How V8 Engines Are Tested for Performance Metrics?

JUL 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Testing Background and Objectives

V8 engine testing has evolved significantly over the past decades, driven by the automotive industry's relentless pursuit of improved performance, efficiency, and reliability. The primary objective of V8 engine testing is to evaluate and optimize various performance metrics, ensuring that these powerful engines meet stringent standards and customer expectations.

The development of V8 engines can be traced back to the early 20th century, with notable advancements occurring during the 1950s and 1960s. As automotive technology progressed, so did the methods and tools used for engine testing. Initially, testing was primarily conducted through physical dynamometer tests and road trials. However, the advent of computer-aided design and simulation technologies in the late 20th century revolutionized the testing process.

Today, V8 engine testing encompasses a wide range of sophisticated techniques, combining both physical and virtual testing methodologies. The primary goal is to assess and enhance key performance metrics such as power output, torque, fuel efficiency, emissions, durability, and noise, vibration, and harshness (NVH) characteristics.

One of the most significant trends in V8 engine testing is the increasing use of advanced simulation software and digital twins. These tools allow engineers to conduct extensive virtual testing before physical prototypes are built, significantly reducing development time and costs. Additionally, the integration of artificial intelligence and machine learning algorithms has enabled more accurate predictive modeling and optimization of engine performance.

Another crucial aspect of modern V8 engine testing is the focus on environmental sustainability. With stringent emissions regulations being implemented worldwide, testing procedures now heavily emphasize the reduction of harmful exhaust emissions and improvement of fuel efficiency. This has led to the development of innovative testing methods that can accurately measure and analyze engine emissions under various operating conditions.

The automotive industry's shift towards electrification has also influenced V8 engine testing objectives. While traditional performance metrics remain important, there is now a growing emphasis on developing hybrid V8 powertrains that can meet both performance and efficiency targets. This has introduced new testing challenges, such as evaluating the integration of electric motors with V8 engines and optimizing power management systems.

As we look to the future, V8 engine testing is expected to become even more sophisticated, with increased reliance on real-time data analytics, IoT sensors, and cloud-based testing platforms. These advancements will enable more comprehensive and accurate performance evaluations, ultimately leading to the development of V8 engines that offer unparalleled performance while meeting increasingly stringent environmental standards.

The development of V8 engines can be traced back to the early 20th century, with notable advancements occurring during the 1950s and 1960s. As automotive technology progressed, so did the methods and tools used for engine testing. Initially, testing was primarily conducted through physical dynamometer tests and road trials. However, the advent of computer-aided design and simulation technologies in the late 20th century revolutionized the testing process.

Today, V8 engine testing encompasses a wide range of sophisticated techniques, combining both physical and virtual testing methodologies. The primary goal is to assess and enhance key performance metrics such as power output, torque, fuel efficiency, emissions, durability, and noise, vibration, and harshness (NVH) characteristics.

One of the most significant trends in V8 engine testing is the increasing use of advanced simulation software and digital twins. These tools allow engineers to conduct extensive virtual testing before physical prototypes are built, significantly reducing development time and costs. Additionally, the integration of artificial intelligence and machine learning algorithms has enabled more accurate predictive modeling and optimization of engine performance.

Another crucial aspect of modern V8 engine testing is the focus on environmental sustainability. With stringent emissions regulations being implemented worldwide, testing procedures now heavily emphasize the reduction of harmful exhaust emissions and improvement of fuel efficiency. This has led to the development of innovative testing methods that can accurately measure and analyze engine emissions under various operating conditions.

The automotive industry's shift towards electrification has also influenced V8 engine testing objectives. While traditional performance metrics remain important, there is now a growing emphasis on developing hybrid V8 powertrains that can meet both performance and efficiency targets. This has introduced new testing challenges, such as evaluating the integration of electric motors with V8 engines and optimizing power management systems.

As we look to the future, V8 engine testing is expected to become even more sophisticated, with increased reliance on real-time data analytics, IoT sensors, and cloud-based testing platforms. These advancements will enable more comprehensive and accurate performance evaluations, ultimately leading to the development of V8 engines that offer unparalleled performance while meeting increasingly stringent environmental standards.

