V8 Engine Construction: Key Milestones Explored

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine, a revolutionary design in automotive engineering, has undergone significant evolution since its inception. This timeline-based analysis explores the key milestones in V8 engine development, showcasing the major technological advancements and solutions that have shaped its progression.

The origins of the V8 engine can be traced back to the early 20th century, with the first production V8 introduced by Cadillac in 1914. This pioneering design set the stage for future developments, featuring a 90-degree V-angle and a flat-plane crankshaft. The 1920s and 1930s saw further refinements, with Ford's introduction of the flathead V8 in 1932 marking a significant milestone in mass-production techniques.

Post-World War II, the 1950s ushered in an era of high-performance V8 engines. Chevrolet's small-block V8, introduced in 1955, became an industry standard for its compact design and versatility. This period also saw advancements in overhead valve (OHV) technology, improving engine efficiency and power output.

The 1960s and 1970s were characterized by the muscle car era, pushing V8 engines to new limits of power and performance. Key developments included the introduction of high-compression ratios, improved fuel delivery systems, and more robust internal components. However, the oil crisis of the 1970s led to a shift towards fuel efficiency, prompting innovations in engine management and emissions control.

The 1980s and 1990s marked a transition towards more sophisticated V8 designs. Electronic fuel injection systems replaced carburetors, offering better fuel economy and emissions control. Variable valve timing (VVT) technology was introduced, allowing for optimized engine performance across different operating conditions.

The turn of the millennium brought about significant advancements in V8 engine technology. Direct fuel injection systems became prevalent, offering improved fuel efficiency and power output. Cylinder deactivation technology was refined, allowing V8 engines to operate on fewer cylinders under light load conditions, further enhancing fuel economy.

Recent years have seen a focus on combining performance with sustainability. Turbocharging and supercharging have become more common in V8 engines, allowing for smaller displacement engines to produce higher power outputs. Additionally, hybrid V8 systems have emerged, integrating electric motors to boost performance while reducing emissions.

Looking ahead, the V8 engine continues to evolve, with ongoing research into advanced materials, improved thermal management, and integration with electric powertrains. These developments aim to preserve the V8's legendary performance while meeting increasingly stringent environmental regulations.

The origins of the V8 engine can be traced back to the early 20th century, with the first production V8 introduced by Cadillac in 1914. This pioneering design set the stage for future developments, featuring a 90-degree V-angle and a flat-plane crankshaft. The 1920s and 1930s saw further refinements, with Ford's introduction of the flathead V8 in 1932 marking a significant milestone in mass-production techniques.

Post-World War II, the 1950s ushered in an era of high-performance V8 engines. Chevrolet's small-block V8, introduced in 1955, became an industry standard for its compact design and versatility. This period also saw advancements in overhead valve (OHV) technology, improving engine efficiency and power output.

The 1960s and 1970s were characterized by the muscle car era, pushing V8 engines to new limits of power and performance. Key developments included the introduction of high-compression ratios, improved fuel delivery systems, and more robust internal components. However, the oil crisis of the 1970s led to a shift towards fuel efficiency, prompting innovations in engine management and emissions control.

The 1980s and 1990s marked a transition towards more sophisticated V8 designs. Electronic fuel injection systems replaced carburetors, offering better fuel economy and emissions control. Variable valve timing (VVT) technology was introduced, allowing for optimized engine performance across different operating conditions.

The turn of the millennium brought about significant advancements in V8 engine technology. Direct fuel injection systems became prevalent, offering improved fuel efficiency and power output. Cylinder deactivation technology was refined, allowing V8 engines to operate on fewer cylinders under light load conditions, further enhancing fuel economy.

Recent years have seen a focus on combining performance with sustainability. Turbocharging and supercharging have become more common in V8 engines, allowing for smaller displacement engines to produce higher power outputs. Additionally, hybrid V8 systems have emerged, integrating electric motors to boost performance while reducing emissions.

