V8 Engine Tuning: Maximizing Potential Uncovered

JUL 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine, a marvel of automotive engineering, has undergone significant evolution since its inception. Initially developed in the early 20th century, this engine configuration has become synonymous with power and performance in the automotive industry. The V8's journey began with simple designs, focusing on raw power output, and has progressed to highly sophisticated systems that balance performance with efficiency and environmental considerations.

In the 1950s and 1960s, V8 engines reached their golden age, particularly in American muscle cars. These engines were characterized by large displacements and high power outputs, often sacrificing fuel efficiency for sheer performance. The oil crisis of the 1970s, however, forced a paradigm shift in V8 engine development. Manufacturers began to focus on improving fuel economy and reducing emissions, leading to the introduction of technologies such as electronic fuel injection and catalytic converters.

The 1980s and 1990s saw further refinements in V8 technology. Computer-controlled engine management systems became prevalent, allowing for more precise control over fuel delivery and ignition timing. This era also witnessed the rise of overhead cam designs, which improved engine efficiency and allowed for higher revving capabilities. Manufacturers began experimenting with lightweight materials and advanced manufacturing techniques to reduce engine weight and improve power-to-weight ratios.

The turn of the millennium brought about a new focus on environmental concerns and stricter emissions regulations. This led to the development of more efficient V8 engines, incorporating technologies such as variable valve timing, direct fuel injection, and cylinder deactivation. These advancements allowed V8 engines to maintain their performance characteristics while significantly improving fuel economy and reducing emissions.

In recent years, the evolution of V8 engines has been driven by the pursuit of both performance and sustainability. Turbocharging and supercharging have become commonplace, allowing smaller displacement V8s to produce power outputs rivaling their larger predecessors. Hybrid technologies have also been integrated into V8 powertrains, further enhancing efficiency and performance. Additionally, advancements in materials science have led to the use of exotic alloys and composites, reducing engine weight and improving thermal efficiency.

The future of V8 engine evolution is likely to be shaped by the ongoing transition towards electrification and alternative fuels. While some manufacturers are phasing out V8 engines in favor of smaller, turbocharged engines or electric powertrains, others are exploring ways to make V8s more sustainable. This includes the development of V8 engines capable of running on hydrogen or synthetic fuels, as well as the integration of more advanced hybrid systems.

In the 1950s and 1960s, V8 engines reached their golden age, particularly in American muscle cars. These engines were characterized by large displacements and high power outputs, often sacrificing fuel efficiency for sheer performance. The oil crisis of the 1970s, however, forced a paradigm shift in V8 engine development. Manufacturers began to focus on improving fuel economy and reducing emissions, leading to the introduction of technologies such as electronic fuel injection and catalytic converters.

The 1980s and 1990s saw further refinements in V8 technology. Computer-controlled engine management systems became prevalent, allowing for more precise control over fuel delivery and ignition timing. This era also witnessed the rise of overhead cam designs, which improved engine efficiency and allowed for higher revving capabilities. Manufacturers began experimenting with lightweight materials and advanced manufacturing techniques to reduce engine weight and improve power-to-weight ratios.

The turn of the millennium brought about a new focus on environmental concerns and stricter emissions regulations. This led to the development of more efficient V8 engines, incorporating technologies such as variable valve timing, direct fuel injection, and cylinder deactivation. These advancements allowed V8 engines to maintain their performance characteristics while significantly improving fuel economy and reducing emissions.

In recent years, the evolution of V8 engines has been driven by the pursuit of both performance and sustainability. Turbocharging and supercharging have become commonplace, allowing smaller displacement V8s to produce power outputs rivaling their larger predecessors. Hybrid technologies have also been integrated into V8 powertrains, further enhancing efficiency and performance. Additionally, advancements in materials science have led to the use of exotic alloys and composites, reducing engine weight and improving thermal efficiency.

The future of V8 engine evolution is likely to be shaped by the ongoing transition towards electrification and alternative fuels. While some manufacturers are phasing out V8 engines in favor of smaller, turbocharged engines or electric powertrains, others are exploring ways to make V8s more sustainable. This includes the development of V8 engines capable of running on hydrogen or synthetic fuels, as well as the integration of more advanced hybrid systems.

Market Demand Analysis

The market demand for V8 engine tuning has been steadily growing, driven by automotive enthusiasts, racing teams, and performance-oriented vehicle manufacturers. This demand stems from the desire to extract maximum power, efficiency, and performance from V8 engines, which are known for their robust design and potential for significant improvements through tuning.

In the automotive aftermarket sector, V8 engine tuning kits and services have seen a surge in popularity. Performance shops and tuning companies report increased requests for V8 engine modifications, ranging from simple ECU remapping to comprehensive engine rebuilds. This trend is particularly strong in markets with a strong car culture, such as the United States, Germany, and Australia.