Market Demand for High-Performance V8 Engines

The market demand for high-performance V8 engines has been steadily growing, driven by various factors in both the automotive and marine industries. In the automotive sector, luxury sports cars and high-end SUVs continue to be the primary consumers of V8 engines, with manufacturers like Ferrari, Lamborghini, and Mercedes-AMG leading the charge. These brands cater to a niche market of enthusiasts and affluent buyers who prioritize power, performance, and prestige.

The racing industry also contributes significantly to the demand for high-performance V8 engines. Formula 1, NASCAR, and other motorsport categories rely heavily on V8 technology, pushing the boundaries of engine performance and efficiency. This not only drives innovation but also creates a trickle-down effect, where advancements in racing technology eventually find their way into consumer vehicles.

In the marine sector, high-performance V8 engines are sought after for luxury yachts, speedboats, and offshore racing vessels. The demand in this segment is fueled by the need for reliable, powerful engines that can withstand harsh marine environments while delivering exceptional performance.

Despite the growing trend towards electrification and downsizing in the automotive industry, there remains a strong market for V8 engines, particularly in regions with less stringent emissions regulations. Countries like the United States, Middle Eastern nations, and parts of Asia continue to show a preference for larger displacement engines, including V8s.

The aftermarket and tuning industry also plays a crucial role in sustaining the demand for high-performance V8 engines. Enthusiasts and custom builders often seek out V8 engines for their projects, ranging from classic car restorations to modern high-performance builds.

However, the market is not without challenges. Stricter emissions regulations in many countries are putting pressure on manufacturers to improve the efficiency and reduce the environmental impact of V8 engines. This has led to innovations such as cylinder deactivation, advanced fuel injection systems, and hybrid technologies being integrated into V8 powertrains.

Looking ahead, the market for high-performance V8 engines is expected to evolve. While traditional applications in luxury vehicles and racing will likely continue, there's potential for growth in niche markets such as high-performance electric vehicle conversions and sustainable fuel applications. Manufacturers are also exploring ways to make V8 engines more environmentally friendly without compromising on performance, which could open up new market opportunities in regions with stricter emissions standards.

The racing industry also contributes significantly to the demand for high-performance V8 engines. Formula 1, NASCAR, and other motorsport categories rely heavily on V8 technology, pushing the boundaries of engine performance and efficiency. This not only drives innovation but also creates a trickle-down effect, where advancements in racing technology eventually find their way into consumer vehicles.

In the marine sector, high-performance V8 engines are sought after for luxury yachts, speedboats, and offshore racing vessels. The demand in this segment is fueled by the need for reliable, powerful engines that can withstand harsh marine environments while delivering exceptional performance.

Despite the growing trend towards electrification and downsizing in the automotive industry, there remains a strong market for V8 engines, particularly in regions with less stringent emissions regulations. Countries like the United States, Middle Eastern nations, and parts of Asia continue to show a preference for larger displacement engines, including V8s.

The aftermarket and tuning industry also plays a crucial role in sustaining the demand for high-performance V8 engines. Enthusiasts and custom builders often seek out V8 engines for their projects, ranging from classic car restorations to modern high-performance builds.

However, the market is not without challenges. Stricter emissions regulations in many countries are putting pressure on manufacturers to improve the efficiency and reduce the environmental impact of V8 engines. This has led to innovations such as cylinder deactivation, advanced fuel injection systems, and hybrid technologies being integrated into V8 powertrains.

Looking ahead, the market for high-performance V8 engines is expected to evolve. While traditional applications in luxury vehicles and racing will likely continue, there's potential for growth in niche markets such as high-performance electric vehicle conversions and sustainable fuel applications. Manufacturers are also exploring ways to make V8 engines more environmentally friendly without compromising on performance, which could open up new market opportunities in regions with stricter emissions standards.

Current V8 Engine Testing Challenges

Testing V8 engines for performance metrics presents several significant challenges in the current landscape. One of the primary difficulties lies in the complexity of modern V8 engine designs, which incorporate numerous advanced technologies and intricate systems. This complexity makes it challenging to isolate and measure specific performance parameters accurately.

The variability of operating conditions poses another substantial challenge. V8 engines are expected to perform optimally across a wide range of environmental conditions, including temperature extremes, altitude variations, and diverse fuel qualities. Replicating these diverse conditions in a controlled testing environment is both technically demanding and resource-intensive.

Furthermore, the integration of electronic control systems and advanced sensors in modern V8 engines adds layers of complexity to performance testing. These systems can significantly influence engine behavior and performance metrics, making it difficult to distinguish between mechanical performance and electronic optimization effects.