Looking ahead, the V8 engine continues to evolve, with ongoing research into advanced materials, improved thermal management, and integration with electric powertrains. These developments aim to preserve the V8's legendary performance while meeting increasingly stringent environmental regulations.

Market Demand Analysis

The market demand for V8 engines has been evolving significantly over the past decades, driven by various factors in the automotive industry. Initially, V8 engines were primarily associated with high-performance vehicles and luxury cars, catering to a niche market of enthusiasts and affluent consumers. However, as automotive technologies advanced and consumer preferences shifted, the demand for V8 engines expanded into broader market segments.

In the passenger vehicle sector, V8 engines have maintained a strong presence in full-size trucks and SUVs, particularly in North America. These vehicles often require the power and torque provided by V8 engines for towing and hauling capabilities. The sustained popularity of large vehicles in this region has contributed to a consistent demand for V8 engines.

The performance car segment continues to be a significant driver of V8 engine demand. Sports cars, muscle cars, and high-end luxury vehicles frequently feature V8 engines as a hallmark of power and prestige. This segment, while smaller in volume compared to mainstream vehicles, represents a high-value market for V8 engines.

However, the automotive industry has been experiencing a shift towards more fuel-efficient and environmentally friendly technologies. This trend has led to increased pressure on V8 engine manufacturers to improve fuel economy and reduce emissions. As a result, many automakers have invested in developing more efficient V8 engines, incorporating technologies such as cylinder deactivation, direct injection, and turbocharging.

The commercial vehicle sector, including heavy-duty trucks and specialized industrial equipment, also contributes to the demand for V8 engines. These applications often require the robust power output and durability that V8 engines can provide, ensuring a steady market in this segment.

Despite these areas of demand, the overall market for V8 engines has faced challenges in recent years. Stricter emissions regulations, particularly in Europe and China, have led to a decline in V8 engine offerings in certain markets. Additionally, the rise of electric vehicles and hybrid powertrains has begun to impact the traditional internal combustion engine market, including V8 engines.

Looking ahead, the market for V8 engines is expected to continue evolving. While there will likely be a sustained demand in specific segments such as performance vehicles and heavy-duty applications, the overall trend points towards a gradual reduction in V8 engine production. Manufacturers are increasingly focusing on developing more efficient V6 engines and electrified powertrains that can match or exceed V8 performance while meeting stricter environmental standards.

In conclusion, the market demand for V8 engines remains significant in certain sectors but is facing long-term challenges due to changing regulatory landscapes and technological advancements. The future of V8 engines will likely involve continued refinement and specialization to meet the needs of specific market niches while adapting to broader industry trends towards electrification and increased efficiency.

In the passenger vehicle sector, V8 engines have maintained a strong presence in full-size trucks and SUVs, particularly in North America. These vehicles often require the power and torque provided by V8 engines for towing and hauling capabilities. The sustained popularity of large vehicles in this region has contributed to a consistent demand for V8 engines.

The performance car segment continues to be a significant driver of V8 engine demand. Sports cars, muscle cars, and high-end luxury vehicles frequently feature V8 engines as a hallmark of power and prestige. This segment, while smaller in volume compared to mainstream vehicles, represents a high-value market for V8 engines.

However, the automotive industry has been experiencing a shift towards more fuel-efficient and environmentally friendly technologies. This trend has led to increased pressure on V8 engine manufacturers to improve fuel economy and reduce emissions. As a result, many automakers have invested in developing more efficient V8 engines, incorporating technologies such as cylinder deactivation, direct injection, and turbocharging.

The commercial vehicle sector, including heavy-duty trucks and specialized industrial equipment, also contributes to the demand for V8 engines. These applications often require the robust power output and durability that V8 engines can provide, ensuring a steady market in this segment.