The racing industry continues to be a significant driver of V8 engine tuning demand. Professional racing series, including NASCAR and various touring car championships, rely heavily on highly tuned V8 engines. This not only fuels the development of advanced tuning techniques but also creates a trickle-down effect to amateur racing and street performance markets.

Luxury and high-performance vehicle manufacturers are also contributing to the market demand. Many premium brands offer factory-tuned V8 engines in their top-tier models, responding to consumer desire for vehicles with exceptional power and performance characteristics. This has led to increased competition among manufacturers to produce the most powerful and efficient V8 engines, further driving innovation in tuning techniques.

Environmental regulations and fuel efficiency standards have paradoxically boosted the demand for V8 engine tuning. As stricter emissions norms are implemented globally, manufacturers and tuners are focusing on developing methods to maintain or increase power output while improving fuel economy and reducing emissions. This has opened up new avenues for advanced tuning technologies, such as variable valve timing optimization and direct injection tuning.

The rise of electric vehicles has, contrary to expectations, not significantly dampened the enthusiasm for V8 engine tuning. Instead, it has created a niche market of enthusiasts who are even more dedicated to preserving and enhancing the performance of traditional V8 engines. This has led to a resurgence in interest for classic V8-powered vehicles and their modernization through advanced tuning techniques.

Market analysis indicates that the global V8 engine tuning market is expected to grow at a steady rate over the next five years. Factors contributing to this growth include the increasing disposable income in emerging markets, the growing popularity of motorsports, and the continuous technological advancements in engine management systems that allow for more sophisticated tuning strategies.

In the automotive aftermarket sector, V8 engine tuning kits and services have seen a surge in popularity. Performance shops and tuning companies report increased requests for V8 engine modifications, ranging from simple ECU remapping to comprehensive engine rebuilds. This trend is particularly strong in markets with a strong car culture, such as the United States, Germany, and Australia.

The racing industry continues to be a significant driver of V8 engine tuning demand. Professional racing series, including NASCAR and various touring car championships, rely heavily on highly tuned V8 engines. This not only fuels the development of advanced tuning techniques but also creates a trickle-down effect to amateur racing and street performance markets.

Luxury and high-performance vehicle manufacturers are also contributing to the market demand. Many premium brands offer factory-tuned V8 engines in their top-tier models, responding to consumer desire for vehicles with exceptional power and performance characteristics. This has led to increased competition among manufacturers to produce the most powerful and efficient V8 engines, further driving innovation in tuning techniques.

Environmental regulations and fuel efficiency standards have paradoxically boosted the demand for V8 engine tuning. As stricter emissions norms are implemented globally, manufacturers and tuners are focusing on developing methods to maintain or increase power output while improving fuel economy and reducing emissions. This has opened up new avenues for advanced tuning technologies, such as variable valve timing optimization and direct injection tuning.

The rise of electric vehicles has, contrary to expectations, not significantly dampened the enthusiasm for V8 engine tuning. Instead, it has created a niche market of enthusiasts who are even more dedicated to preserving and enhancing the performance of traditional V8 engines. This has led to a resurgence in interest for classic V8-powered vehicles and their modernization through advanced tuning techniques.

Market analysis indicates that the global V8 engine tuning market is expected to grow at a steady rate over the next five years. Factors contributing to this growth include the increasing disposable income in emerging markets, the growing popularity of motorsports, and the continuous technological advancements in engine management systems that allow for more sophisticated tuning strategies.

Technical Challenges

V8 engine tuning presents several technical challenges that require careful consideration and innovative solutions. One of the primary obstacles is the delicate balance between performance enhancement and engine reliability. As tuners push the boundaries of power output, they must contend with increased thermal and mechanical stresses on engine components.

The complexity of modern V8 engines, with their sophisticated electronic control systems and integrated technologies, adds another layer of difficulty to the tuning process. Modifying one aspect of the engine's performance often has cascading effects on other systems, necessitating a holistic approach to tuning.

Fuel management poses a significant challenge, particularly when increasing power output. Achieving the optimal air-fuel ratio across a wide range of operating conditions becomes increasingly difficult as engine performance is enhanced. This challenge is compounded by the need to maintain emissions compliance, which often requires advanced strategies and aftermarket solutions.

Thermal management is another critical hurdle in V8 engine tuning. As power output increases, so does heat generation, potentially leading to issues such as detonation, reduced efficiency, and accelerated wear. Developing effective cooling solutions that can handle the increased thermal load without compromising performance or reliability is a constant challenge for tuners.

The advent of forced induction in many modern V8 engines introduces additional complexities. Turbocharging and supercharging systems require careful calibration to optimize boost pressure, minimize lag, and ensure consistent power delivery across the rev range. Balancing these factors while maintaining drivability and longevity is a delicate task.