The need for long-term durability testing presents additional challenges. V8 engines, particularly those used in high-performance or heavy-duty applications, must demonstrate reliability over extended periods. Conducting accelerated life cycle tests that accurately predict long-term performance and wear characteristics is a complex and time-consuming process.

Another significant challenge is the evolving regulatory landscape. Stringent emissions standards and fuel efficiency requirements necessitate continuous adaptation of testing protocols. Balancing performance optimization with compliance to these regulations adds complexity to the testing process and often requires sophisticated equipment and expertise.

The increasing focus on noise, vibration, and harshness (NVH) characteristics also complicates V8 engine testing. Measuring and analyzing these subjective factors requires specialized equipment and methodologies, adding another dimension to the already complex testing procedures.

Moreover, the advent of hybrid and electrified powertrains that incorporate V8 engines introduces new testing challenges. Evaluating the performance of the V8 engine in conjunction with electric motors and battery systems requires innovative testing approaches and integrated measurement techniques.

Lastly, the cost and time associated with comprehensive V8 engine testing remain significant hurdles. High-fidelity testing equipment, specialized facilities, and skilled personnel contribute to substantial testing expenses. Balancing the need for thorough testing with time-to-market pressures and budget constraints continues to be a persistent challenge in the industry.

The variability of operating conditions poses another substantial challenge. V8 engines are expected to perform optimally across a wide range of environmental conditions, including temperature extremes, altitude variations, and diverse fuel qualities. Replicating these diverse conditions in a controlled testing environment is both technically demanding and resource-intensive.

Furthermore, the integration of electronic control systems and advanced sensors in modern V8 engines adds layers of complexity to performance testing. These systems can significantly influence engine behavior and performance metrics, making it difficult to distinguish between mechanical performance and electronic optimization effects.

The need for long-term durability testing presents additional challenges. V8 engines, particularly those used in high-performance or heavy-duty applications, must demonstrate reliability over extended periods. Conducting accelerated life cycle tests that accurately predict long-term performance and wear characteristics is a complex and time-consuming process.

Another significant challenge is the evolving regulatory landscape. Stringent emissions standards and fuel efficiency requirements necessitate continuous adaptation of testing protocols. Balancing performance optimization with compliance to these regulations adds complexity to the testing process and often requires sophisticated equipment and expertise.

The increasing focus on noise, vibration, and harshness (NVH) characteristics also complicates V8 engine testing. Measuring and analyzing these subjective factors requires specialized equipment and methodologies, adding another dimension to the already complex testing procedures.

Moreover, the advent of hybrid and electrified powertrains that incorporate V8 engines introduces new testing challenges. Evaluating the performance of the V8 engine in conjunction with electric motors and battery systems requires innovative testing approaches and integrated measurement techniques.

Lastly, the cost and time associated with comprehensive V8 engine testing remain significant hurdles. High-fidelity testing equipment, specialized facilities, and skilled personnel contribute to substantial testing expenses. Balancing the need for thorough testing with time-to-market pressures and budget constraints continues to be a persistent challenge in the industry.

Existing V8 Engine Performance Testing Methods

01 Performance monitoring and analysis

Systems and methods for monitoring and analyzing V8 engine performance metrics. This includes real-time data collection, processing, and visualization of various engine parameters to assess efficiency, power output, and overall performance. Advanced analytics tools are used to interpret the data and provide insights for optimization.- Performance monitoring and analysis: V8 engine performance can be monitored and analyzed using various metrics and tools. This includes real-time data collection, performance benchmarking, and analysis of key indicators such as fuel efficiency, power output, and emissions. Advanced monitoring systems can help identify potential issues and optimize engine performance.

- Engine control and optimization: Sophisticated control systems and algorithms are used to optimize V8 engine performance. These systems can adjust various parameters such as fuel injection, ignition timing, and valve timing in real-time to maximize efficiency and power output while minimizing emissions. Machine learning and AI techniques may be employed to continuously improve engine performance.

- Emissions reduction and environmental impact: Improving V8 engine performance includes efforts to reduce emissions and environmental impact. This involves developing advanced catalytic converters, implementing exhaust gas recirculation systems, and optimizing combustion processes. Performance metrics in this area focus on meeting increasingly stringent emissions standards while maintaining power and efficiency.

