Racing Cars and V8 Engines: A Legacy of Speed

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception, marking key milestones in automotive engineering and racing history. The journey began in the early 20th century when the first V8 engines were developed for aircraft and luxury automobiles. These early designs laid the foundation for what would become a symbol of power and performance in the automotive world.

In the 1930s and 1940s, V8 engines gained popularity in American cars, with manufacturers like Ford and Chevrolet introducing iconic models. The Ford Flathead V8, introduced in 1932, revolutionized the industry by making V8 power accessible to the mass market. This period saw advancements in manufacturing techniques and materials, allowing for more reliable and powerful engines.

The 1950s and 1960s marked the golden age of V8 engines in racing and high-performance street cars. Innovations such as overhead valve designs, higher compression ratios, and multiple carburetors significantly increased power output. Notable developments included Chevrolet's small-block V8 in 1955 and Ford's 427 cubic inch V8, which dominated NASCAR races.

The 1970s brought challenges with fuel crises and emissions regulations, forcing manufacturers to focus on efficiency. This led to the development of electronic fuel injection systems and computer-controlled engine management, which improved fuel economy without sacrificing performance. Despite these challenges, V8 engines remained a staple in muscle cars and luxury vehicles.

The 1980s and 1990s saw a resurgence of V8 power, with advancements in materials science and computer-aided design. Aluminum block engines became more common, reducing weight while maintaining strength. Variable valve timing and multi-valve cylinder heads further enhanced efficiency and power output.

In the 21st century, V8 engines have continued to evolve, incorporating technologies like direct fuel injection, turbocharging, and cylinder deactivation. These innovations have allowed V8 engines to meet stringent emissions standards while still delivering impressive performance. High-output V8 engines in modern supercars and racing vehicles now routinely produce over 600 horsepower, showcasing the ongoing potential of this engine configuration.

The latest trend in V8 evolution is the integration of hybrid and electric technologies. Performance hybrid systems that combine V8 engines with electric motors are pushing the boundaries of power and efficiency, demonstrating that the V8 engine continues to adapt and remain relevant in an increasingly electrified automotive landscape.

In the 1930s and 1940s, V8 engines gained popularity in American cars, with manufacturers like Ford and Chevrolet introducing iconic models. The Ford Flathead V8, introduced in 1932, revolutionized the industry by making V8 power accessible to the mass market. This period saw advancements in manufacturing techniques and materials, allowing for more reliable and powerful engines.

The 1950s and 1960s marked the golden age of V8 engines in racing and high-performance street cars. Innovations such as overhead valve designs, higher compression ratios, and multiple carburetors significantly increased power output. Notable developments included Chevrolet's small-block V8 in 1955 and Ford's 427 cubic inch V8, which dominated NASCAR races.

The 1970s brought challenges with fuel crises and emissions regulations, forcing manufacturers to focus on efficiency. This led to the development of electronic fuel injection systems and computer-controlled engine management, which improved fuel economy without sacrificing performance. Despite these challenges, V8 engines remained a staple in muscle cars and luxury vehicles.

The 1980s and 1990s saw a resurgence of V8 power, with advancements in materials science and computer-aided design. Aluminum block engines became more common, reducing weight while maintaining strength. Variable valve timing and multi-valve cylinder heads further enhanced efficiency and power output.

In the 21st century, V8 engines have continued to evolve, incorporating technologies like direct fuel injection, turbocharging, and cylinder deactivation. These innovations have allowed V8 engines to meet stringent emissions standards while still delivering impressive performance. High-output V8 engines in modern supercars and racing vehicles now routinely produce over 600 horsepower, showcasing the ongoing potential of this engine configuration.

The latest trend in V8 evolution is the integration of hybrid and electric technologies. Performance hybrid systems that combine V8 engines with electric motors are pushing the boundaries of power and efficiency, demonstrating that the V8 engine continues to adapt and remain relevant in an increasingly electrified automotive landscape.