Material limitations also present challenges in V8 engine tuning. As power levels increase, stock components may reach their structural limits, necessitating upgrades to stronger, often more expensive materials. This can significantly impact the cost-effectiveness of tuning projects and may require extensive modifications to supporting systems.

Lastly, the regulatory landscape poses an ongoing challenge for V8 engine tuning. Stringent emissions standards and noise regulations vary across regions, requiring tuners to develop solutions that not only enhance performance but also maintain legal compliance. This often involves sophisticated engine management strategies and the integration of advanced aftermarket emissions control systems.

The complexity of modern V8 engines, with their sophisticated electronic control systems and integrated technologies, adds another layer of difficulty to the tuning process. Modifying one aspect of the engine's performance often has cascading effects on other systems, necessitating a holistic approach to tuning.

Fuel management poses a significant challenge, particularly when increasing power output. Achieving the optimal air-fuel ratio across a wide range of operating conditions becomes increasingly difficult as engine performance is enhanced. This challenge is compounded by the need to maintain emissions compliance, which often requires advanced strategies and aftermarket solutions.

Thermal management is another critical hurdle in V8 engine tuning. As power output increases, so does heat generation, potentially leading to issues such as detonation, reduced efficiency, and accelerated wear. Developing effective cooling solutions that can handle the increased thermal load without compromising performance or reliability is a constant challenge for tuners.

The advent of forced induction in many modern V8 engines introduces additional complexities. Turbocharging and supercharging systems require careful calibration to optimize boost pressure, minimize lag, and ensure consistent power delivery across the rev range. Balancing these factors while maintaining drivability and longevity is a delicate task.

Material limitations also present challenges in V8 engine tuning. As power levels increase, stock components may reach their structural limits, necessitating upgrades to stronger, often more expensive materials. This can significantly impact the cost-effectiveness of tuning projects and may require extensive modifications to supporting systems.

Lastly, the regulatory landscape poses an ongoing challenge for V8 engine tuning. Stringent emissions standards and noise regulations vary across regions, requiring tuners to develop solutions that not only enhance performance but also maintain legal compliance. This often involves sophisticated engine management strategies and the integration of advanced aftermarket emissions control systems.

Current Tuning Methods

01 Improved V8 engine design and performance

Advancements in V8 engine design focus on enhancing overall performance, efficiency, and power output. These improvements include optimized combustion processes, advanced fuel injection systems, and innovative cylinder configurations. Such enhancements contribute to increased horsepower, better fuel economy, and reduced emissions in V8 engines.- Improved V8 Engine Design: Advancements in V8 engine design focus on enhancing performance, efficiency, and power output. These improvements include optimized cylinder configurations, advanced valve timing systems, and innovative combustion chamber designs. Such enhancements contribute to increased horsepower, better fuel economy, and reduced emissions.