- Fuel efficiency and consumption analysis: Measuring and improving fuel efficiency is a critical aspect of V8 engine performance. This includes analyzing fuel consumption patterns, developing more efficient fuel injection systems, and implementing technologies such as cylinder deactivation. Performance metrics in this area focus on maximizing power output while minimizing fuel consumption.

- Durability and reliability testing: Ensuring the longevity and reliability of V8 engines is crucial for overall performance. This involves extensive testing procedures, including stress tests, endurance runs, and simulated extreme conditions. Performance metrics in this area focus on engine wear, component lifespan, and maintenance intervals to optimize long-term performance and reliability.

02 Fuel efficiency optimization

Techniques for improving fuel efficiency in V8 engines through advanced control systems and algorithms. This involves adaptive fuel injection timing, cylinder deactivation strategies, and intelligent engine management to maximize fuel economy without compromising performance.Expand Specific Solutions03 Power output enhancement

Methods for increasing the power output of V8 engines, including turbocharging, supercharging, and variable valve timing technologies. These enhancements aim to boost horsepower and torque while maintaining reliability and meeting emissions standards.Expand Specific Solutions04 Emissions reduction and environmental performance

Innovations focused on reducing emissions and improving the environmental performance of V8 engines. This includes advanced exhaust gas recirculation systems, catalytic converter technologies, and engine control strategies to meet stringent emissions regulations while maintaining high performance.Expand Specific Solutions05 Diagnostic and predictive maintenance

Advanced diagnostic systems and predictive maintenance algorithms for V8 engines. These technologies use machine learning and data analytics to predict potential failures, optimize maintenance schedules, and ensure peak engine performance over time.Expand Specific Solutions

Key Players in V8 Engine Testing Industry

The V8 engine performance testing landscape is characterized by a mature market with established players and advanced technologies. The industry is in a consolidation phase, with major automotive manufacturers and specialized testing companies dominating the field. Market size is substantial, driven by the ongoing demand for high-performance engines in various sectors. Technologically, the field is highly sophisticated, with companies like Toyota, Honda, and Nissan leading in innovation. AVL List GmbH and HORIBA Instruments, Inc. are key players in developing cutting-edge testing equipment and methodologies. The competition is intense, with a focus on precision, efficiency, and real-time data analysis in performance metrics evaluation.

Toyota Motor Corp.

Technical Solution: Toyota employs a comprehensive V8 engine testing methodology that includes dynamometer testing, road load simulation, and real-world driving conditions. They utilize advanced data acquisition systems to measure performance metrics such as horsepower, torque, fuel efficiency, and emissions. Toyota's approach involves long-duration endurance tests, often exceeding 10,000 hours[1], to ensure reliability and durability. They also implement thermal imaging and vibration analysis to identify potential issues in engine components. Toyota's testing process incorporates AI and machine learning algorithms to analyze vast amounts of data collected during tests, enabling predictive maintenance and performance optimization[2].

Strengths: Comprehensive testing methodology, advanced data analysis capabilities, and focus on long-term reliability. Weaknesses: Potentially time-consuming and resource-intensive testing process.

Honda Motor Co., Ltd.

Technical Solution: Honda's V8 engine testing protocol focuses on precision and innovation. They utilize a combination of in-house developed testing equipment and industry-standard tools to evaluate performance metrics. Honda's approach includes high-speed imaging technology to analyze combustion processes in real-time, allowing for fine-tuning of fuel injection and ignition timing[3]. They also employ advanced CFD (Computational Fluid Dynamics) simulations to optimize engine design before physical prototyping. Honda's testing regimen includes extreme condition testing, subjecting engines to high temperatures, altitudes, and varying fuel qualities to ensure consistent performance across diverse operating environments[4].

Strengths: Innovative testing technologies, focus on optimizing design through simulation. Weaknesses: Potential over-reliance on simulations compared to real-world testing.