Despite these areas of demand, the overall market for V8 engines has faced challenges in recent years. Stricter emissions regulations, particularly in Europe and China, have led to a decline in V8 engine offerings in certain markets. Additionally, the rise of electric vehicles and hybrid powertrains has begun to impact the traditional internal combustion engine market, including V8 engines.

Looking ahead, the market for V8 engines is expected to continue evolving. While there will likely be a sustained demand in specific segments such as performance vehicles and heavy-duty applications, the overall trend points towards a gradual reduction in V8 engine production. Manufacturers are increasingly focusing on developing more efficient V6 engines and electrified powertrains that can match or exceed V8 performance while meeting stricter environmental standards.

In conclusion, the market demand for V8 engines remains significant in certain sectors but is facing long-term challenges due to changing regulatory landscapes and technological advancements. The future of V8 engines will likely involve continued refinement and specialization to meet the needs of specific market niches while adapting to broader industry trends towards electrification and increased efficiency.

Technical Challenges

The V8 engine, developed by Google for its Chrome browser, has faced numerous technical challenges throughout its evolution. One of the primary obstacles has been achieving high performance while maintaining compatibility across various JavaScript implementations. This has required intricate optimizations and constant refinement of the engine's architecture.

A significant challenge in V8's development has been the implementation of efficient just-in-time (JIT) compilation. The engine must rapidly convert JavaScript code into machine code, balancing speed with the quality of the generated code. This process involves complex heuristics and adaptive techniques to optimize frequently executed code paths.

Memory management has been another critical hurdle for V8. JavaScript's dynamic nature necessitates sophisticated garbage collection mechanisms to prevent memory leaks and ensure efficient memory utilization. The engine has had to evolve its garbage collection strategies to minimize pause times and maintain smooth application performance, especially in long-running web applications.

The ever-changing landscape of JavaScript features and ECMAScript specifications has posed ongoing challenges for V8. Each new language feature requires careful implementation to maintain backwards compatibility while leveraging the latest optimizations. This has led to the development of complex parsing and execution pipelines capable of handling both legacy and modern JavaScript code.

V8's performance on different hardware architectures has been a persistent challenge. Optimizing the engine for various CPU architectures, from x86 to ARM, requires specialized knowledge and tailored optimizations. This has necessitated the development of platform-specific code generation and optimization techniques.

The increasing complexity of web applications has pushed V8 to improve its handling of large codebases. Techniques such as lazy parsing and incremental compilation have been developed to reduce startup times and memory usage for complex applications. However, balancing these optimizations with overall runtime performance remains an ongoing challenge.

Security has been a paramount concern in V8's development. As a core component of web browsers, the engine must be resilient against various forms of attacks, including JIT spraying and type confusion vulnerabilities. Implementing robust security measures while maintaining high performance has required innovative approaches to sandboxing and code isolation.

Lastly, the integration of WebAssembly support into V8 has presented new challenges. Ensuring seamless interoperability between JavaScript and WebAssembly, while maintaining optimal performance for both, has required significant architectural changes and optimizations within the engine.

A significant challenge in V8's development has been the implementation of efficient just-in-time (JIT) compilation. The engine must rapidly convert JavaScript code into machine code, balancing speed with the quality of the generated code. This process involves complex heuristics and adaptive techniques to optimize frequently executed code paths.

Memory management has been another critical hurdle for V8. JavaScript's dynamic nature necessitates sophisticated garbage collection mechanisms to prevent memory leaks and ensure efficient memory utilization. The engine has had to evolve its garbage collection strategies to minimize pause times and maintain smooth application performance, especially in long-running web applications.

The ever-changing landscape of JavaScript features and ECMAScript specifications has posed ongoing challenges for V8. Each new language feature requires careful implementation to maintain backwards compatibility while leveraging the latest optimizations. This has led to the development of complex parsing and execution pipelines capable of handling both legacy and modern JavaScript code.