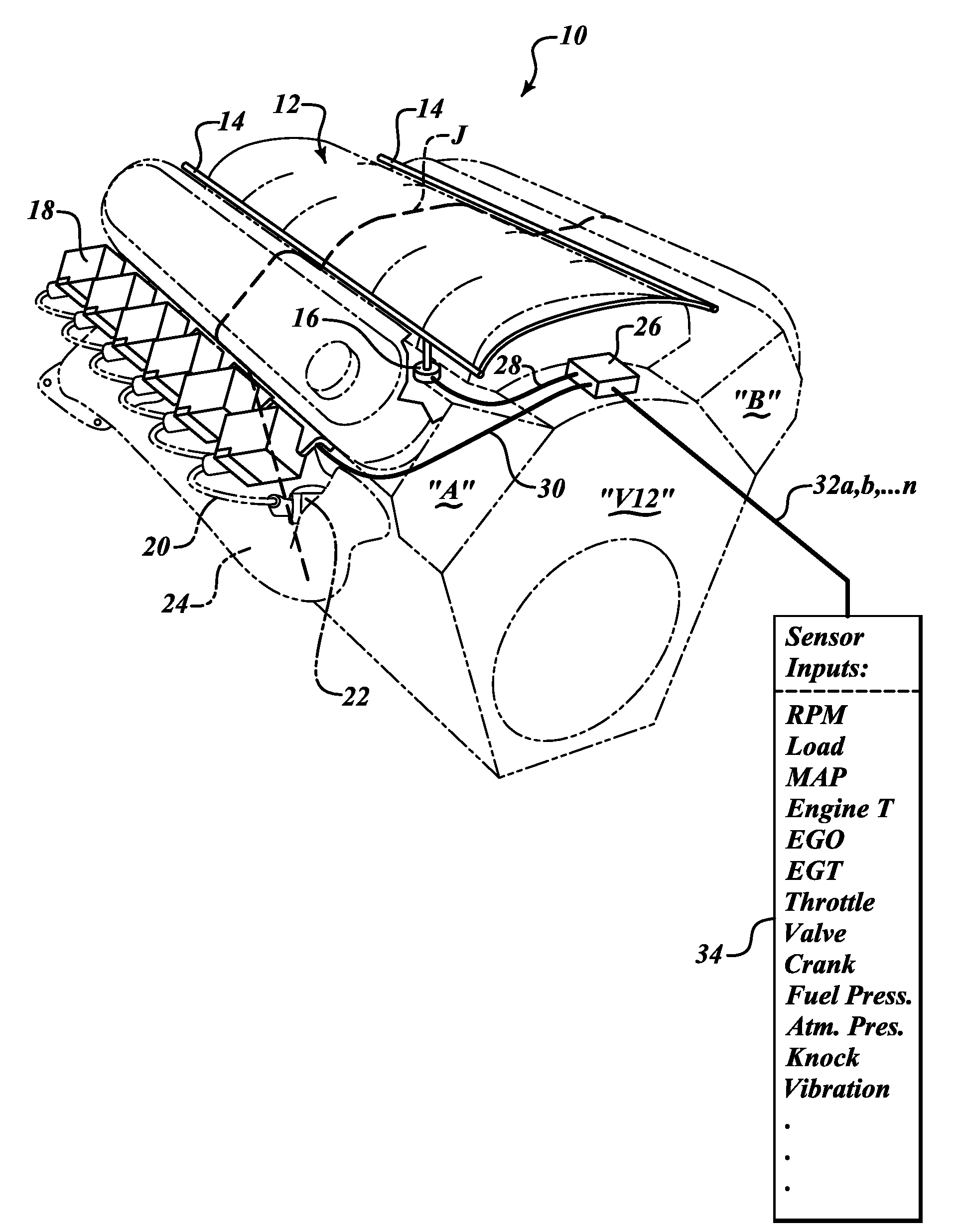

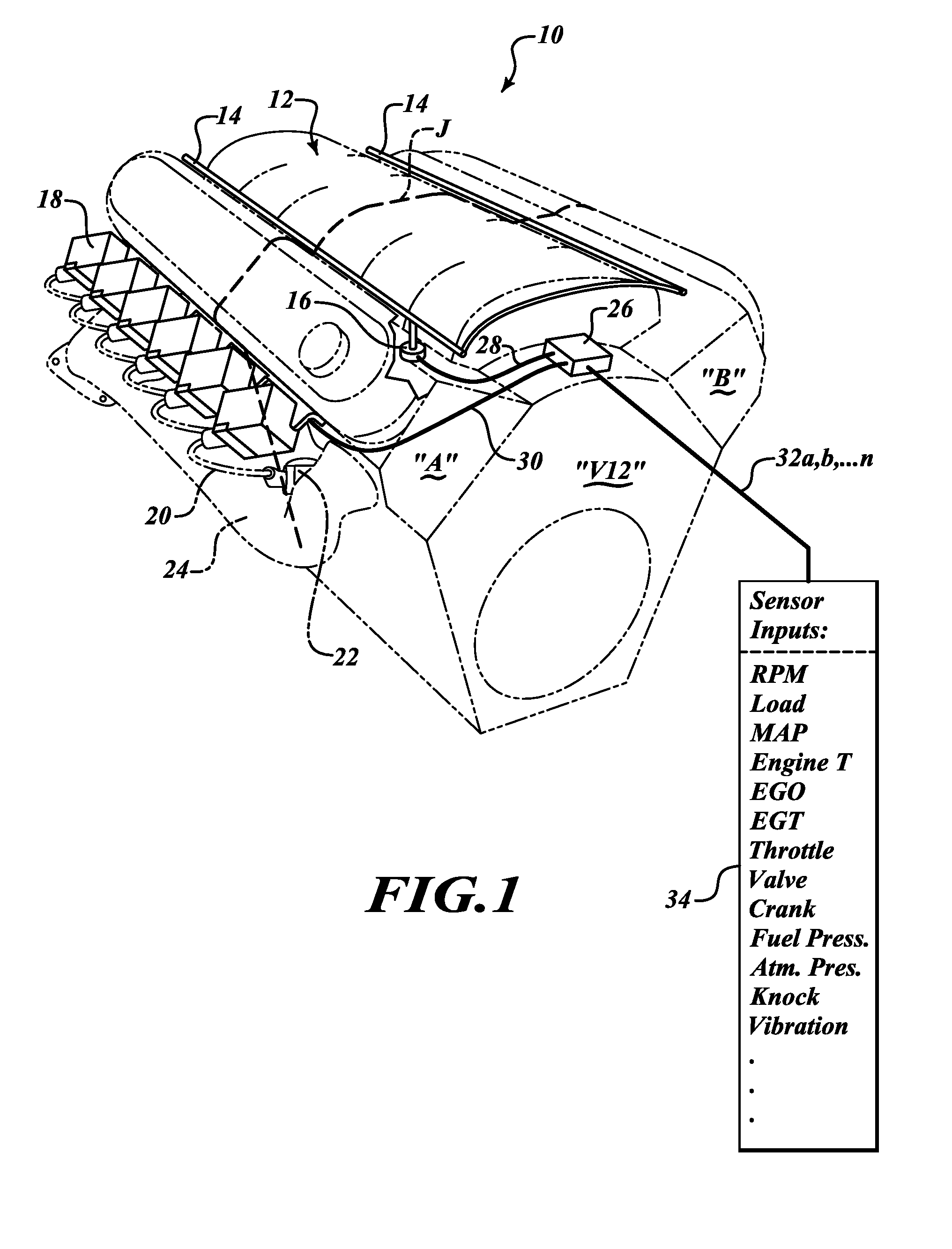

- V8 Engine Control Systems: Modern V8 engines incorporate sophisticated control systems to optimize performance and efficiency. These systems include advanced engine management units, variable valve timing controllers, and intelligent fuel injection systems. Such technologies enable precise control over engine parameters, resulting in improved power delivery and reduced fuel consumption.

- V8 Engine Turbocharging and Supercharging: Forced induction technologies, such as turbocharging and supercharging, are increasingly applied to V8 engines to boost power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and resulting in increased power without significantly increasing engine size or weight.

- V8 Engine Materials and Manufacturing: Advancements in materials science and manufacturing techniques contribute to the potential of V8 engines. The use of lightweight, high-strength materials and precision manufacturing processes allows for the creation of more durable and efficient engine components, leading to improved performance and longevity.

- V8 Engine Emissions Reduction: To meet stringent environmental regulations, V8 engines are being developed with advanced emissions reduction technologies. These include improved catalytic converters, exhaust gas recirculation systems, and particulate filters. Such innovations allow V8 engines to maintain high performance while significantly reducing harmful emissions.

02 V8 engine control systems and electronic management

Modern V8 engines incorporate sophisticated control systems and electronic management technologies. These systems optimize engine performance by regulating fuel injection, ignition timing, and valve operation. Advanced sensors and computerized control units enable real-time adjustments to engine parameters, resulting in improved efficiency and responsiveness across various operating conditions.Expand Specific Solutions03 V8 engine components and materials

Innovations in V8 engine components and materials focus on improving durability, reducing weight, and enhancing heat management. Advanced materials such as high-strength alloys and composites are used in critical engine parts. These improvements contribute to increased engine longevity, better power-to-weight ratios, and improved thermal efficiency.Expand Specific Solutions04 V8 engine turbocharging and supercharging