Racing Car Market Trends

The racing car market has experienced significant shifts in recent years, driven by technological advancements, changing consumer preferences, and evolving regulatory landscapes. The global market for high-performance vehicles, including racing cars, continues to grow steadily. This growth is fueled by increasing disposable incomes in emerging markets, a rising interest in motorsports, and the development of more accessible racing experiences for enthusiasts.

One notable trend is the increasing focus on sustainability and environmental consciousness within the racing industry. Many racing series, including Formula 1, have introduced hybrid powertrains and are exploring alternative fuel options. This shift is influencing the broader market, with manufacturers developing more efficient and environmentally friendly high-performance engines for both racing and road-going vehicles.

The integration of advanced technologies is another key trend shaping the racing car market. The use of lightweight materials, such as carbon fiber composites, is becoming more widespread, improving performance and fuel efficiency. Additionally, the incorporation of sophisticated aerodynamics, advanced suspension systems, and cutting-edge electronics is enhancing the overall performance and safety of racing cars.

The rise of electric and hybrid racing series, such as Formula E and Extreme E, is creating new market segments and driving innovation in electric vehicle technology. This trend is expected to have a significant impact on the traditional racing car market, potentially leading to a gradual shift away from conventional internal combustion engines in certain racing categories.

Customization and personalization have become increasingly important in the racing car market. Manufacturers are offering more bespoke options and limited-edition models to cater to discerning enthusiasts and collectors. This trend is particularly evident in the high-end supercar and hypercar segments, where exclusivity and unique features command premium prices.

The growing popularity of sim racing and esports is also influencing the racing car market. Virtual racing platforms are providing new avenues for fan engagement and brand exposure, while also serving as testing grounds for real-world racing technologies and strategies. This convergence of digital and physical racing experiences is creating new opportunities for manufacturers and racing teams to connect with younger audiences and develop innovative marketing strategies.

In terms of regional trends, emerging markets in Asia and the Middle East are showing strong growth potential for racing cars and high-performance vehicles. These regions are investing heavily in motorsports infrastructure and events, driving demand for both professional racing cars and road-legal performance vehicles.

One notable trend is the increasing focus on sustainability and environmental consciousness within the racing industry. Many racing series, including Formula 1, have introduced hybrid powertrains and are exploring alternative fuel options. This shift is influencing the broader market, with manufacturers developing more efficient and environmentally friendly high-performance engines for both racing and road-going vehicles.

The integration of advanced technologies is another key trend shaping the racing car market. The use of lightweight materials, such as carbon fiber composites, is becoming more widespread, improving performance and fuel efficiency. Additionally, the incorporation of sophisticated aerodynamics, advanced suspension systems, and cutting-edge electronics is enhancing the overall performance and safety of racing cars.

The rise of electric and hybrid racing series, such as Formula E and Extreme E, is creating new market segments and driving innovation in electric vehicle technology. This trend is expected to have a significant impact on the traditional racing car market, potentially leading to a gradual shift away from conventional internal combustion engines in certain racing categories.

Customization and personalization have become increasingly important in the racing car market. Manufacturers are offering more bespoke options and limited-edition models to cater to discerning enthusiasts and collectors. This trend is particularly evident in the high-end supercar and hypercar segments, where exclusivity and unique features command premium prices.

The growing popularity of sim racing and esports is also influencing the racing car market. Virtual racing platforms are providing new avenues for fan engagement and brand exposure, while also serving as testing grounds for real-world racing technologies and strategies. This convergence of digital and physical racing experiences is creating new opportunities for manufacturers and racing teams to connect with younger audiences and develop innovative marketing strategies.

In terms of regional trends, emerging markets in Asia and the Middle East are showing strong growth potential for racing cars and high-performance vehicles. These regions are investing heavily in motorsports infrastructure and events, driving demand for both professional racing cars and road-legal performance vehicles.

V8 Tech Challenges

V8 engines have long been synonymous with high-performance racing cars, but they face several technical challenges in the modern era of motorsports. One of the primary issues is the balance between power output and fuel efficiency. As racing regulations increasingly focus on sustainability, V8 engines must adapt to produce maximum power while consuming less fuel. This has led to the development of more sophisticated fuel injection systems and the integration of hybrid technologies in some racing categories.

