V8 engines has been a subject of increasing concern in recent years, as the automotive industry grapples with the need to balance performance with sustainability. V8 engines, known for their power and distinctive sound, have long been associated with high-performance vehicles and luxury cars. However, their significant fuel consumption and emissions output have placed them under scrutiny in an era of heightened environmental awareness.

One of the primary environmental concerns surrounding V8 engines is their relatively high fuel consumption. These engines typically require more fuel to operate compared to smaller, more efficient engine configurations. This increased fuel usage directly translates to higher carbon dioxide (CO2) emissions, a major contributor to global warming and climate change. The carbon footprint of vehicles equipped with V8 engines is often substantially larger than that of cars with smaller engines or alternative powertrains.

Emissions from V8 engines extend beyond CO2. These powerplants also produce higher levels of nitrogen oxides (NOx) and particulate matter, which contribute to air pollution and can have detrimental effects on human health and the environment. In urban areas, where air quality is already a concern, the concentration of vehicles with V8 engines can exacerbate existing pollution problems.

The manufacturing process of V8 engines also carries environmental implications. These larger, more complex engines require more raw materials and energy to produce compared to smaller engines. The extraction and processing of these materials, along with the energy-intensive manufacturing processes, contribute to the overall environmental impact of V8-powered vehicles before they even hit the road.

However, it's important to note that advancements in engine technology have led to significant improvements in the efficiency and emissions of V8 engines. Modern V8s often incorporate technologies such as direct injection, variable valve timing, and cylinder deactivation, which can help reduce fuel consumption and emissions under certain driving conditions. Some manufacturers have also introduced hybrid V8 powertrains, combining the power of a V8 with electric motors to improve efficiency and reduce environmental impact.

Despite these improvements, the overall trend in the automotive industry is moving towards downsizing and electrification. Many manufacturers are phasing out V8 engines in favor of smaller, turbocharged engines or fully electric powertrains. This shift is driven by increasingly stringent emissions regulations and a growing consumer demand for more environmentally friendly vehicles.

In conclusion, while V8 engines continue to offer unparalleled performance characteristics, their environmental impact remains a significant concern. The automotive industry faces the challenge of balancing the desire for high-performance vehicles with the urgent need to reduce the environmental footprint of transportation. As technology advances and regulations tighten, the future of V8 engines will likely involve further innovations in efficiency and emissions reduction, or a gradual transition towards alternative powertrain technologies.

One of the primary environmental concerns surrounding V8 engines is their relatively high fuel consumption. These engines typically require more fuel to operate compared to smaller, more efficient engine configurations. This increased fuel usage directly translates to higher carbon dioxide (CO2) emissions, a major contributor to global warming and climate change. The carbon footprint of vehicles equipped with V8 engines is often substantially larger than that of cars with smaller engines or alternative powertrains.

Emissions from V8 engines extend beyond CO2. These powerplants also produce higher levels of nitrogen oxides (NOx) and particulate matter, which contribute to air pollution and can have detrimental effects on human health and the environment. In urban areas, where air quality is already a concern, the concentration of vehicles with V8 engines can exacerbate existing pollution problems.

The manufacturing process of V8 engines also carries environmental implications. These larger, more complex engines require more raw materials and energy to produce compared to smaller engines. The extraction and processing of these materials, along with the energy-intensive manufacturing processes, contribute to the overall environmental impact of V8-powered vehicles before they even hit the road.

However, it's important to note that advancements in engine technology have led to significant improvements in the efficiency and emissions of V8 engines. Modern V8s often incorporate technologies such as direct injection, variable valve timing, and cylinder deactivation, which can help reduce fuel consumption and emissions under certain driving conditions. Some manufacturers have also introduced hybrid V8 powertrains, combining the power of a V8 with electric motors to improve efficiency and reduce environmental impact.

Despite these improvements, the overall trend in the automotive industry is moving towards downsizing and electrification. Many manufacturers are phasing out V8 engines in favor of smaller, turbocharged engines or fully electric powertrains. This shift is driven by increasingly stringent emissions regulations and a growing consumer demand for more environmentally friendly vehicles.

In conclusion, while V8 engines continue to offer unparalleled performance characteristics, their environmental impact remains a significant concern. The automotive industry faces the challenge of balancing the desire for high-performance vehicles with the urgent need to reduce the environmental footprint of transportation. As technology advances and regulations tighten, the future of V8 engines will likely involve further innovations in efficiency and emissions reduction, or a gradual transition towards alternative powertrain technologies.

V8 Engine Efficiency Optimization Strategies

V8 engine efficiency optimization strategies have become increasingly crucial in redefining vehicle performance standards. As automotive manufacturers strive to meet stringent emissions regulations while maintaining high performance, several key approaches have emerged to enhance V8 engine efficiency.