Forced induction technologies, including turbocharging and supercharging, are increasingly applied to V8 engines to boost power output and efficiency. These systems compress the intake air, allowing for increased fuel combustion and power generation. Advanced designs in compressor geometry and intercooling systems further enhance the potential of forced induction in V8 engines.Expand Specific Solutions05 V8 engine emissions reduction and environmental considerations

Efforts to reduce emissions and improve the environmental impact of V8 engines involve various technologies and strategies. These include advanced exhaust gas recirculation systems, catalytic converters, and particulate filters. Additionally, research into alternative fuels and hybrid V8 configurations aims to balance high performance with reduced environmental impact.Expand Specific Solutions

Key Industry Players

The V8 engine tuning market is in a mature stage, with established players and a stable market size. The global automotive engine market, including V8 engines, is projected to reach $103.7 billion by 2025. Technologically, V8 engine tuning has reached a high level of sophistication, with companies like Toyota, Ford, and BMW leading innovation. These manufacturers, along with specialized tuning firms, are continually pushing the boundaries of performance and efficiency. The competitive landscape is diverse, featuring major automakers, aftermarket tuning companies, and niche performance specialists, each striving to maximize the potential of V8 engines through advanced technologies and engineering expertise.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced V8 engine tuning techniques focusing on variable valve timing and lift (VVT/VVL) systems. Their Coyote V8 engine utilizes Twin Independent Variable Camshaft Timing (Ti-VCT) technology, allowing for precise control of valve timing for both intake and exhaust camshafts independently[1]. This system optimizes engine breathing across the entire RPM range, improving both low-end torque and high-end power. Ford has also implemented direct and port fuel injection in their V8 engines, which allows for better fuel atomization and more precise fuel delivery[2]. Additionally, they have explored cylinder deactivation technology to improve fuel efficiency during light load conditions[3].