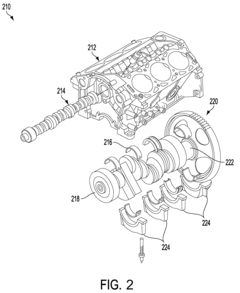

Another significant challenge is weight reduction. V8 engines are traditionally heavier than their smaller counterparts, which can negatively impact a race car's overall performance. Engineers are constantly seeking ways to reduce engine weight without compromising structural integrity or power output. This has resulted in the use of lighter materials such as aluminum and carbon fiber composites in engine construction.

Heat management is a critical concern for V8 engines in racing applications. The high-performance nature of these engines generates substantial heat, which can lead to decreased efficiency and potential mechanical failures. Advanced cooling systems and thermal management techniques are essential to maintain optimal engine performance throughout a race.

Durability and reliability remain ongoing challenges for V8 racing engines. The extreme conditions of motorsports, including high RPMs and prolonged periods of maximum output, put immense stress on engine components. Manufacturers must continually innovate to develop materials and designs that can withstand these demanding conditions while maintaining consistent performance.

The complexity of modern V8 engines also presents challenges in terms of maintenance and serviceability. As these engines become more sophisticated, with the integration of electronic control systems and advanced materials, the expertise required for maintenance and repairs increases. This can lead to higher operational costs for racing teams and potentially longer downtimes for repairs.

Emissions regulations pose a significant challenge for V8 engines in racing. While motorsports often operate under different rules than road vehicles, there is increasing pressure to reduce the environmental impact of racing. This has led to the exploration of alternative fuels and the development of more efficient combustion processes to minimize harmful emissions without sacrificing performance.

Lastly, the rise of electric and hybrid technologies in motorsports presents an existential challenge to traditional V8 engines. As racing series begin to embrace electrification, the role of V8 engines in future racing categories is uncertain. This has spurred research into hybrid V8 powertrains and the potential for synthetic fuels to extend the viability of these iconic engines in the evolving landscape of motorsports.

Another significant challenge is weight reduction. V8 engines are traditionally heavier than their smaller counterparts, which can negatively impact a race car's overall performance. Engineers are constantly seeking ways to reduce engine weight without compromising structural integrity or power output. This has resulted in the use of lighter materials such as aluminum and carbon fiber composites in engine construction.

Heat management is a critical concern for V8 engines in racing applications. The high-performance nature of these engines generates substantial heat, which can lead to decreased efficiency and potential mechanical failures. Advanced cooling systems and thermal management techniques are essential to maintain optimal engine performance throughout a race.

Durability and reliability remain ongoing challenges for V8 racing engines. The extreme conditions of motorsports, including high RPMs and prolonged periods of maximum output, put immense stress on engine components. Manufacturers must continually innovate to develop materials and designs that can withstand these demanding conditions while maintaining consistent performance.

The complexity of modern V8 engines also presents challenges in terms of maintenance and serviceability. As these engines become more sophisticated, with the integration of electronic control systems and advanced materials, the expertise required for maintenance and repairs increases. This can lead to higher operational costs for racing teams and potentially longer downtimes for repairs.

Emissions regulations pose a significant challenge for V8 engines in racing. While motorsports often operate under different rules than road vehicles, there is increasing pressure to reduce the environmental impact of racing. This has led to the exploration of alternative fuels and the development of more efficient combustion processes to minimize harmful emissions without sacrificing performance.

Lastly, the rise of electric and hybrid technologies in motorsports presents an existential challenge to traditional V8 engines. As racing series begin to embrace electrification, the role of V8 engines in future racing categories is uncertain. This has spurred research into hybrid V8 powertrains and the potential for synthetic fuels to extend the viability of these iconic engines in the evolving landscape of motorsports.