One primary strategy involves advanced fuel injection systems. Direct fuel injection technology has been widely adopted, allowing for precise control over fuel delivery and combustion timing. This results in improved fuel atomization and more complete combustion, leading to increased power output and reduced fuel consumption. Some manufacturers have further refined this technology by implementing dual injection systems, combining direct and port fuel injection to optimize performance across various operating conditions.

Cylinder deactivation technology has also gained prominence in V8 engine optimization. This system selectively deactivates a portion of the cylinders during low-load conditions, effectively reducing fuel consumption without compromising overall performance. When full power is required, all cylinders are reactivated seamlessly. This dynamic approach to engine management significantly improves fuel efficiency, particularly in highway driving scenarios.

Variable valve timing and lift systems have been extensively developed to optimize engine breathing across different RPM ranges. These systems adjust valve timing and lift profiles in real-time, enhancing both low-end torque and high-end power. Some advanced V8 engines now feature camless valve actuation, using electromagnetic or hydraulic actuators to provide infinite variability in valve control, further improving efficiency and performance.

Turbocharging and supercharging technologies have been refined to address the inherent inefficiencies of naturally aspirated V8 engines. Modern forced induction systems, often featuring twin-scroll turbochargers or electric superchargers, provide significant power boosts while allowing for engine downsizing. This approach maintains or even increases performance metrics while reducing overall engine displacement and fuel consumption.

Thermal management has become a critical focus in V8 engine optimization. Advanced cooling systems, including split cooling circuits and precision coolant flow control, help maintain optimal operating temperatures across various engine components. Additionally, exhaust heat recovery systems are being implemented to capture and utilize waste heat, improving overall thermal efficiency.

Materials science advancements have led to the development of lighter, stronger engine components. The use of high-strength alloys, composite materials, and advanced manufacturing techniques has resulted in reduced engine weight and improved durability. These innovations contribute to better power-to-weight ratios and enhanced fuel efficiency.

Lastly, the integration of hybrid technologies with V8 engines has opened new avenues for efficiency optimization. Mild hybrid systems, featuring integrated starter-generators, provide torque assistance and enable extended start-stop functionality. More advanced hybrid configurations, including plug-in systems, allow for electric-only operation in certain conditions, significantly reducing overall fuel consumption while maintaining the performance characteristics of V8 engines.

One primary strategy involves advanced fuel injection systems. Direct fuel injection technology has been widely adopted, allowing for precise control over fuel delivery and combustion timing. This results in improved fuel atomization and more complete combustion, leading to increased power output and reduced fuel consumption. Some manufacturers have further refined this technology by implementing dual injection systems, combining direct and port fuel injection to optimize performance across various operating conditions.

Cylinder deactivation technology has also gained prominence in V8 engine optimization. This system selectively deactivates a portion of the cylinders during low-load conditions, effectively reducing fuel consumption without compromising overall performance. When full power is required, all cylinders are reactivated seamlessly. This dynamic approach to engine management significantly improves fuel efficiency, particularly in highway driving scenarios.

Variable valve timing and lift systems have been extensively developed to optimize engine breathing across different RPM ranges. These systems adjust valve timing and lift profiles in real-time, enhancing both low-end torque and high-end power. Some advanced V8 engines now feature camless valve actuation, using electromagnetic or hydraulic actuators to provide infinite variability in valve control, further improving efficiency and performance.

Turbocharging and supercharging technologies have been refined to address the inherent inefficiencies of naturally aspirated V8 engines. Modern forced induction systems, often featuring twin-scroll turbochargers or electric superchargers, provide significant power boosts while allowing for engine downsizing. This approach maintains or even increases performance metrics while reducing overall engine displacement and fuel consumption.

Thermal management has become a critical focus in V8 engine optimization. Advanced cooling systems, including split cooling circuits and precision coolant flow control, help maintain optimal operating temperatures across various engine components. Additionally, exhaust heat recovery systems are being implemented to capture and utilize waste heat, improving overall thermal efficiency.

Materials science advancements have led to the development of lighter, stronger engine components. The use of high-strength alloys, composite materials, and advanced manufacturing techniques has resulted in reduced engine weight and improved durability. These innovations contribute to better power-to-weight ratios and enhanced fuel efficiency.

Lastly, the integration of hybrid technologies with V8 engines has opened new avenues for efficiency optimization. Mild hybrid systems, featuring integrated starter-generators, provide torque assistance and enable extended start-stop functionality. More advanced hybrid configurations, including plug-in systems, allow for electric-only operation in certain conditions, significantly reducing overall fuel consumption while maintaining the performance characteristics of V8 engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!