Strengths: Improved power output and fuel efficiency across a wide RPM range. Weaknesses: Increased complexity and potential maintenance costs.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to V8 engine tuning focuses on their i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This technology combines VTEC (Variable Valve Timing and Lift Electronic Control) with VTC (Variable Timing Control) to optimize both valve lift and timing[4]. Honda has also implemented direct injection and a high compression ratio in their V8 engines to improve thermal efficiency. Their Earth Dreams Technology initiative has led to the development of a 3.5-liter V6 engine that matches the power output of many V8 engines while maintaining better fuel efficiency[5]. Although Honda doesn't currently produce V8 engines for mass-market vehicles, their racing division continues to develop high-performance V8 engines for motorsports applications[6].

Strengths: High specific output and fuel efficiency. Weaknesses: Limited application in current production vehicles.

Innovative Tuning Tech

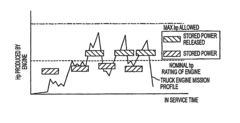

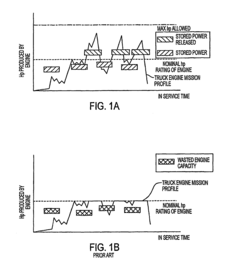

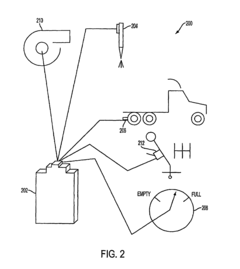

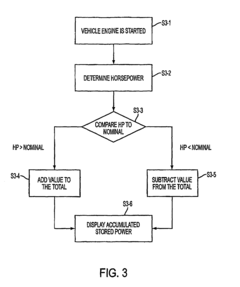

Engine power storage device and method

PatentInactiveUS7463966B2

Innovation

- A system and method utilizing an engine control unit (ECU) with sensors to calculate and display unused engine capacity, allowing for increased power output without compromising engine durability by releasing stored power through turbocharging and fuel flow adjustments.