Current V8 Solutions

01 V8 Engine Design Optimization

Improvements in V8 engine design focus on enhancing speed and performance. This includes optimizing cylinder configurations, valve timing, and combustion efficiency. Advanced materials and manufacturing techniques are employed to reduce weight and increase durability, allowing for higher operating speeds.- V8 Engine Design Optimization: Improvements in V8 engine design focus on optimizing performance and speed. This includes modifications to the cylinder arrangement, valve timing, and combustion chamber design to enhance power output and efficiency. Advanced materials and manufacturing techniques are employed to reduce weight and improve overall engine performance.

- Turbocharging and Supercharging Systems: Implementation of forced induction systems such as turbochargers and superchargers in V8 engines significantly increases power output and speed. These systems compress the incoming air, allowing for more fuel to be burned and resulting in higher engine performance. Various designs and configurations are explored to maximize efficiency and reduce turbo lag.

- Electronic Engine Management: Advanced electronic control systems are utilized to optimize V8 engine performance and speed. These systems manage fuel injection, ignition timing, and valve control with precision, allowing for real-time adjustments based on driving conditions. Integration of sensors and sophisticated algorithms enables improved power delivery and fuel efficiency.

- Lightweight Materials and Construction: Utilization of lightweight materials such as aluminum alloys and carbon fiber composites in V8 engine construction reduces overall weight, leading to improved power-to-weight ratios and increased speed potential. Advanced manufacturing techniques are employed to maintain structural integrity while minimizing mass.

- Variable Valve Timing and Lift: Implementation of variable valve timing and lift systems in V8 engines allows for optimized air intake and exhaust across different engine speeds. This technology enables better performance at both low and high RPMs, improving overall engine efficiency and speed capabilities. Various mechanical and hydraulic systems are developed to achieve precise valve control.

02 Turbocharging and Supercharging Systems

Forced induction systems, such as turbochargers and superchargers, are utilized to increase the power output and speed capabilities of V8 engines. These systems compress the intake air, allowing for more fuel to be burned and resulting in higher engine speeds and overall performance.Expand Specific Solutions03 Electronic Engine Management

Advanced electronic control units (ECUs) and engine management systems are implemented to optimize V8 engine performance. These systems precisely control fuel injection, ignition timing, and other parameters to maximize speed and efficiency across various operating conditions.Expand Specific Solutions04 Lightweight Components and Materials

The use of lightweight materials such as aluminum alloys, carbon fiber, and advanced composites in V8 engine components reduces overall engine weight. This weight reduction allows for higher engine speeds and improved power-to-weight ratios, enhancing overall vehicle performance.Expand Specific Solutions05 Variable Valve Timing and Lift

Implementation of variable valve timing and lift systems in V8 engines allows for optimized airflow at different engine speeds. These systems adjust valve operation based on engine load and speed, improving performance across a wide range of operating conditions and enabling higher maximum speeds.Expand Specific Solutions

Key Racing Car Makers

The racing car and V8 engine market is in a mature stage, characterized by established players and steady growth. The global market size for high-performance vehicles and engines is substantial, driven by motorsports, luxury car segments, and enthusiast demand. Technologically, V8 engines have reached a high level of sophistication, with companies like GM Global Technology Operations, Ford Global Technologies, and Automobili Lamborghini leading innovation. However, the industry faces challenges from electrification trends, with traditional manufacturers like Toyota, Hyundai, and BYD investing heavily in alternative powertrains. This shift is prompting legacy V8 producers to focus on efficiency improvements and hybrid integration to maintain relevance in a changing automotive landscape.

GM Global Technology Operations LLC

Technical Solution: GM has been at the forefront of V8 engine development for racing cars, particularly with their Chevrolet brand. Their latest V8 engine technology focuses on improving power-to-weight ratio and fuel efficiency while maintaining the iconic V8 sound and performance. GM has implemented advanced direct fuel injection systems and variable valve timing to optimize combustion efficiency[1]. They've also integrated lightweight materials such as aluminum alloys and carbon fiber components to reduce overall engine weight without compromising strength[2]. GM's racing V8 engines now feature sophisticated engine management systems that allow for real-time adjustments to fuel mixture and ignition timing, maximizing performance across various racing conditions[3].