Core Innovations in V8 Engine Testing Technologies

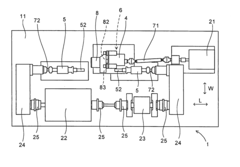

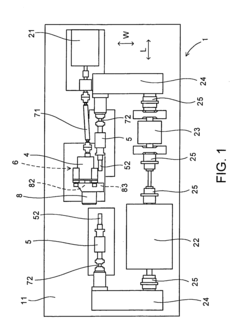

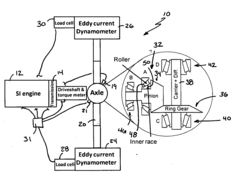

Powertrain testing apparatus

PatentInactiveUS20050257606A1

Innovation

- A powertrain testing apparatus equipped with a vibration generator to simulate road surface vibrations and adjustable units for changing inter-shaft distances, including vertical and horizontal adjustments, along with constant velocity joints and dampers to replicate engine rotation and inertial resistance.

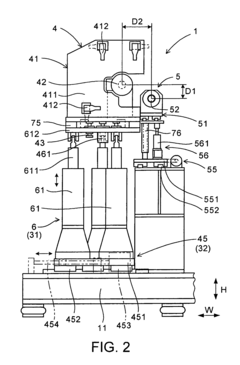

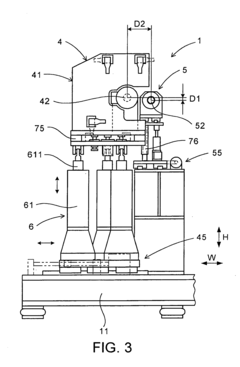

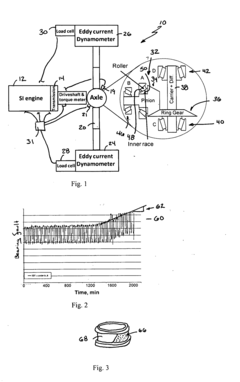

Bearing Durability Test Apparatus and Method

PatentInactiveUS20110179882A1

Innovation

- A test apparatus and method that simulates the conditions of the R-392 on-road test using a test rig with a Ford 8.8″ hypoid axle, a V-8 engine, and pinion torque meter, replicating high-stress environments like Toprock Hill and Union Pass segments to evaluate bearing durability through pinion torque and speed variations, with in-house software for data acquisition and control.

Environmental Impact of V8 Engine Testing

The environmental impact of V8 engine testing is a critical consideration in the automotive industry, particularly as sustainability becomes an increasingly important factor in vehicle development. Testing procedures for V8 engines, while necessary for performance optimization and reliability assurance, can contribute significantly to carbon emissions and resource consumption.

Engine testing facilities typically operate powerful dynamometers that simulate real-world driving conditions. These systems consume substantial amounts of energy, often derived from fossil fuel sources, leading to increased carbon footprints. Additionally, the fuel burned during testing contributes directly to greenhouse gas emissions. A single V8 engine undergoing extensive performance testing can consume hundreds of liters of fuel over its test cycle.

Water usage is another environmental concern in V8 engine testing. Cooling systems for both the engine and testing equipment require large volumes of water, which may strain local water resources, especially in water-scarce regions. The disposal of this water, often contaminated with oils and other chemicals, presents further environmental challenges.

The production and disposal of test oils and lubricants also contribute to the environmental impact. These substances often contain harmful chemicals that can pollute soil and water if not properly managed. Furthermore, the frequent oil changes required during rigorous testing cycles generate significant amounts of waste oil that must be carefully handled and recycled.

Noise pollution is an often-overlooked aspect of engine testing. V8 engines, known for their powerful sound, can generate high noise levels during performance tests. This can have negative impacts on local ecosystems and communities near testing facilities, potentially disrupting wildlife and affecting human health.

To mitigate these environmental impacts, many automotive companies are implementing more sustainable testing practices. These include investing in advanced simulation technologies that can reduce the need for physical testing, implementing energy recovery systems in dynamometers, and utilizing renewable energy sources to power testing facilities. Some companies are also exploring the use of synthetic fuels during testing to reduce overall emissions.

As the automotive industry shifts towards electrification, the environmental impact of V8 engine testing may decrease. However, for the foreseeable future, V8 engines will continue to play a role in certain vehicle segments, necessitating ongoing efforts to balance performance testing requirements with environmental responsibility.

Engine testing facilities typically operate powerful dynamometers that simulate real-world driving conditions. These systems consume substantial amounts of energy, often derived from fossil fuel sources, leading to increased carbon footprints. Additionally, the fuel burned during testing contributes directly to greenhouse gas emissions. A single V8 engine undergoing extensive performance testing can consume hundreds of liters of fuel over its test cycle.