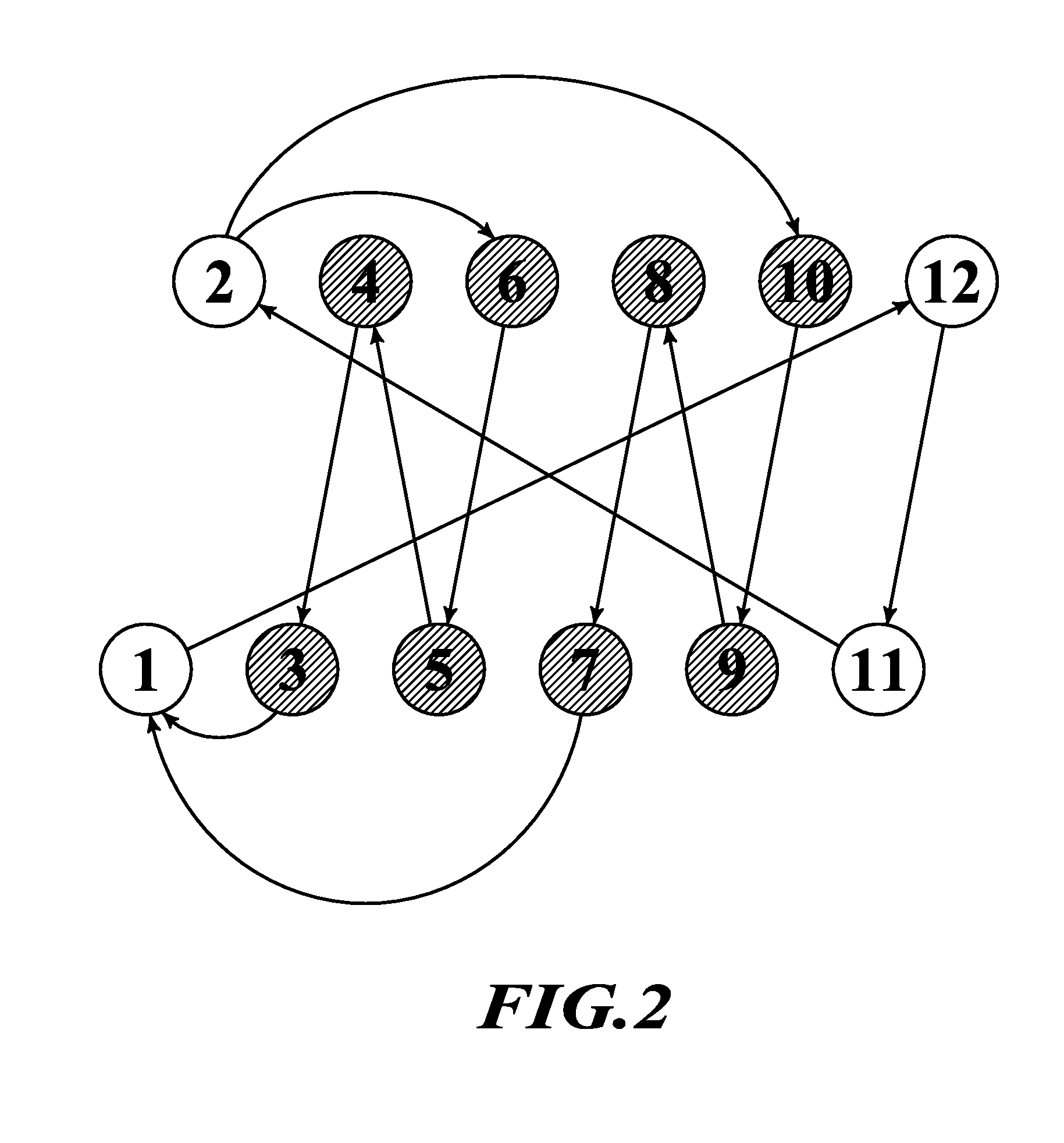

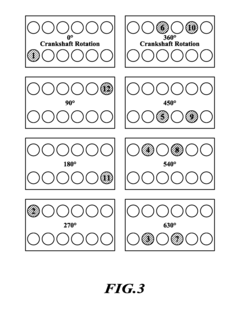

Even fire 90a°v12 IC engines, fueling and firing sequence controllers, and methods of operation by PS/p technology and IFR compensation by fuel feed control

PatentInactiveUS20090099755A1

Innovation

- Implementing a Progressive Single/Pair (PS/P) fueling and firing sequence in a 90° V12 engine, controlled by a Powertrain Control Module (PCM), which allows for Even Fire operation by selectively reducing fuel feed to specific cylinders during imbalance frequency ranges, effectively converting the engine to a balanced V8 operation during peak vibrations.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development and tuning of V8 engines. These regulations aim to reduce harmful pollutants and greenhouse gas emissions from vehicles, pushing manufacturers to innovate and adapt their engine designs. The primary focus of these regulations is on reducing carbon dioxide (CO2), nitrogen oxides (NOx), particulate matter (PM), and hydrocarbon emissions.

In the context of V8 engine tuning, emissions regulations present both challenges and opportunities. Engine designers and tuners must balance the desire for increased performance with the need to meet strict emissions standards. This has led to the development of various technologies and strategies to optimize engine efficiency while minimizing harmful emissions.

One of the key approaches to meeting emissions regulations in V8 engines is the implementation of advanced fuel injection systems. Direct injection technology, for instance, allows for more precise control over fuel delivery, resulting in improved combustion efficiency and reduced emissions. Additionally, variable valve timing and lift systems have been widely adopted to optimize engine breathing across different operating conditions, further enhancing efficiency and reducing emissions.

Exhaust gas recirculation (EGR) systems have also become a crucial component in V8 engine tuning for emissions compliance. By recirculating a portion of the exhaust gases back into the combustion chamber, EGR systems help reduce NOx emissions by lowering peak combustion temperatures. However, tuners must carefully balance EGR rates to maintain performance while meeting emissions targets.

Aftertreatment systems play a vital role in meeting emissions regulations for V8 engines. Catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems are commonly employed to reduce harmful emissions before they exit the exhaust system. Tuners must consider the impact of these systems on engine performance and ensure that the engine's calibration is optimized to work effectively with the aftertreatment components.

The advent of hybrid powertrains has introduced new possibilities for V8 engine tuning within the constraints of emissions regulations. By combining a V8 engine with electric motors, manufacturers can achieve high performance while significantly reducing overall emissions. This approach allows for downsizing of the V8 engine without sacrificing power output, as the electric motors can provide additional torque when needed.

As emissions regulations continue to evolve, V8 engine tuners must stay abreast of the latest technologies and strategies to maximize performance while ensuring compliance. This includes exploring advanced combustion concepts, such as homogeneous charge compression ignition (HCCI) and low-temperature combustion, which offer the potential for significant reductions in emissions without compromising engine output.

In the context of V8 engine tuning, emissions regulations present both challenges and opportunities. Engine designers and tuners must balance the desire for increased performance with the need to meet strict emissions standards. This has led to the development of various technologies and strategies to optimize engine efficiency while minimizing harmful emissions.

One of the key approaches to meeting emissions regulations in V8 engines is the implementation of advanced fuel injection systems. Direct injection technology, for instance, allows for more precise control over fuel delivery, resulting in improved combustion efficiency and reduced emissions. Additionally, variable valve timing and lift systems have been widely adopted to optimize engine breathing across different operating conditions, further enhancing efficiency and reducing emissions.