Strengths: Long history of V8 development, strong brand recognition in racing, advanced fuel injection and valve timing technologies. Weaknesses: Increasing pressure to move away from large displacement engines due to environmental concerns, high development costs for racing-specific engines.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V8 engines in racing cars has evolved with a focus on both performance and sustainability. Their latest V8 technology incorporates EcoBoost principles, using turbocharging and direct injection to extract maximum power from smaller displacement engines[1]. Ford has also been experimenting with hybrid assist systems in their racing V8s, allowing for energy recovery during braking and deployment during acceleration[2]. The company has made significant strides in thermal management, using advanced cooling systems and heat-resistant materials to maintain optimal engine performance under extreme racing conditions[3]. Ford's racing V8s now feature variable geometry turbochargers and advanced aerodynamic designs to reduce pumping losses and improve overall efficiency.

Strengths: Innovative hybrid technologies, successful integration of EcoBoost principles in racing engines, strong presence in multiple racing series. Weaknesses: Balancing traditional V8 characteristics with new technologies may alienate some purists, high costs associated with hybrid system development.

V8 Innovations Analysis

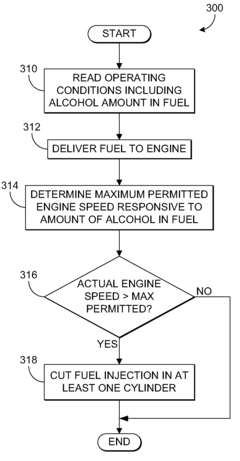

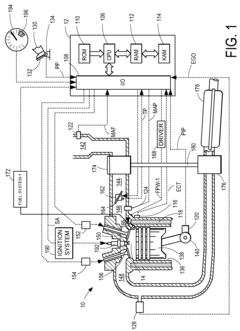

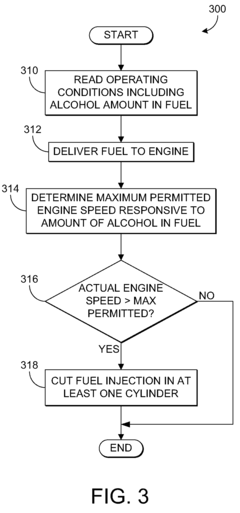

Engine control responsive to varying amounts of alcohol in fuel

PatentInactiveUS7826957B2

Innovation

- Implementing a control system that limits engine speed based on the alcohol content in the fuel, using either an absolute or soft speed limit, and adjusting the shift schedule to prevent engine degradation, while maintaining common bearing designs and fuel economy.

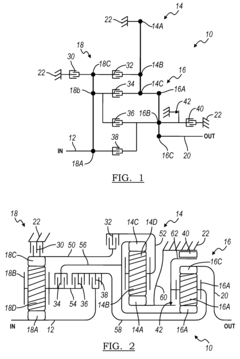

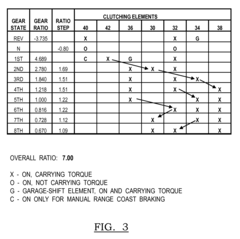

Efficient eight speed automatic transmission

PatentInactiveUS7871351B2

Innovation

- An eight speed automatic transmission design incorporating three planetary gear sets, four friction clutches, a friction brake, a band brake, and an optional freewheeling or overrunning clutch, which enhances gear mesh efficiency and reduces pinion speeds, improving the quality of first gear to second gear shifts.

Environmental Regulations

Environmental regulations have become increasingly stringent in recent years, posing significant challenges to the racing car industry and V8 engine manufacturers. These regulations aim to reduce carbon emissions, improve fuel efficiency, and promote sustainable practices in motorsports.

One of the primary focuses of environmental regulations is the reduction of greenhouse gas emissions. Racing organizations and governing bodies have implemented strict limits on carbon dioxide emissions from vehicles participating in competitions. This has led to the development of more fuel-efficient engines and the exploration of alternative fuel sources, such as biofuels and synthetic fuels.