V8's performance on different hardware architectures has been a persistent challenge. Optimizing the engine for various CPU architectures, from x86 to ARM, requires specialized knowledge and tailored optimizations. This has necessitated the development of platform-specific code generation and optimization techniques.

The increasing complexity of web applications has pushed V8 to improve its handling of large codebases. Techniques such as lazy parsing and incremental compilation have been developed to reduce startup times and memory usage for complex applications. However, balancing these optimizations with overall runtime performance remains an ongoing challenge.

Security has been a paramount concern in V8's development. As a core component of web browsers, the engine must be resilient against various forms of attacks, including JIT spraying and type confusion vulnerabilities. Implementing robust security measures while maintaining high performance has required innovative approaches to sandboxing and code isolation.

Lastly, the integration of WebAssembly support into V8 has presented new challenges. Ensuring seamless interoperability between JavaScript and WebAssembly, while maintaining optimal performance for both, has required significant architectural changes and optimizations within the engine.

Current V8 Solutions

01 V8 Engine Design and Configuration

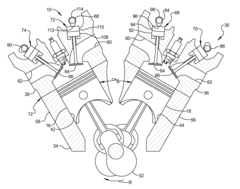

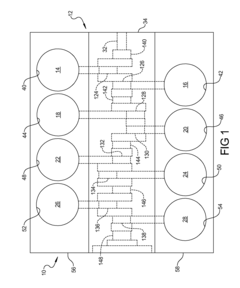

V8 engines are characterized by their V-shaped configuration of eight cylinders. This design allows for a compact engine layout while providing high power output. The arrangement of cylinders in two banks of four, set at an angle to each other, contributes to improved balance and smoother operation compared to inline configurations.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and balanced operation. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery and combustion efficiency lead to increased power output, reduced emissions, and better fuel economy in V8 engines.

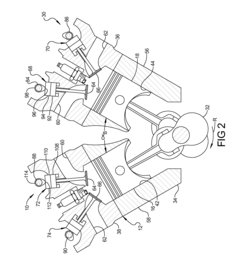

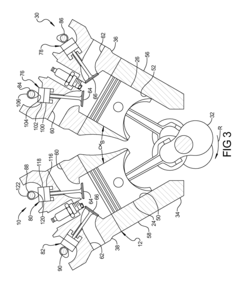

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to boost power output. These systems compress the intake air, allowing more fuel to be burned and increasing engine performance. Various designs and configurations of turbochargers and superchargers are used to optimize V8 engine power and efficiency.

- Cooling and Lubrication Systems: Effective cooling and lubrication systems are essential for V8 engine reliability and longevity. Advanced cooling systems manage engine temperature, while sophisticated lubrication systems ensure proper oil distribution to all moving parts. Innovations in these areas focus on improving heat dissipation, reducing friction, and enhancing overall engine efficiency.

- Engine Management and Control Systems: Modern V8 engines utilize advanced electronic control systems to optimize performance, fuel efficiency, and emissions. These systems include engine control units (ECUs), sensors, and actuators that continuously monitor and adjust engine parameters. Innovations in engine management focus on improving responsiveness, adaptability, and integration with vehicle systems.

02 Fuel Efficiency and Performance Enhancements

Innovations in V8 engine technology focus on improving fuel efficiency while maintaining high performance. This includes advancements in fuel injection systems, variable valve timing, and cylinder deactivation technologies. These enhancements allow V8 engines to deliver power when needed while conserving fuel during less demanding driving conditions.Expand Specific Solutions03 Cooling and Lubrication Systems

Effective cooling and lubrication are crucial for V8 engine performance and longevity. Advanced cooling systems manage heat distribution across the engine, while improved lubrication systems ensure proper oil flow to all critical components. These systems help maintain optimal operating temperatures and reduce wear on engine parts.Expand Specific Solutions04 Emissions Control and Environmental Considerations