Exhaust gas recirculation (EGR) systems have also become a crucial component in V8 engine tuning for emissions compliance. By recirculating a portion of the exhaust gases back into the combustion chamber, EGR systems help reduce NOx emissions by lowering peak combustion temperatures. However, tuners must carefully balance EGR rates to maintain performance while meeting emissions targets.

Aftertreatment systems play a vital role in meeting emissions regulations for V8 engines. Catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems are commonly employed to reduce harmful emissions before they exit the exhaust system. Tuners must consider the impact of these systems on engine performance and ensure that the engine's calibration is optimized to work effectively with the aftertreatment components.

The advent of hybrid powertrains has introduced new possibilities for V8 engine tuning within the constraints of emissions regulations. By combining a V8 engine with electric motors, manufacturers can achieve high performance while significantly reducing overall emissions. This approach allows for downsizing of the V8 engine without sacrificing power output, as the electric motors can provide additional torque when needed.

As emissions regulations continue to evolve, V8 engine tuners must stay abreast of the latest technologies and strategies to maximize performance while ensuring compliance. This includes exploring advanced combustion concepts, such as homogeneous charge compression ignition (HCCI) and low-temperature combustion, which offer the potential for significant reductions in emissions without compromising engine output.

Performance Metrics

Performance metrics play a crucial role in evaluating and optimizing V8 engine tuning efforts. These metrics provide quantifiable measures of engine performance, allowing engineers and tuners to assess the effectiveness of their modifications and identify areas for improvement. Key performance metrics for V8 engine tuning include horsepower, torque, fuel efficiency, and emissions.

Horsepower is a fundamental metric that quantifies the engine's overall power output. It is typically measured at the crankshaft or wheels using a dynamometer. Tuners aim to increase horsepower through various modifications, such as improving air intake, optimizing fuel delivery, and enhancing exhaust flow. Torque, on the other hand, represents the rotational force produced by the engine and is particularly important for acceleration and towing capacity.

Fuel efficiency is another critical performance metric, especially in an era of increasing environmental awareness and rising fuel costs. It is measured in miles per gallon (MPG) or liters per 100 kilometers (L/100km). Tuners strive to balance increased power output with optimal fuel consumption, often employing advanced engine management systems and fine-tuning fuel injection parameters.

Emissions performance is becoming increasingly important due to stringent environmental regulations. Metrics such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) levels are monitored to ensure compliance with emission standards. Tuners must carefully balance performance gains with emissions control, often utilizing catalytic converters and exhaust gas recirculation (EGR) systems.

Additional performance metrics include throttle response, which measures how quickly the engine reacts to driver input, and power-to-weight ratio, which indicates the engine's efficiency in propelling the vehicle. Acceleration times, such as 0-60 mph or quarter-mile times, are also commonly used to gauge overall vehicle performance resulting from engine tuning.

To accurately measure and analyze these performance metrics, tuners employ sophisticated diagnostic tools and data logging systems. These include on-board diagnostics (OBD) scanners, wideband oxygen sensors, and engine management software that can record and display real-time performance data. By continuously monitoring these metrics throughout the tuning process, engineers can make informed decisions and fine-tune engine parameters for optimal performance.

Horsepower is a fundamental metric that quantifies the engine's overall power output. It is typically measured at the crankshaft or wheels using a dynamometer. Tuners aim to increase horsepower through various modifications, such as improving air intake, optimizing fuel delivery, and enhancing exhaust flow. Torque, on the other hand, represents the rotational force produced by the engine and is particularly important for acceleration and towing capacity.

Fuel efficiency is another critical performance metric, especially in an era of increasing environmental awareness and rising fuel costs. It is measured in miles per gallon (MPG) or liters per 100 kilometers (L/100km). Tuners strive to balance increased power output with optimal fuel consumption, often employing advanced engine management systems and fine-tuning fuel injection parameters.

Emissions performance is becoming increasingly important due to stringent environmental regulations. Metrics such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) levels are monitored to ensure compliance with emission standards. Tuners must carefully balance performance gains with emissions control, often utilizing catalytic converters and exhaust gas recirculation (EGR) systems.

Additional performance metrics include throttle response, which measures how quickly the engine reacts to driver input, and power-to-weight ratio, which indicates the engine's efficiency in propelling the vehicle. Acceleration times, such as 0-60 mph or quarter-mile times, are also commonly used to gauge overall vehicle performance resulting from engine tuning.

To accurately measure and analyze these performance metrics, tuners employ sophisticated diagnostic tools and data logging systems. These include on-board diagnostics (OBD) scanners, wideband oxygen sensors, and engine management software that can record and display real-time performance data. By continuously monitoring these metrics throughout the tuning process, engineers can make informed decisions and fine-tune engine parameters for optimal performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!