The push for improved fuel efficiency has also resulted in the introduction of energy recovery systems in racing cars. These systems capture and store energy that would otherwise be wasted during braking or deceleration, allowing it to be reused for additional power. This technology has not only improved the overall efficiency of racing cars but has also found applications in road-going vehicles.

Noise pollution regulations have also impacted the racing industry, particularly affecting V8 engines known for their distinctive sound. Many racing series now enforce strict noise limits, requiring manufacturers to develop innovative exhaust systems and engine designs to meet these requirements while maintaining performance.

The shift towards electrification in the automotive industry has begun to influence motorsports as well. Formula E, an all-electric racing series, has gained popularity and serves as a testbed for electric vehicle technology. This trend has prompted traditional racing series to consider hybrid powertrains and even fully electric vehicles in the future.

Manufacturers are investing heavily in research and development to meet these environmental challenges while maintaining the high-performance standards expected in motorsports. Advanced materials, aerodynamics, and powertrain technologies are being explored to reduce weight, improve efficiency, and minimize environmental impact.

The impact of environmental regulations extends beyond the racetrack, influencing the development of road cars and driving innovation in the broader automotive industry. Technologies developed for racing, such as lightweight materials and efficient engines, often find their way into consumer vehicles, contributing to overall improvements in fuel economy and emissions reduction.

As environmental concerns continue to grow, the racing industry faces the challenge of balancing its legacy of speed and performance with the need for sustainability. This has led to a new era of innovation, where engineers and designers are tasked with creating high-performance vehicles that meet increasingly stringent environmental standards while still delivering the excitement and spectacle that fans expect from motorsports.

One of the primary focuses of environmental regulations is the reduction of greenhouse gas emissions. Racing organizations and governing bodies have implemented strict limits on carbon dioxide emissions from vehicles participating in competitions. This has led to the development of more fuel-efficient engines and the exploration of alternative fuel sources, such as biofuels and synthetic fuels.

The push for improved fuel efficiency has also resulted in the introduction of energy recovery systems in racing cars. These systems capture and store energy that would otherwise be wasted during braking or deceleration, allowing it to be reused for additional power. This technology has not only improved the overall efficiency of racing cars but has also found applications in road-going vehicles.

Noise pollution regulations have also impacted the racing industry, particularly affecting V8 engines known for their distinctive sound. Many racing series now enforce strict noise limits, requiring manufacturers to develop innovative exhaust systems and engine designs to meet these requirements while maintaining performance.

The shift towards electrification in the automotive industry has begun to influence motorsports as well. Formula E, an all-electric racing series, has gained popularity and serves as a testbed for electric vehicle technology. This trend has prompted traditional racing series to consider hybrid powertrains and even fully electric vehicles in the future.

Manufacturers are investing heavily in research and development to meet these environmental challenges while maintaining the high-performance standards expected in motorsports. Advanced materials, aerodynamics, and powertrain technologies are being explored to reduce weight, improve efficiency, and minimize environmental impact.

The impact of environmental regulations extends beyond the racetrack, influencing the development of road cars and driving innovation in the broader automotive industry. Technologies developed for racing, such as lightweight materials and efficient engines, often find their way into consumer vehicles, contributing to overall improvements in fuel economy and emissions reduction.

As environmental concerns continue to grow, the racing industry faces the challenge of balancing its legacy of speed and performance with the need for sustainability. This has led to a new era of innovation, where engineers and designers are tasked with creating high-performance vehicles that meet increasingly stringent environmental standards while still delivering the excitement and spectacle that fans expect from motorsports.

Performance Optimization

Performance optimization in racing cars, particularly those equipped with V8 engines, has been a continuous pursuit in the automotive industry. The quest for speed and efficiency has led to numerous advancements in engine design, aerodynamics, and overall vehicle performance.