Modern V8 engines incorporate various technologies to reduce emissions and meet stringent environmental standards. This includes the use of advanced catalytic converters, exhaust gas recirculation systems, and precise engine management controls. These innovations aim to minimize the environmental impact of V8 engines while preserving their performance characteristics.Expand Specific Solutions05 Integration with Hybrid and Electric Systems

To meet evolving market demands and regulations, V8 engines are being integrated with hybrid and electric systems. This integration allows for improved fuel efficiency and reduced emissions while maintaining the power and performance associated with V8 engines. Such hybrid V8 configurations can provide electric assist during acceleration and allow for short-distance electric-only operation.Expand Specific Solutions

Key Industry Players

The V8 engine construction market is in a mature stage, with established players dominating the landscape. The global market size for V8 engines is substantial, driven by demand in high-performance vehicles and luxury segments. Technologically, V8 engines have reached a high level of sophistication, with companies like GM, Toyota, BMW, and Honda leading innovation. These manufacturers are focusing on improving efficiency, reducing emissions, and integrating hybrid technologies to meet stringent environmental regulations. The competitive landscape is characterized by intense rivalry among major automakers, with each striving to differentiate through performance enhancements and technological advancements in their V8 offerings.

GM Global Technology Operations LLC

Technical Solution: GM has made significant strides in V8 engine construction, focusing on performance and efficiency. Their latest V8 engines feature direct fuel injection, variable valve timing, and cylinder deactivation technology[1]. GM's V8 engines, such as the 6.2L LT2 used in the Corvette, incorporate advanced materials like aluminum block and heads to reduce weight while maintaining strength[2]. The company has also implemented a Dynamic Fuel Management system, which can deactivate up to seven cylinders for improved fuel economy[3]. GM's V8 engines utilize a hot V configuration, placing the turbochargers between the cylinder banks for improved throttle response and reduced lag[4].

Strengths: Advanced fuel management systems, lightweight materials, and innovative turbocharger placement. Weaknesses: Complexity of systems may lead to higher maintenance costs, and the focus on performance may result in lower fuel efficiency compared to smaller engines.

Honda Motor Co., Ltd.

Technical Solution: Honda has focused on improving V8 engine efficiency and performance through innovative technologies. Their V8 engines, primarily used in racing applications, feature a compact design with a flat-plane crankshaft for higher revving capabilities[5]. Honda has implemented advanced valve control systems, including VTEC (Variable Valve Timing and Lift Electronic Control), to optimize performance across different RPM ranges[6]. The company has also explored the use of direct fuel injection and turbocharging in their V8 designs to increase power output while maintaining fuel efficiency[7]. Honda's racing V8 engines have demonstrated exceptional durability and power-to-weight ratios, contributing to their success in motorsports[8].

Strengths: High-revving capabilities, advanced valve control systems, and proven performance in racing applications. Weaknesses: Limited experience in mass-production V8 engines for consumer vehicles, potentially higher production costs due to specialized technologies.

Core V8 Innovations

Engine assembly including crankshaft for v8 arrangement

PatentInactiveUS20120210958A1

Innovation

- A V8 engine crankshaft design with rotationally offset and aligned crank pins, allowing for primary balance without balance shafts and maintaining consistent firing intervals across all eight cylinders, as well as during operation with six or seven cylinders, through a specific arrangement of crank pins and bearing journals.

Eight-cylinder engine

PatentInactiveEP1740812A1

Innovation

- The engine is configured with two valve drive units, where one drives fuel injection valves for cylinders with combustion and expansion strokes at equal intervals, and the other drives those at different intervals, mimicking the operation of a four-cylinder engine to maintain consistent energization intervals and allow sufficient charging time.

Performance Benchmarks

Performance benchmarks play a crucial role in evaluating the progress and effectiveness of V8 engine construction over time. These benchmarks provide quantitative measures of various aspects of engine performance, allowing developers and researchers to track improvements and compare different versions or implementations.