Water usage is another environmental concern in V8 engine testing. Cooling systems for both the engine and testing equipment require large volumes of water, which may strain local water resources, especially in water-scarce regions. The disposal of this water, often contaminated with oils and other chemicals, presents further environmental challenges.

The production and disposal of test oils and lubricants also contribute to the environmental impact. These substances often contain harmful chemicals that can pollute soil and water if not properly managed. Furthermore, the frequent oil changes required during rigorous testing cycles generate significant amounts of waste oil that must be carefully handled and recycled.

Noise pollution is an often-overlooked aspect of engine testing. V8 engines, known for their powerful sound, can generate high noise levels during performance tests. This can have negative impacts on local ecosystems and communities near testing facilities, potentially disrupting wildlife and affecting human health.

To mitigate these environmental impacts, many automotive companies are implementing more sustainable testing practices. These include investing in advanced simulation technologies that can reduce the need for physical testing, implementing energy recovery systems in dynamometers, and utilizing renewable energy sources to power testing facilities. Some companies are also exploring the use of synthetic fuels during testing to reduce overall emissions.

As the automotive industry shifts towards electrification, the environmental impact of V8 engine testing may decrease. However, for the foreseeable future, V8 engines will continue to play a role in certain vehicle segments, necessitating ongoing efforts to balance performance testing requirements with environmental responsibility.

Standardization of V8 Engine Performance Metrics

The standardization of V8 engine performance metrics plays a crucial role in ensuring consistent and reliable testing procedures across the automotive industry. This standardization process involves establishing uniform methods for measuring and evaluating various performance parameters of V8 engines. These metrics typically include horsepower, torque, fuel efficiency, emissions, and durability.

One of the primary organizations responsible for developing and maintaining these standards is the Society of Automotive Engineers (SAE). The SAE has established a set of guidelines known as the J1349 standard, which outlines the procedures for measuring engine horsepower and torque. This standard ensures that all manufacturers follow the same testing protocols, allowing for fair comparisons between different V8 engines.

In addition to the SAE standards, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards have also contributed to the standardization of performance metrics, particularly in terms of fuel efficiency and emissions. These regulations require manufacturers to adhere to specific testing procedures and reporting methods for their V8 engines.

The standardization process also involves the use of specialized testing equipment and facilities. Dynamometers, for instance, are widely used to measure engine power output under controlled conditions. These devices allow engineers to simulate various driving conditions and load scenarios, providing consistent and repeatable results across different testing facilities.

Another important aspect of standardization is the development of common terminology and units of measurement. This ensures that performance data can be easily understood and compared across different manufacturers and markets. For example, horsepower and torque are typically reported in both metric (kilowatts and Newton-meters) and imperial (horsepower and pound-feet) units to facilitate global comparisons.

As V8 engine technology continues to evolve, the standardization of performance metrics must also adapt to new developments. This includes incorporating new testing procedures for advanced technologies such as cylinder deactivation, variable valve timing, and direct injection. The ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions is essential in maintaining up-to-date and relevant standards for V8 engine performance testing.

One of the primary organizations responsible for developing and maintaining these standards is the Society of Automotive Engineers (SAE). The SAE has established a set of guidelines known as the J1349 standard, which outlines the procedures for measuring engine horsepower and torque. This standard ensures that all manufacturers follow the same testing protocols, allowing for fair comparisons between different V8 engines.

In addition to the SAE standards, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards have also contributed to the standardization of performance metrics, particularly in terms of fuel efficiency and emissions. These regulations require manufacturers to adhere to specific testing procedures and reporting methods for their V8 engines.

The standardization process also involves the use of specialized testing equipment and facilities. Dynamometers, for instance, are widely used to measure engine power output under controlled conditions. These devices allow engineers to simulate various driving conditions and load scenarios, providing consistent and repeatable results across different testing facilities.

Another important aspect of standardization is the development of common terminology and units of measurement. This ensures that performance data can be easily understood and compared across different manufacturers and markets. For example, horsepower and torque are typically reported in both metric (kilowatts and Newton-meters) and imperial (horsepower and pound-feet) units to facilitate global comparisons.

As V8 engine technology continues to evolve, the standardization of performance metrics must also adapt to new developments. This includes incorporating new testing procedures for advanced technologies such as cylinder deactivation, variable valve timing, and direct injection. The ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions is essential in maintaining up-to-date and relevant standards for V8 engine performance testing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!