One of the primary areas of focus in performance optimization is engine tuning. V8 engines, known for their power and distinctive sound, have undergone significant improvements over the years. Engineers have worked tirelessly to enhance combustion efficiency, reduce friction, and optimize fuel delivery systems. Advanced technologies such as direct fuel injection, variable valve timing, and turbocharging have been implemented to extract maximum power from these engines while maintaining fuel efficiency.

Aerodynamics plays a crucial role in racing car performance. Extensive wind tunnel testing and computational fluid dynamics simulations have led to the development of sophisticated body designs that minimize drag and maximize downforce. Features such as front splitters, rear diffusers, and carefully sculpted bodywork contribute to improved handling and stability at high speeds.

Weight reduction is another key aspect of performance optimization. The use of lightweight materials such as carbon fiber, titanium, and advanced alloys has become prevalent in racing car construction. Every component, from the chassis to the smallest bolt, is scrutinized for potential weight savings without compromising structural integrity.

Suspension systems have also seen significant advancements. Adaptive damping, active ride height control, and sophisticated electronic stability control systems have been developed to enhance cornering ability and overall vehicle dynamics. These technologies allow for real-time adjustments to suit varying track conditions and driving styles.

Tire technology has evolved in tandem with other performance enhancements. Specialized compounds and tread designs have been developed to provide optimal grip and heat dissipation, crucial factors in maintaining performance throughout a race.

The integration of advanced electronics and telemetry systems has revolutionized performance optimization. Real-time data analysis allows engineers to fine-tune various aspects of the car's performance during races, making split-second adjustments to maximize efficiency and speed.

In recent years, hybrid technologies have begun to make their way into racing, even in traditionally V8-dominated categories. These systems not only contribute to improved fuel efficiency but also provide additional power boosts, further pushing the boundaries of performance.

As regulations in motorsports continue to evolve, often with a focus on sustainability and safety, the challenge of performance optimization becomes increasingly complex. Engineers must now balance raw power and speed with energy efficiency and emissions reduction, leading to innovative solutions that often find their way into road-going vehicles.

One of the primary areas of focus in performance optimization is engine tuning. V8 engines, known for their power and distinctive sound, have undergone significant improvements over the years. Engineers have worked tirelessly to enhance combustion efficiency, reduce friction, and optimize fuel delivery systems. Advanced technologies such as direct fuel injection, variable valve timing, and turbocharging have been implemented to extract maximum power from these engines while maintaining fuel efficiency.

Aerodynamics plays a crucial role in racing car performance. Extensive wind tunnel testing and computational fluid dynamics simulations have led to the development of sophisticated body designs that minimize drag and maximize downforce. Features such as front splitters, rear diffusers, and carefully sculpted bodywork contribute to improved handling and stability at high speeds.

Weight reduction is another key aspect of performance optimization. The use of lightweight materials such as carbon fiber, titanium, and advanced alloys has become prevalent in racing car construction. Every component, from the chassis to the smallest bolt, is scrutinized for potential weight savings without compromising structural integrity.

Suspension systems have also seen significant advancements. Adaptive damping, active ride height control, and sophisticated electronic stability control systems have been developed to enhance cornering ability and overall vehicle dynamics. These technologies allow for real-time adjustments to suit varying track conditions and driving styles.

Tire technology has evolved in tandem with other performance enhancements. Specialized compounds and tread designs have been developed to provide optimal grip and heat dissipation, crucial factors in maintaining performance throughout a race.

The integration of advanced electronics and telemetry systems has revolutionized performance optimization. Real-time data analysis allows engineers to fine-tune various aspects of the car's performance during races, making split-second adjustments to maximize efficiency and speed.

In recent years, hybrid technologies have begun to make their way into racing, even in traditionally V8-dominated categories. These systems not only contribute to improved fuel efficiency but also provide additional power boosts, further pushing the boundaries of performance.

As regulations in motorsports continue to evolve, often with a focus on sustainability and safety, the challenge of performance optimization becomes increasingly complex. Engineers must now balance raw power and speed with energy efficiency and emissions reduction, leading to innovative solutions that often find their way into road-going vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!