One of the most widely used benchmark suites for JavaScript engines is the Octane benchmark, developed by Google. Octane includes a diverse set of tests that simulate real-world JavaScript applications, covering areas such as code execution speed, memory management, and garbage collection efficiency. The V8 team has consistently used Octane to measure and report performance gains across different versions of the engine.

Another significant benchmark is JetStream, which combines a variety of JavaScript and WebAssembly benchmarks to measure browser performance. JetStream includes tests from the SunSpider and Octane benchmark suites, as well as additional tests developed by Apple and others. This benchmark provides a comprehensive view of V8's performance in various scenarios, including both traditional JavaScript execution and newer WebAssembly workloads.

The SpiderMonkey team at Mozilla has developed the Kraken benchmark, which focuses on realistic and forward-looking use cases for JavaScript. While not specifically designed for V8, Kraken has been used to compare V8's performance against other JavaScript engines and to identify areas for improvement.

In recent years, the V8 team has also developed and utilized more specialized benchmarks to target specific aspects of engine performance. For example, the ARES-6 benchmark focuses on measuring the performance of modern web applications that make heavy use of ES6 features. This benchmark has been particularly useful in evaluating the effectiveness of optimizations for newer JavaScript language features.

To assess real-world performance, the V8 team has increasingly relied on telemetry data from actual Chrome users. This approach provides insights into how engine improvements translate to better performance in real-world scenarios, complementing the more controlled environment of synthetic benchmarks.

As V8 has evolved, its performance on these benchmarks has shown significant improvements. For instance, between V8 version 5.9 and 6.5, the team reported a 35% improvement in Octane scores and a 25% improvement in ARES-6 scores. These gains reflect the continuous optimization efforts and architectural improvements made to the engine over time.

It's worth noting that while benchmarks provide valuable insights, they don't always perfectly represent real-world performance. The V8 team has been transparent about this limitation and has worked to develop more representative benchmarks and measurement techniques to ensure that improvements translate to better user experiences in actual web applications.

One of the most widely used benchmark suites for JavaScript engines is the Octane benchmark, developed by Google. Octane includes a diverse set of tests that simulate real-world JavaScript applications, covering areas such as code execution speed, memory management, and garbage collection efficiency. The V8 team has consistently used Octane to measure and report performance gains across different versions of the engine.

Another significant benchmark is JetStream, which combines a variety of JavaScript and WebAssembly benchmarks to measure browser performance. JetStream includes tests from the SunSpider and Octane benchmark suites, as well as additional tests developed by Apple and others. This benchmark provides a comprehensive view of V8's performance in various scenarios, including both traditional JavaScript execution and newer WebAssembly workloads.

The SpiderMonkey team at Mozilla has developed the Kraken benchmark, which focuses on realistic and forward-looking use cases for JavaScript. While not specifically designed for V8, Kraken has been used to compare V8's performance against other JavaScript engines and to identify areas for improvement.

In recent years, the V8 team has also developed and utilized more specialized benchmarks to target specific aspects of engine performance. For example, the ARES-6 benchmark focuses on measuring the performance of modern web applications that make heavy use of ES6 features. This benchmark has been particularly useful in evaluating the effectiveness of optimizations for newer JavaScript language features.

To assess real-world performance, the V8 team has increasingly relied on telemetry data from actual Chrome users. This approach provides insights into how engine improvements translate to better performance in real-world scenarios, complementing the more controlled environment of synthetic benchmarks.

As V8 has evolved, its performance on these benchmarks has shown significant improvements. For instance, between V8 version 5.9 and 6.5, the team reported a 35% improvement in Octane scores and a 25% improvement in ARES-6 scores. These gains reflect the continuous optimization efforts and architectural improvements made to the engine over time.

It's worth noting that while benchmarks provide valuable insights, they don't always perfectly represent real-world performance. The V8 team has been transparent about this limitation and has worked to develop more representative benchmarks and measurement techniques to ensure that improvements translate to better user experiences in actual web applications.

Environmental Impact

The environmental impact of V8 engine construction has been a significant concern throughout its development history. As automotive technology has progressed, manufacturers have faced increasing pressure to reduce the ecological footprint of their engines, including V8s.

Early V8 engines were notorious for their high fuel consumption and emissions. However, advancements in engine design and materials have led to substantial improvements in efficiency and environmental performance. The introduction of electronic fuel injection systems in the 1980s marked a crucial milestone, allowing for more precise fuel metering and reduced emissions.

The implementation of catalytic converters became widespread in V8 engines during the 1990s, further reducing harmful exhaust emissions. This technology, combined with improved engine management systems, helped V8-powered vehicles meet increasingly stringent environmental regulations.

In recent years, the focus has shifted towards reducing carbon dioxide emissions and improving fuel economy. Variable valve timing and cylinder deactivation technologies have been widely adopted in V8 engines, allowing for better fuel efficiency without sacrificing performance. Some manufacturers have also introduced start-stop systems in V8 engines, which automatically shut off the engine when the vehicle is stationary, further reducing fuel consumption and emissions in urban environments.

The use of lightweight materials in V8 engine construction has also contributed to improved environmental performance. Aluminum alloys and composite materials have replaced heavier components, reducing overall vehicle weight and improving fuel efficiency. Additionally, advanced manufacturing techniques have allowed for more precise machining and assembly, resulting in engines with tighter tolerances and reduced friction, further enhancing efficiency.

Despite these improvements, V8 engines still face challenges in meeting future environmental standards. As a result, many manufacturers are exploring hybrid and electric powertrains as alternatives to traditional V8 engines. Some have developed hybrid V8 systems that combine the power of a V8 engine with electric motors, offering improved fuel economy and reduced emissions while maintaining high performance.

Looking ahead, the environmental impact of V8 engine construction will likely continue to be a driving force for innovation. As regulations become more stringent, manufacturers will need to further refine their designs and explore new technologies to ensure that V8 engines remain viable in an increasingly environmentally conscious automotive landscape.

Early V8 engines were notorious for their high fuel consumption and emissions. However, advancements in engine design and materials have led to substantial improvements in efficiency and environmental performance. The introduction of electronic fuel injection systems in the 1980s marked a crucial milestone, allowing for more precise fuel metering and reduced emissions.

The implementation of catalytic converters became widespread in V8 engines during the 1990s, further reducing harmful exhaust emissions. This technology, combined with improved engine management systems, helped V8-powered vehicles meet increasingly stringent environmental regulations.

In recent years, the focus has shifted towards reducing carbon dioxide emissions and improving fuel economy. Variable valve timing and cylinder deactivation technologies have been widely adopted in V8 engines, allowing for better fuel efficiency without sacrificing performance. Some manufacturers have also introduced start-stop systems in V8 engines, which automatically shut off the engine when the vehicle is stationary, further reducing fuel consumption and emissions in urban environments.

The use of lightweight materials in V8 engine construction has also contributed to improved environmental performance. Aluminum alloys and composite materials have replaced heavier components, reducing overall vehicle weight and improving fuel efficiency. Additionally, advanced manufacturing techniques have allowed for more precise machining and assembly, resulting in engines with tighter tolerances and reduced friction, further enhancing efficiency.

Despite these improvements, V8 engines still face challenges in meeting future environmental standards. As a result, many manufacturers are exploring hybrid and electric powertrains as alternatives to traditional V8 engines. Some have developed hybrid V8 systems that combine the power of a V8 engine with electric motors, offering improved fuel economy and reduced emissions while maintaining high performance.

Looking ahead, the environmental impact of V8 engine construction will likely continue to be a driving force for innovation. As regulations become more stringent, manufacturers will need to further refine their designs and explore new technologies to ensure that V8 engines remain viable in an increasingly environmentally conscious automotive landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!